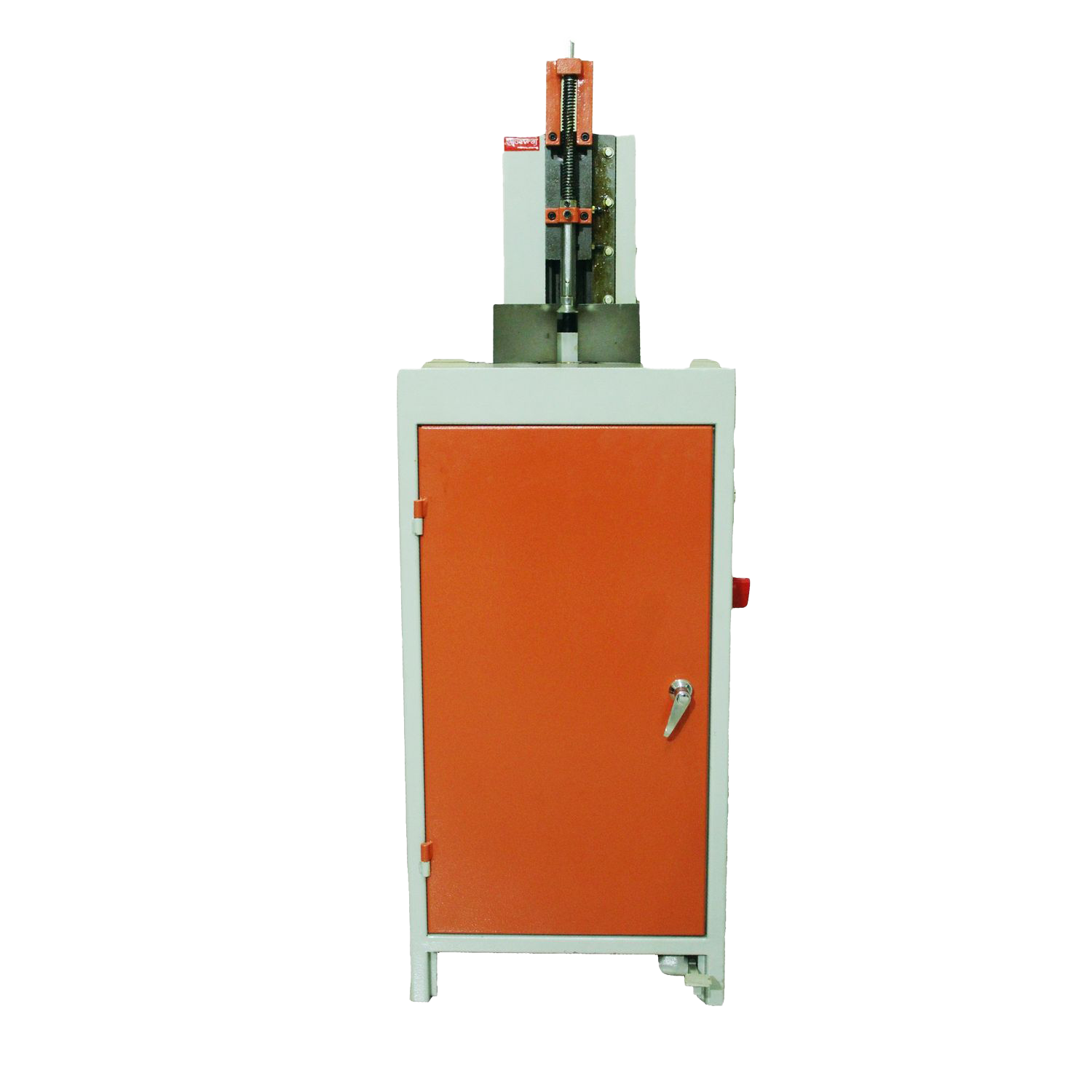

Okoboji Hot Stamping 12″ X 15.74″ 3T Presure HD 3040 3T

SPECIFICATIONS

PRODUCT VIDEO

PRODUCT DESCRIPTION

The Okoboji Hot Stamping 12″ X 15.74″ 3T Pressure HD 3040 3T represents the pinnacle of high-definition foil stamping technology, specifically engineered for the most demanding applications across India’s premium manufacturing sectors. This advanced machine delivers an impressive 3-tonne (3000KG) pressure capacity within a precision 12″ x 15.74″ working area, enabling exceptional foil application quality on the most challenging substrates including thick leather goods, rigid packaging materials, and industrial components. The machine’s substantial pressure capability combined with high-definition precision controls ensures flawless foil transfer even on textured surfaces, embossed materials, and complex three-dimensional shapes that conventional machines cannot handle effectively.

Designed for applications requiring the highest quality standards, this Okoboji machine incorporates advanced pressure distribution technology and precision temperature controls to deliver consistently superior results across extended production runs. The high-definition designation reflects the machine’s ability to achieve exceptional detail reproduction, sharp edge definition, and uniform foil coverage that meets the exacting standards of luxury packaging, premium leather goods, and high-end promotional materials. With its robust 3-tonne capacity and precision engineering, this machine enables manufacturers to offer premium foil finishing services that command top-tier pricing whilst maintaining the reliability and consistency that commercial operations demand.

Upgrade Your Experience

Okoboji Digital Foil Printer 250 X 350mm Automatic 3025XY

Okoboji Digital Foil Printer 57 X 250mm X axis 8025

Okoboji Digital Foil Printer for Ribbon 150R

Okoboji Thermal Head Ribbon Printer 75mm

KEY FEATURES

- Exceptional 3-tonne (3000KG) pressure capacity enables flawless foil application on the most challenging substrates including thick leather, rigid packaging, and textured materials.

- High-definition precision controls deliver exceptional detail reproduction and sharp edge definition for luxury packaging and premium promotional applications.

- Advanced pressure distribution technology ensures uniform foil coverage across complex shapes, embossed surfaces, and three-dimensional substrates with professional consistency.

- Generous 12" x 15.74" working area accommodates large-format applications whilst maintaining the precision required for detailed graphics and fine text reproduction.

- Precision temperature control system with high-definition calibration enables optimal foil transfer across diverse substrate materials and specialty foil formulations.

- Industrial-grade construction provides exceptional stability and vibration dampening required for precision foil application in demanding commercial environments.

- Comprehensive safety systems including pressure monitoring, emergency stops, and protective guards ensure safe operation with high-pressure capabilities.

- Okoboji's advanced engineering delivers exceptional reliability and performance specifically optimized for premium finishing applications requiring the highest quality standards.

FREQUENTLY ASKED QUESTIONS

What applications require the 3-tonne pressure capability of this HD machine?

This exceptional pressure capacity is essential for thick leather goods, rigid packaging materials, deeply embossed substrates, and industrial components requiring maximum foil adhesion strength.

How does the high-definition designation improve foil stamping quality?

HD precision controls enable exceptional detail reproduction, sharp edge definition, and uniform coverage that meets luxury packaging standards and premium promotional material requirements.

Can this machine handle complex three-dimensional surfaces?

Yes, the 3-tonne pressure combined with advanced pressure distribution technology ensures consistent foil application across curved surfaces, embossed areas, and complex shapes.

Is this machine suitable for luxury packaging and premium applications?

Absolutely, the high-definition capabilities and exceptional pressure make it ideal for luxury packaging, premium leather goods, and high-end promotional materials requiring superior quality.

What safety considerations are important with 3-tonne pressure capacity?

Comprehensive safety systems include pressure monitoring, emergency stops, protective guards, and proper operator training to ensure safe operation with high-pressure capabilities.

How precise is the temperature control for specialty foil applications?

The advanced HD temperature control system provides precise calibration for specialty foils, holographic materials, and complex substrate combinations requiring exact thermal parameters.

What training is required for operators of this advanced machine?

Professional training covering pressure settings, temperature calibration, safety procedures, and HD precision techniques ensures operators can achieve optimal results safely and consistently.

How does this compare to standard hot stamping machines for commercial use?

The 3-tonne capacity and HD precision controls enable applications impossible with standard machines, including thick substrates, complex shapes, and premium finishing requirements.

What maintenance is required for this high-pressure precision machine?

Professional maintenance including pressure system calibration, temperature verification, safety system checks, and precision component inspection ensures optimal performance and safety.

Does Okoboji provide specialized support for this advanced machine?

Yes, Okoboji offers comprehensive support including professional installation, advanced operator training, precision calibration services, and specialized maintenance programmes.

Customers also bought

Okoboji Corner Cutter Electric Heavy Duty Orange

Okoboji Corner Cutter Electric Raduis upto 20mm 5 Dye Raduis upto 20mm 5 Dye

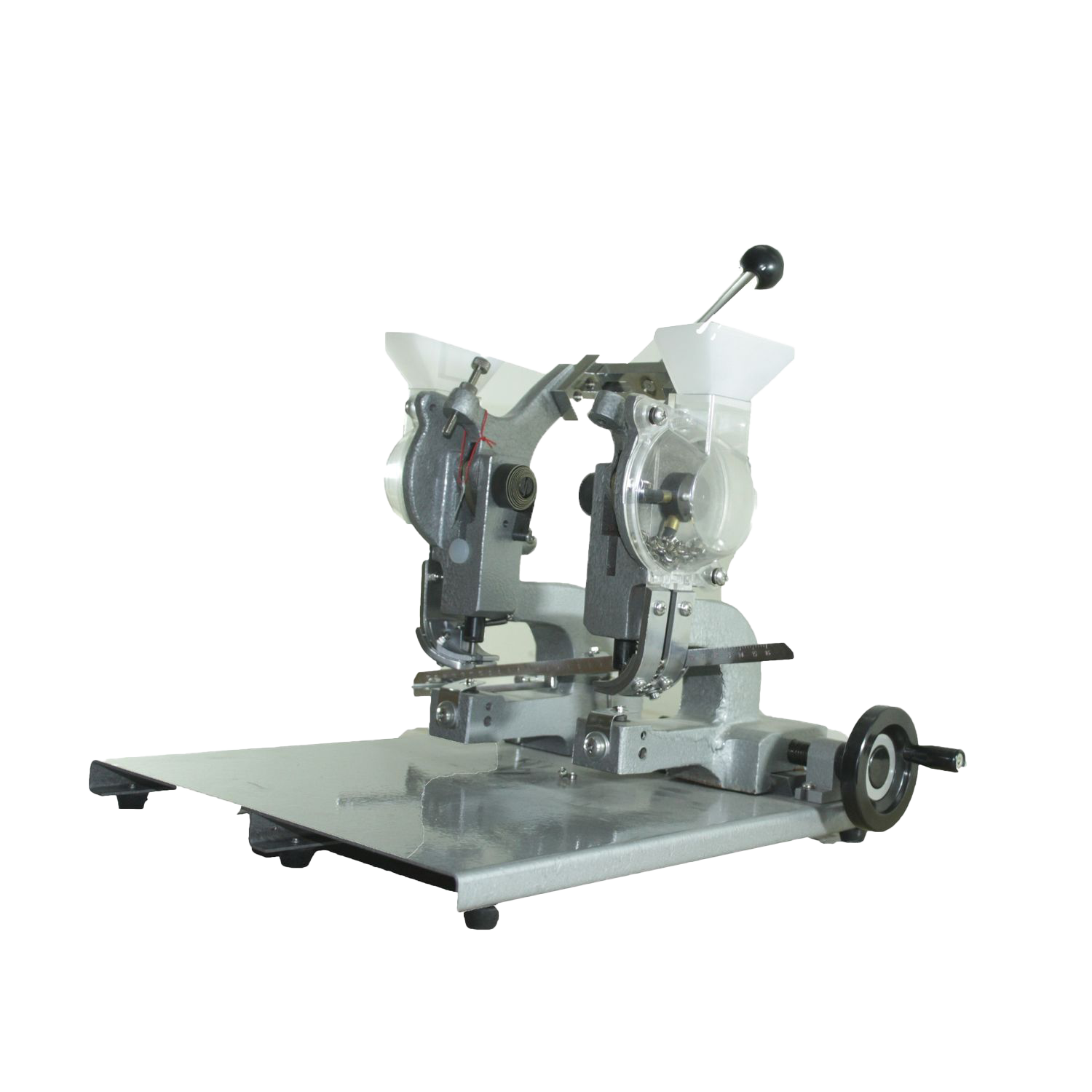

Okoboji Eyelet Manual Dual Head 4mm DJS4 4mm