Okoboji ID Card Fusing A4 100

SPECIFICATIONS

PRODUCT VIDEO

PRODUCT DESCRIPTION

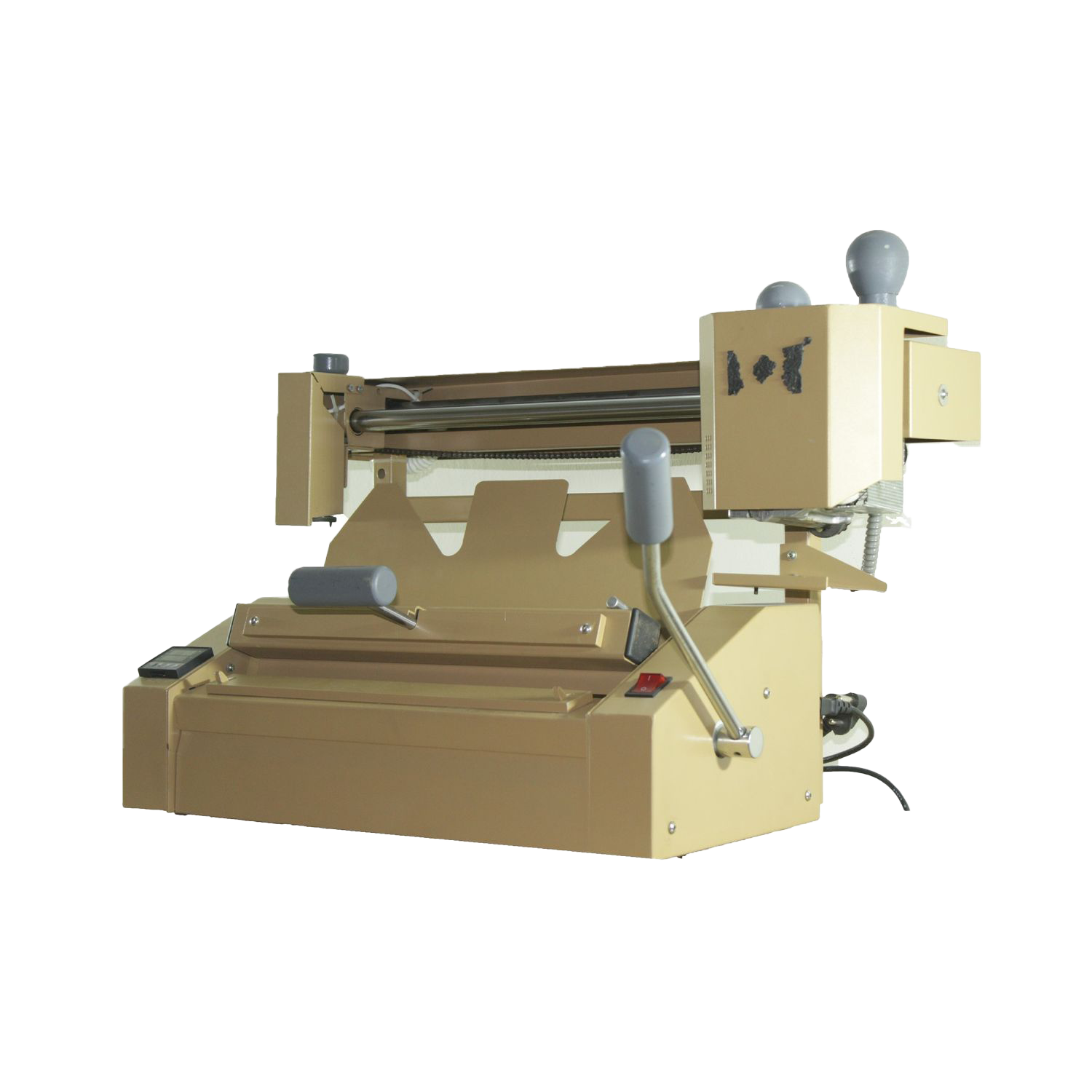

Okoboji’s ID Card Fusing A4 100 represents the pinnacle of professional card lamination technology, designed specifically for high-volume card production requirements across Indian businesses, educational institutions, and government organisations. This advanced fusing machine utilises precision heat and pressure application to create durable, tamper-proof identification cards that meet international ISO standards. The machine accommodates A4-sized sheets, enabling simultaneous processing of multiple card layouts, making it particularly valuable for institutions requiring bulk card production such as schools preparing student identity cards, corporations issuing employee badges, or membership organisations creating loyalty cards.

The sophisticated digital control system ensures consistent temperature regulation between 0-200°C, whilst the automatic air cooling mechanism guarantees optimal card quality without warping or discolouration. With an impressive efficiency rating exceeding 200-300 cards per hour, this machine significantly reduces processing time compared to traditional lamination methods. The robust construction and user-friendly operation make it suitable for both experienced technicians and operators new to card production technology, ensuring reliable performance across diverse Indian working environments.

Upgrade Your Experience

Okoboji ID Card Fusing A6 20

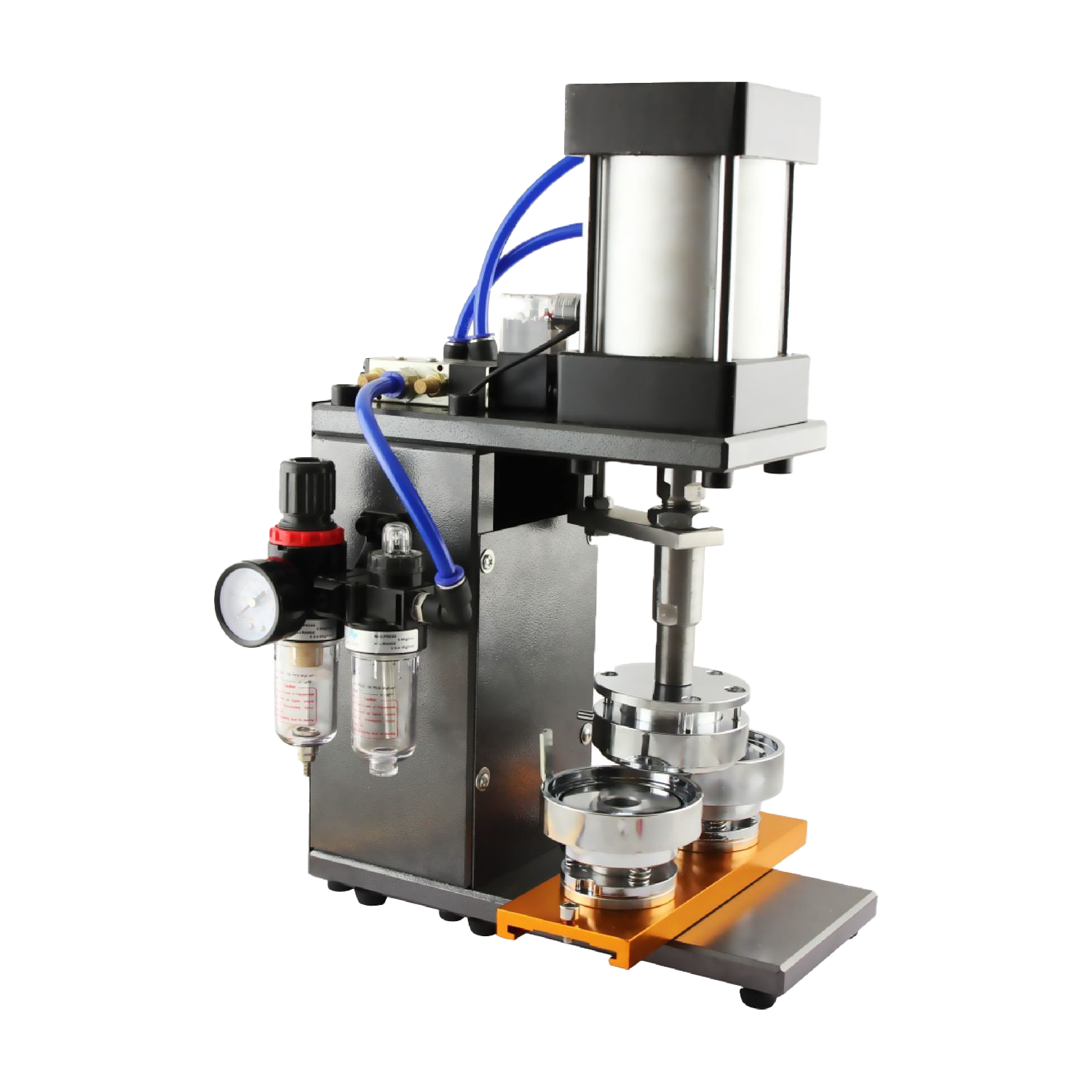

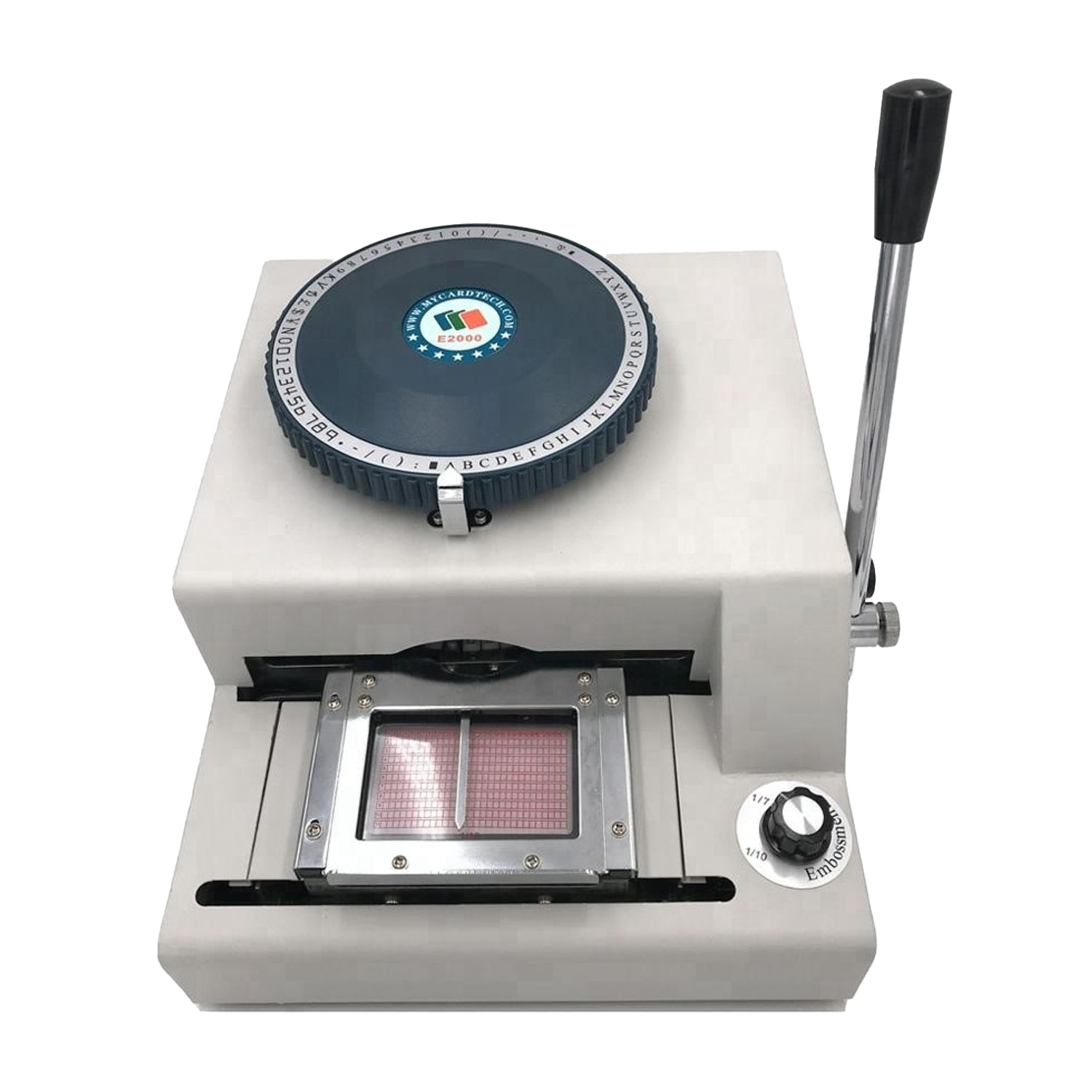

Okoboji ID Card PVC Embossing Machine EM PVC

Okoboji ID Card PVC Foil Tipper WTJ90A

Okoboji PVC Card Cutter 8251

KEY FEATURES

- Digital temperature control system with precise 0-200°C range ensures consistent lamination quality and prevents card damage during the fusing process

- High-capacity A4 format processing capability allows simultaneous production of multiple cards, maximising productivity for bulk orders and institutional requirements

- Exceptional work efficiency producing over 400 cards per hour, making it ideal for high-volume operations in schools, offices, and commercial card printing services

- Automatic air cooling system eliminates manual intervention and ensures cards achieve optimal structural integrity without warping or thermal damage

- Flexible lamination layer capacity handling 1-12 layers accommodates various card thickness requirements and security feature integration preferred by Indian organisations

- Professional 45mm opening height provides adequate clearance for different card materials whilst maintaining consistent pressure distribution across the entire lamination surface

- Single-operator design reduces labour costs and training requirements, making it suitable for small businesses and large enterprises across India

- Okoboji's proven reliability and comprehensive warranty support ensure long-term investment protection for professional card production operations

FREQUENTLY ASKED QUESTIONS

What types of cards can be produced using the Okoboji A4 ID Card Fusing Machine?

This machine is perfect for creating employee ID cards, student identity cards, membership cards, access control cards, visitor badges, and loyalty cards using standard PVC materials and lamination films.

How does the automatic cooling system benefit card production quality?

The automatic air cooling prevents card warping, ensures consistent lamination adhesion, eliminates manual cooling time, and maintains production efficiency whilst protecting card integrity throughout the fusing process.

What is the recommended maintenance schedule for optimal machine performance?

Clean the heating plates weekly, inspect pressure mechanisms monthly, calibrate temperature settings quarterly, and schedule professional servicing annually to maintain Okoboji's performance standards and warranty coverage.

Can this machine handle different card thicknesses and lamination materials?

Yes, the machine accommodates 1-12 lamination layers, works with various PVC thicknesses, supports different overlay films, and adjusts pressure settings to accommodate standard ID card specifications used across India.

What training is required for operators to use this equipment effectively?

Basic training covers temperature setting procedures, material loading techniques, safety protocols, and quality control measures. Okoboji provides comprehensive operation manuals and technical support for new users.

How does the 20-minute cycle time compare to manual lamination methods?

This represents a 70% time reduction compared to manual processes, enables consistent quality output, reduces labour costs, and allows operators to manage other tasks during the automated cooling phase.

What safety features are integrated into the machine design?

Temperature control prevents overheating, automatic shutoff mechanisms protect against power fluctuations, ergonomic design reduces operator strain, and clear operational indicators ensure safe operation throughout production cycles.

Is the machine suitable for small printing businesses or only large-scale operations?

The machine is ideal for both small printing services producing 50-100 cards daily and large institutions requiring 500+ cards per day, offering scalable solutions for diverse Indian market requirements.

What electrical requirements and installation considerations apply to this machine?

Standard 220V power supply, stable electrical connection, adequate ventilation space, level installation surface, and proximity to card material storage are essential for optimal Okoboji machine performance.

How does Okoboji's technical support assist customers experiencing operational issues?

Okoboji provides telephone support, online troubleshooting guides, replacement parts availability, on-site service options in major Indian cities, and comprehensive warranty coverage for all fusing machine components.

Customers also bought

Okoboji Badge Magentic Mould Oval 57x45mm

Okoboji Perfect Binder A3 Side Glue

Okoboji Perfect Binder Desktop Manual T30