Okoboji Sublimation Combo Heat Press DCH600

SPECIFICATIONS

PRODUCT VIDEO

PRODUCT DESCRIPTION

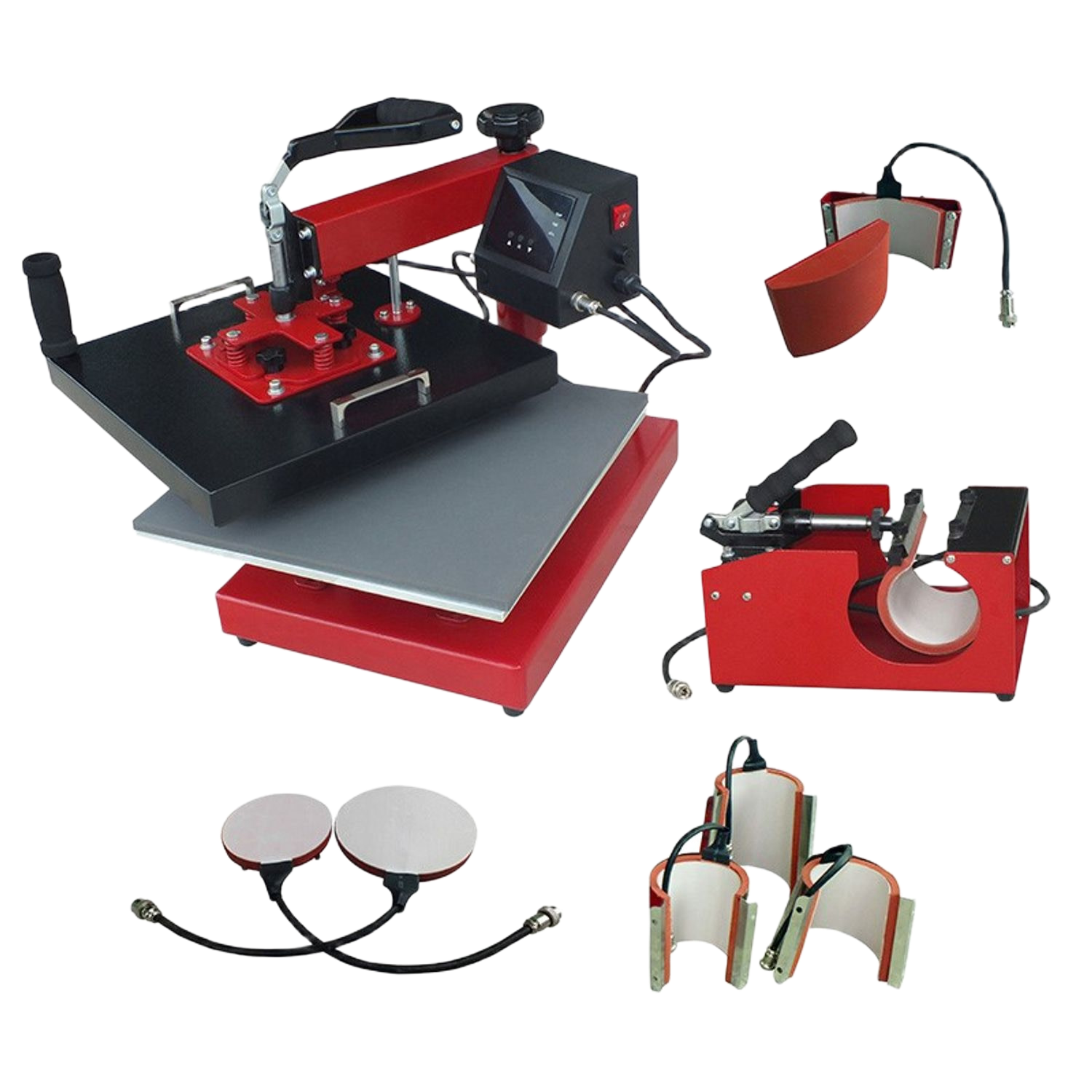

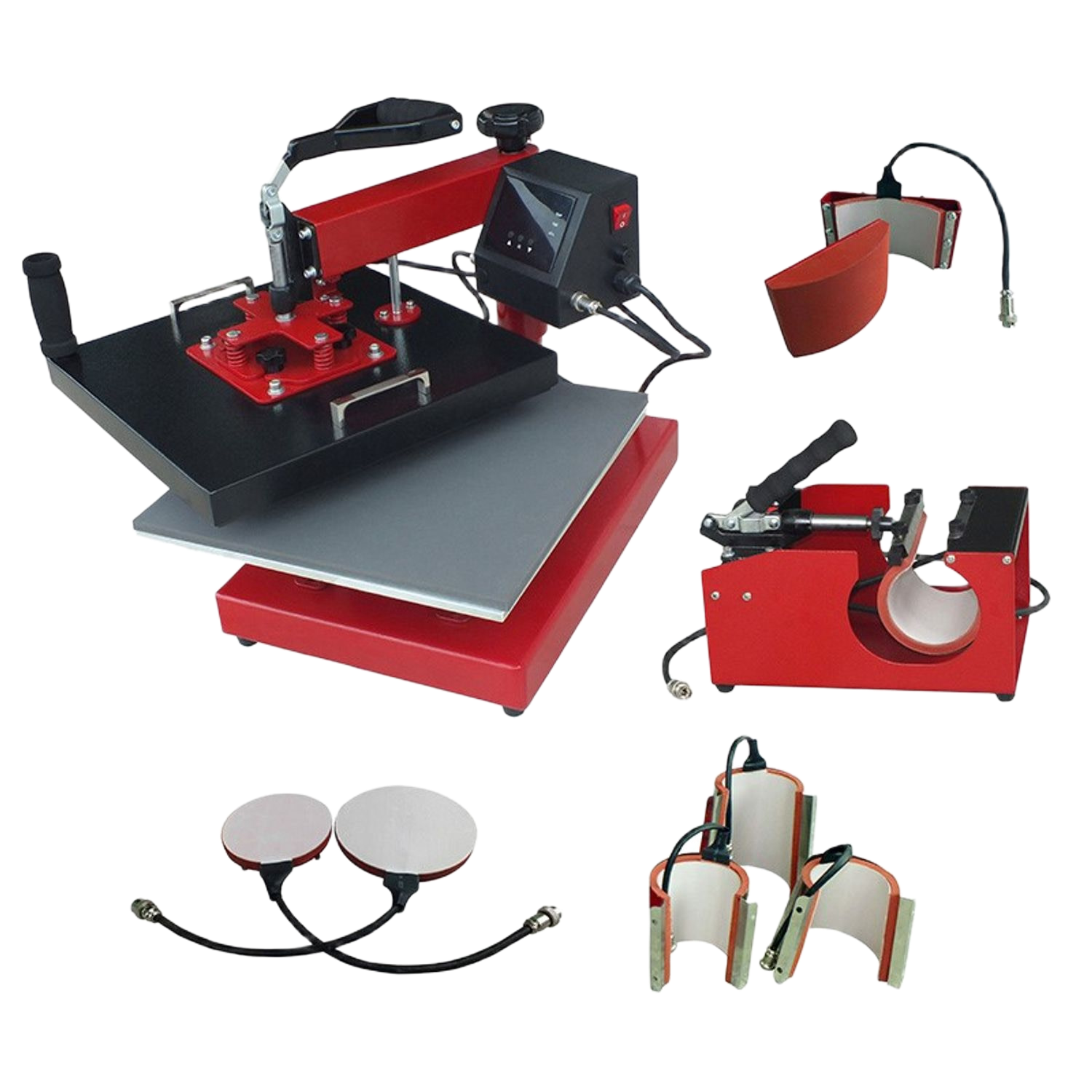

The Okoboji Sublimation Combo Heat Press DCH600 represents the pinnacle of professional-grade multifunctional heat transfer equipment, designed specifically for commercial operations requiring superior performance, precision, and reliability. This advanced manual swing-away system combines the functionality of multiple specialised presses into one comprehensive unit, featuring a substantial 15×15 inch (38x38cm) heating Bed that accommodates larger substrates whilst maintaining the versatility to handle various specialized applications through its extensive range of optional heating elements.

Built to meet the demanding requirements of established sublimation businesses in India, the DCH600 incorporates the advanced GY-04 digital time and temperature control system, ensuring precise operation parameters across all applications. The machine’s robust construction and commercial-grade components make it particularly suitable for high-volume production environments, print shops, and businesses serving corporate clients with demanding quality standards. Its ability to handle substrates up to 30-40mm thickness, combined with the precision temperature control accurate to ±0.5%, ensures consistent professional results across diverse materials and applications.

The comprehensive range of optional heaters included with the DCH600 enables operators to serve virtually every segment of the custom printing market, from promotional products and corporate gifts to personalised merchandise and artistic applications. This versatility, combined with Okoboji’s reputation for reliability and comprehensive support, makes the DCH600 the preferred choice for serious sublimation professionals seeking to maximise their operational capabilities whilst maintaining the highest quality standards.

Upgrade Your Experience

Okoboji Sublimation Combo Heat Press DCH800

Okoboji Sublimation Heat Press Auto with Slideout SHP15LP3MS

Okoboji Sublimation Heat Press Dual Station Pneumatic

Okoboji Sublimation Heat Press Auto Open 3838

KEY FEATURES

- Professional 15x15 inch (38x38cm) heating Bed provides ample space for large format printing on t-shirts, bags, cushions, and other substantial substrates

- Advanced GY-04 digital time and temperature control system with ±0.5% accuracy ensures precise operation and consistent results across all applications

- Comprehensive optional heater package includes multiple mug sizes (6 oz,11oz,), plate heaters (12.6cm, 15.2cm), and cap heater (9x15.5cm)

- Manual swing-away multifunctional design with robust construction handles substrates up to 30-40mm thickness for versatile application possibilities

- Commercial-grade power options (1.5KW/1.8KW) with dual voltage compatibility (120V/220V) ensure reliable performance under demanding production conditions

- Professional temperature range up to 225°C with 0-999 second timing control provides flexibility for various sublimation materials and specialized applications

- Okoboji's proven engineering excellence and comprehensive technical support ensure reliable operation and maximum productivity for commercial printing operations

- Heavy-duty construction with precision components designed for high-volume commercial use and extended operational life under demanding conditions

FREQUENTLY ASKED QUESTIONS

What makes the DCH600 suitable for commercial sublimation printing operations?

The DCH600 features commercial-grade construction, precision temperature control (±0.5% accuracy), large 15x15 inch Bed, and comprehensive heater options, making it ideal for high-volume production and diverse customer requirements.

How do I switch between different optional heaters on the DCH600?

The Okoboji DCH600 uses a quick-change heater system allowing operators to swap between mug, plate, and cap heaters in under 5 minutes, maximising production efficiency and minimising downtime.

What is the maximum substrate thickness the DCH600 can accommodate?

The machine handles substrates up to 30-40mm thickness, accommodating thick fabrics, padded items, wooden products, and other substantial materials commonly used in commercial sublimation applications.

Can the DCH600 handle both small and large production runs efficiently?

Yes, the precision digital controls and multiple heater options make it equally effective for small custom orders and large commercial runs, providing the flexibility needed for diverse business operations.

What training does Okoboji provide for the advanced GY-04 control system?

Okoboji offers comprehensive training on the GY-04 system's advanced features, including temperature profiling, production counting, and maintenance procedures to ensure optimal performance and longevity.

How does the temperature accuracy of ±0.5% benefit commercial printing quality?

This precision ensures consistent colour reproduction, proper ink transfer, and reduced waste across production runs, meeting the quality standards demanded by commercial clients and reducing costly reprints.

What optional heaters are recommended for starting a comprehensive printing business?

The standard package includes all essential heaters for mugs (multiple sizes), plates, and caps, providing immediate capability to serve the most popular sublimation product categories in the Indian market.

Is the DCH600 suitable for printing on corporate promotional products?

Absolutely, the large Bed size, precision controls, and professional construction make it perfect for corporate branding applications requiring consistent, high-quality results across various promotional items.

What maintenance schedule should I follow for commercial DCH600 usage?

Regular cleaning of heating elements, monthly calibration checks, and periodic inspection of pressure mechanisms ensure optimal performance. Okoboji provides detailed commercial maintenance protocols and support.

How does Okoboji support commercial customers using the DCH600 in India?

Okoboji offers priority technical support, on-site service options, training programs, and dedicated account management for commercial customers to ensure uninterrupted business operations.

Customers also bought

Okoboji Badge Slide Mould Round 75mm

Okoboji PVC CARD CUTTER Electric 3082

Okoboji Sublimation Mug Press 2in1 MP20B