Okoboji Sublimation Heat Press Drawer Out 003 2 3838

SPECIFICATIONS

PRODUCT VIDEO

PRODUCT DESCRIPTION

The Okoboji Sublimation Heat Press Drawer Out 003 2 3838 introduces innovative drawer-out design technology combined with advanced star high-pressure capabilities, creating a sophisticated solution that enhances operational efficiency through intelligent workspace organization and superior pressure application. This New High Pressure Model incorporates cutting-edge drawer mechanism that allows operators to prepare substrates whilst current transfers are in progress, significantly reducing cycle times and increasing overall production efficiency in commercial sublimation operations.

Engineered with star high-pressure technology and powered by a reliable 1800W heating system, this advanced press delivers exceptional pressure application and thermal performance across the substantial 38x38cm surface whilst the innovative drawer-out design revolutionizes workflow optimization. The combination of high-pressure capabilities with efficient workspace design creates the perfect solution for commercial operations seeking both superior print quality and enhanced productivity through intelligent equipment design.

This premium drawer-out heat press is particularly valuable for busy commercial operations, print shops requiring maximum efficiency, and businesses seeking to optimize their workspace utilization whilst maintaining professional-quality results. Whether operating in space-constrained environments, managing high-volume production schedules, or seeking competitive advantages through operational efficiency, the Drawer Out 003 2 delivers the innovation and performance needed to succeed in the competitive Indian commercial sublimation market.

Upgrade Your Experience

Okoboji Sublimation Combo Heat Press 5in1

Okoboji Sublimation Heat Press 3838

Okoboji Sublimation Heat Press Dual Station Pneumatic

Okoboji Sublimation Heat Press Swing SA20

KEY FEATURES

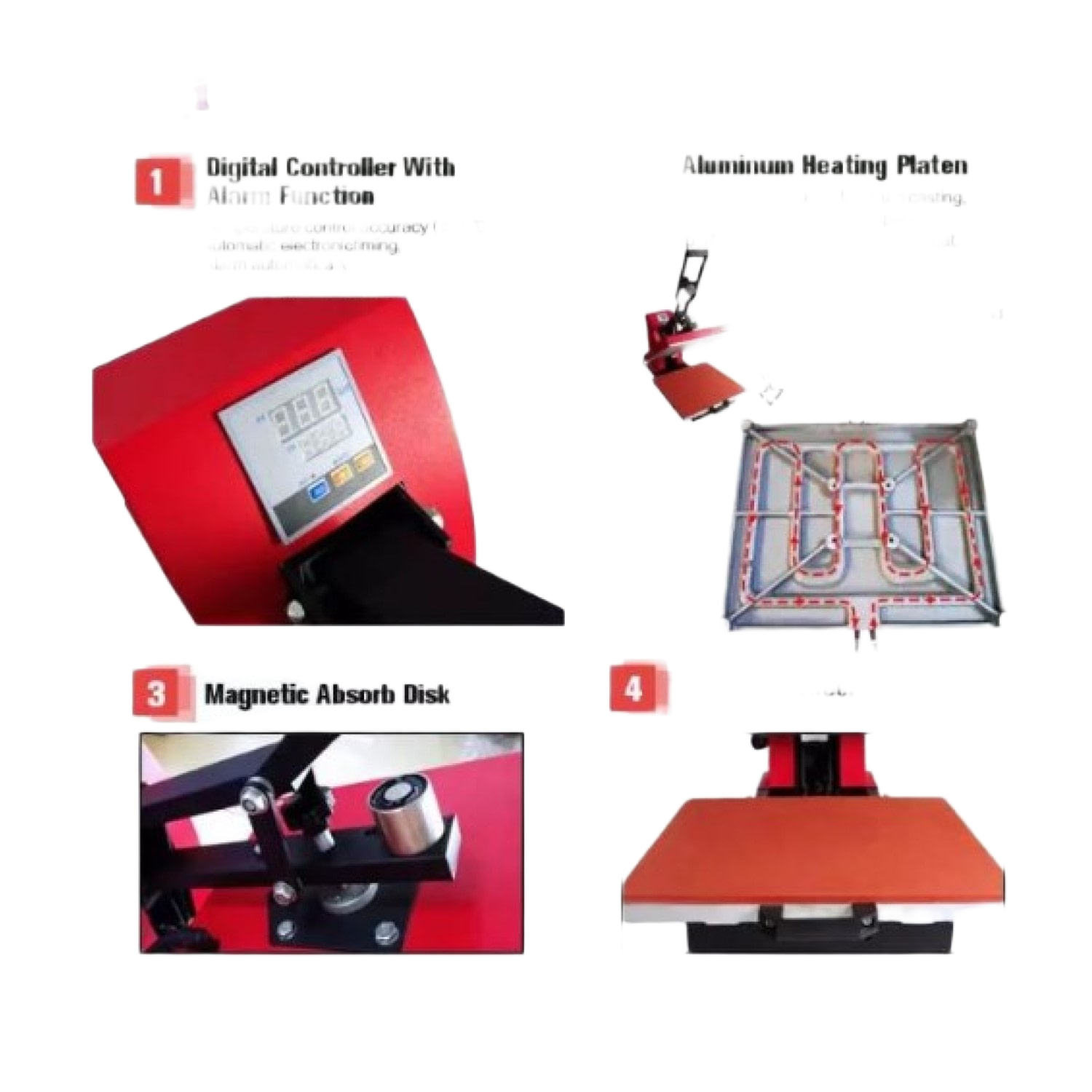

- Innovative drawer-out design enables substrate preparation whilst current transfer is processing, significantly reducing cycle times and increasing production efficiency

- Advanced star high-pressure technology provides superior pressure application for enhanced colour vibrancy, improved adhesion, and professional-quality results

- Optimal 38x38cm printing capacity accommodates standard commercial applications whilst the drawer mechanism optimizes workspace utilization and operator comfort

- Professional 1800W heating system with digital controls ensures rapid heating and consistent temperature distribution for reliable commercial operation

- New High Pressure Model designation demonstrates advanced engineering with enhanced pressure capabilities superior to standard commercial heat presses

- Compact yet robust construction with 26kg weight provides excellent stability whilst remaining suitable for various workshop environments and space constraints

- Digital control panel with temperature range up to 399°C and precision timing (0-999 seconds) optimized for high-pressure drawer-out operation

- Okoboji's innovative engineering excellence with advanced design features and comprehensive technical support for commercial printing operations

FREQUENTLY ASKED QUESTIONS

What advantages does the drawer-out design provide for commercial production efficiency?

The drawer mechanism enables substrate preparation during pressing cycles, reduces idle time, increases throughput, and optimizes workflow for maximum productivity in commercial operations.

How does star high-pressure technology improve print quality compared to standard systems?

Star technology provides enhanced pressure distribution, improved contact consistency, superior colour transfer, and professional results that exceed standard pressure capabilities.

What types of commercial operations benefit most from drawer-out workspace efficiency?

Busy print shops, high-volume commercial operations, space-constrained facilities, and businesses requiring maximum efficiency benefit from the innovative drawer design.

How does the drawer mechanism affect substrate loading and operator comfort?

The drawer design provides easier access, improved ergonomics, reduced operator fatigue, and enhanced workflow organization for extended commercial production periods.

Can the high-pressure system handle diverse commercial substrates effectively?

Yes, the enhanced pressure capabilities accommodate various materials including difficult-to-transfer substrates whilst the 70mm thickness capacity handles diverse commercial applications.

What makes this model suitable for space-constrained commercial environments?

The drawer design optimizes workspace utilization, reduces footprint requirements, and enables efficient operation in smaller commercial facilities without compromising performance.

How does the 25kg weight provide stability whilst maintaining workshop flexibility?

The optimized weight ensures consistent pressure application and operational stability whilst remaining manageable for workshop installation and potential relocation.

What training is required for operators using drawer-out high-pressure equipment?

Training covers drawer operation techniques, high-pressure optimization, workflow efficiency, safety procedures, and advanced sublimation methods for maximum results.

Is the drawer mechanism reliable for continuous commercial operation?

Yes, the robust drawer design provides consistent operation, enhanced durability, and reliable performance suitable for demanding commercial production schedules."

What support does Okoboji provide for its Sublimation 3838 machine users?

Okoboji offers comprehensive support including installation guidance, operator training, maintenance instruction, spare parts supply, and technical assistance. Our service network understands the specific requirements of manual machine operations and provides appropriate support.

Customers also bought

Okoboji Badge Slide Mould Round 75mm

Okoboji ID Card Fusing A4 100

Okoboji Sublimation Mug Press 5-IN-1 MPA500B