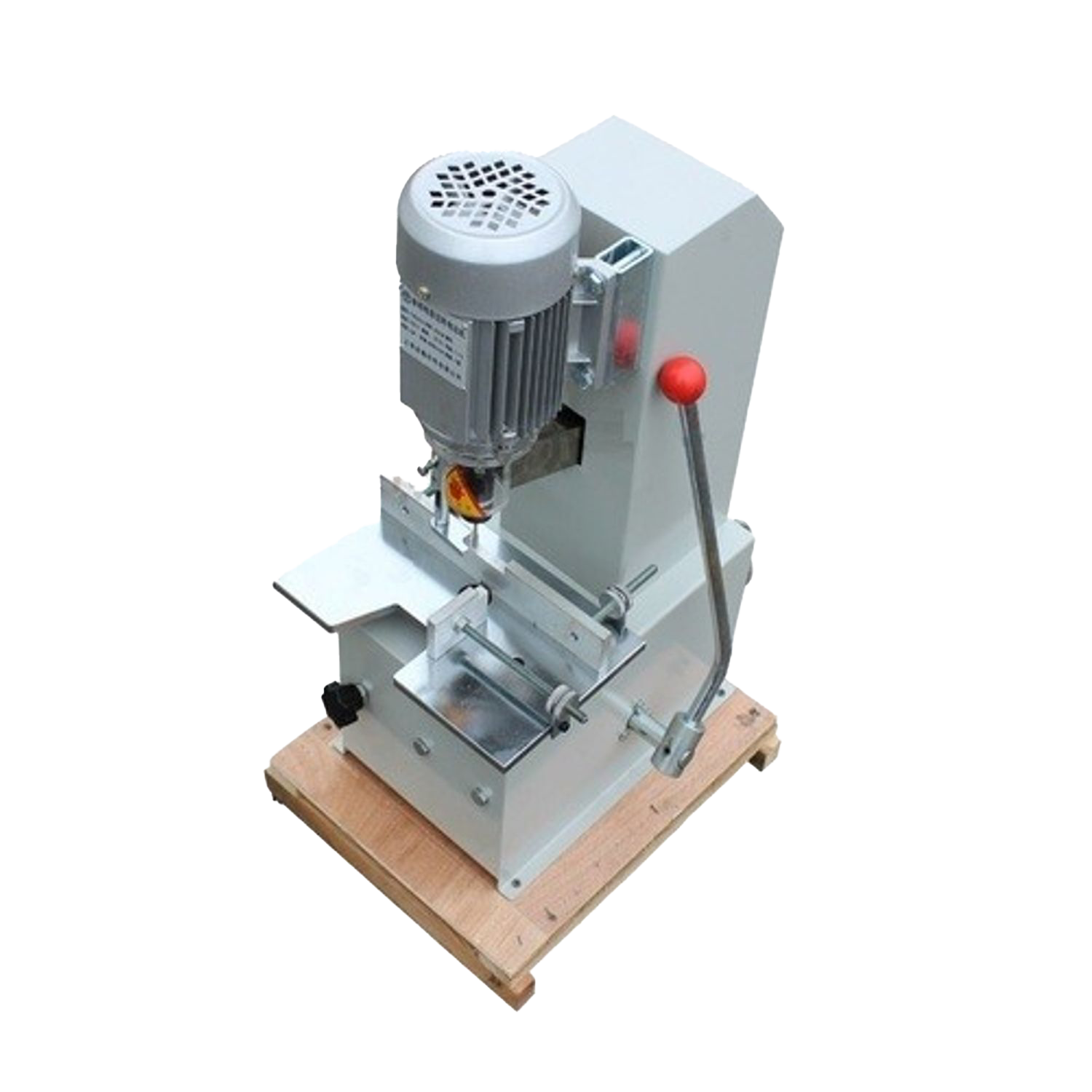

Okoboji Hole Punch Electric Drill 3 Head HD WYWB830

SPECIFICATIONS

PRODUCT VIDEO

PRODUCT DESCRIPTION

The Okoboji Electric Drill 3 Head HD WYWB830 represents the pinnacle of electric hole punching technology for premium commercial applications across India. This advanced triple-head electric punch machine delivers unmatched productivity with an exceptional 500-page punching capacity, making it the ultimate solution for large-scale commercial printing, educational institutions, and professional binding services requiring the highest levels of efficiency and precision. The sophisticated three-head configuration creates perfectly aligned holes with precision spacing of 83mm and 80mm, ensuring flawless compatibility with premium binding systems and professional presentation requirements demanded by India’s leading educational and commercial establishments.

The robust 35kg construction provides uncompromising stability and vibration control during intensive operation, while the precision-engineered electric mechanism delivers consistent, powerful punching force that effortlessly handles thick document stacks and various binding materials. The adjustable hole diameter range of 3-6mm accommodates everything from delicate spiral binding to heavy-duty ring binder applications, making this versatile machine suitable for premium course materials, corporate presentations, training documentation, and high-end commercial binding projects. The generous work plate design ensures accurate positioning across multiple document formats while the adjustable margin feature provides the flexibility required for custom applications. When reliability, precision, and high-volume capacity are non-negotiable requirements, the Okoboji WYWB830 delivers professional results that exceed expectations while maintaining the durability standards essential for continuous commercial operation.

Upgrade Your Experience

Okoboji Handheld Punch Single T35

Okoboji Hole Punch Electric Drill 1 Head HD

Okoboji Hole Punch Manual 2 Head WY290A

Okoboji Hole Punch Manual 4 Head WY290C

KEY FEATURES

- Premium triple-head configuration delivers three perfectly aligned holes simultaneously, maximising productivity for high-end commercial and educational binding applications

- Exceptional 500-page punching capacity handles massive document volumes efficiently, making it ideal for textbook production, commercial printing, and large-scale binding operations

- Precision hole spacing (83mm and 80mm) ensures perfect alignment with premium binding systems and professional presentation standards required by leading institutions

- Heavy-duty 35kg construction provides unmatched stability and vibration control during intensive operation while ensuring long-term durability under demanding commercial conditions

- Professional adjustable diameter (3-6mm) accommodates premium binding methods from delicate spiral systems to heavy-duty ring binders for diverse commercial applications

- Advanced electric mechanism delivers consistent, powerful punching force with minimal operator effort, enabling continuous high-volume operation for commercial productivity

- Flexible margin adjustment (8-35mm) ensures precise hole placement for various document formats and custom binding requirements, reducing material waste and improving efficiency

- Okoboji premium engineering represents the highest quality standards with comprehensive commercial support and proven reliability for critical business applications

FREQUENTLY ASKED QUESTIONS

What makes the 3-head design superior for commercial binding applications?

The triple-head configuration creates three perfectly aligned holes simultaneously, providing optimal binding strength and professional appearance while maximising productivity for commercial operations.

How does the 35kg weight contribute to operational performance and stability?

The substantial weight ensures vibration-free operation, precise hole alignment, and stability during high-volume processing, essential for maintaining consistent quality in commercial applications.

Can this machine handle the demanding requirements of educational textbook production?

Absolutely, the 500-page capacity and robust construction make it ideal for educational publishers, printing houses, and institutions requiring high-volume, consistent textbook binding capabilities.

What types of binding systems are compatible with the 83mm and 80mm hole spacing?

These spacing options accommodate standard ring binders, premium spiral binding systems, and custom binding requirements commonly used in educational and commercial applications.

Is professional installation and training available for this premium equipment?

Yes, Okoboji provides comprehensive installation services, operator training, and ongoing technical support to ensure optimal performance and safe operation for commercial customers.

How does the electric operation impact productivity compared to manual alternatives?

Electric operation eliminates operator fatigue, provides consistent force, dramatically reduces processing time, and enables continuous operation essential for meeting commercial production schedules.

What preventive maintenance is required to ensure reliable commercial operation?

Regular cleaning, lubrication, electrical connection inspection, and adherence to Okoboji's maintenance schedule ensure optimal performance and prevent costly downtime in commercial environments.

Can this machine process different document sizes and binding cover materials?

The adjustable margin and generous work plate accommodate various document sizes, while the 50mm capacity handles different paper weights and light binding covers effectively.

What warranty and service support does Okoboji provide for commercial customers?

Okoboji offers comprehensive commercial warranties, rapid parts availability, technical support, and service networks designed to minimise downtime for business-critical applications.

How does this premium model justify the investment for commercial operations?

The exceptional productivity, consistent quality, reduced labour requirements, and long-term reliability provide significant return on investment for commercial binding operations with high-volume requirements.

Customers also bought

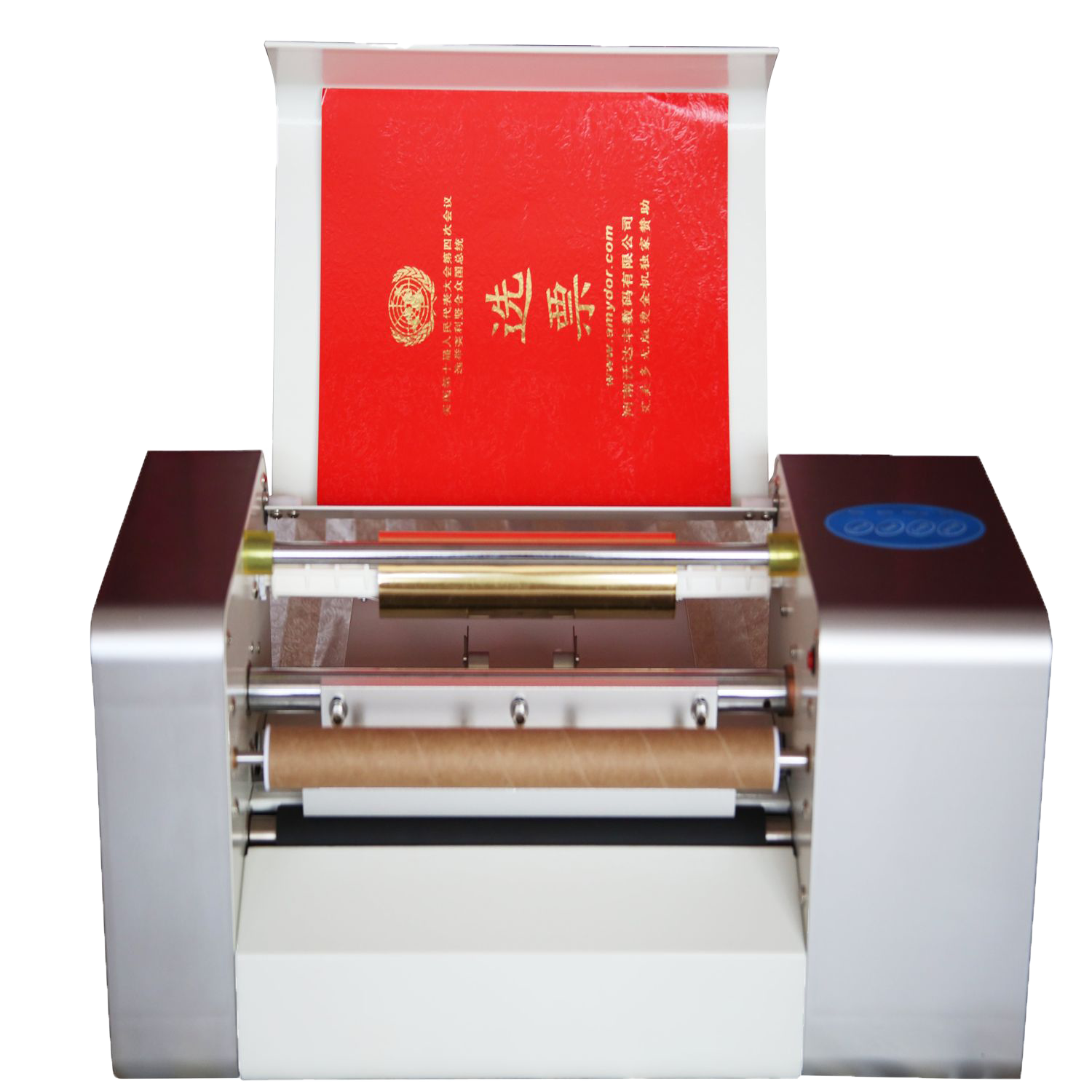

Okoboji Digital Foil Printer 350mm 360A

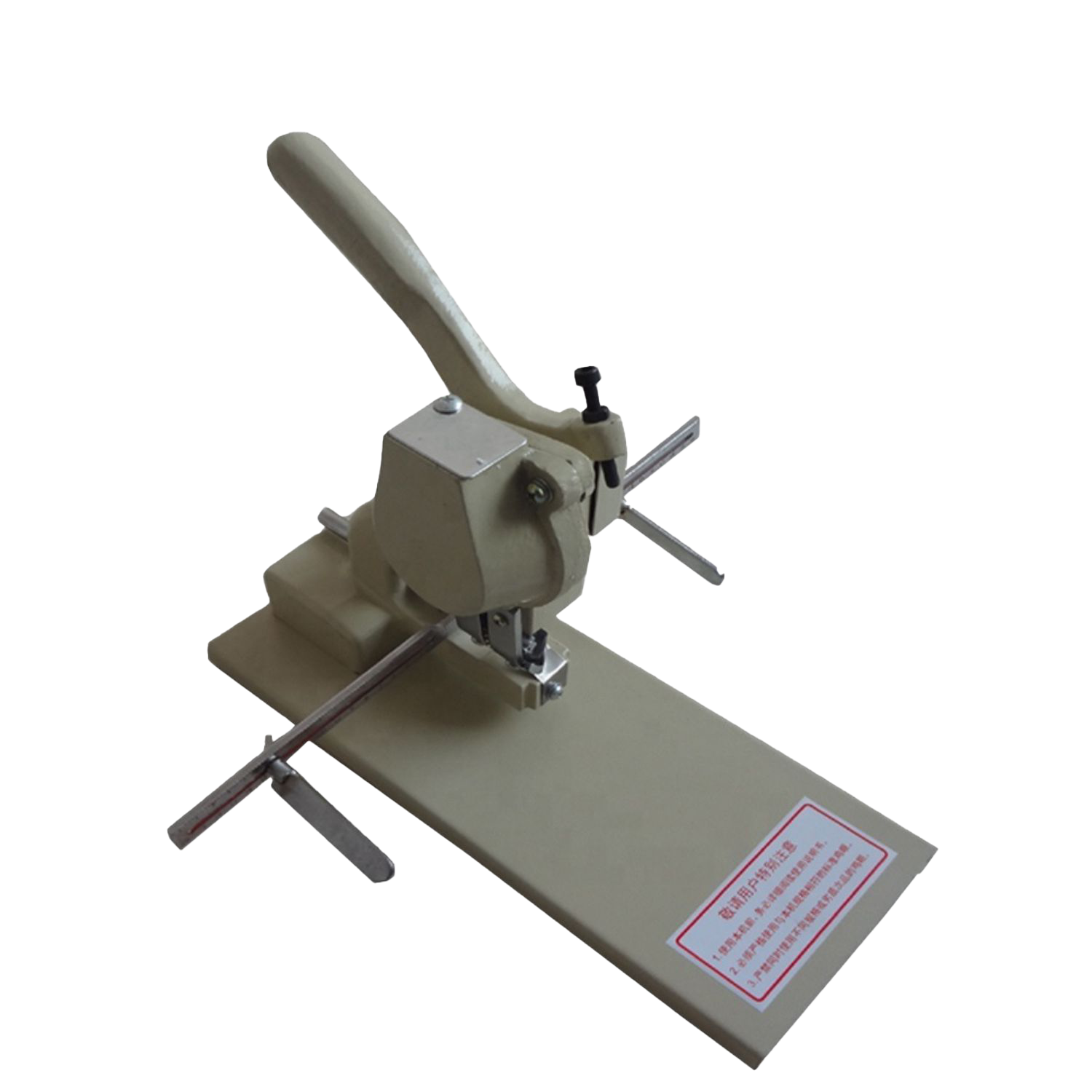

Okoboji Eyelet Desktop Manual DT

Okoboji Eyelet Manual Single Head 5.5mm DJC4