Okoboji Sublimation 3D Vaccum Press ST420

SPECIFICATIONS

PRODUCT VIDEO

PRODUCT DESCRIPTION

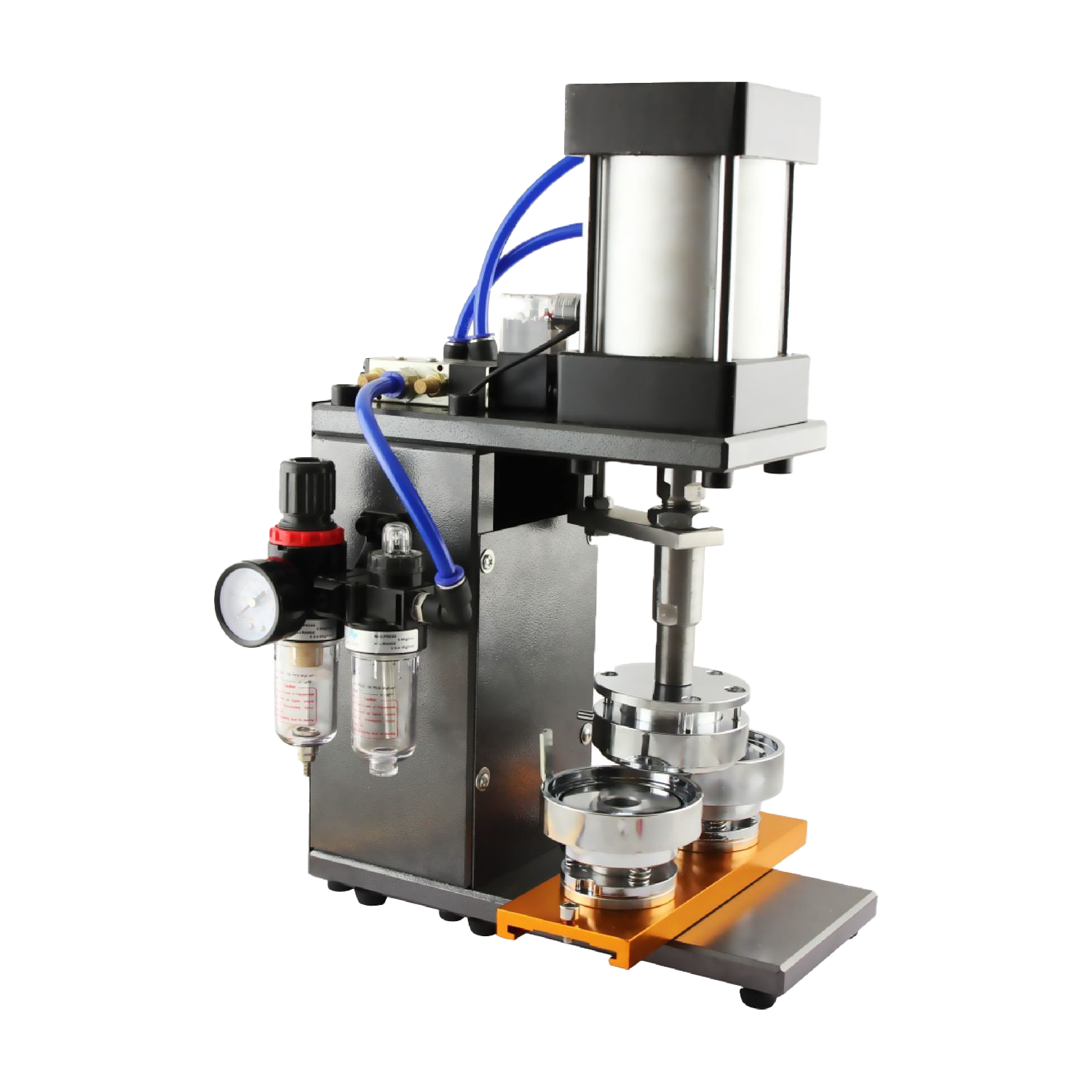

The Okoboji Sublimation 3D Vacuum Press ST420 represents the pinnacle of three-dimensional sublimation technology, featuring advanced auto-pneumatic operation that revolutionizes the printing process for curved and irregular surfaces. This sophisticated vacuum press incorporates dual 800W heating elements with intelligent pneumatic automation, creating optimal conditions for professional 3D sublimation printing whilst eliminating the manual operation challenges associated with traditional vacuum systems.

Engineered with comprehensive automation capabilities, the ST420 includes an integrated air pump system that maintains precise vacuum conditions whilst the dual heating elements ensure even temperature distribution across complex three-dimensional surfaces. The machine’s advanced design supports all sublimatable materials including t-shirts, flat surfaces, vertical applications, and three-dimensional objects, whilst incorporating all the proven functionality of the ST-3042 model with enhanced automation and user convenience features.

This premium auto-pneumatic 3D vacuum press is specifically designed for commercial operations requiring both versatility and automation, enabling operators to achieve professional results on curved surfaces whilst reducing manual intervention and operator skill requirements. Whether serving the mobile case printing market, custom promotional products industry, or diverse 3D sublimation applications, the ST420 delivers the automation, precision, and reliability needed to establish competitive advantages in the rapidly growing Indian 3D sublimation printing market.

Upgrade Your Experience

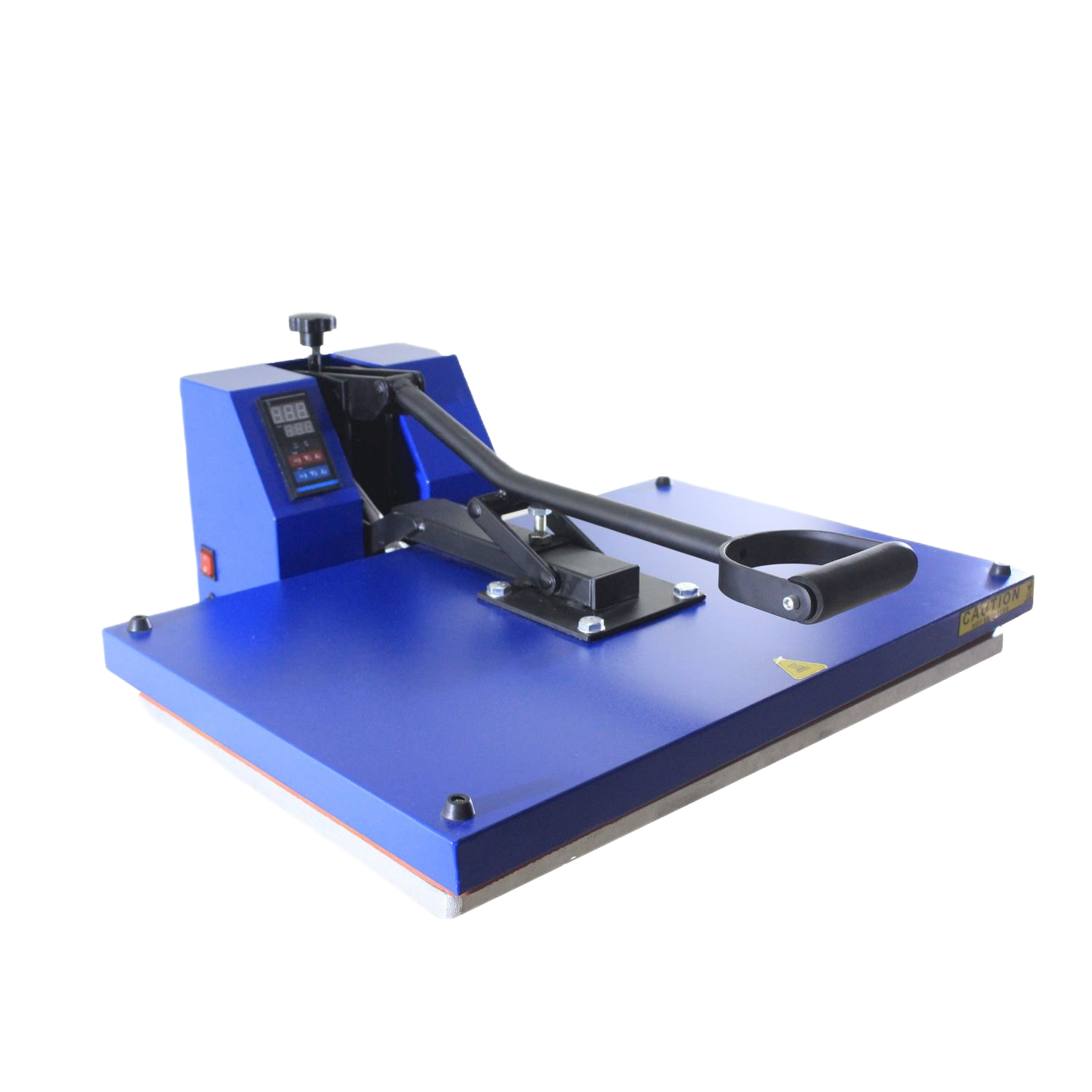

Okoboji Sublimation Combo Heat Press 5in1

Okoboji Sublimation Combo Heat Press DCH800

Okoboji Sublimation Heat Press 4060

Okoboji Sublimation Heat Press Auto Open 3838

KEY FEATURES

- Advanced auto-pneumatic operation with integrated air pump eliminates manual vacuum control whilst ensuring optimal pressure conditions for professional 3D sublimation results

- Dual 800W heating elements provide superior thermal performance and even temperature distribution across complex three-dimensional surfaces for consistent quality

- Comprehensive sublimation capabilities supporting all materials including t-shirts, flat surfaces, vertical applications, and three-dimensional objects in a single versatile machine

- Proven ST-3042 functionality enhanced with automation features, providing reliability and performance with improved operator convenience and reduced skill requirements

- Five programmable user presets enable customized settings for different materials and applications, ensuring consistent results and simplified operation for various substrates

- Professional 297mm x 420mm transfer size accommodates diverse 3D applications whilst maintaining precision control and optimal results across all supported materials

- Compact 35kg design with integrated pneumatic system provides professional capabilities whilst remaining suitable for various workshop environments and space constraints

- Okoboji's advanced 3D vacuum technology with comprehensive automation features and technical support designed for professional commercial sublimation operations

FREQUENTLY ASKED QUESTIONS

What advantages does auto-pneumatic operation provide over manual 3D vacuum systems?

Auto-pneumatic operation eliminates guesswork, ensures consistent vacuum pressure, reduces operator skill requirements, and provides automated control for repeatable professional results across all applications.

How do the dual 800W heating elements improve 3D sublimation quality?

Dual heating provides superior temperature distribution, faster heating times, better heat penetration for curved surfaces, and consistent thermal performance essential for professional 3D applications.

What types of materials and products work best with the ST420's versatile capabilities?

Mobile phone cases, curved mugs, bottles, irregularly shaped promotional items, textured surfaces, and any sublimatable material requiring three-dimensional heat transfer applications.

How do the five programmable presets improve operational efficiency?

Presets eliminate setup time, ensure consistent settings for repeat jobs, reduce operator error, and enable quick switching between different materials and applications for enhanced productivity.

Is the integrated air pump sufficient for continuous commercial operation?

Yes, the included air pump system is designed for commercial use, providing reliable vacuum pressure, consistent performance, and the automation needed for professional production environments.

How does the ST420 compare to the ST-3042 in terms of capabilities and automation?

The ST420 includes all ST-3042 functions plus auto-pneumatic operation, integrated air pump, programmable presets, and enhanced automation features for superior convenience and consistency.

What training is required for operators of auto-pneumatic 3D vacuum equipment?

Basic training covering preset programming, material selection, automation features, and troubleshooting enables operators to achieve professional results with minimal learning curve.

Can the ST420 handle high-volume production of 3D items effectively?

The automation features, dual heating, and consistent pneumatic operation make it suitable for commercial production whilst maintaining quality standards across volume runs.

What maintenance is required for the pneumatic system and dual heating elements?

Regular air pump maintenance, heating element inspection, vacuum system checks, and calibration ensure optimal performance. Okoboji provides comprehensive maintenance guidance.

How does the 35kg weight affect portability and workshop installation?

The optimized weight provides stability for 3D operations whilst remaining manageable for workshop installation, balancing performance requirements with practical considerations for various environments.

Customers also bought

Okoboji Badge Magentic Mould Round 58mm

Okoboji Punch for Badge Pneumatic MAQ

Okoboji PVC CARD CUTTER Electric 3082