Okoboji Sublimation Mug Press 2in1 MP20B

SPECIFICATIONS

PRODUCT VIDEO

PRODUCT DESCRIPTION

The Okoboji Sublimation Mug Press 2in1 MP20B revolutionises productivity for custom printing businesses by enabling simultaneous processing of two 11oz mugs with its innovative dual-heating system. This professionally engineered machine features two independent 300W heating elements totalling 600W of power, dramatically reducing processing time whilst maintaining consistent quality across both mugs. The advanced GY04N digital controller ensures precise temperature and timing coordination for both heating zones, making it an ideal choice for businesses experiencing growing demand for personalised drinkware.

Designed specifically for commercial applications, the MP20B incorporates adjustable pressure mechanisms and easy heater exchange capabilities, allowing operators to fine-tune settings for different mug materials and design requirements. The robust construction handles continuous operation whilst the intelligent temperature control system maintains accuracy within ±0.5% across both heating elements. Whether serving corporate clients requiring bulk orders or handling diverse customer requests in retail environments, this Okoboji dual mug press delivers the efficiency and reliability needed to scale sublimation operations profitably in India’s expanding personalisation market.

Upgrade Your Experience

Okoboji Sublimation Mug Press Electric Press MP99A

Okoboji Sublimation Mug Press MP10A

Okoboji Sublimation Mug Press MP80B

Okoboji Sublimation Pneumatic Mug Press ST110

KEY FEATURES

- Dual Mug Processing : Simultaneously processes two 11oz mugs with independent 300W heating elements, doubling productivity compared to single mug presses.

- Advanced GY04N Controller : Professional-grade digital controller manages timing and temperature for both heating zones with exceptional precision and reliability.

- Powerful 600W System : Combined 600W heating power (2x300W) ensures rapid heat-up times and consistent temperature maintenance throughout extended operations.

- Adjustable Pressure Control : Manual pressure adjustment allows operators to optimise compression for different mug materials and achieve perfect transfer results.

- Easy Heater Exchange : Quick-change heater design enables rapid switching between different mug sizes and types, maximising operational flexibility.

- Professional Temperature Range : Operates up to 220°C (437°F) with ±0.5% accuracy, suitable for all standard sublimation applications and specialty materials.

- Dual Voltage Compatibility : Supports both 110V and 220V electrical systems, ensuring compatibility across diverse Indian electrical infrastructure configurations.

- Okoboji Commercial Quality : Built to withstand demanding commercial environments whilst delivering consistent, professional-grade sublimation results that justify premium pricing.

FREQUENTLY ASKED QUESTIONS

How much faster is the dual mug processing compared to single mug presses?

The MP20B processes two 11oz mugs simultaneously, effectively doubling productivity and reducing per-unit processing time by approximately 50% compared to single mug machines.

Can I process different designs on both mugs at the same time?

Yes, each heating element operates independently, allowing you to process completely different designs simultaneously whilst maintaining optimal temperature control for both mugs.

What is the power consumption and electrical requirements for this machine?

The 600W system draws 2.8A at 220V or 5.5A at 110V, operating at 50-60Hz frequency, compatible with standard commercial electrical installations across India.

How do I adjust the pressure for different types of mugs and materials?

The manual pressure adjustment system allows fine-tuning compression levels based on mug thickness, material composition, and design requirements for optimal transfer quality.

Is the heater exchange process complicated for different mug sizes?

No, the easy heater exchange system enables quick switching between different mug configurations without tools, maximising operational efficiency and versatility.

What safety precautions should I follow when operating this dual heating system?

Ensure proper ventilation, use heat-resistant gloves, maintain safe distance from heating elements, and follow all digital controller warnings for safe operation.

How does Okoboji ensure quality control across both heating elements?

Each heating element undergoes rigorous testing, and the GY04N controller monitors both zones independently to maintain consistent temperature accuracy within ±0.5%.

Can this machine handle continuous commercial operation throughout the day?

Yes, the robust 14kg construction and commercial-grade components are designed for extended operation in demanding business environments with proper maintenance.

What maintenance schedule is recommended for optimal dual heating performance?

Regular cleaning after every 50 cycles, monthly calibration checks, and quarterly professional servicing ensure consistent performance across both heating elements.

How does this model's efficiency impact profitability for sublimation businesses?

Doubled processing capacity significantly reduces labour costs per mug whilst enabling higher daily output, typically improving profit margins by 30-40% compared to single mug operations.

Customers also bought

Okoboji Badge Magentic Mould Round 58mm

Okoboji PVC CARD CUTTER Electric 3082

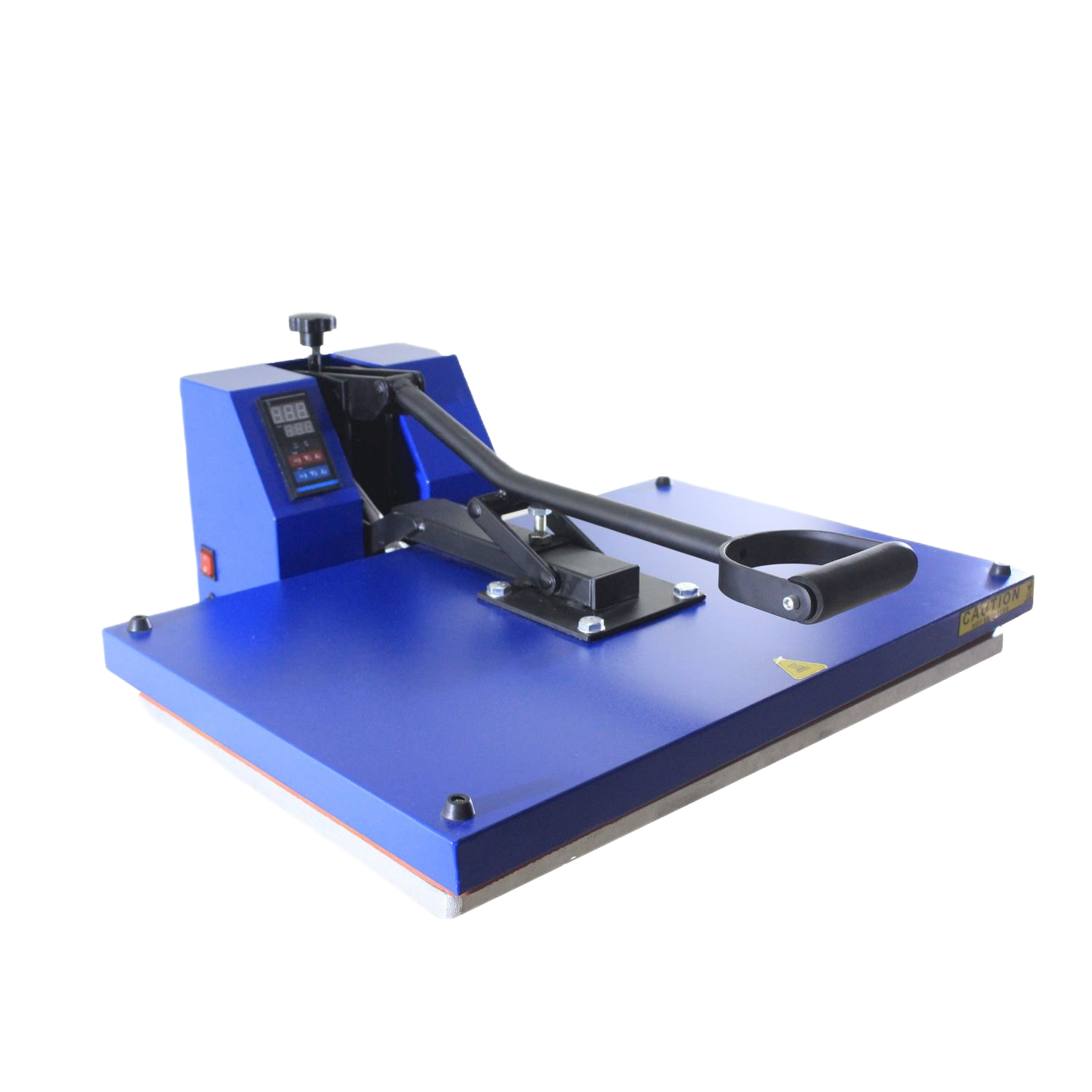

Okoboji Sublimation Heat Press 4060