Okoboji Laminator Pouch 320 Meter

SPECIFICATIONS

PRODUCT VIDEO

PRODUCT DESCRIPTION

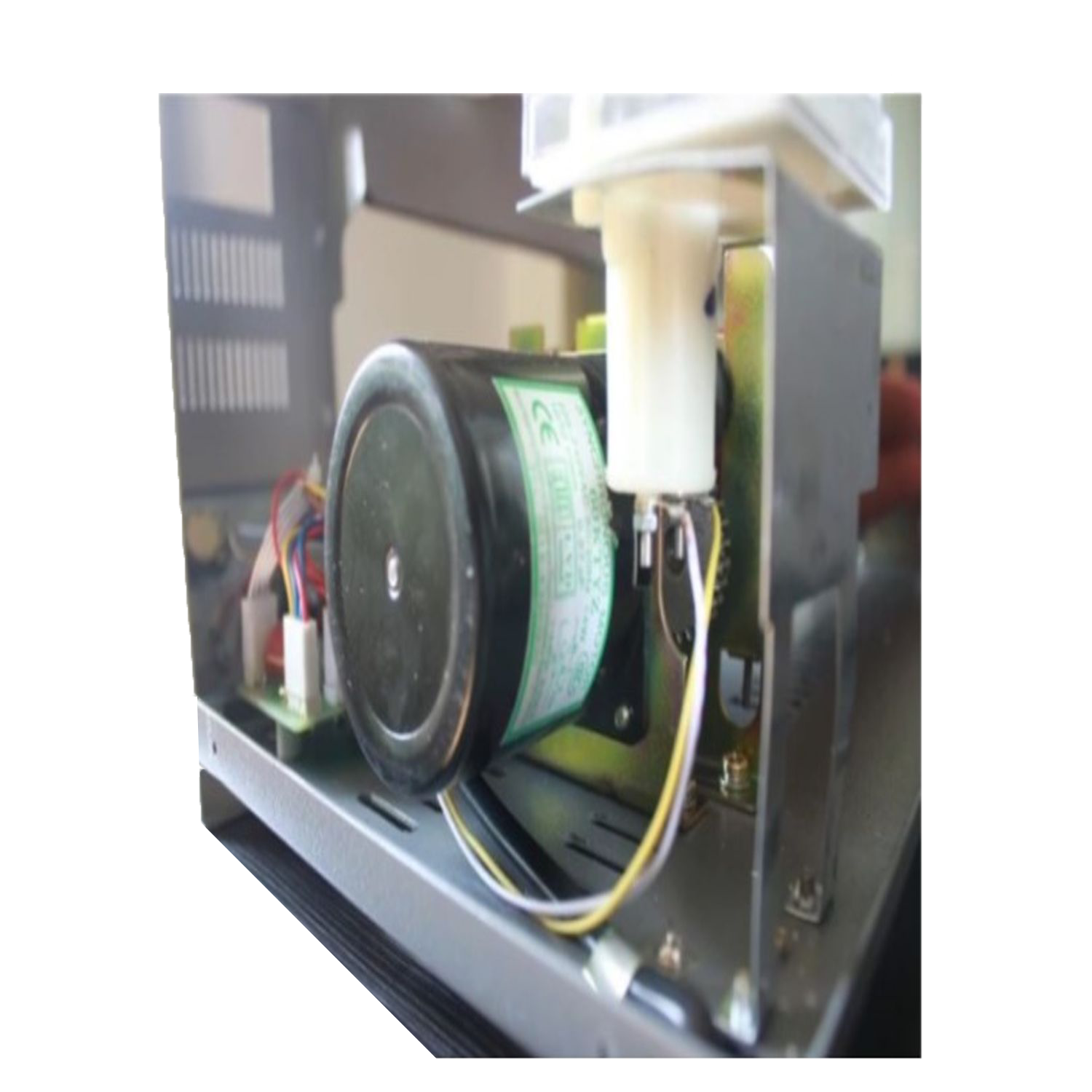

The Okoboji Laminator Pouch 320 Meter represents advanced lamination technology featuring digital meter controls for precise operation in professional environments. This sophisticated machine combines 6-roller technology with digital monitoring systems to deliver exceptional lamination quality for demanding applications across Indian educational institutions, corporate offices, and commercial print shops. The integrated digital display provides real-time feedback on temperature, speed, and operational status, ensuring consistent professional results.

Engineered for high-volume applications, this laminator accommodates A3-size documents up to 320mm width whilst maintaining superior quality control through its advanced roller configuration. The digital meter system eliminates guesswork in temperature and speed settings, making it ideal for operators requiring consistent, repeatable results. Whether processing certificates, creating educational materials, or producing commercial signage, the Okoboji 320 Meter delivers the precision and reliability that professional Indian businesses demand.

Upgrade Your Experience

Okoboji Laminator Pouch 320 Knob

Okoboji Laminator Pouch HD 3306

Okoboji Laminator Pouch Pingda 330c

Okoboji Pouch Laminator 18" meter

KEY FEATURES

- Advanced digital meter display providing precise control over temperature, speed, and operational parameters for consistent professional results

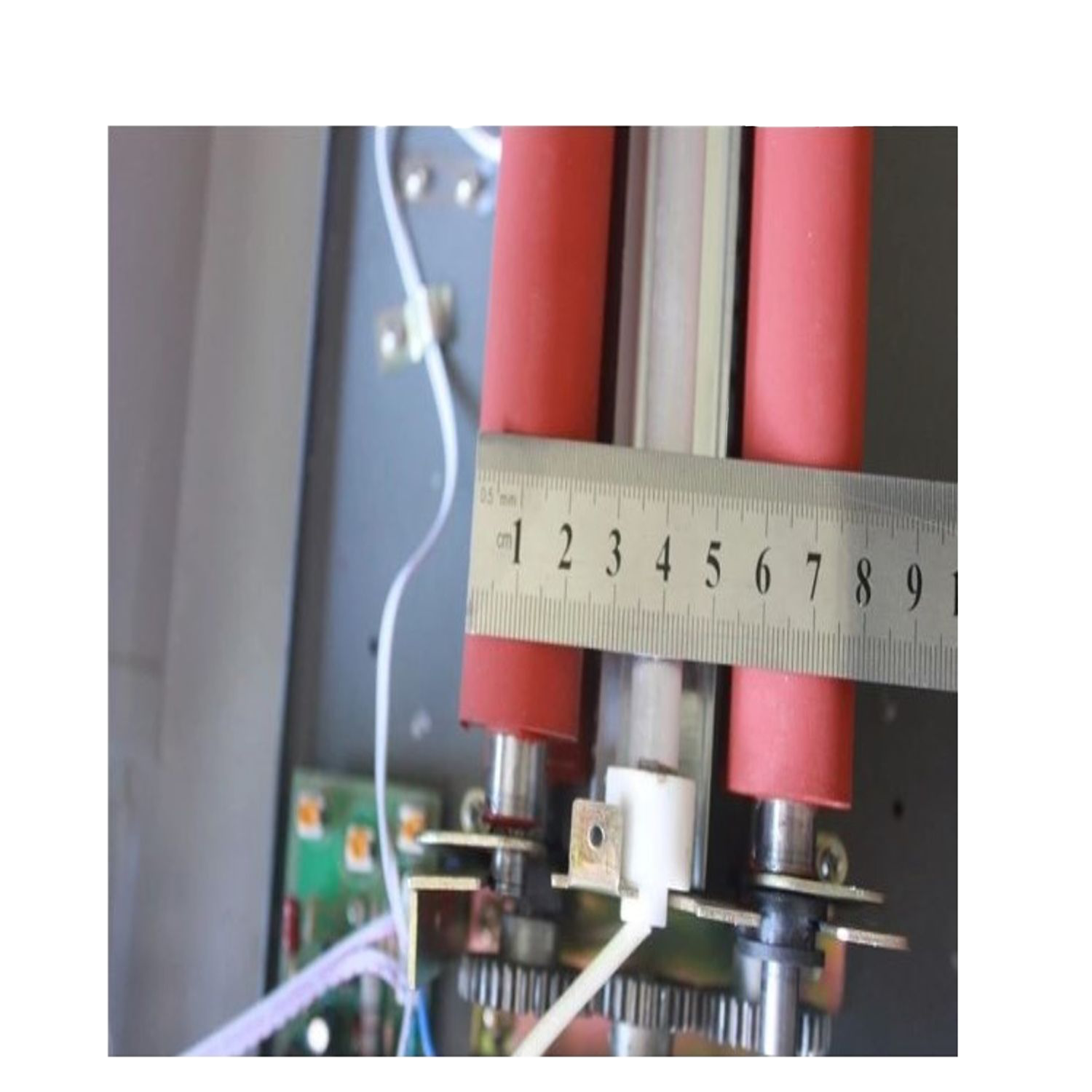

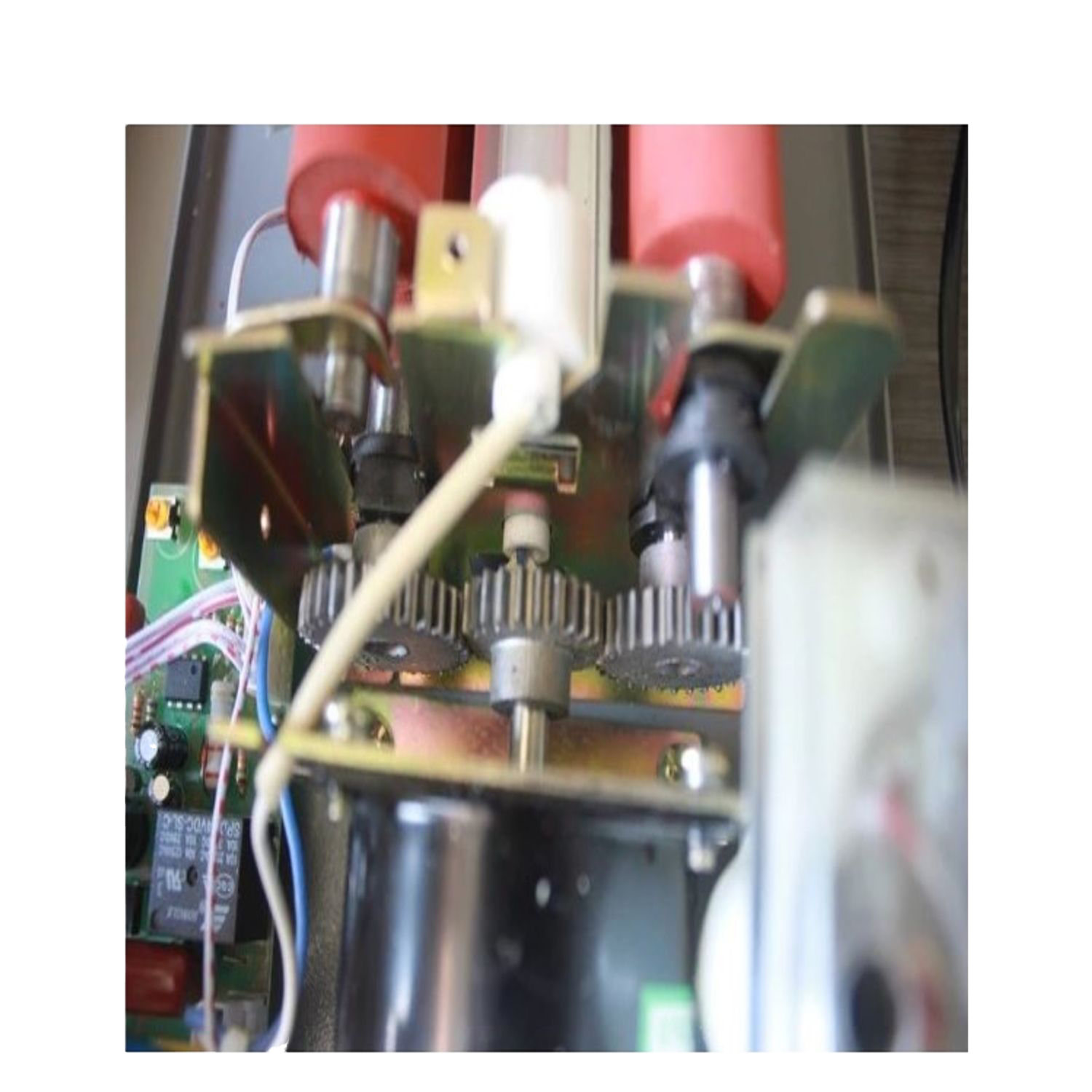

- Professional 4-roller system including 2 heated and 2 cold rollers ensuring superior lamination quality and bubble elimination

- 320mm maximum width capacity accommodating A3 documents, certificates, educational posters, and commercial presentation materials

- Variable speed control from 600 to 2100mm per minute optimised for different pouch thicknesses and material requirements

- Digital temperature control with precise settings from 0°C to 160°C enabling optimal processing of diverse laminating materials

- Professional-grade construction by Okoboji designed for high-volume educational and commercial applications throughout India

- Enhanced thickness capacity handling pouches from 0 to 2.5mm accommodating light office documents through heavy-duty protection applications

- Intelligent monitoring systems providing operational feedback and ensuring consistent quality control in demanding professional environments

FREQUENTLY ASKED QUESTIONS

How does the digital meter system improve lamination consistency?

The digital display provides precise temperature and speed readouts, eliminating guesswork and ensuring repeatable settings for consistent professional-quality results across multiple documents.

What advantages does the 4-roller system provide over standard configurations?

The 4-roller arrangement with 2 hot and 2 cold rollers ensures optimal heat distribution, superior pressure application, and gradual cooling for bubble-free, professional-grade lamination.

Can this machine handle both thin and thick laminating pouches effectively?

Yes, the 0 to 2.5mm thickness capacity accommodates everything from 75-micron office pouches to heavy-duty 250-micron pouches for maximum protection applications.

What types of documents benefit most from this laminator's capabilities?

Ideal for certificates, educational materials, corporate presentations, signage, menus, and any documents requiring professional appearance and long-term protection in Indian business environments.

How does the speed control optimise lamination for different materials?

Variable speed settings from 600-2100mm/minute allow optimization for different pouch thicknesses, ensuring proper adhesion for thin pouches and preventing overheating of sensitive materials.

What maintenance procedures keep the digital systems functioning properly?

Regular cleaning of sensors, calibration checks of digital displays, and proper shutdown procedures maintain accuracy and longevity of the electronic control systems.

Is this laminator suitable for continuous operation in busy commercial environments?

Yes, the robust construction and digital monitoring systems enable extended operation periods ideal for print shops, copy centres, and high-volume educational institutions.

How does the cold roller system prevent document damage?

The 2 cold rollers provide gradual cooling and final pressure application, preventing heat damage and ensuring proper adhesion without warping or bubbling.

What safety features are integrated with the digital control system?

Digital monitoring includes thermal protection, automatic shut-off, and error detection systems ensuring safe operation and preventing damage to documents or equipment.

How does Okoboji support digital laminator calibration and servicing?

Okoboji provides technical training for digital systems calibration and maintains service networks across India ensuring accurate operation and professional support.

Customers also bought

Okoboji Cold & Thermal Laminator L1700T1

Okoboji Corner Cutter Electric DT W Cover WH08C

Okoboji Paper Cutter Digital Electric 490mm