Okoboji Visiting Card Cutter Heavy Duty A4

SPECIFICATIONS

PRODUCT VIDEO

PRODUCT DESCRIPTION

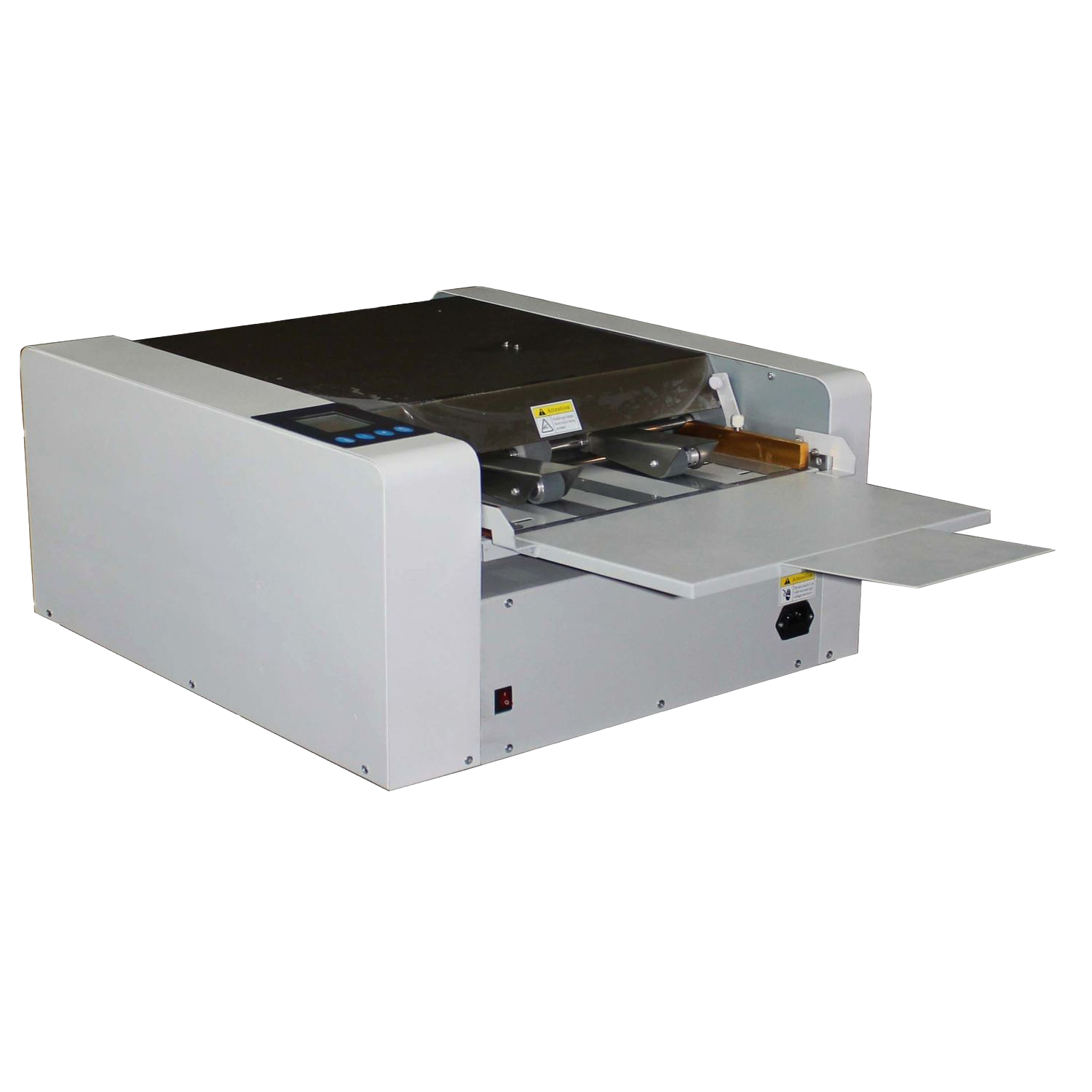

The Okoboji Visiting Card Cutter Heavy Duty A4 represents advanced automation in business card production, specifically designed to streamline operations for medium-scale printing businesses, digital print shops, and corporate in-house printing departments across India. This sophisticated machine combines automatic paper feeding with precision cutting technology to eliminate manual handling errors whilst maintaining the consistent quality essential for professional business card production. The A4 format capability makes it ideal for businesses processing standard print runs whilst requiring the reliability and efficiency that distinguishes successful operations from competitors struggling with manual processes.

Engineered with user-friendly automation features, the Heavy Duty A4 addresses common production bottlenecks through its innovative double rubbing paper feeding system and dual cutting mechanisms. The machine’s ability to handle various paper weights and finishes, from standard cardstock to laminated materials, makes it invaluable for businesses serving diverse clientele with varying quality requirements. For printing professionals seeking to enhance productivity whilst maintaining operator comfort and safety, the Okoboji A4 delivers the perfect balance of automation, precision, and reliability that supports sustainable business growth in India’s dynamic printing industry.

Upgrade Your Experience

Okoboji Paper Cutter Digital Electric 490T

Okoboji Paper Cutter Digital Hydraulic 520mm

Okoboji Visiting Card Cutter 331SSC

Okoboji Visiting Card Cutter Heavy Duty A3 Plus

KEY FEATURES

- Advanced automatic paper feeding with double rubbing system eliminates manual positioning errors and ensures consistent paper alignment for professional cutting results

- Efficient 30 cards per minute cutting speed optimises productivity whilst maintaining precision, ideal for medium to high-volume production requirements

- Dual cutting mechanism featuring longitudinal rolled cutting and horizontal long blade cutting provides versatility for different card orientations and cutting patterns

- Comprehensive paper compatibility handling 180-350gsm materials including laminated papers up to 100mic film thickness, accommodating diverse client requirements

- Compact professional design with 590x520x330mm dimensions fits efficiently in most workshop spaces whilst providing full commercial cutting capabilities

- Precision cutting size options (longitudinal - 89-95mm, horizontal- 40-250mm) accommodate standard business cards and custom specialty card applications

- Advanced environmental operation capability (-15°C to +40°C, 35-70% humidity) ensures reliable performance across various Indian climate conditions

- Okoboji's proven reliability backed by comprehensive technical support ensures consistent productivity and minimal downtime for growing businesses

FREQUENTLY ASKED QUESTIONS

How does the automatic double rubbing paper feeding system improve cutting accuracy?

The double rubbing system ensures precise paper positioning and eliminates skewing common with manual feeding, resulting in consistently aligned cuts and reduced waste material.

What types of laminated papers can the A4 cutter handle effectively?

The machine accommodates laminated papers with film thickness up to 100 microns combined with 250gsm base paper, covering most standard lamination applications used in business card production.

Can the dual cutting mechanism handle different card layouts on the same sheet?

Yes, the longitudinal rolled cutting and horizontal blade cutting can be configured for various card arrangements, maximising sheet utilisation and production efficiency.

What operator skill level is required for efficient operation of this automated machine?

Basic training typically requires 1-2 hours, with operators achieving proficiency within a day due to the intuitive automatic feeding and cutting systems.

How does the wide voltage range (90-260V) benefit Indian businesses?

The universal voltage compatibility ensures reliable operation across different regions and power conditions common in India, reducing installation complexity and power-related issues.

What maintenance schedule ensures optimal performance of the automatic feeding system?

Daily cleaning of feeding rollers, weekly inspection of cutting blades, and monthly lubrication of moving components maintain consistent performance and prevent feeding problems.

Can the machine handle specialty paper finishes like textured or coated cardstock?

Yes, the adjustable cutting parameters and robust feeding system accommodate various paper textures and coatings within the specified weight range.

How quickly can operators switch between different cutting size configurations?

Standard size changes require 5-10 minutes with experienced operators able to complete adjustments in 3-5 minutes for frequently used configurations.

What quality control features ensure consistent cutting results across production runs?

Precision guides, automatic paper positioning, and consistent blade pressure ensure repeatable results with minimal variation between cards throughout extended production runs.

How does the compact design benefit workshop space utilisation without compromising functionality?

The efficient 590x520x330mm footprint maximises workspace efficiency whilst providing full commercial capabilities, ideal for businesses operating in premium commercial spaces.

Customers also bought

Okoboji Corner Cutter Electric DT WH08

Okoboji Corner Cutter Manual S100

Okoboji Corner Cutter Electric Raduis upto 20mm 5 Dye Raduis upto 20mm 5 Dye

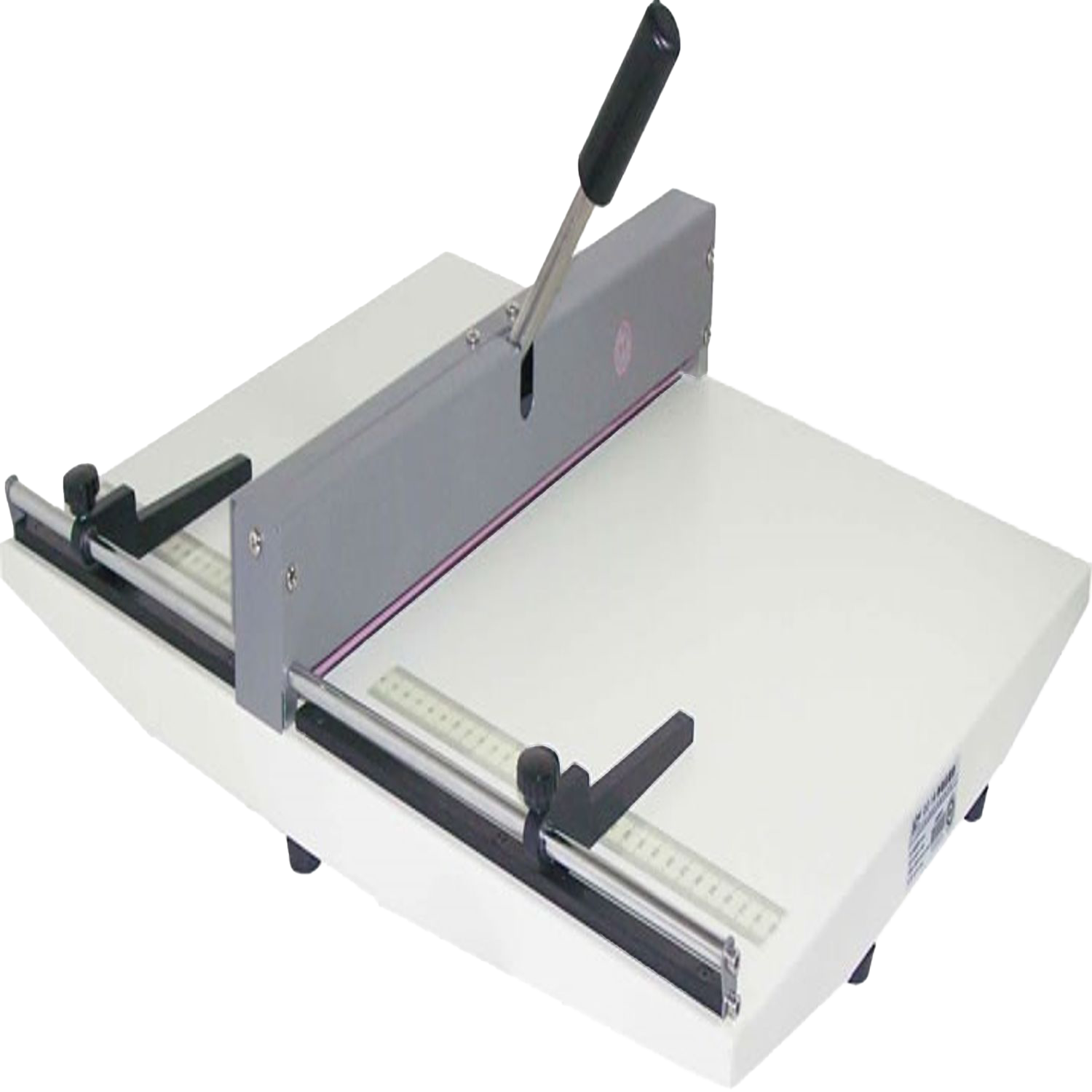

Okoboji Paper Creaser Manual A3 Size H460