Okoboji Hole Punch Electric Drill 1 Head HD

SPECIFICATIONS

PRODUCT VIDEO

PRODUCT DESCRIPTION

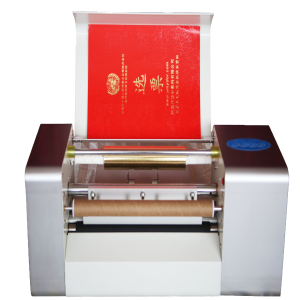

The Okoboji Electric Drill 1 Head HD represents cutting-edge electric punching technology designed for Indian manufacturing, workshops, and heavy-duty commercial applications. This powerful single-head electric punch machine delivers exceptional drilling performance with a maximum thickness capacity of 40mm, making it the ideal solution for metal fabrication, plastic processing, and thick material drilling requirements that manual punches simply cannot handle. Powered by a robust 0.25kW motor operating at 220V 50Hz, this industrial-grade equipment provides consistent, high-speed operation at 2800 RPM, ensuring clean, precise holes across various materials.

The versatile hole diameter range of 2-8mm accommodates diverse industrial applications from fine precision work to standard fabrication tasks. With a maximum central distance of 180mm, this electric punch offers exceptional flexibility for complex drilling patterns and custom positioning requirements. The substantial 30kg construction ensures vibration-free operation and long-term durability under demanding industrial conditions. Whether you’re working with sheet metal, thick plastics, leather goods, or industrial materials, the Okoboji Electric Drill HD delivers professional results that enhance productivity while maintaining the precision standards required for quality manufacturing and fabrication processes.

Upgrade Your Experience

Okoboji Hole Punch Electric Drill 2 Head HD WYT50

Okoboji Hole Punch Electric Drill 3 Head HD WYWB830

Okoboji Hole Punch Manual 3 Head WY290B

Okoboji Hole Punch Manual 4 Head WY290C

KEY FEATURES

- Powerful 0.25kW electric motor operating at 2800 RPM provides consistent high-speed drilling performance for industrial applications and heavy-duty material processing

- Impressive 40mm maximum drilling thickness handles thick metals, plastics, and industrial materials that manual punches cannot accommodate effectively

- Variable hole diameter capability (2-8mm) offers precision control for diverse applications from fine detail work to standard industrial drilling requirements

- Professional 180mm central distance capacity enables complex drilling patterns and custom positioning for specialised manufacturing and fabrication projects

- Heavy-duty 30kg industrial construction ensures vibration-free operation, stability, and long-term durability under demanding commercial and industrial usage

- Standard 220V 50Hz power compatibility integrates seamlessly with Indian electrical systems, reducing installation complexity and operational costs

- Compact 480x420x560mm dimensions optimise workspace utilisation while providing the stability and power required for professional-grade drilling operations

- Okoboji engineering excellence delivers reliable performance backed by comprehensive service support and industrial-grade component quality standards

FREQUENTLY ASKED QUESTIONS

What industrial applications benefit most from this electric hole punch?

Packaging industries, printing companies, manufacturing facilities, cardboard processing, industrial assembly lines, and any applications requiring consistent hole punching in thick materials or high-volume production.

How does the 40mm drilling capacity compare to manual alternatives?

Electric operation enables effortless processing of thick materials that would be impossible or extremely difficult with manual punches, dramatically improving productivity and reducing operator strain.

What power requirements and electrical considerations apply in Indian facilities?

The 220V 50Hz specification matches standard Indian industrial power supply. Ensure proper electrical connection, consider power fluctuation protection, and verify adequate circuit capacity for reliable operation.

Can this machine handle continuous operation in production environments?

Yes, the industrial-grade motor and robust construction enable continuous operation suitable for production lines, though regular maintenance intervals should be observed for optimal performance.

How does the 30kg weight contribute to operational performance?

The substantial weight provides exceptional stability during high-speed operation, eliminates vibration and movement, ensures precise hole placement, and indicates robust construction for industrial durability.

What safety considerations apply when operating this electric hole punch?

Ensure proper electrical grounding, maintain clear workspace, use appropriate eye protection, keep hands clear of drilling area, and follow standard industrial safety protocols for power equipment.

How do I select appropriate hole diameters for different applications?

Choose 2-3mm for binding applications, 4-5mm for standard industrial uses, 6-8mm for heavy-duty applications, and match requirements to your specific material thickness and binding system specifications.

What maintenance schedule ensures optimal performance and longevity?

Daily cleaning and inspection, weekly lubrication of moving parts, monthly motor ventilation cleaning, and quarterly professional service maintain peak performance and extend equipment life.

Can this machine accommodate specialty materials used in Indian manufacturing?

Yes, the powerful motor and adjustable diameter settings handle cardboard, industrial papers, thin plastics, and various sheet materials commonly used in Indian manufacturing and packaging industries.

What technical support and service does Okoboji provide for industrial equipment?

Okoboji offers professional technical support, industrial equipment servicing, spare parts supply, and warranty coverage through their established Indian industrial service network ensuring minimal production downtime.

Customers also bought

Okoboji Digital Foil Printer 350mm 360A

Okoboji Hot Stamping 9" X 12" FSA4

Okoboji Paper Cutter Digital Hydraulic 490mm