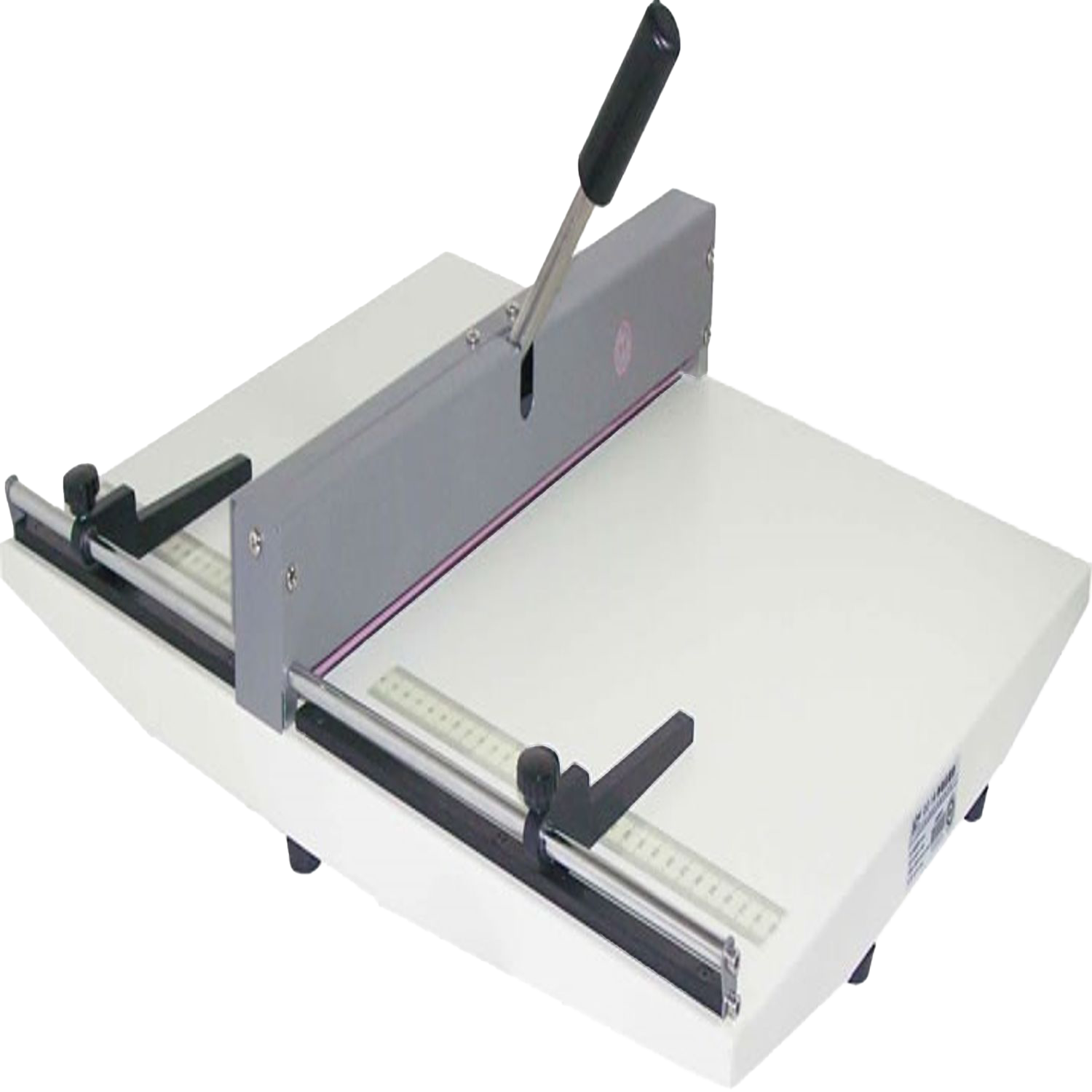

Okoboji Perfect Binder Creaser PBC

SPECIFICATIONS

PRODUCT VIDEO

PRODUCT DESCRIPTION

The Okoboji Perfect Binder Creaser PBC represents an essential accessory that significantly enhances the professional quality and appearance of perfect bound publications. This precision-engineered creasing device features an innovative three-wheel configuration that creates sharp, uniform creases along book covers and spines, eliminating the flat, unprofessional appearance common in basic perfect binding operations. The creaser’s sophisticated mechanical design ensures consistent pressure application and precise crease placement, transforming standard perfect bound documents into professional-grade publications that rival commercially produced books in appearance and structural integrity.

Specifically designed to complement Okoboji’s perfect binding machines, this creasing accessory addresses the critical finishing stage that often distinguishes amateur from professional binding results. The three-wheel system provides superior control over crease depth and consistency, accommodating various cover materials from lightweight paper to heavy cardstock. This enhanced finishing capability proves invaluable for businesses seeking to elevate their document presentation quality, particularly for client proposals, marketing materials, educational publications, and any bound documents where professional appearance directly impacts perceived value and credibility.

Upgrade Your Experience

Okoboji Glue Binding Machine A4 Semi Auto

Okoboji Glue Binding Machine B40F

Okoboji Glue Binding Machine B40M

Okoboji PVC Tubebind Automatic TBA

KEY FEATURES

- Advanced three-wheel creasing technology delivers precise, uniform creases that create professional spine definition and enhance overall binding appearance for commercial-quality results

- Seamless integration with Okoboji perfect binding machines optimises workflow efficiency by incorporating creasing directly into the binding process without additional handling steps

- Versatile material compatibility accommodates cover stocks ranging from 200gsm to 400gsm, including coated papers, cardstock, and specialty cover materials for diverse application requirements

- Precision pressure control ensures consistent crease depth across production runs, eliminating variations that can compromise professional appearance in commercial binding operations

- Durable construction with industrial-grade components guarantees reliable performance in high-volume commercial environments whilst maintaining precise creasing accuracy over extended use periods

- Cost-effective enhancement solution significantly improves binding quality and perceived value without requiring substantial capital investment compared to complete system upgrades

- User-friendly operation integrates easily into existing binding workflows, requiring minimal additional training whilst delivering immediate improvements in finished product quality

- Compact design maintains efficient workspace utilisation whilst adding essential professional finishing capabilities to standard perfect binding operations for enhanced productivity

FREQUENTLY ASKED QUESTIONS

What specific improvements does the Okoboji creaser provide to perfect bound publications?

The Okoboji Perfect Binder Creaser PBC creates sharp, professional spine creases that improve both aesthetic appearance and structural integrity, resulting in books that lay flatter, stack better, and present a more professional image comparable to commercially published materials.

Is the creaser compatible with all Okoboji perfect binding machine models?

Yes, the Okoboji Creaser PBC is specifically designed for seamless integration with all current Okoboji perfect binding machines, with straightforward installation and operation that maintains existing workflow efficiency.

What range of cover materials can be effectively processed with this creasing system?

The three-wheel creasing mechanism accommodates cover materials from 200gsm lightweight covers to 400gsm heavy cardstock, including coated papers, textured stocks, and specialty binding covers commonly used in commercial applications.

How does the three-wheel configuration improve creasing quality compared to single-wheel systems?

The three-wheel design provides superior pressure distribution and control, creating more uniform creases with reduced material stress and better adaptation to varying cover thicknesses, resulting in consistent professional quality across production runs.

What installation and setup procedures are required for the creaser accessory?

Installation typically requires 10 minutes with basic tools, following Okoboji's detailed instructions, with most operators able to complete setup independently or with minimal technical assistance from local service representatives.

Does using the creaser significantly slow down the binding production process?

The integrated design adds only 5-10 seconds per book to the binding cycle, with the improved quality and professional appearance typically justifying the minimal speed reduction for quality-focused operations.

What maintenance requirements are associated with the creasing mechanism?

Regular maintenance includes weekly cleaning of wheel surfaces, monthly lubrication of bearing points, and periodic inspection for wear, requiring approximately 10 minutes weekly for optimal performance maintenance.

Can the creaser be retrofitted to existing perfect binding machines from other manufacturers?

The Okoboji Creaser PBC is optimised for Okoboji machines, though compatibility with other brands may be possible with custom modifications - consultation with Okoboji technical support is recommended for non-Okoboji applications.

What return on investment can businesses expect from adding professional creasing capability?

Businesses typically report 15-25% premium pricing opportunities for creased publications, plus reduced reprints due to improved quality, with payback periods typically ranging from 3-6 months for moderate-volume operations.

How does professional creasing impact client perception and market positioning?

Professional creasing significantly enhances perceived quality and value, with many Okoboji customers reporting improved client satisfaction, increased repeat business, and ability to compete for higher-value projects previously dominated by larger commercial printers.

Customers also bought

Okoboji Corner Cutter Electric DT WH08

Okoboji Paper Creaser Manual A3 Size H460

Okoboji Paper Cutter Digital Electric 720mm