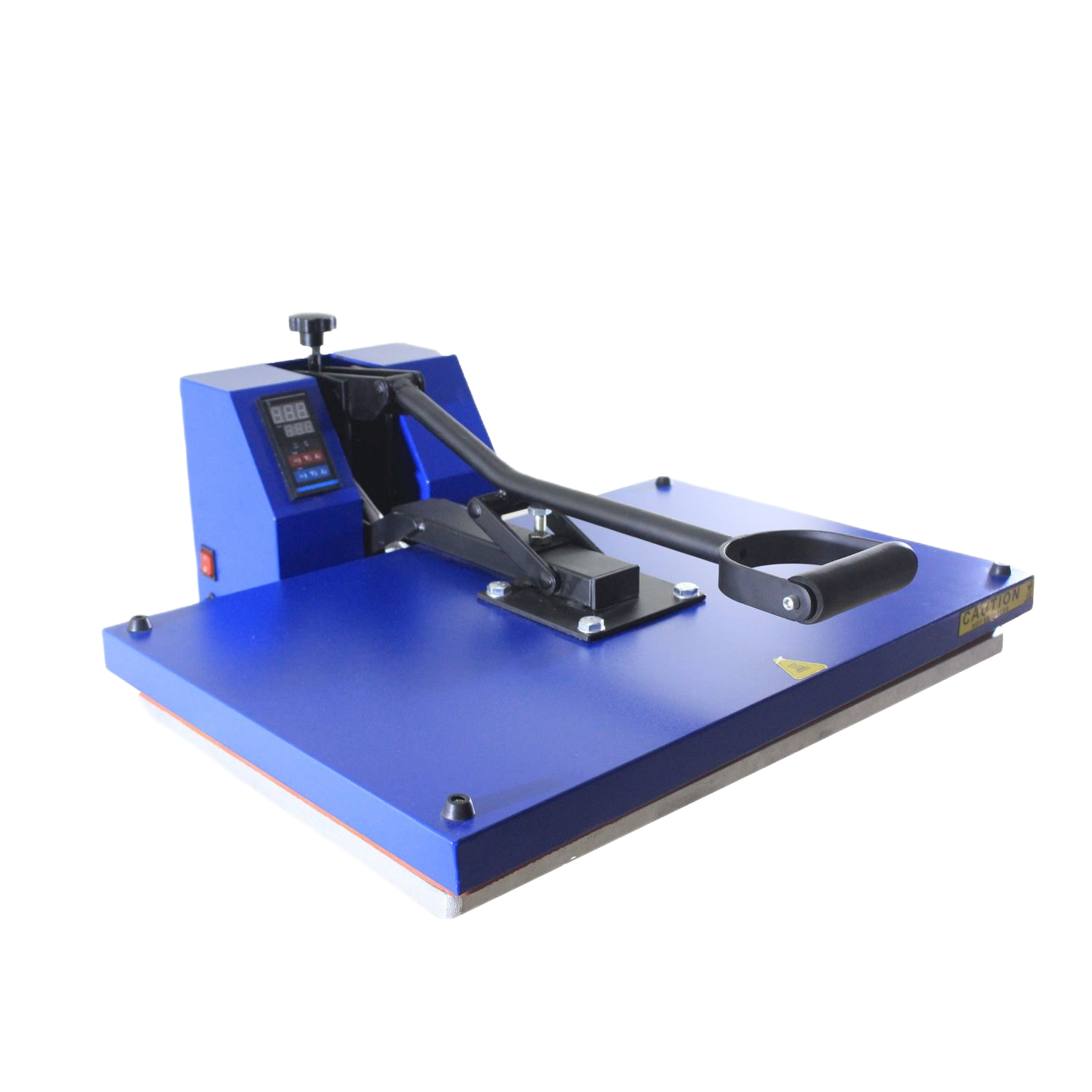

Okoboji Sublimation Heat Press 3838

SPECIFICATIONS

PRODUCT VIDEO

PRODUCT DESCRIPTION

The Okoboji Sublimation Heat Press 3838 delivers professional-grade performance in a perfectly sized format, specifically engineered to serve the diverse needs of small to medium-scale sublimation printing operations across India. This Generation Clamshell Heat Press Machine features a generous 38x38cm printing area that accommodates standard t-shirts, medium-sized bags, cushion covers, and various flat substrates whilst maintaining the precision and reliability demanded by professional printing applications in today’s competitive market.

Built with advanced aluminum heating plate technology and robust construction, this heat press ensures even temperature distribution across the entire surface, eliminating hot spots and cold zones that can compromise print quality. The powerful 1800W heating system combined with precise digital controls provides optimal thermal performance for consistent sublimation results across various materials and substrate thicknesses up to 70mm, making it ideal for diverse applications from promotional products to custom merchandise.

The machine’s intelligent design incorporates anti-scald protection and strong springs that ensure operator safety whilst providing consistent pressure application for professional-quality results. Whether you’re establishing a sublimation printing business, expanding existing capabilities, or serving commercial clients with demanding quality requirements, the Okoboji Heat Press 3838 offers the perfect balance of performance, reliability, and operational efficiency needed to succeed in the growing Indian custom printing market.

Upgrade Your Experience

Okoboji Sublimation Combo Heat Press 5in1

Okoboji Sublimation Combo Heat Press DCH800

Okoboji Sublimation Heat Press 4060

Okoboji Sublimation Heat Press Auto Open 3838

KEY FEATURES

- Professional 38x38cm heating platen provides optimal capacity for standard t-shirts, medium-sized graphics, and diverse flat substrates up to 70mm thickness

- Powerful 1800W heating system with advanced aluminum plate technology ensures rapid heating and even temperature distribution for consistent sublimation results

- Precision digital control panel with temperature range up to 399°C and timing control (0-999 seconds) enables accurate heat transfer across different materials

- Generation Clamshell design with anti-scald protecting cover and strong spring system ensures safe operation whilst maintaining consistent pressure application

- Dual voltage compatibility (110V/220V) with professional power management makes it suitable for Indian electrical standards whilst ensuring reliable performance

- Okoboji's proven engineering excellence and comprehensive technical support backed by extensive experience in the Indian sublimation printing market

- Compact yet robust construction with 22kg weight provides stability for consistent results whilst remaining suitable for various workshop environments

- Professional-grade components designed for extended commercial use and reliable operation under demanding production conditions

FREQUENTLY ASKED QUESTIONS

What types of products work best with the 38x38cm printing area of the Okoboji Heat Press?

This size perfectly accommodates standard t-shirts, medium cushion covers, tote bags, mouse pads, small banners, and multiple smaller items simultaneously, making it ideal for diverse commercial printing applications.

How does the aluminum heating plate improve print quality compared to standard plates?

Aluminum heating plates provide superior thermal conductivity, ensuring even heat distribution across the entire surface, faster heating times, and consistent temperature maintenance for professional sublimation results.

What safety features does the Okoboji 3838 include for operator protection?

The machine includes anti-scald protecting cover, strong spring system for controlled pressure, heat-resistant handles, and digital temperature controls to ensure safe operation during high-temperature printing processes.

Can this heat press handle thick substrates like padded jackets or thick cushions?

Yes, the 70mm thickness capacity accommodates thick fabrics, padded items, promotional products, and substantial materials commonly used in commercial sublimation printing applications.

What maintenance schedule ensures optimal performance of the Okoboji 3838?

Regular cleaning of the heating plate, pressure calibration checks, and periodic temperature verification ensure consistent performance. Okoboji provides detailed maintenance guidelines and technical support for Indian customers.

Is the 1800W power consumption energy-efficient for commercial operations?

The 1800W power system provides optimal heating performance whilst maintaining energy efficiency, heating quickly to reduce cycle times and operating costs in commercial printing environments.

How does the digital control system improve operational consistency?

Precise digital controls eliminate guesswork, enable repeatable settings for different materials, provide temperature accuracy, and allow operators to maintain consistent quality across production runs.

What training does Okoboji provide for new users of the Heat Press 3838?

Okoboji offers comprehensive training materials, video tutorials, and technical support covering proper operation techniques, material selection, and troubleshooting for optimal results.

Can I use this machine for both sublimation and heat transfer vinyl applications?

Yes, the versatile design and precise temperature controls make it suitable for sublimation transfers, heat transfer vinyl, and various other heat application techniques used in commercial printing.

What support does Okoboji provide for its Sublimation 3838 machine users?

Okoboji offers comprehensive support including installation guidance, operator training, maintenance instruction, spare parts supply, and technical assistance. Our service network understands the specific requirements of manual machine operations and provides appropriate support.

Customers also bought

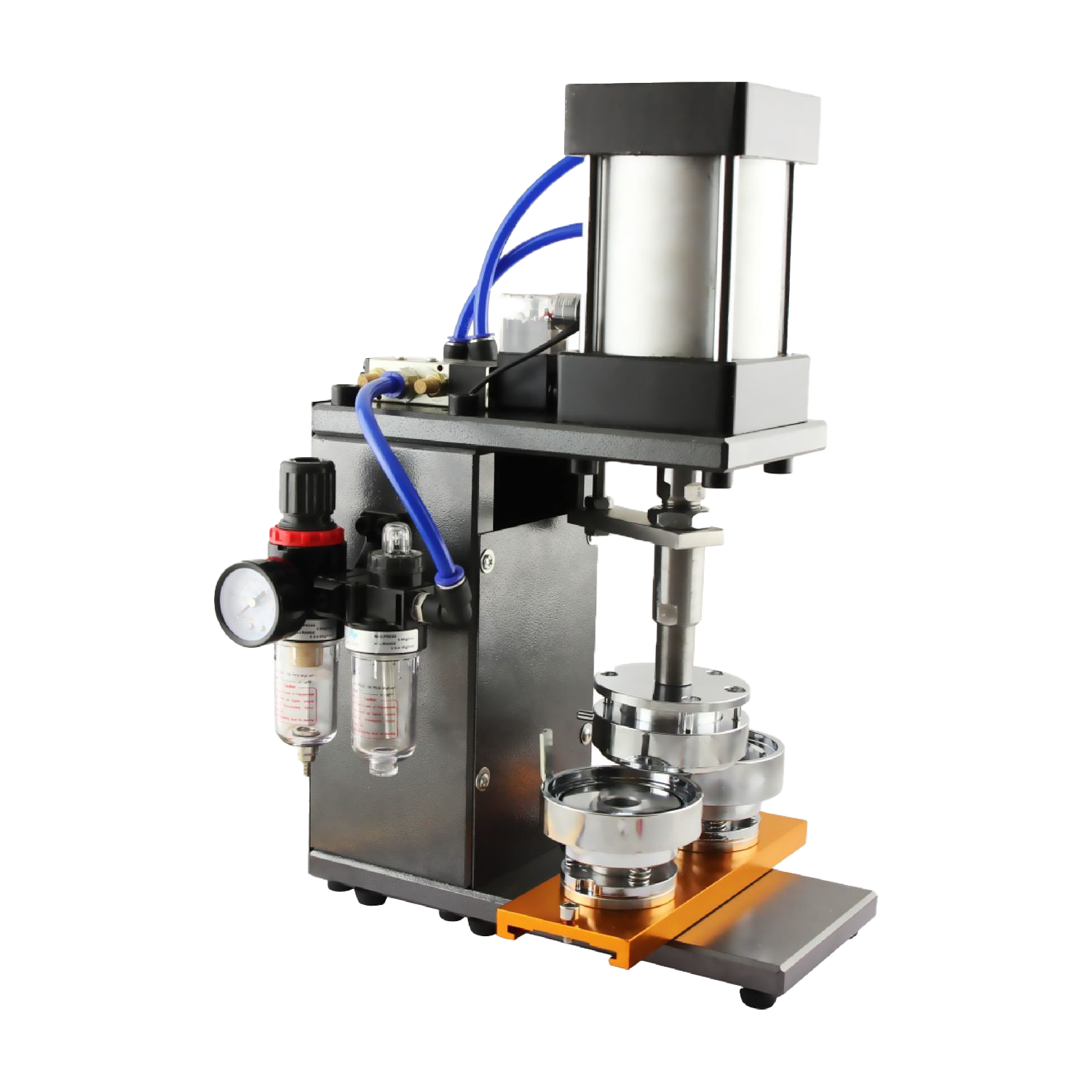

Okoboji Punch for Badge Pneumatic MAQ

Okoboji Badge Slide Mould Round 75mm

Okoboji Badge Magentic Mould Round 58mm

Okoboji ID Card Fusing A4 100

Okoboji PVC CARD CUTTER Electric 3082

Okoboji Sublimation Mug Press 2in1 MP20B

Okoboji Sublimation Pneumatic Mug Press ST110