Okoboji Laminator Cold Roll to Roll 63 inch

SPECIFICATIONS

PRODUCT VIDEO

PRODUCT DESCRIPTION

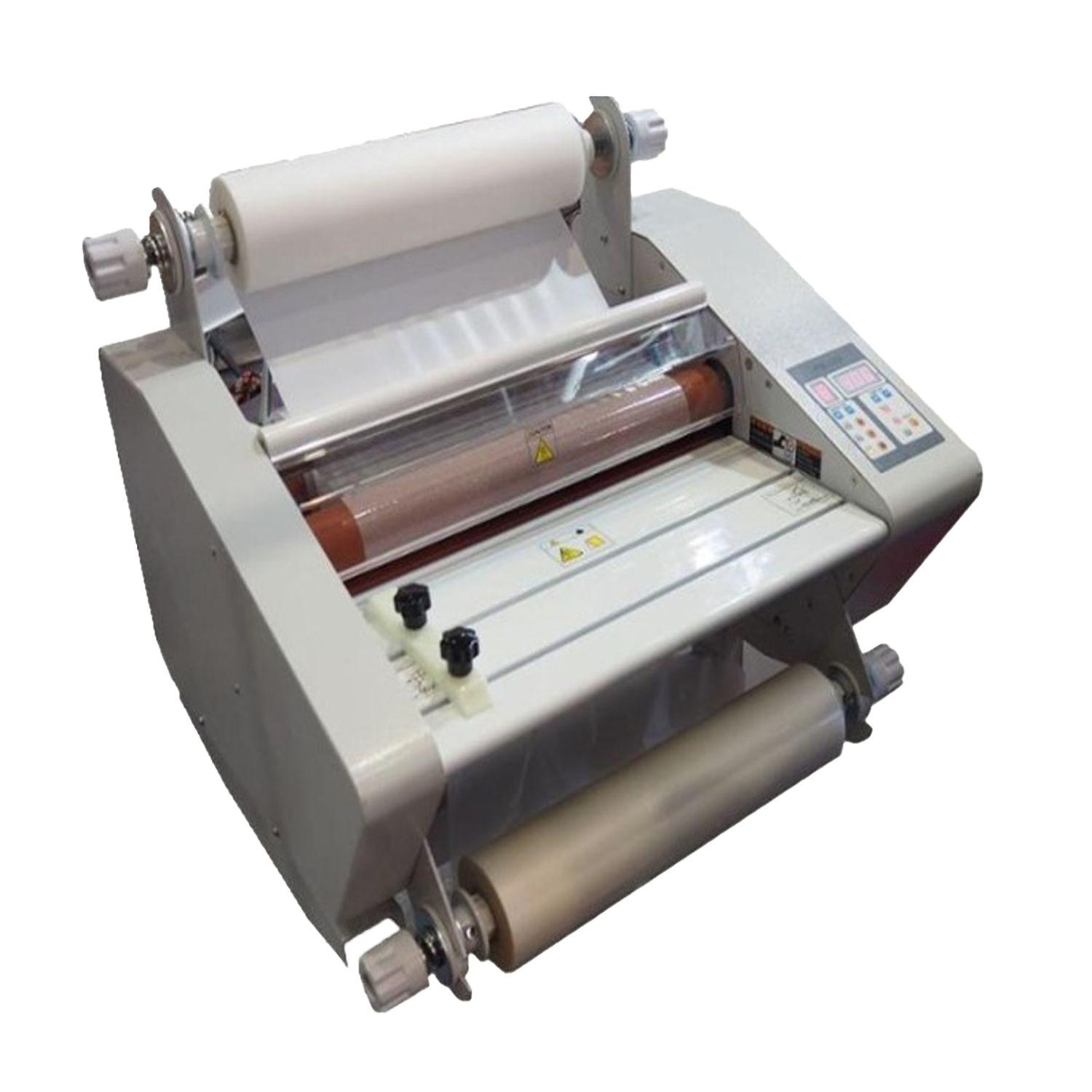

The Okoboji Laminator Cold Roll to Roll 63 inch represents cutting-edge technology for continuous laminating applications, specifically engineered for high-volume commercial operations across India’s dynamic print and graphics industry. This advanced roll-to-roll system excels in processing continuous materials, making it indispensable for businesses specialising in banner production, vehicle wraps, architectural displays, and large-scale commercial signage projects. The sophisticated 63-inch width capability combined with 10m/min processing speed delivers exceptional productivity whilst maintaining the precision and quality that professional applications demand.

Designed with intelligent engineering that accommodates 3-inch core materials and dual voltage compatibility (110V/220V), this Okoboji system provides unmatched flexibility for diverse production environments. The 20mm maximum gap between upper and lower rollers ensures accommodation of various material thicknesses, whilst the 200W power system delivers consistent performance throughout extended production runs. Whether processing protective films for outdoor graphics, mounting adhesive applications for display materials, or continuous laminating for commercial signage, this roll-to-roll system combines the efficiency of automated processing with the reliability and precision that defines Okoboji’s reputation in India’s competitive commercial laminating market.

Upgrade Your Experience

Okoboji Cold &Thermal Laminator 1600mm

Okoboji Cold Laminator Desktop LBS700

Okoboji Cold Laminator Elec Pneumatic 63" 1600mm

Okoboji Cold Laminator Electric 40" 1000 mm

KEY FEATURES

- Advanced roll-to-roll technology - Continuous processing capability perfect for high-volume commercial applications including banners, vehicle wraps, and large format graphics

- High-speed 10m/min processing - Exceptional productivity for commercial operations requiring rapid turnaround times whilst maintaining professional quality standards throughout production runs

- Professional 63-inch working width - Accommodates large format commercial materials, banners, architectural displays, and specialty applications requiring wide format capability

- Flexible 20mm material gap - Handles various material thicknesses from thin films to mounting boards, providing versatility for diverse commercial laminating and mounting applications

- Dual voltage compatibility - 110V/220V power supply options provide installation flexibility for different electrical environments and international compatibility requirements

- 3-inch core accommodation - Standard core size compatibility ensures easy material loading and compatibility with most commercial film and adhesive roll materials

- Consistent 200W power delivery - Reliable electrical performance ensures consistent processing speed and pressure throughout extended commercial production runs

- Okoboji commercial reliability - Professional-grade construction ensures dependable performance in demanding production environments with minimal maintenance requirements

FREQUENTLY ASKED QUESTIONS

What commercial applications benefit most from this roll-to-roll Okoboji system?

Perfect for banner production, vehicle wrap installation, architectural graphics, large format signage, protective film application, mounting adhesive projects, and continuous laminating operations requiring high-speed processing and professional quality.

How does the 10m/min speed impact commercial productivity?

The 10m/min processing speed dramatically increases throughput for commercial operations, allowing rapid completion of large projects whilst maintaining quality. This speed is ideal for meeting tight deadlines and high-volume production requirements.

What materials can this 63-inch roll-to-roll system accommodate?

Handles pressure-sensitive films, mounting adhesives, protective laminates, vinyl graphics, banners, architectural films, vehicle wrap materials, and specialty substrates within the 20mm gap specification for comprehensive commercial applications.

How does the 20mm roller gap benefit different material applications?

The 20mm gap accommodates thin films through thick mounting materials, allowing processing of layered applications, thick substrates, and various material combinations commonly used in commercial graphics and display applications.

What advantages does dual voltage compatibility provide?

110V/220V compatibility ensures installation flexibility in different electrical environments, international compatibility, and ability to adapt to various facility electrical specifications without requiring electrical modifications or special transformers.

How does the 3-inch core system benefit commercial operations?

Standard 3-inch cores are widely available and compatible with most commercial film and adhesive materials, ensuring easy sourcing, quick material changes, and compatibility with industry-standard material supplies.

Is this machine suitable for vehicle wrap and automotive applications?

Absolutely, the 63-inch width, continuous processing capability, and 10m/min speed make this system ideal for vehicle wrap preparation, protective film application, and automotive graphics requiring consistent pressure and professional results.

How does roll-to-roll processing compare to sheet-fed laminating?

Roll-to-roll processing provides continuous operation, higher productivity, consistent results across long runs, and eliminates sheet joints. This is ideal for banners, wraps, and applications requiring seamless continuous materials.

What maintenance does this advanced Okoboji roll-to-roll system require?

Regular roller cleaning, checking electrical connections, maintaining proper roller alignment, lubricating moving components, and ensuring consistent power supply. The advanced system requires systematic maintenance for optimal performance.

Does Okoboji provide comprehensive support for this professional roll-to-roll equipment?

Yes, Okoboji offers professional installation, comprehensive operator training for roll-to-roll applications, technical support, genuine parts availability, and maintenance guidance across India to ensure optimal performance in commercial environments.

Customers also bought

Okoboji Laminator Pouch 320 Knob

Okoboji Laminator Pouch HD 3306

Okoboji Thermal Roll Laminator 3816