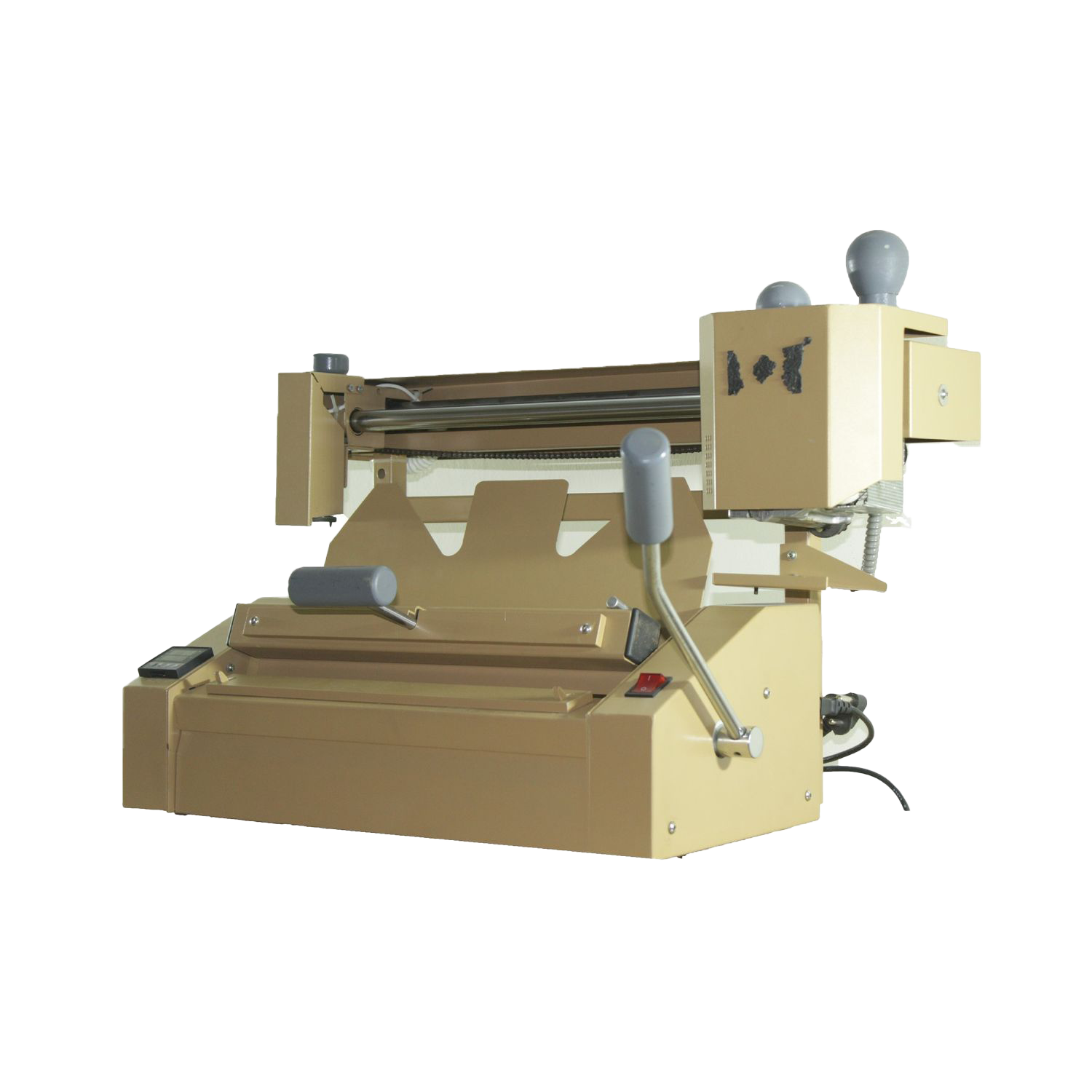

Okoboji Creasing and Perforation Rotary Electric A3

SPECIFICATIONS

PRODUCT VIDEO

PRODUCT DESCRIPTION

The Okoboji Rotary Electric A3 Creasing and Perforation Machine represents advanced rotary technology designed for high-volume commercial applications requiring superior speed and precision in paper finishing operations. This sophisticated electric machine combines creasing and perforation capabilities in a single rotary system, delivering exceptional throughput of 3600 sheets per hour whilst maintaining professional quality standards. The 660mm maximum width capacity accommodates A3 documents and larger materials, making it perfect for commercial printing facilities, large offices, and packaging operations where productivity and consistency are essential for business success.

This powerful rotary machine excels in demanding environments where traditional linear systems cannot match the required processing speeds. The rotary design ensures continuous, smooth operation whilst the 90W motor provides reliable performance across extended production runs. Perfect for processing brochures, marketing materials, packaging inserts, and commercial documents, this machine significantly reduces processing time whilst maintaining the precision demanded by professional applications. The robust 62kg construction guarantees exceptional stability during high-speed rotary operations, whilst the manual feeding system allows operators to maintain quality control over critical positioning requirements for each application.

Upgrade Your Experience

Okoboji Paper Creaser Automatic W auto pickup K330C

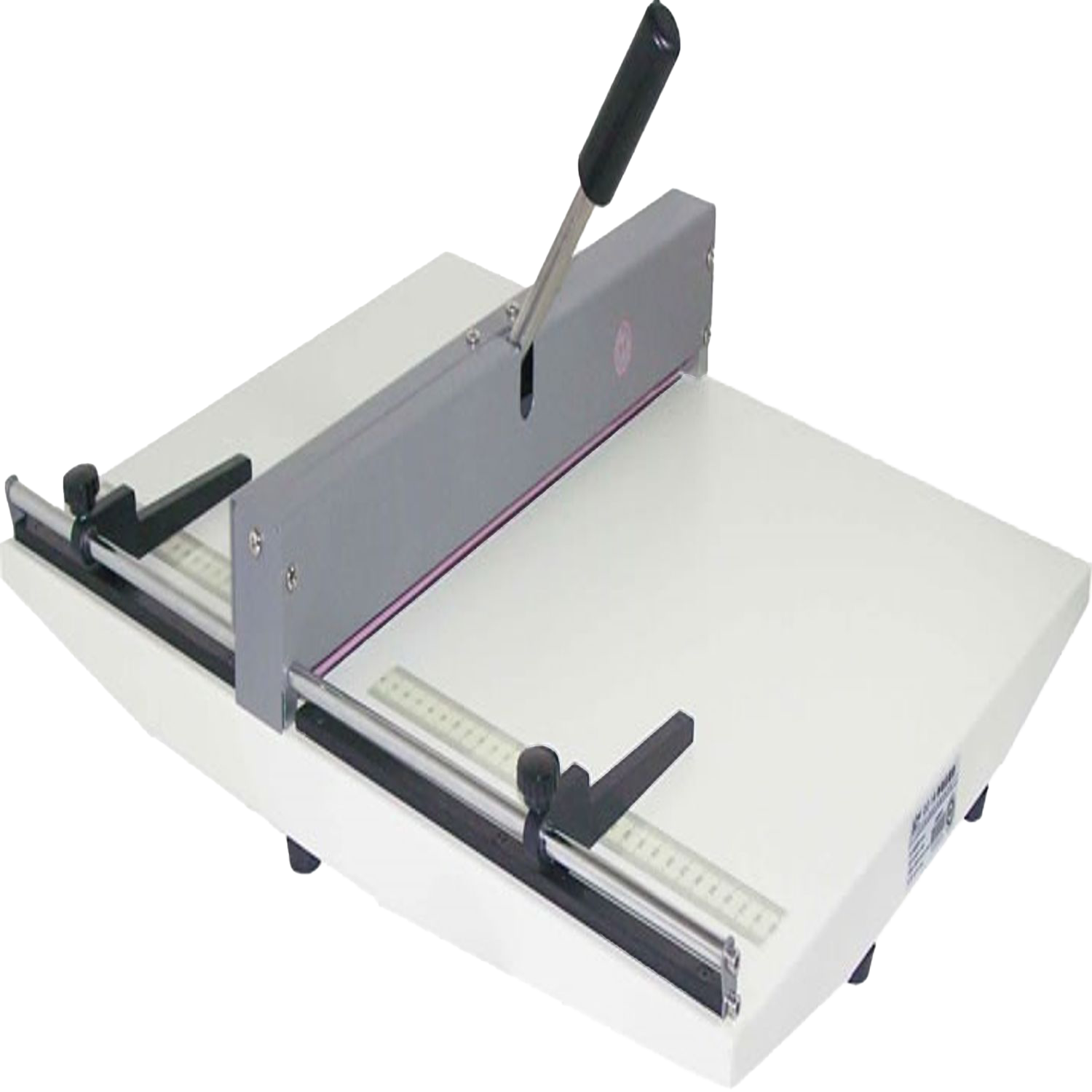

Okoboji Paper Creaser Manual A3 Size H460

Okoboji Paper Creasing, Perforation Manual 460 2in1

Okoboji Paper Half Cutting 600mm HC600

KEY FEATURES

- High-Speed Rotary Technology : Advanced rotary system delivers exceptional 3600 sheets per hour throughput, dramatically outperforming linear alternatives for high-volume commercial applications

- A3+ Wide Format Capability : 660mm maximum width accommodates A3 documents, large brochures, packaging materials, and oversized commercial applications requiring wide-format processing

- Dual Function Excellence : Seamlessly combines precision creasing and micro-perforation in one rotary system, maximising versatility and eliminating the need for multiple specialised machines

- Heavy-Duty Commercial Construction : Massive 62kg industrial frame ensures vibration-free operation and exceptional stability during continuous high-speed rotary processing

- Professional Paper Handling : Processes papers up to 400gsm including cardstock, coated materials, and specialty papers commonly used in commercial printing and packaging applications

- Okoboji Rotary Innovation : Advanced rotary technology with comprehensive warranty and nationwide service support ensuring reliable operation for critical commercial production schedules

- Energy-Efficient 90W Motor : Optimised power consumption delivers consistent performance whilst maintaining cost-effective operation for extended commercial production runs

- Manual Feed Precision : Operator-controlled feeding system ensures accurate positioning whilst benefiting from automated rotary processing speed and consistency

FREQUENTLY ASKED QUESTIONS

How does the rotary system benefit high-volume production compared to linear machines?

Rotary technology provides continuous processing at 3600 sheets/hour with smoother operation, reduced vibration, and superior consistency compared to traditional linear systems.

What paper types work best with the Okoboji rotary creasing system?

Processes all paper types from 80gsm office paper to 400gsm cardstock, including coated papers, digital prints, and specialty materials without surface damage.

Can this machine handle both creasing and perforation in the same production run?

Yes, the dual-function rotary system allows seamless switching between creasing and perforation or combining both functions for complex applications.

What maintenance is required for the rotary mechanism?

Regular lubrication of rotary components, periodic alignment checks, and cleaning procedures ensure optimal performance; Okoboji provides comprehensive maintenance schedules.

How does the 660mm width capacity benefit A3 and larger format work?

The wide capacity accommodates A3+ documents, large brochures, packaging sheets, and oversized materials commonly used in commercial printing operations.

Is the 90W power consumption efficient for continuous commercial operation?

Yes, the optimised motor provides excellent power efficiency whilst delivering consistent high-speed performance, reducing operational costs for extended production runs.

What safety features protect operators during high-speed rotary operation?

Comprehensive safety systems including emergency stops, protective guards, and operator safety features meeting international standards for commercial rotary equipment.

How does Okoboji support commercial users with service and technical assistance?

Professional service network with certified technicians specialising in rotary systems, guaranteed spare parts, and rapid response support for commercial operations.

Can this machine handle laminated and coated materials effectively?

Yes, the rotary system works excellently with laminated papers, coated stocks, and specialty finishes without delamination or surface marking.

What training is recommended for operators using rotary creasing equipment?

Professional training covers rotary system operation, safety procedures, and maintenance practices; Okoboji provides certified training programmes for commercial users.

Customers also bought

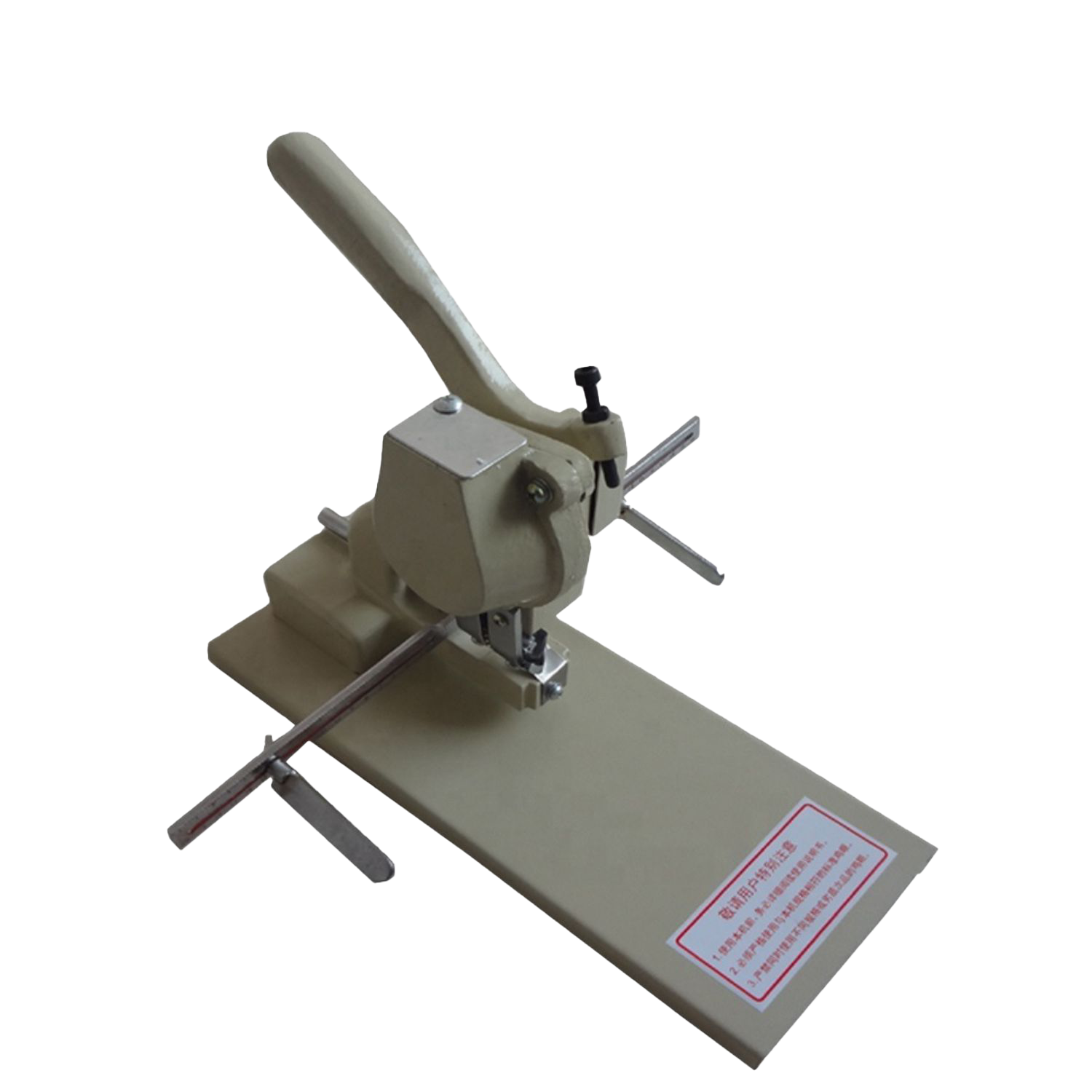

Okoboji Eyelet Manual Single Head 5.5mm DJC4

Okoboji Eyelet Manual Single Head Foot Pedal 5.5mm DJJ4

Okoboji Glue Binding Machine A4 Semi Auto