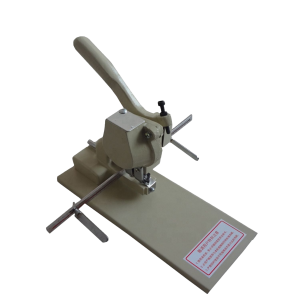

Okoboji Hole Punch Manual 2 Head WY290A

SPECIFICATIONS

PRODUCT DESCRIPTION

The Okoboji Manual Hole Punch 2 Head WY290A offers the perfect balance of portability and performance for medium-volume document processing requirements. This precision-engineered hole punch features a compact, lightweight design at just 3.5kg, making it ideal for shared office environments, mobile workstations, and educational settings where equipment needs to be frequently relocated. Despite its compact footprint, the WY290A delivers reliable 150-sheet punching capacity with adjustable hole spacing that accommodates both European and North American binding standards.

Built specifically for versatility and user convenience, this dual-head hole punch addresses the diverse needs of Indian offices and institutions. The adjustable hole distance feature (70/80mm) ensures compatibility with various ring binder systems, whilst the 3-6mm diameter range accommodates different binding requirements. Whether you’re preparing training materials, organising files, or creating bound presentations, the Okoboji WY290A combines professional performance with practical portability, making it an excellent investment for businesses prioritising flexible document management solutions.

Upgrade Your Experience

Okoboji Handheld Punch Single T35

Okoboji Hole Punch Electric Drill 2 Head HD WYT50

Okoboji Hole Punch Electric Drill 3 Head HD WYWB830

Okoboji Hole Punch Manual 3 Head WY290B

KEY FEATURES

- Medium-capacity punching handles 150 sheets (15mm thickness) efficiently whilst maintaining compact, portable design for flexible office use

- Dual-head configuration with adjustable hole spacing (70/80mm) accommodates both European and North American ring binder standards

- Variable hole diameter from 3-6.0mm provides compatibility with various binding systems and ring configurations commonly used in India

- Lightweight 3.5kg construction with compact 318x159x132mm dimensions makes it perfect for shared workspaces and mobile applications

- Precision-engineered punching mechanism ensures consistent hole quality and professional document presentation across all applications

- Cost-effective 3-piece packaging option ideal for bulk purchases by educational institutions and large office environments

- Manual operation provides reliable performance without electricity dependency, suitable for any working environment across India

- Okoboji quality assurance delivers dependable performance with excellent customer support and spare parts availability nationwide

FREQUENTLY ASKED QUESTIONS

What distinguishes the Punch 700 from standard wiro binding machines available in India?

The Punch 700 features industrial-grade 400W motor, 40-sheet capacity, 1-second cycle time, and modular design specifically engineered for high-volume commercial operations exceeding 10,000 sheets daily.

How does the 24,000 sheets per hour capacity translate to real-world productivity gains?

This capacity enables processing large projects like annual reports, catalogues, and training materials within tight deadlines, reducing labour costs and allowing businesses to accept larger contracts confidently.

What electrical requirements must be met for optimal Punch 700 performance?

The machine requires stable 400W power supply with proper grounding, surge protection, and dedicated circuit to prevent voltage fluctuations that could affect precision and motor longevity.

Can the Punch 700 handle specialised materials like PVC, cardstock, and laminated covers?

Yes, the robust motor and precision engineering accommodate materials up to 4.0mm thickness, including heavy cardstock, laminated covers, PVC sheets, and multi-layer documents effectively.

What training requirements ensure operators maximise the Punch 700's capabilities safely?

Okoboji provides comprehensive operator training covering safety protocols, maintenance procedures, troubleshooting techniques, and efficiency optimisation to ensure maximum return on investment and safe operation.

How do interchangeable die sets expand the machine's versatility for different applications?

Optional die sets accommodate various hole patterns, wire sizes, and speciality binding requirements, allowing adaptation for calendars, notebooks, technical manuals, and custom binding applications.

What maintenance schedule ensures optimal performance and prevents costly downtime?

Daily cleaning of punch waste, weekly lubrication of moving parts, monthly inspection of cutting dies, and quarterly professional servicing maintain peak performance and extend equipment lifespan.

Does the modular design provide advantages for workspace organisation and efficiency?

The separate punching and closing components allow flexible workspace arrangement, simultaneous operation by multiple staff, and easier maintenance access compared to integrated binding machines.

What cost savings can businesses expect from investing in the Okoboji Punch 700?

Reduced labour costs, increased throughput capacity, improved binding quality, and enhanced customer satisfaction typically provide return on investment within 12-18 months for high-volume operations.

How does Okoboji support Punch 700 users with technical assistance and parts availability?

Comprehensive support includes 24/7 technical helpline, nationwide service network, guaranteed spare parts availability, and field service technicians for prompt resolution of operational issues.

Customers also bought

Okoboji Digital Foil Printer 250 X 350mm Automatic 3025XY

Okoboji Eyelet Manual Single Head 5.5mm DJC4

Okoboji Eyelet Pneumatic 4 Head Punch EPNQ4