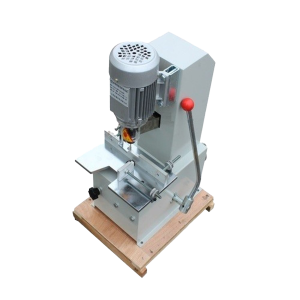

Okoboji Hole Punch Manual 4 Head WY290C

SPECIFICATIONS

PRODUCT VIDEO

PRODUCT DESCRIPTION

The Okoboji Manual Hole Punch 4 Head WY290C represents the pinnacle of manual hole punching technology with its advanced four-head configuration designed for sophisticated binding and filing applications. This premium hole punch delivers unparalleled document organisation capabilities, creating four perfectly aligned holes that accommodate spiral binding, specialty ring systems, and comprehensive filing solutions used in professional environments across India. With robust 5.8kg construction and 150-sheet capacity, the WY290C handles demanding documentation requirements whilst maintaining exceptional hole quality and precision alignment.

Specifically engineered for high-end applications, this four-head hole punch addresses the complex binding needs of architectural firms, design studios, technical documentation centres, and premium presentation requirements. The quadruple-hole configuration provides superior document stability and security, whilst the adjustable spacing ensures compatibility with international binding standards. Whether you’re creating technical manuals, presentation portfolios, or comprehensive documentation systems, the Okoboji WY290C delivers professional-grade performance that meets the most demanding quality and presentation standards in modern business environments.

Upgrade Your Experience

Okoboji Hole Punch Electric Drill 1 Head HD

Okoboji Hole Punch Electric Drill 2 Head HD WYT50

Okoboji Hole Punch Electric Drill 3 Head HD WYWB830

Okoboji Hole Punch Electric Drill 3 Hole Adj WYWB50B

KEY FEATURES

- Advanced four-head punching system creates quad-hole configurations for spiral binding and specialty filing applications requiring maximum document security

- Professional 150-sheet capacity (15mm thickness) efficiently processes substantial document volumes whilst maintaining precision hole quality and perfect alignment

- Adjustable hole spacing (70/80mm) accommodates international binding standards and specialty configurations for diverse professional applications

- Premium hole diameter range from 3.0-6.0mm provides compatibility with advanced binding systems and specialty ring configurations

- Heavy-duty 5.8kg construction with robust 318x132x300mm dimensions ensures exceptional stability and long-term reliability under demanding use

- Precision-engineered mechanism delivers consistent four-hole placement crucial for professional spiral binding and advanced presentation materials

- Manual operation provides dependable performance without electricity requirements, ideal for diverse Indian working environments and locations

- Okoboji premium quality engineering ensures superior performance with comprehensive technical support and customer service across India

FREQUENTLY ASKED QUESTIONS

What production advantages does the pneumatic MAQ system offer over manual badge punch machines?

The pneumatic system delivers 400-500 pieces per hour, eliminates operator fatigue, ensures consistent pressure application, and provides automated operation ideal for high-volume production.

What air pressure requirements are needed to operate the MAQ pneumatic badge punch effectively?

The system requires standard workshop pneumatic pressure, typically supplied by industrial air compressors commonly used in manufacturing environments throughout India.

How does the universal mould compatibility benefit diverse badge production operations?

Compatibility with all mould sizes up to 75mm enables production of various badge formats without equipment changes, maximising production flexibility and equipment utilisation.

Can this Okoboji pneumatic system maintain quality consistency during high-speed production?

Yes, the pneumatic operation ensures consistent pressure application and precise timing that maintains uniform badge quality regardless of production speed or volume.

What maintenance procedures are required to keep the pneumatic MAQ system operating optimally?

Regular pneumatic system checks, lubrication of moving parts, air filter maintenance, and periodic inspection ensure optimal performance and extended operational life.

How does the energy efficiency of pneumatic operation compare to electric alternatives?

Pneumatic operation eliminates electrical consumption, reduces energy costs, provides environmentally sustainable manufacturing, and often proves more cost-effective for continuous production.

What training is required for operators to use this automatic pneumatic badge system?

The automated operation simplifies training requirements, with operators primarily needing to understand mould changes, material loading, and basic pneumatic system operation.

Does Okoboji provide installation and commissioning support for the MAQ pneumatic system?

Okoboji offers comprehensive installation support, operator training, commissioning assistance, and ongoing technical support to ensure optimal system performance.

How does the MAQ production capacity compare to other automated badge manufacturing systems?

The 400-500 pieces per hour capacity positions the MAQ as a high-efficiency system ideal for commercial production whilst maintaining excellent quality standards.

What quality assurance measures ensure consistent high-speed badge production with the pneumatic MAQ?

Precision pneumatic controls, consistent pressure application, robust construction, and comprehensive testing guarantee reliable high-speed production and professional results.

Customers also bought

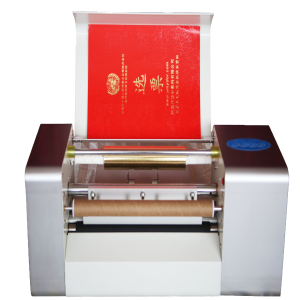

Okoboji Digital Foil Printer 350mm 360A

Okoboji Eyelet Desktop Manual DT

Okoboji Eyelet Manual Single Head Foot Pedal 5.5mm DJJ4