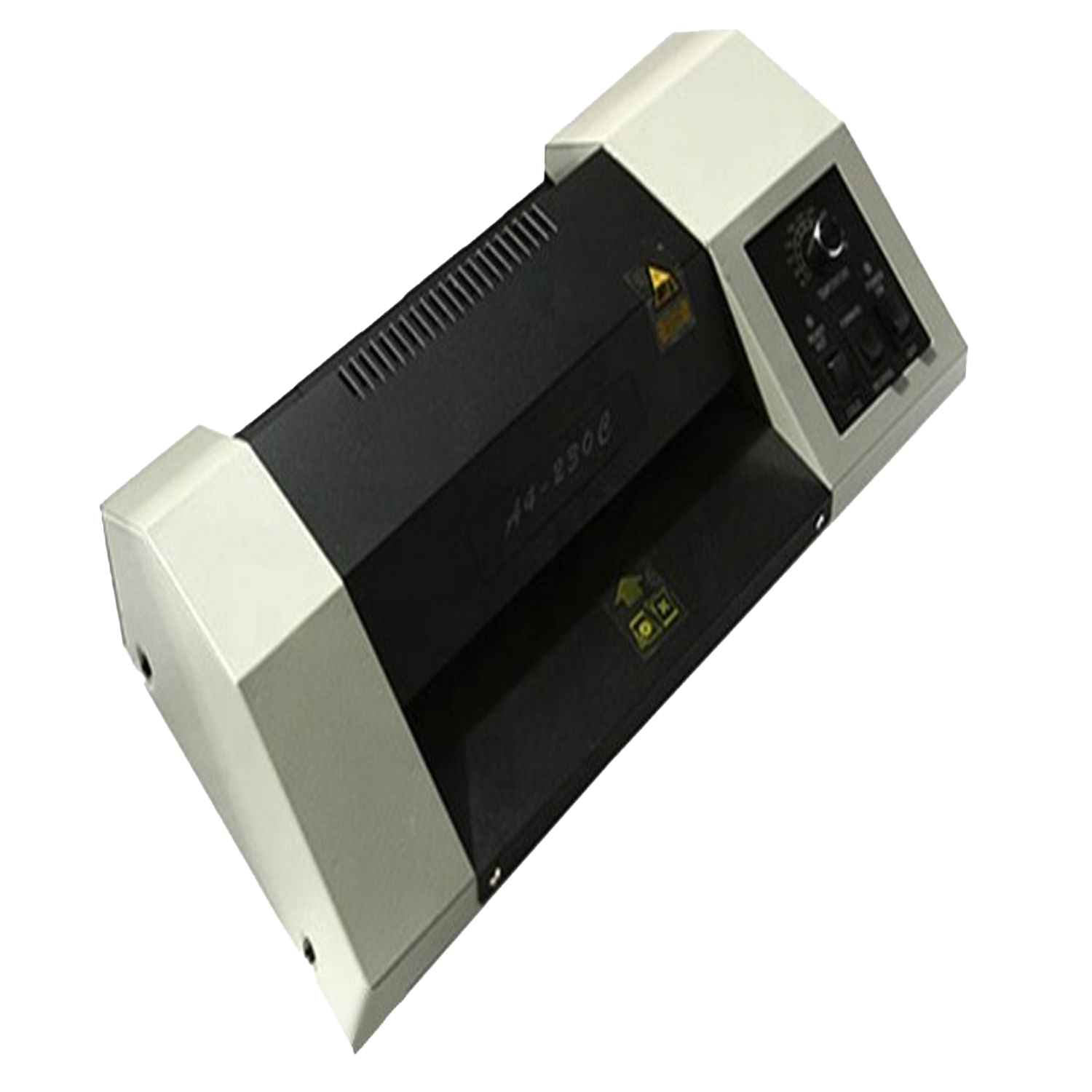

Okoboji Laminator Pouch Pingda 330c

SPECIFICATIONS

PRODUCT VIDEO

PRODUCT DESCRIPTION

The Okoboji Laminator Pouch Pingda 330c combines advanced digital technology with professional lamination capabilities to deliver exceptional results for demanding commercial and educational applications. This sophisticated machine features precise digital controls, cold lamination functionality, and enhanced 330mm working width to accommodate diverse document protection requirements across Indian institutions and businesses. The Pingda 330c represents the latest evolution in lamination technology, providing intelligent operation and superior quality control.

Engineered for versatility, this laminator accommodates laminating thicknesses from 40 to 250 microns whilst maintaining precise temperature control up to 180°C. The integrated cold lamination function expands application possibilities to include heat-sensitive materials, whilst the digital control system ensures consistent, repeatable results. Whether processing certificates, creating educational materials, or protecting valuable documents, the Okoboji Pingda 330c delivers the professional performance and reliability that modern Indian businesses demand.

Upgrade Your Experience

Okoboji Laminator Pouch 320 Knob

Okoboji Laminator Pouch 320 Meter

Okoboji Laminator Pouch HD 3306

Okoboji Pouch Laminator 18" meter

KEY FEATURES

- Advanced 330mm laminating width accommodating oversized documents, certificates, and large-format educational materials beyond standard A3 capacity

- Professional digital control system providing precise temperature and speed settings for consistent, repeatable lamination results

- Integrated cold lamination function enabling processing of heat-sensitive documents, photographs, and thermal-printed materials without damage

- Enhanced thickness capacity from 40 to 250 microns accommodating diverse pouch types from light protection through heavy-duty applications

- High-temperature capability reaching 180°C maximum working temperature for efficient processing of thick pouches and specialty materials

- Professional 4-roller system engineered by Okoboji for bubble-free lamination and superior finish quality in commercial applications

- Variable speed control with multiple preset options optimising processing for different material types and thickness requirements

- Robust construction designed for continuous operation in demanding educational and commercial environments throughout India

FREQUENTLY ASKED QUESTIONS

What makes the Pingda 330c ideal for professional document protection applications?

The combination of 330mm width, digital controls, cold lamination capability, and high temperature range makes it perfect for diverse professional applications requiring consistent quality.

How does the cold lamination function benefit sensitive document processing?

Cold lamination preserves heat-sensitive materials like photographs, thermal receipts, and inkjet prints without colour distortion or material damage, expanding application versatility.

What thickness range provides optimal versatility for different applications?

The 40-250 micron range accommodates light office protection through heavy-duty applications, providing flexibility for certificates, signage, and educational materials.

How does the 180°C maximum temperature improve lamination efficiency?

Higher temperatures enable faster processing of thick pouches and specialty materials, improving productivity whilst ensuring complete adhesion and professional finish quality.

Can this laminator handle both standard and oversized documents effectively?

Yes, the 330mm width accommodates standard A3 documents plus oversized certificates, signage, and multiple smaller documents processed simultaneously for efficiency.

What digital control features enhance operational consistency?

While this model features manual controls, the precise temperature adjustment and consistent heat distribution ensure repeatable professional results for demanding applications.

Is this suitable for educational institutions with diverse lamination needs?

Absolutely, the combination of cold/hot lamination, variable thickness capacity, and robust construction makes it ideal for protecting teaching materials, certificates, and displays.

How does the 4-roller system ensure bubble-free professional results?

The precision-engineered roller configuration provides even pressure distribution and optimal heat transfer, eliminating air bubbles and ensuring professional-quality lamination.

What maintenance procedures optimise performance for continuous operation?

Regular roller cleaning, temperature calibration, and proper storage procedures maintain peak performance and extend equipment lifespan in demanding environments.

How does Okoboji ensure consistent parts availability for the Pingda series?

Okoboji maintains comprehensive spare parts inventory and service networks across India ensuring minimal downtime and continued professional operation.

Customers also bought

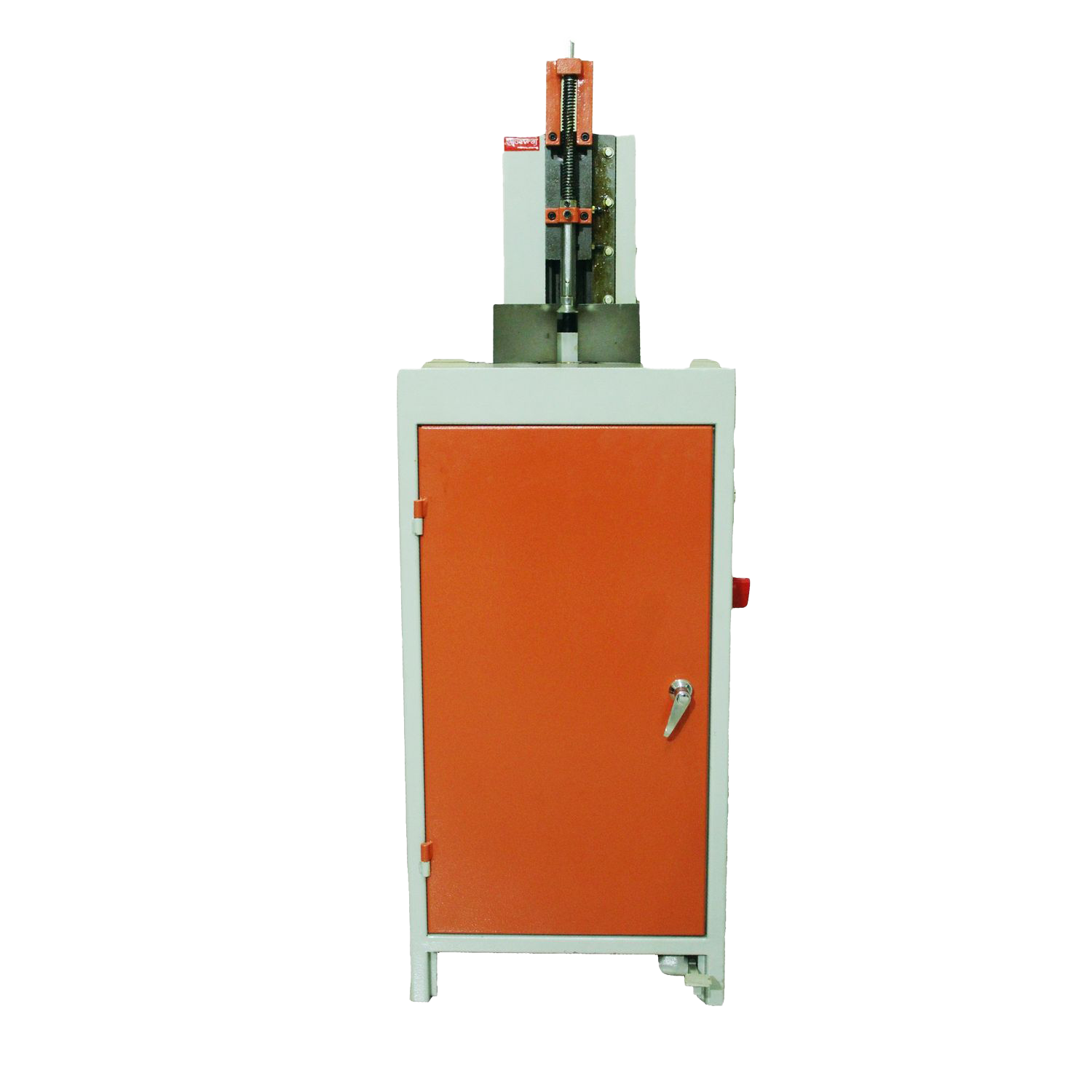

Okoboji Corner Cutter Electric Heavy Duty Orange

Okoboji Laminator Thermal & Cold 1700W2

Okoboji Paper Cutter Digital Electric 720mm