Okoboji Sublimation Mug Press Electric Press MP99A

SPECIFICATIONS

PRODUCT VIDEO

PRODUCT DESCRIPTION

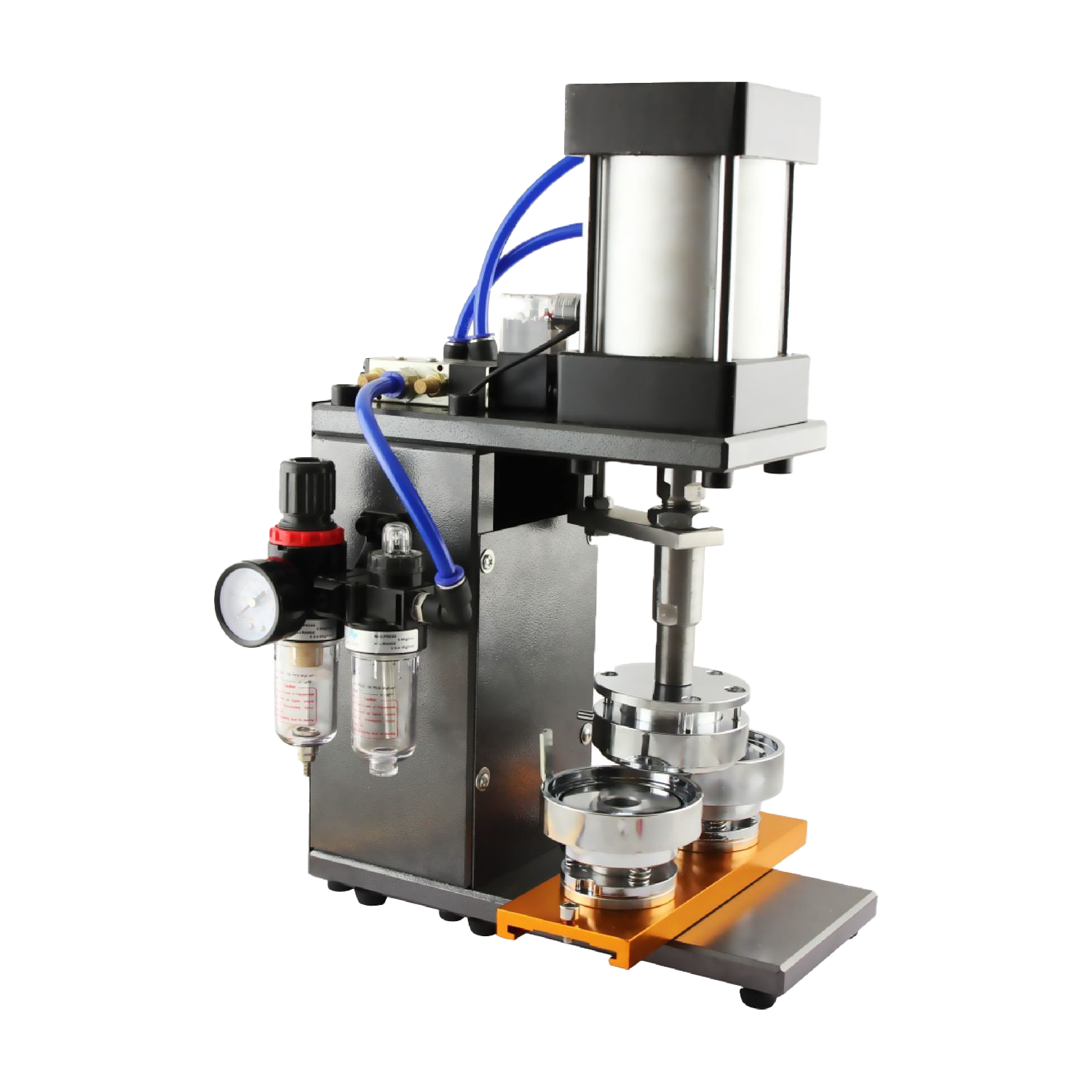

The Okoboji Sublimation Mug Press Electric Press MP99A introduces semi-automatic pneumatic technology to enhance operational efficiency whilst maintaining precise control over the sublimation process. This innovative machine features automatic pressure application and release, eliminating operator fatigue whilst ensuring consistent compression across all transfers. The precision-engineered aluminium die-casting construction provides superior heat distribution and durability, making it ideal for businesses seeking to upgrade from manual operations without compromising quality control. The compact yet robust design particularly suits operators handling moderate to high-volume orders requiring consistent pressure application.

Designed with operator comfort and productivity in mind, the MP99A incorporates advanced GY05N digital controls capable of reaching 230°C for specialty applications whilst maintaining exceptional temperature accuracy. The pneumatic system ensures uniform pressure distribution across the entire mug surface, virtually eliminating pressure-related transfer defects common in manual operations. This Okoboji machine represents the perfect balance between automation and operator control, enabling businesses to achieve professional results with reduced physical demands whilst building towards fully automated production systems as operations expand in India’s growing personalisation market.

Upgrade Your Experience

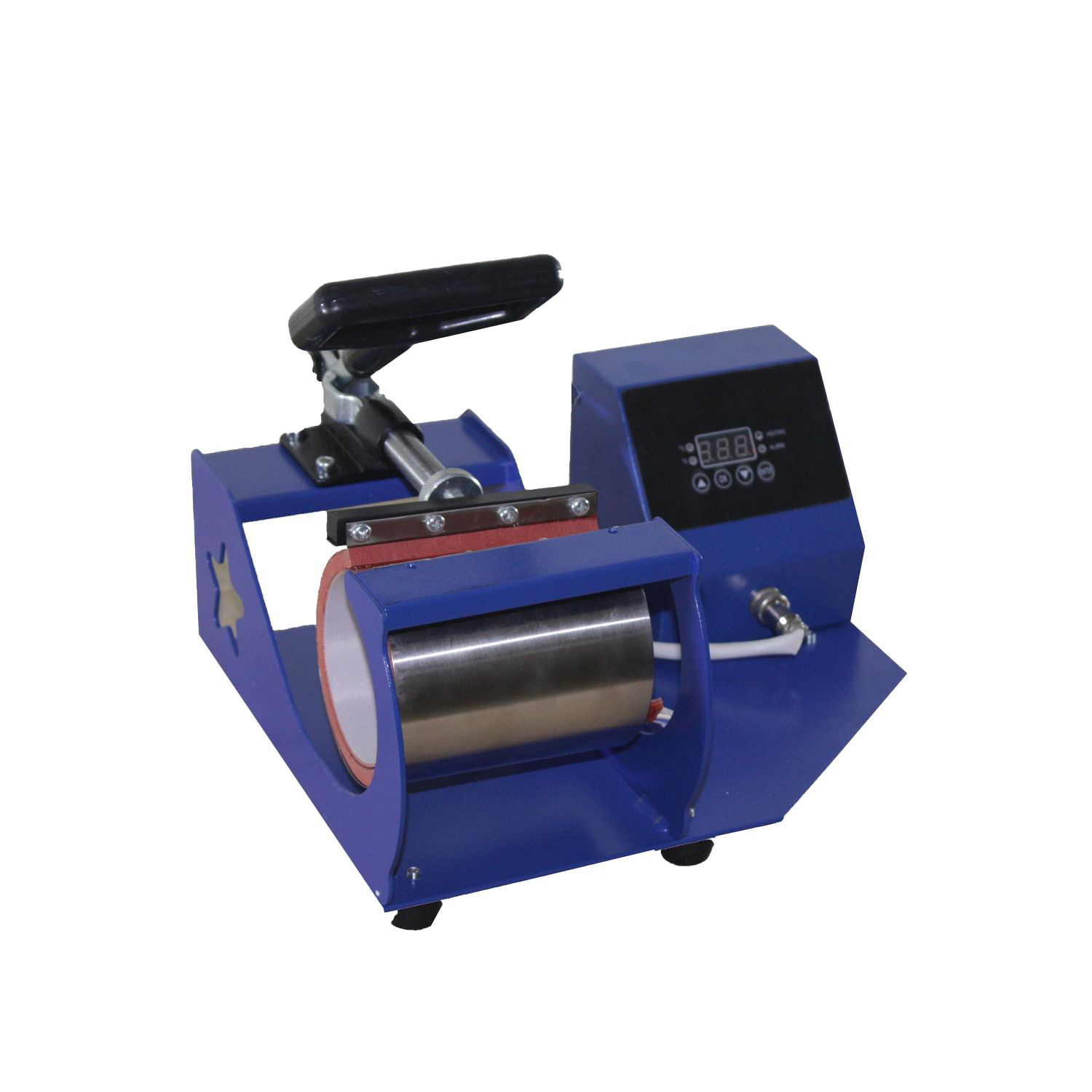

Okoboji Sublimation Mug Press 2in1 MP20B

Okoboji Sublimation Mug Press 5-IN-1 MPA500B

Okoboji Sublimation Mug press Horizontal XY012A

Okoboji Sublimation Pneumatic Mug Press ST110

KEY FEATURES

- Semi-Automatic Pneumatic Operation : Automatic pressure application and release reduces operator fatigue whilst ensuring consistent compression for professional-quality transfers.

- Precision Aluminium Die-Casting : Superior construction provides exceptional heat distribution and durability compared to standard steel heating elements.

- Advanced GY05N Controller : Professional digital control system manages temperature up to 230°C with precise timing from 0-999 seconds for speciality applications.

- 11oz Optimised Design : Specially engineered 8mm thickness heater (Dia 7.5-9cm) ensures complete heat coverage for standard 11oz full-wrap transfers.

- Compact Professional Build : Space-efficient 324x216x187mm design maximises workspace utility whilst maintaining industrial-grade performance standards.

- Enhanced Temperature Range : 230°C maximum temperature capability accommodates specialty materials and challenging sublimation applications beyond standard ranges.

- Dual Voltage Compatibility : Supports both 220V and 110V electrical systems, ensuring installation flexibility across diverse Indian electrical configurations.

- Okoboji Pneumatic Innovation : Purpose-built to bridge manual and fully automatic operations, providing upgrade path for growing sublimation businesses.

FREQUENTLY ASKED QUESTIONS

How does the pneumatic system improve consistency compared to manual pressure application?

The pneumatic system applies uniform pressure automatically, eliminating human variation and ensuring consistent compression across all transfers for professional results.

What is the advantage of aluminium die-casting construction over standard heating elements?

Aluminium die-casting provides superior heat distribution, faster heat-up times, better temperature stability, and increased durability compared to conventional steel elements.

Can I control the pneumatic pressure for different mug materials and thicknesses?

Yes, the semi-automatic system allows pressure adjustment for different materials whilst maintaining automatic application and release for operator convenience.

How much space savings does this compact design provide compared to larger manual presses?

The 324x216x187mm footprint occupies approximately 60% less space than comparable manual systems whilst delivering superior performance and consistency.

Is the 260W power consumption suitable for extended commercial operations?

Yes, the efficient 260W power draw reduces operating costs whilst providing adequate heating performance for continuous commercial sublimation operations.

What maintenance is required for the pneumatic pressure system?

Regular inspection of pneumatic components, periodic lubrication as recommended, and annual professional servicing ensure optimal pneumatic system performance.

How does the GY05N controller differ from standard digital controllers?

The GY05N offers enhanced precision, wider temperature range up to 230°C, extended timing options, and improved stability for demanding commercial applications.

What safety features are included with the pneumatic operation system?

Safety features include automatic pressure release, temperature monitoring, timing controls, and emergency stop capability for secure pneumatic operation.

Can this machine handle specialty sublimation materials requiring higher temperatures?

Yes, the 230°C maximum temperature capability accommodates specialty substrates and challenging materials beyond standard sublimation temperature ranges.

How does this semi-automatic system prepare my business for future automation upgrades?

The MP99A introduces automated pressure control concepts whilst maintaining manual oversight, providing training foundation for eventual fully automatic system adoption.

Customers also bought

Okoboji ID Card Fusing A4 100

Okoboji Punch for Badge Pneumatic MAQ

Okoboji Punch for Badge Slide MA03