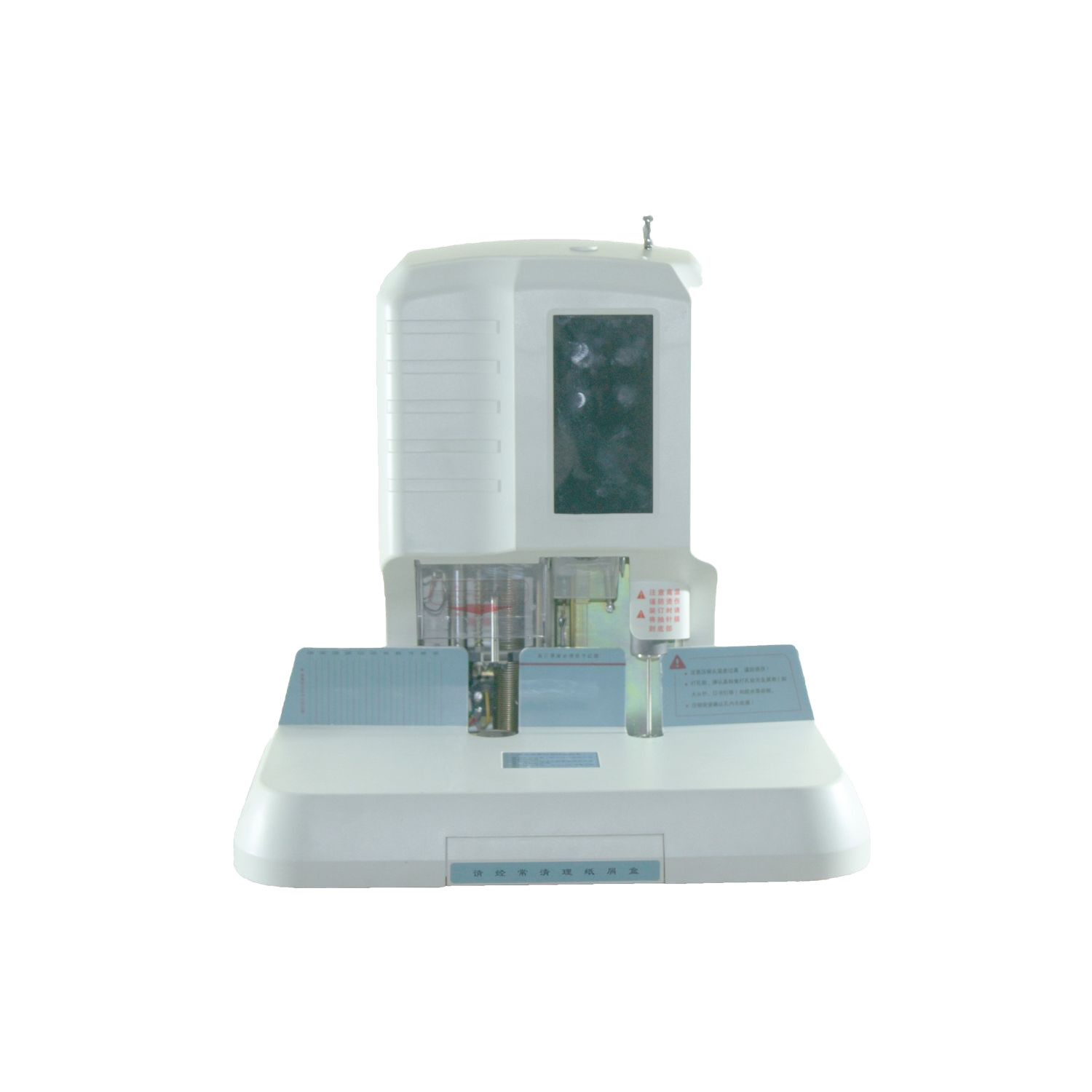

Okoboji Glue Binding Machine B40M

SPECIFICATIONS

PRODUCT VIDEO

PRODUCT DESCRIPTION

The Okoboji Glue Binding Machine B40M represents professional-grade perfect binding technology specifically designed to meet the diverse requirements of printing businesses, publishers, and commercial binderies across India. This sophisticated semi-automatic machine transforms the complex process of book binding into an efficient, streamlined operation that consistently delivers professional-quality bound documents, manuals, catalogues, and books. The B40M designation indicates its 40mm binding thickness capability, making it ideal for businesses handling a wide range of binding applications from thin brochures to substantial reference manuals and academic publications.

Engineered with commercial reliability in mind, this machine addresses the critical needs of businesses seeking to enhance their service offerings whilst improving operational efficiency. The advanced milling and gluing systems ensure strong, durable bindings that withstand regular use, whilst the LCD control panel provides operators with precise control over all binding parameters. For printing businesses looking to expand into perfect binding services or upgrade their existing capabilities, the Okoboji B40M delivers the reliability, quality, and productivity necessary to compete effectively in India’s growing publishing and commercial printing markets whilst building customer satisfaction through consistently superior results.

Upgrade Your Experience

Okoboji Glue Binding Machine B40F

Okoboji Perfect Binder A3 Side Glue

Okoboji PVC Tubebind Automatic TBA

Okoboji PVC Tubebind Semi Automatic Machine TBSA

KEY FEATURES

- Impressive binding capacity handles up to 40mm thickness and 425mm length, accommodating diverse applications from brochures to comprehensive manuals and academic publications

- High-productivity operation achieves 200-400 books per hour, enabling businesses to handle large orders efficiently whilst maintaining consistent quality standards

- Advanced milling system with solar and small milling cutters ensures optimal spine preparation for strong, durable glue adhesion and professional binding quality

- Professional LCD control panel provides precise parameter control and monitoring, simplifying operation whilst ensuring consistent results across all production runs

- Comprehensive glue system with single-roller configuration capability ensures complete adhesion coverage for maximum binding strength and durability

- Efficient heating system with 35-minute glue melt time minimises setup delays and enables quick job changeovers for improved productivity

- Robust construction with 60kg weight provides stability during operation whilst incorporating advanced safety features for operator protection

- Okoboji's commitment to reliability and comprehensive service support ensures consistent performance and minimal downtime for growing businesses

FREQUENTLY ASKED QUESTIONS

What types of publications can be bound effectively using the Okoboji B40M perfect binding machine?

The B40M handles books, manuals, catalogues, reports, academic publications, training materials, and commercial documents up to 40mm thickness with professional-quality results.

How does the dual milling cutter system improve binding quality compared to single cutter alternatives?

The solar and small milling cutter combination ensures optimal spine roughening for maximum glue penetration, creating stronger, more durable bindings that withstand regular use.

What cover weight range can the machine accommodate for different binding applications?

The machine handles cover materials from 50-400gsm, accommodating everything from lightweight covers to heavy cardstock for premium publications and specialty applications.

How quickly can operators complete job changeovers between different book sizes and specifications?

Standard changeovers require 10-15 minutes with experienced operators completing adjustments in 5-8 minutes for frequently used configurations, maximising production efficiency.

What maintenance procedures ensure optimal glue system performance and binding quality?

Daily glue tank cleaning, weekly roller inspection and cleaning, monthly temperature calibration, and periodic pump maintenance ensure consistent performance and binding quality.

Can the machine handle both softcover and hardcover binding applications?

Yes, the B40M accommodates both softcover perfect binding and can prepare book blocks for hardcover case binding, providing versatility for diverse client requirements.

How does the LCD control panel improve operator efficiency and binding consistency?

The LCD interface provides clear parameter display, temperature monitoring, cycle timing, and error diagnostics, enabling precise control and consistent results across production runs.

What glue types are compatible with the B40M binding system?

The machine works with EVA hot melt adhesives, PUR reactive adhesives, and specialty binding glues, providing flexibility for different binding requirements and durability needs.

How does the side glue feature enhance binding strength for thick publications?

Side gluing applies additional adhesive to the front and back of the book block, significantly increasing binding strength for heavy books and frequently handled publications.

What training and technical support does Okoboji provide for the B40M perfect binding machine?

Comprehensive training includes operation procedures, maintenance protocols, troubleshooting guidance, and ongoing technical support through Okoboji's service network across India.

Customers also bought

Okoboji Corner Cutter Manual S100

Okoboji Paper Creasing, Perforation Manual 460 2in1

Okoboji Thermal Roll Laminator 1100mm FM1100