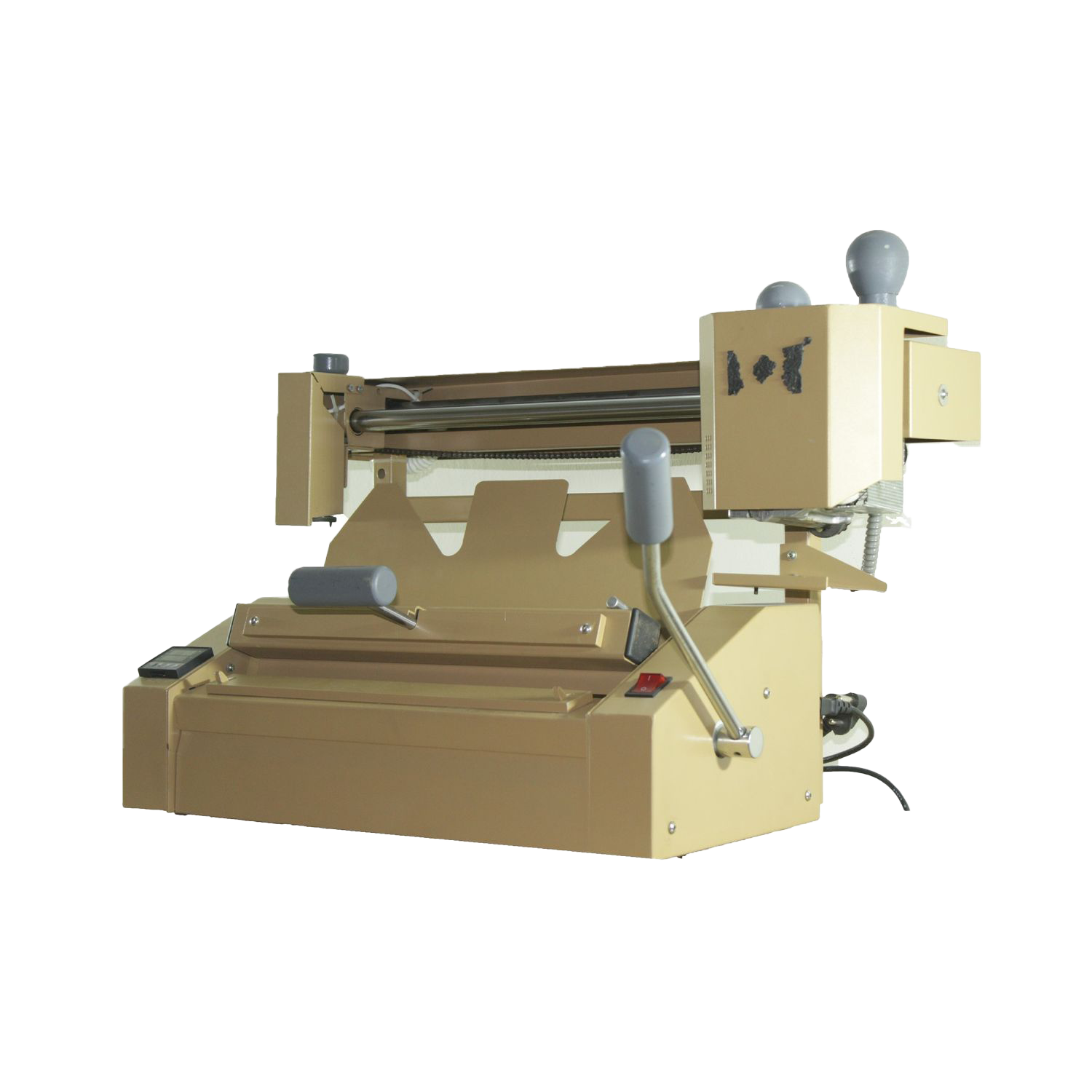

Okoboji Gluing Machine Hot and Cold 700mm/27.55″ GM700

SPECIFICATIONS

PRODUCT VIDEO

PRODUCT DESCRIPTION

The Okoboji GM700 Hot and Cold Gluing Machine represents a versatile solution for professional bookbinding and industrial adhesive applications across India’s printing and packaging industries. This robust 700mm wide gluing system combines both hot and cold adhesive capabilities, making it ideal for diverse materials ranging from standard offset papers to coated stocks and specialty substrates. The machine’s dual-functionality allows operators to switch between hot melt adhesives for quick-setting permanent bonds and cold adhesives for temperature-sensitive materials or specialty applications.

Designed specifically for Indian manufacturing environments, this Okoboji gluing machine delivers exceptional performance in high-volume production settings whilst maintaining precise adhesive application control. The variable speed motor (0-20 metres per minute) enables operators to match processing speeds to specific material requirements and production demands. Whether you’re operating a commercial printing press in Mumbai, a packaging facility in Chennai, or a bookbinding operation in Delhi, this machine’s bottom gluing method ensures consistent adhesive distribution across the entire substrate width, resulting in professional-grade finished products with superior bond strength and durability.

The compact dimensions (980×980×1200mm) and efficient 0.25HP motor make this machine suitable for both standalone operations and integration into existing production lines. Its ability to handle materials up to 3mm thickness on standard use basis makes it particularly valuable for binding applications requiring multiple sheet thickness variations, from thin brochures to thick catalogues and industrial manuals.

Upgrade Your Experience

Okoboji Glue Binding Machine B40F

Okoboji Perfect Binder A3

Okoboji Perfect Binder Desktop Manual T30

Okoboji Sublimation Combo Heat Press 5in1

KEY FEATURES

- Dual Hot and Cold Adhesive System : Okoboji's advanced technology allows seamless switching between hot melt and cold adhesive applications, providing flexibility for diverse substrate requirements and temperature-sensitive materials commonly used in Indian printing industry.

- Variable Speed Control (0-20m/min) : Precision motor speed adjustment enables optimal processing rates for different paper weights, adhesive types, and production volumes, ensuring consistent quality across varying Indian manufacturing conditions.

- 700mm Wide Processing Capacity : Accommodates standard A3+ formats and custom sizes popular in Indian commercial printing, making it ideal for books, catalogues, packaging materials, and industrial documentation applications.

- 3mm Maximum Thickness Handling : Robust construction supports binding of substantial document thicknesses including multi-page reports, technical manuals, and premium publications required by Indian businesses and educational institutions.

- Bottom Gluing Application Method : Ensures even adhesive distribution and superior penetration into paper fibres, resulting in strong, professional binds that meet Indian quality standards for export and domestic markets.

- Compact Industrial Design : Space-efficient 980×980×1200mm footprint fits into existing production environments whilst providing easy access for operation and maintenance by Indian technical staff.

- Energy-Efficient 0.25HP Motor : Optimised power consumption reduces operational costs whilst delivering reliable performance in Indian electrical supply conditions, supporting sustainable manufacturing practices.

- Professional Build Quality : Okoboji engineering ensures consistent performance under demanding Indian industrial conditions, providing reliable operation for high-volume commercial applications across diverse climate zones.

FREQUENTLY ASKED QUESTIONS

What types of adhesives can be used with the Okoboji GM700 gluing machine?

The GM700 supports both hot melt adhesives (EVA-based) for permanent bookbinding and cold adhesives (water-based) for temperature-sensitive materials, making it versatile for various Indian printing applications.

How does the variable speed control benefit different production requirements?

The 0-20m/min speed range allows operators to optimise processing rates for different paper weights, adhesive curing times, and production volumes, ensuring quality consistency across diverse Indian manufacturing conditions.

What is the maximum material thickness this Okoboji gluing machine can handle?

The GM700 can process materials up to 3mm thickness on standard use basis, suitable for binding thick catalogues, technical manuals, and multi-page documents common in Indian commercial and educational sectors.

Is this machine suitable for both small-scale and large-scale printing operations in India?

Yes, the Okoboji GM700's compact design and variable speed capability make it ideal for both small printing shops and large commercial operations across Indian cities, from local businesses to export-oriented manufacturers.

What maintenance requirements does this gluing machine have?

Regular cleaning of adhesive application systems, periodic lubrication of moving parts, and routine inspection of heating elements (for hot adhesive mode) ensure optimal performance in Indian industrial environments.

Does Okoboji provide technical support and service for this equipment in India?

Okoboji offers comprehensive technical support, including installation guidance, operator training, and maintenance services through authorised dealers across major Indian industrial centres.

How does the bottom gluing method compare to other adhesive application techniques?

Bottom gluing provides superior adhesive penetration into paper fibres and even distribution across substrate width, resulting in stronger bonds compared to side-gluing methods, particularly important for Indian export quality requirements.

What types of finished products can be created using this Okoboji gluing machine?

The GM700 is ideal for perfect-bound books, catalogues, brochures, packaging materials, industrial manuals, and specialty publications required by Indian businesses, educational institutions, and export markets.

Are there any specific power or installation requirements for Indian facilities?

The 0.25HP motor operates on standard Indian electrical supply, requiring minimal installation modifications and offering energy-efficient operation suitable for cost-conscious Indian manufacturing environments.

How does this machine perform with different paper grades commonly used in India?

The dual hot/cold capability and variable speed control make the Okoboji GM700 suitable for various Indian paper grades, from standard offset papers to coated stocks and specialty substrates used in premium printing applications.

Customers also bought

Okoboji Box Moon Cutting Machine BMC

Okoboji Corner Taping Machine CTM

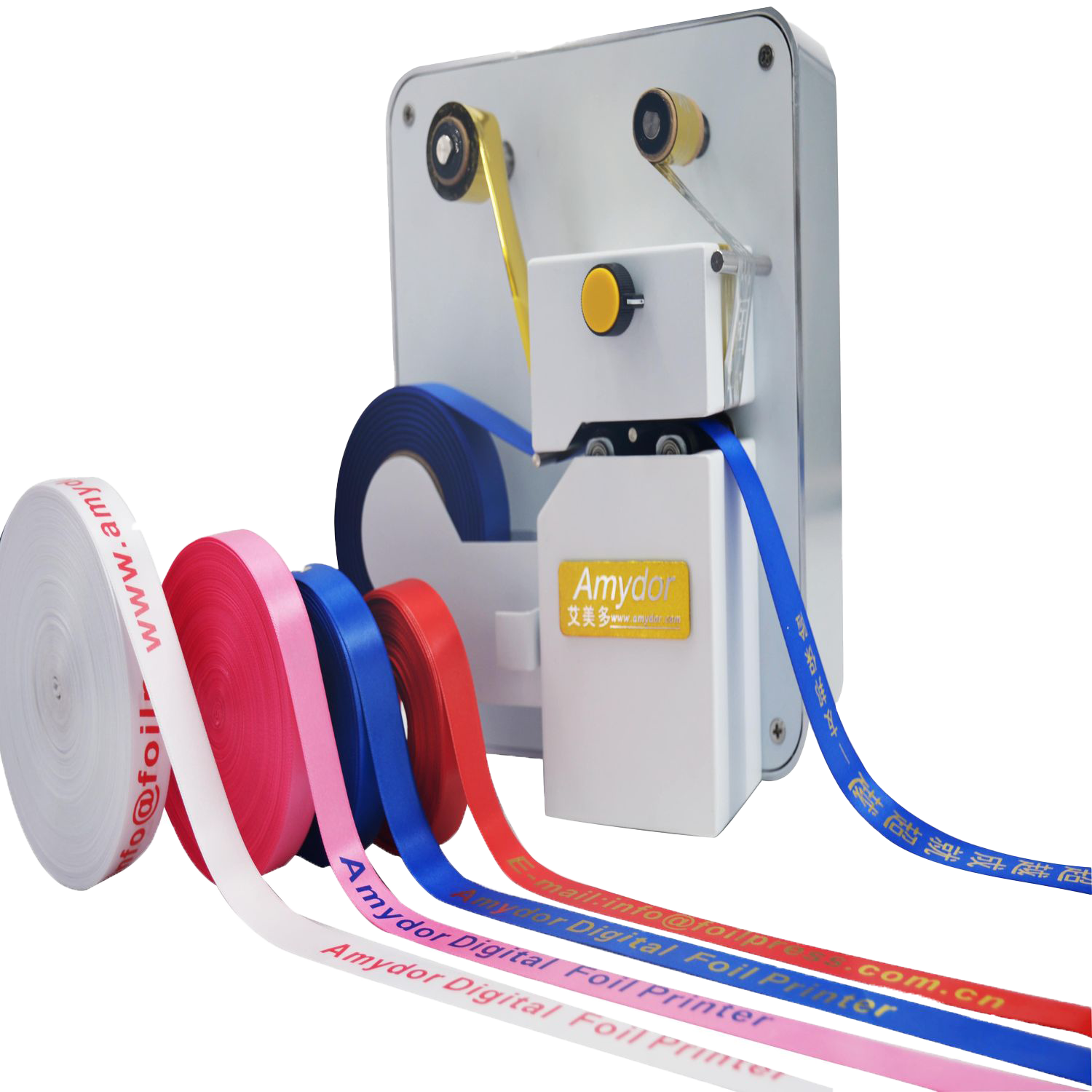

Okoboji Digital Foil Printer for LanYard 32mm 320R