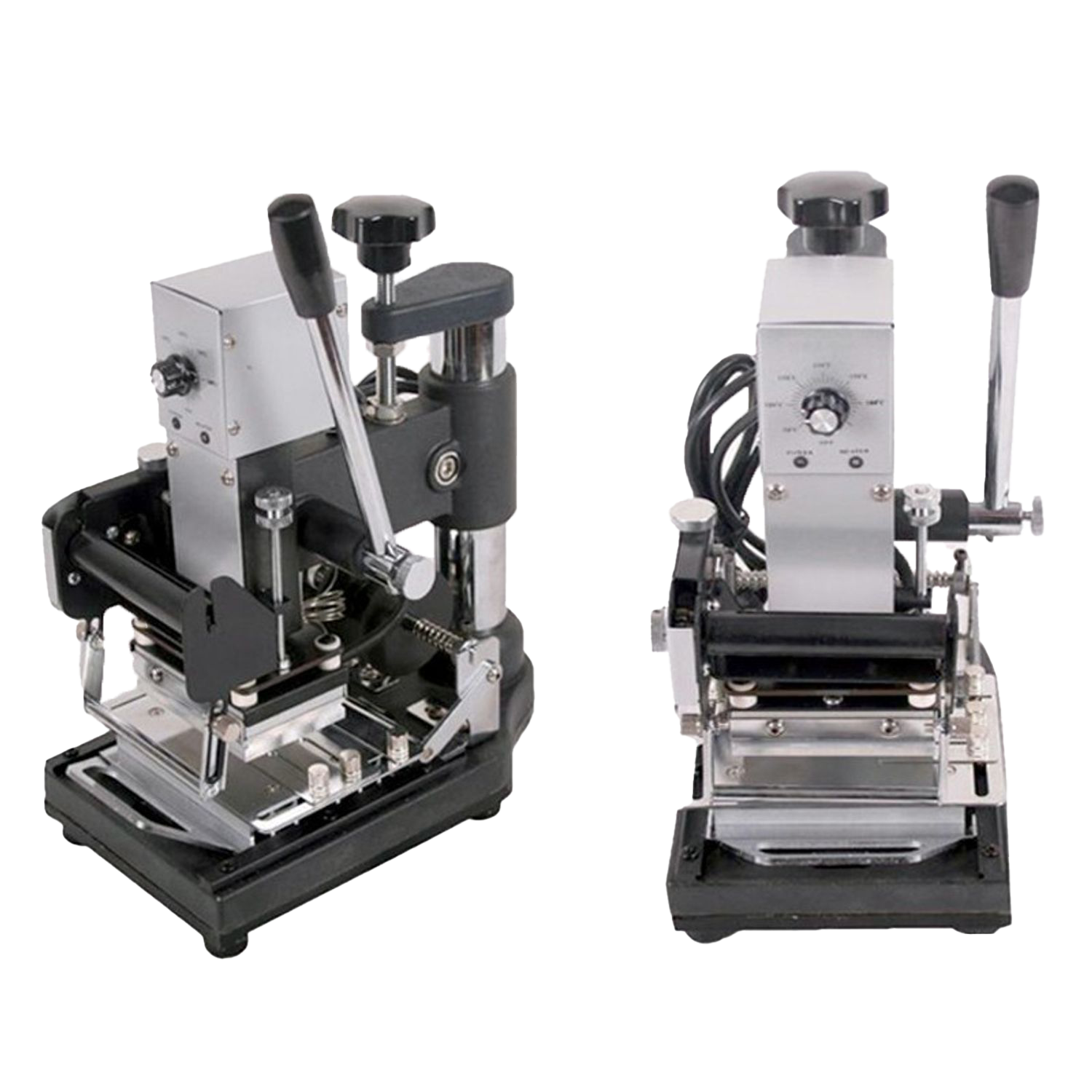

Okoboji ID Card PVC Foil Tipper WTJ90A

SPECIFICATIONS

PRODUCT VIDEO

PRODUCT DESCRIPTION

Okoboji’s ID Card PVC Foil Tipper WTJ90A delivers professional hot foil stamping capabilities for creating premium, luxury-finish identification cards, business cards, and membership credentials. This sophisticated machine applies metallic foils, holographic films, and decorative finishes to PVC cards through precise temperature and pressure control, enabling Indian businesses to produce high-end cards that convey prestige and authenticity. The machine serves premium market segments including luxury retail loyalty programmes, VIP membership clubs, high-end banking services, and corporate executive identification systems where visual impact and perceived value are paramount considerations.

The versatile temperature control system accommodates diverse material requirements, from delicate business card papers requiring lower temperatures to robust PVC cards demanding higher heat application. This flexibility makes the machine invaluable for custom printing services, boutique design studios, and organisations requiring varied foil application across different card materials. The compact design and efficient 300W power consumption make it suitable for small to medium-sized operations whilst delivering professional results that compete with larger commercial printing facilities. The machine’s reliability and consistent output quality ensure that businesses can confidently offer premium foil stamping services to their customers across India’s growing luxury market segment.

Upgrade Your Experience

Okoboji ID Card Fusing A4 100

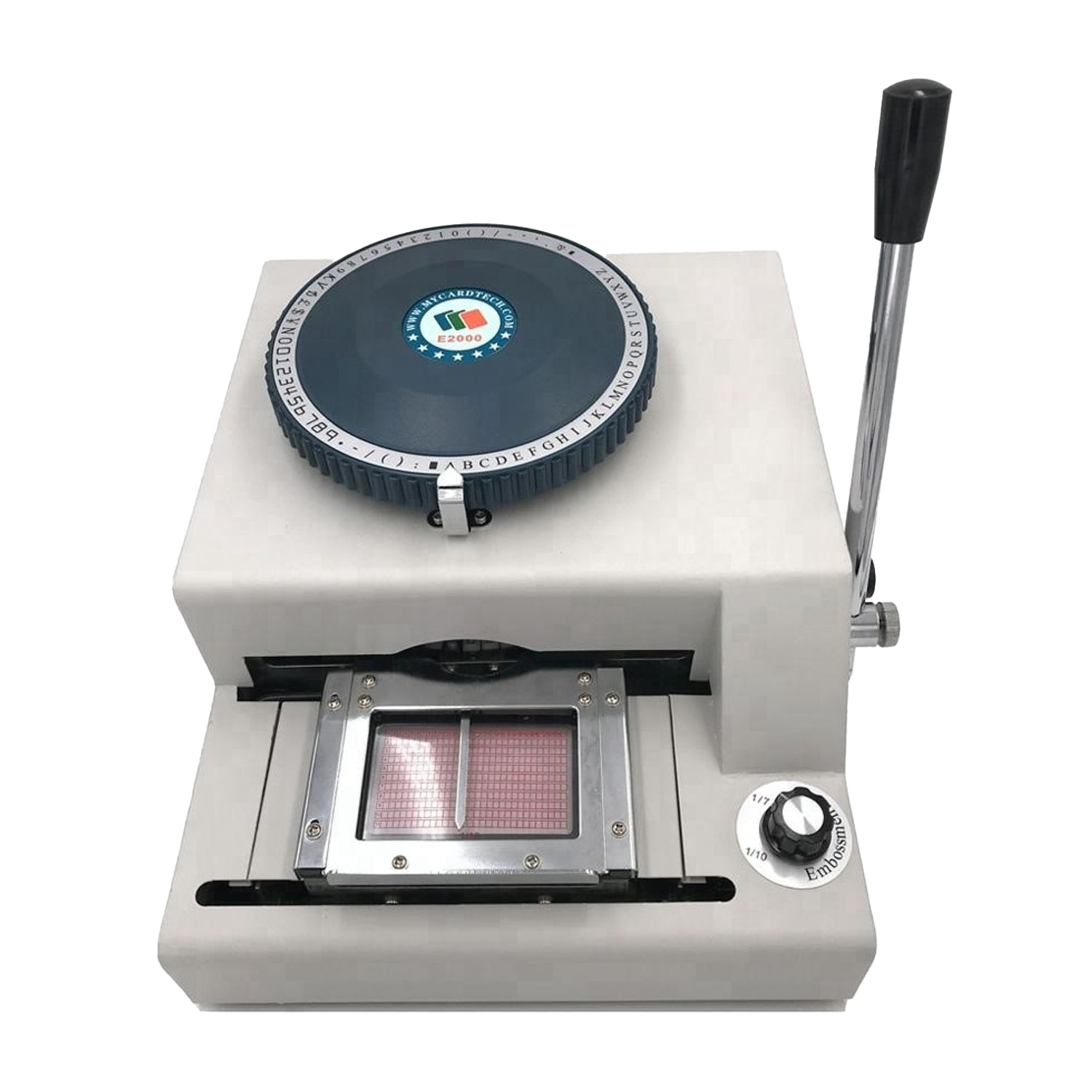

Okoboji ID Card PVC Embossing Machine EM PVC

Okoboji PVC CARD CUTTER Electric 3082

Okoboji PVC CARD CUTTER HEAVY Duty D0012

KEY FEATURES

- Versatile temperature control system (0-200°C) accommodates diverse material requirements from delicate papers to robust PVC cards, ensuring optimal foil adhesion across all applications

- Generous 60x90mm stamping area provides adequate space for logos, text, and decorative elements commonly used in Indian premium card applications and corporate branding requirements

- Multi-material compatibility handles business card paper, leather, PVC cards, soft adhesive papers, rubber, and wooden products, offering versatile foil application capabilities for diverse projects

- Efficient 300W power consumption ensures cost-effective operation whilst delivering professional hot foil stamping results suitable for small to medium-sized Indian businesses

- Compact 280x150x310mm design allows installation in space-constrained environments typical of Indian small businesses, design studios, and printing services without workflow disruption

- Precise temperature ranges optimised for different materials (100-150°C for papers/leather, 150-180°C for PVC/rubber) ensure consistent professional results across various substrates

- Standard 220V operation integrates seamlessly with Indian electrical systems without requiring special power configurations or additional electrical modifications

- Okoboji's proven engineering reliability and comprehensive support network ensure dependable performance and readily available technical assistance for foil stamping operations

FREQUENTLY ASKED QUESTIONS

What types of foil finishes can be applied using this Okoboji hot stamping machine?

This machine applies gold foil, silver foil, holographic films, coloured metallic finishes, and specialty decorative foils commonly used for premium cards, luxury packaging, and high-end branding applications.

How does temperature control ensure optimal foil adhesion across different materials?

Precise temperature settings prevent foil burning, ensure proper adhesion, accommodate material thermal properties, and maintain consistent finish quality across papers, PVC, leather, and rubber substrates.

What is the recommended foil stamping process for achieving professional results?

Proper material preparation, correct temperature setting, adequate pressure application, appropriate dwell time, and quality foil selection ensure optimal results. Okoboji provides detailed operation guidelines for various applications.

Can this machine handle custom logo and text stamping for business applications?

Yes, the 60x90mm stamping area accommodates most business logos, company names, decorative borders, and custom text layouts commonly required for corporate cards and premium business applications.

What safety precautions are essential when operating hot foil stamping equipment?

Temperature awareness, proper ventilation, protective equipment use, safe material handling, and adherence to Okoboji's safety guidelines prevent accidents and ensure safe operation in professional environments.

How does the 300W power consumption affect operational costs for small businesses?

Low power consumption reduces electricity costs, enables continuous operation, minimises operational overhead, and makes premium foil stamping services financially viable for small Indian businesses.

What types of businesses benefit most from hot foil stamping capabilities?

Luxury retailers, premium printing services, boutique design studios, high-end membership clubs, exclusive restaurants, and corporate branding services find hot foil stamping essential for premium applications.

Is special training required for operators to achieve consistent foil stamping results?

Basic training covers temperature settings, material preparation, foil handling techniques, and quality control procedures. Okoboji provides comprehensive operation manuals and technical support for new operators.

What maintenance procedures ensure optimal stamping performance and machine longevity?

Regular cleaning of heating plates, inspection of pressure mechanisms, calibration of temperature controls, and periodic professional servicing maintain optimal Okoboji machine performance and extend operational lifespan.

How does Okoboji's technical support assist customers with foil stamping applications and troubleshooting?

Okoboji provides telephone support, application guides, troubleshooting assistance, replacement parts availability, and regional service networks ensuring successful foil stamping operations across India.

Customers also bought

Okoboji Paper Cutter Digital Electric 490mm

Okoboji Paper Cutter Digital Hydraulic 490mm

Okoboji Sublimation Combo Heat Press 5in1