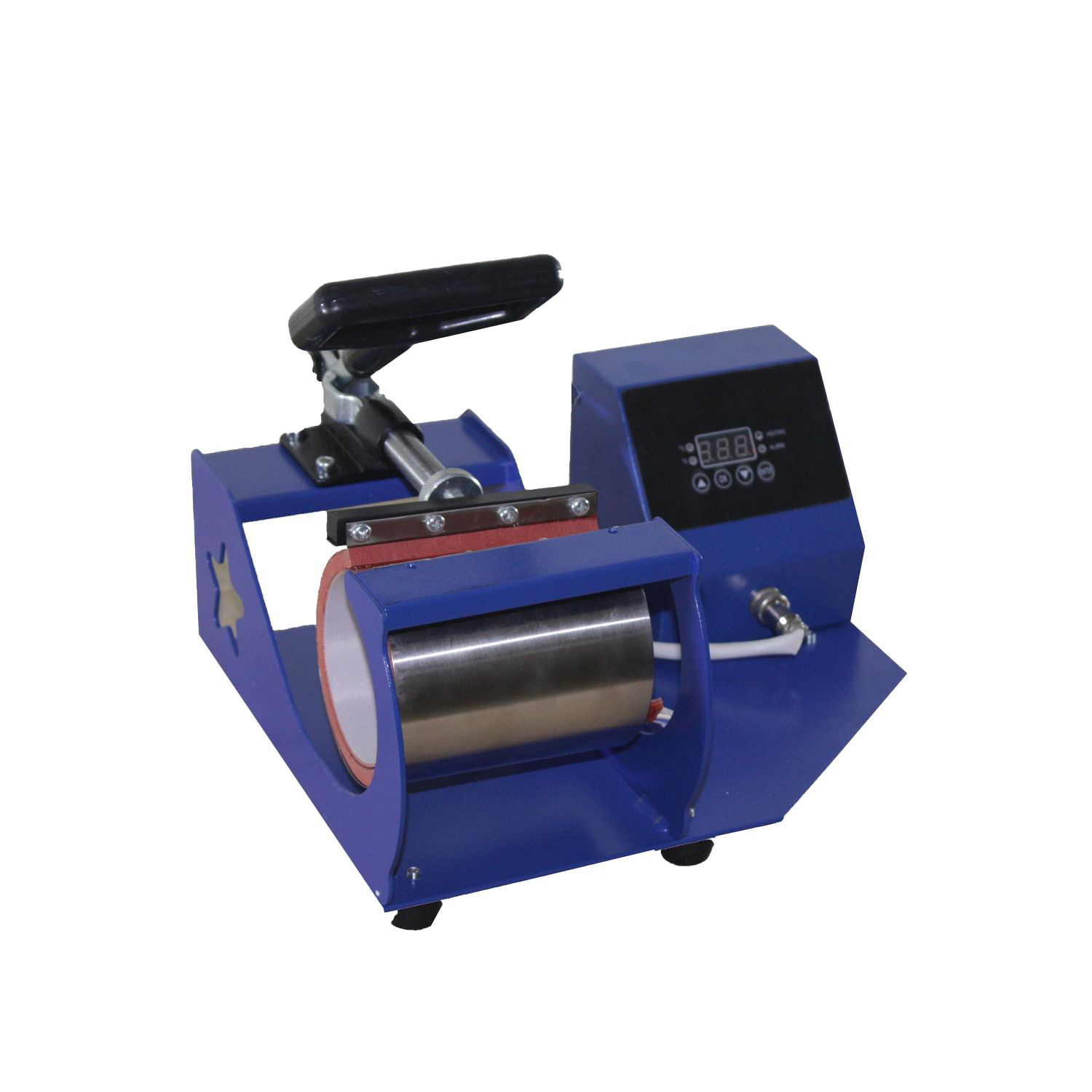

Okoboji Sublimation Mug press Horizontal XY012A

SPECIFICATIONS

PRODUCT VIDEO

PRODUCT DESCRIPTION

The Okoboji Sublimation Mug press Horizontal XY012A offers a unique horizontal configuration that maximises workspace efficiency whilst delivering exceptional sublimation performance through its advanced digital panel control system. This innovative design provides excellent visibility during operation and simplified mug loading, making it particularly suitable for high-frequency operations where operator efficiency directly impacts productivity. The powerful 350W heating system reaches impressive maximum temperatures of 399°C, accommodating specialty materials and challenging sublimation applications that standard machines cannot handle effectively.

Engineered for versatility and reliability, the XY012A features comprehensive digital controls with precise timing up to 999 seconds, enabling operators to perfect their sublimation techniques across diverse materials and applications. The compact 390x330x290mm package design makes it ideal for space-constrained environments whilst the adjustable pressure system ensures optimal transfer quality regardless of mug specifications. This Okoboji machine represents exceptional value for businesses requiring professional capabilities in a space-efficient format, particularly suited to operators seeking reliable performance for standard and specialty sublimation applications in India’s diverse printing market.

Upgrade Your Experience

Okoboji Sublimation Mug Press 2in1 MP20B

Okoboji Sublimation Mug Press 5-IN-1 MPA500B

Okoboji Sublimation Mug Press Electric Press MP99A

Okoboji Sublimation Pneumatic Mug Press ST110

KEY FEATURES

- Innovative Horizontal Configuration : Unique horizontal design provides excellent operator visibility, simplified mug loading, and efficient workspace utilisation for high-frequency operations.

- Advanced Digital Panel Control : Comprehensive digital interface offers precise control over temperature, timing, and pressure settings for optimal sublimation results.

- High-Temperature Capability : Impressive 399°C maximum temperature accommodates specialty materials and challenging applications beyond standard sublimation ranges.

- Powerful 350W Heating System : Efficient heating element provides rapid heat-up times and consistent temperature maintenance throughout extended operational periods.

- Extended Timing Range : Precise timing control from 0-999 seconds enables perfect sublimation techniques across diverse materials and complex design requirements.

- Adjustable Pressure System : Manual pressure adjustment ensures optimal compression for different mug thicknesses, materials, and transfer requirements.

- Space-Efficient Design : Compact 390x330x290mm footprint maximises workspace utility whilst maintaining professional-grade performance capabilities.

- Okoboji Horizontal Innovation : Purpose-designed to provide professional results in space-constrained environments whilst accommodating diverse sublimation applications and specialty materials.

FREQUENTLY ASKED QUESTIONS

What are the advantages of the horizontal configuration compared to vertical mug presses?

The horizontal design provides better operator visibility, easier mug loading/unloading, reduced operator fatigue, and more efficient workflow in high-frequency operations.

How does the 399°C maximum temperature benefit sublimation operations?

The high temperature capability enables processing of specialty materials, faster transfer times, and superior colour saturation that standard temperature ranges cannot achieve.

Is the digital panel control system user-friendly for operators with minimal experience?

Yes, the intuitive digital panel provides clear displays and straightforward controls that simplify operation whilst offering advanced settings for experienced users.

How much workspace does this horizontal design actually save compared to standard vertical presses?

The horizontal configuration typically reduces required workspace depth by 40-50% whilst providing equivalent or superior operational efficiency and accessibility.

Can I process different mug materials that require varying temperature settings?

Yes, the wide temperature range and precise digital controls accommodate ceramic, metal-coated, and specialty substrates with optimal settings for each material type.

What safety precautions are important when operating at 399°C maximum temperature?

Use heat-resistant protective equipment, ensure adequate ventilation, maintain safe distances from heating elements, and follow all digital panel safety warnings.

How does the adjustable pressure system work with the horizontal configuration?

The pressure adjustment mechanism maintains optimal compression regardless of orientation, ensuring consistent transfer quality across different mug specifications and materials.

What maintenance schedule is recommended for the high-temperature heating system?

Monthly inspection of heating elements, quarterly calibration checks, and annual professional servicing ensure optimal performance at elevated operating temperatures.

How does this compact model compare to larger machines in terms of output quality?

The XY012A delivers equivalent quality to larger systems whilst offering superior workspace efficiency and operational convenience for appropriate volume levels.

Is this machine suitable for both standard and specialty sublimation applications?

Yes, the wide temperature range, precise controls, and horizontal design make it excellent for standard operations whilst accommodating specialty materials and techniques.

Customers also bought

Okoboji Badge Magentic Mould Round 58mm

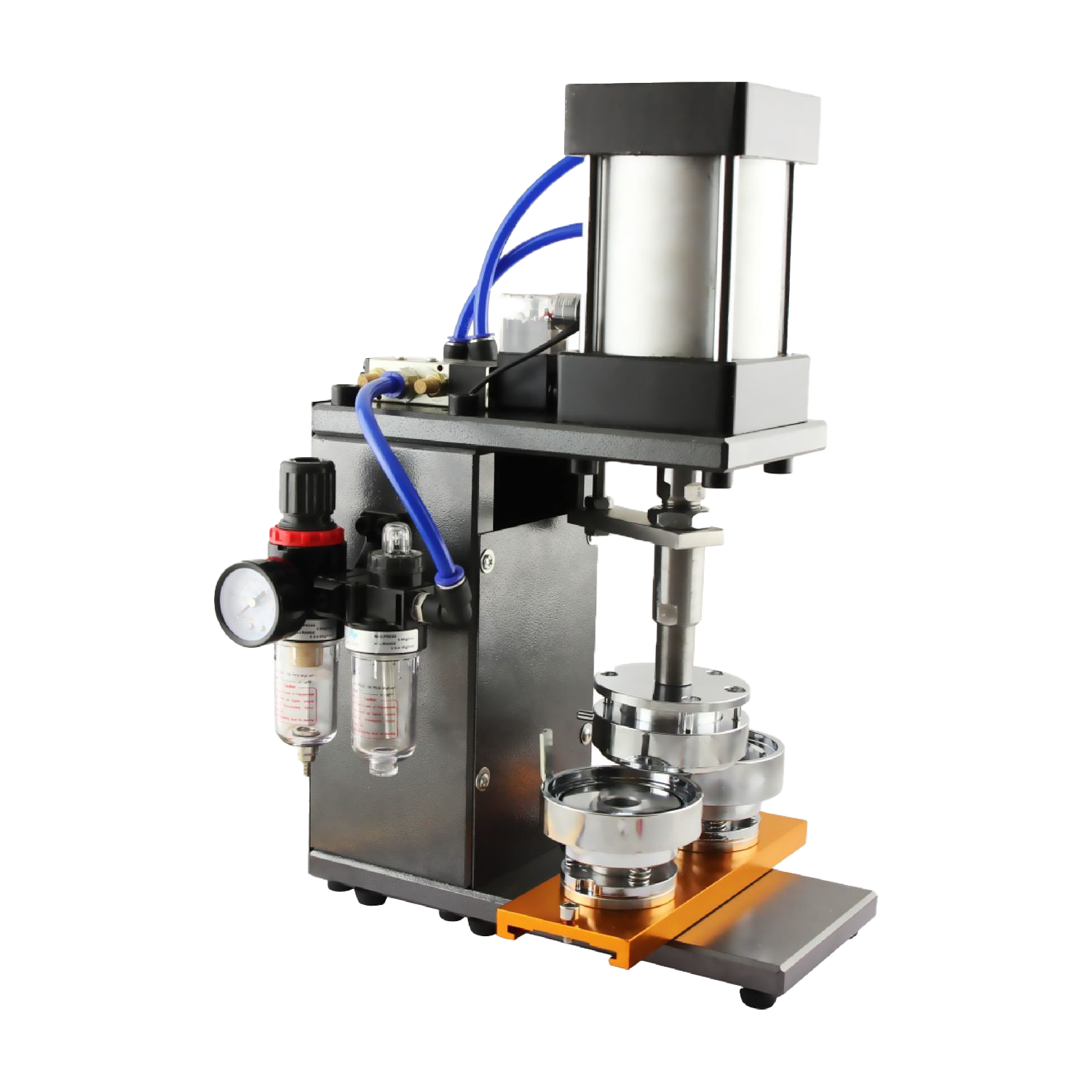

Okoboji Punch for Badge Pneumatic MAQ

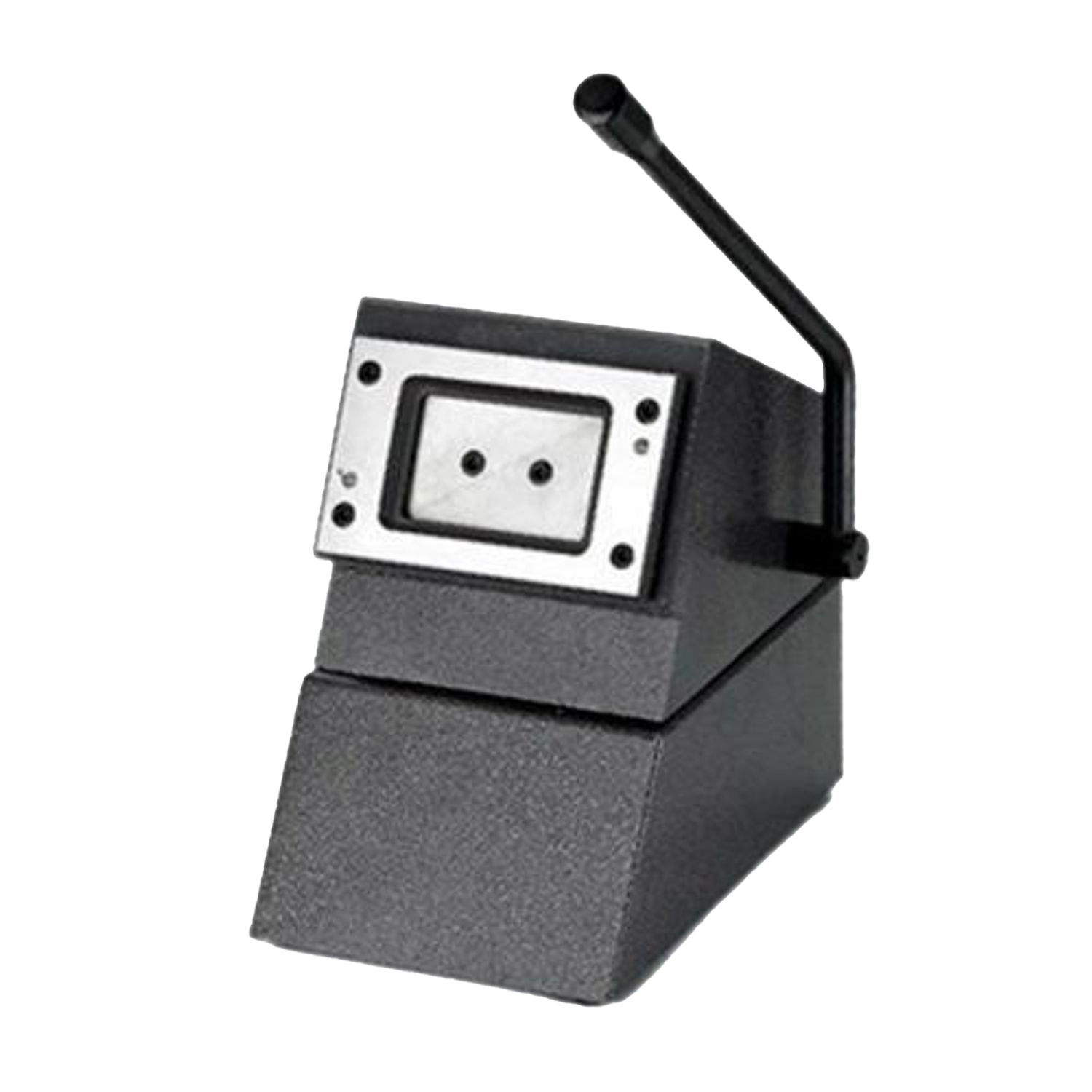

Okoboji PVC CARD CUTTER HEAVY Duty D0012