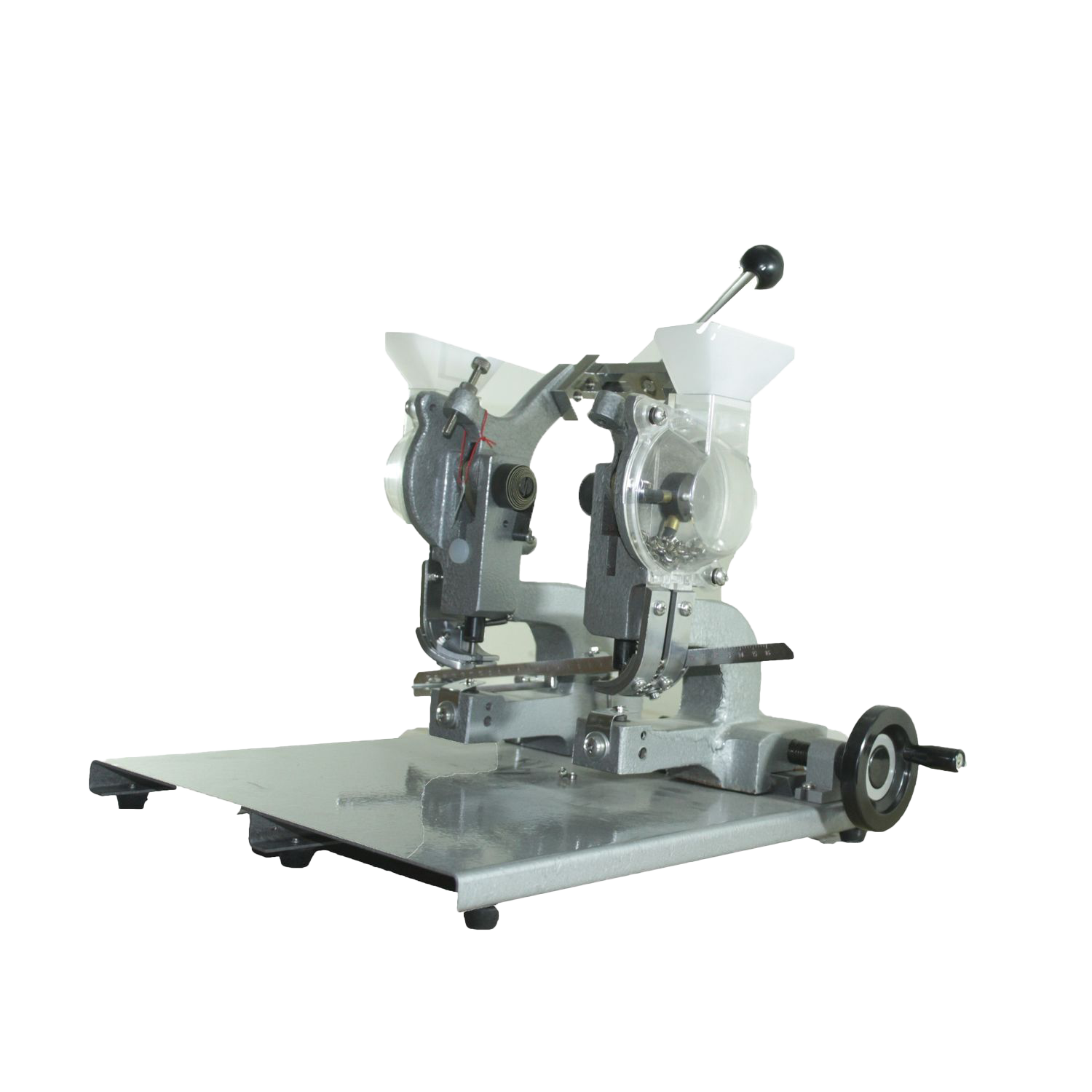

Okoboji Eyelet Pneumatic 4 Head Punch EPNQ4

SPECIFICATIONS

PRODUCT VIDEO

PRODUCT DESCRIPTION

The Okoboji Pneumatic 4 Head Punch EPNQ4 represents the pinnacle of industrial eyelet technology, engineered for high-volume manufacturing environments where maximum productivity, consistent quality, and operational flexibility are essential for competitive success. This advanced machine demonstrates how sophisticated pneumatic engineering can transform eyelet installation from a labour-intensive process into a highly efficient, automated operation that dramatically improves manufacturing capability.

Understanding that modern manufacturing demands both speed and flexibility, this Okoboji system provides selectable operation from one to four eyelets per stroke, allowing operators to optimise productivity based on specific product requirements. This intelligent design means manufacturers can handle diverse production runs efficiently, from single eyelet precision work to maximum four-eyelet productivity, all within the same machine platform.

The pneumatic operation delivers consistent, powerful performance that manual or electric alternatives cannot match, whilst the multi-size capability (4mm, 4.5mm, 5.5mm, and 6mm) ensures this Okoboji machine can handle virtually any eyelet requirement within its range. The impressive 60 strokes per minute capability, combined with up to four eyelets per stroke, means potential output of 240 eyelets per minute, representing productivity levels that can transform manufacturing economics for high-volume operations.

Upgrade Your Experience

Okoboji Eyelet Electric 5.5mm Single Head

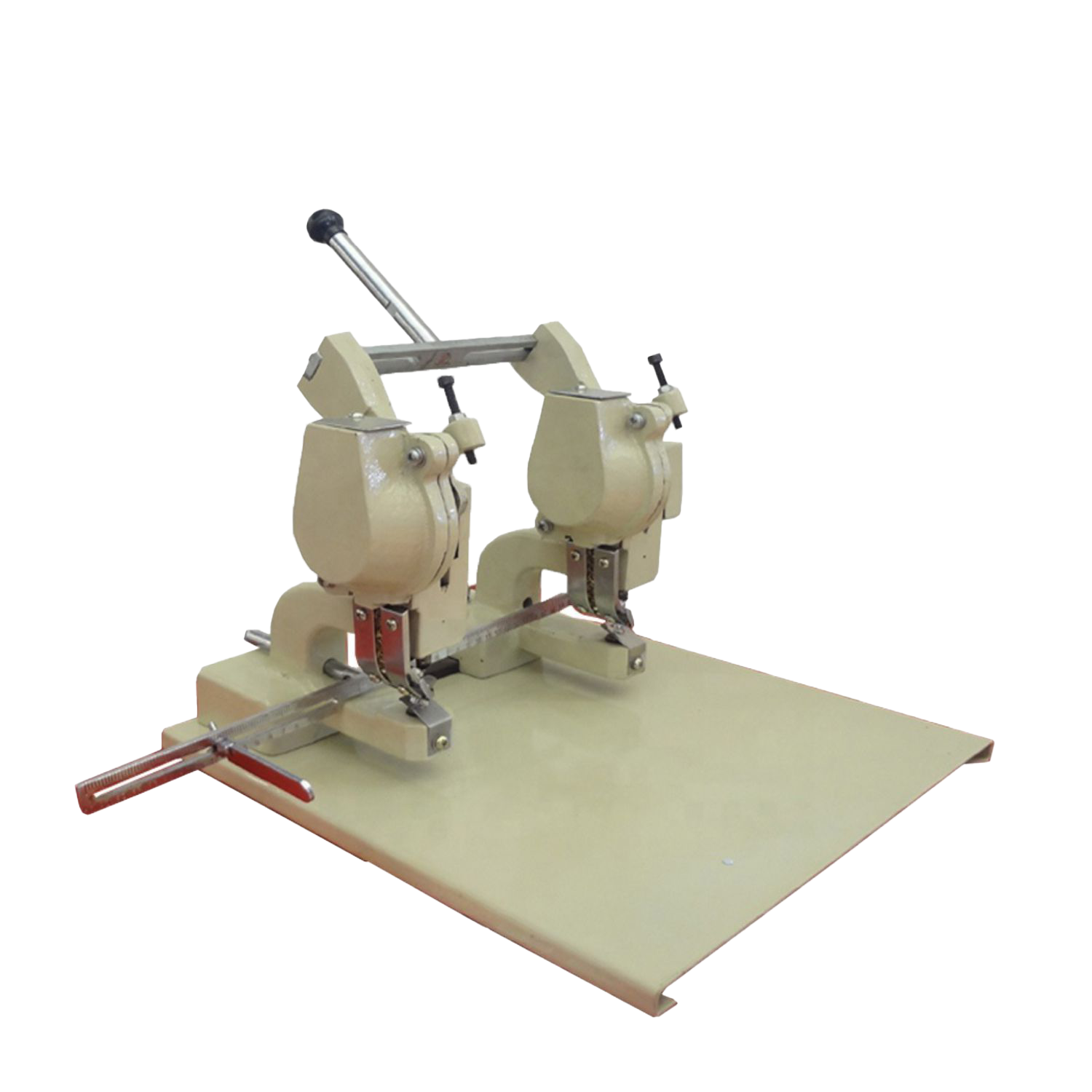

Okoboji Eyelet Manual 2 Head Foot Pedal EPDM2

Okoboji Eyelet Manual Dual Head 4mm DJS4 4mm

Okoboji Eyelet Manual Dual Head 5.5mm DJS4

KEY FEATURES

- Revolutionary 4-Head Pneumatic Design : Advanced pneumatic system enables installation of up to four eyelets simultaneously per stroke, providing maximum productivity potential of 240 eyelets per minute whilst maintaining precise control and consistent quality across all installation points.

- Selectable Output Flexibility : Intelligent design allows operators to select between 1, 2, 3, or 4 eyelets per stroke based on product requirements, providing exceptional flexibility to handle diverse production runs efficiently within the same Okoboji machine platform.

- Multi-Size Eyelet Capability : Accommodates four different eyelet sizes (4mm, 4.5mm, 5.5mm, and 6mm) with easy changeover, making this Okoboji machine versatile enough to handle virtually any eyelet requirement across diverse manufacturing applications and product lines.

- Industrial Pneumatic Power : High-pressure pneumatic operation (5-6 MPa) delivers consistent, powerful performance that ensures reliable eyelet installation across varying material thicknesses whilst maintaining the speed and precision essential for industrial production requirements.

- Easy Make-Ready Efficiency : Sophisticated design minimises setup and changeover time between different eyelet sizes and configurations, enabling this Okoboji machine to maintain high productivity even when handling diverse production requirements throughout manufacturing schedules.

- Professional 220V Integration : Standard industrial electrical compatibility ensures easy integration into existing manufacturing facilities whilst the robust 120kg construction provides the stability and durability essential for continuous high-volume industrial operation.

- High-Speed Production Capability : Achieves up to 60 strokes per minute with potential for 240 eyelets per minute output, providing productivity levels that can satisfy the most demanding industrial production schedules whilst maintaining consistent quality standards.

- Bag Making Specialisation : Specifically optimised for bag making and packaging applications where multiple eyelets are frequently required, making this Okoboji machine ideal for manufacturers in textile, packaging, and industrial fabric sectors requiring high-volume eyelet installation.

FREQUENTLY ASKED QUESTIONS

How does the selectable 1-4 eyelet capability benefit manufacturing flexibility?

This Okoboji feature allows manufacturers to optimise production for different products without machine changes. Single eyelet mode provides precision for detailed work, whilst four-eyelet mode maximises productivity for high-volume applications, all within the same machine platform.

What productivity advantages does pneumatic operation provide over electric alternatives?

Pneumatic power delivers consistent force regardless of material thickness, operates at higher speeds than electric motors, and provides instant response. This Okoboji pneumatic system ensures reliable performance throughout demanding industrial production schedules with minimal speed variation.

How does the multi-size capability (4-6mm) benefit diverse manufacturing operations?

The four eyelet size options enable manufacturers to handle diverse product lines without multiple machines. This Okoboji versatility reduces equipment investment whilst providing flexibility to adapt to changing market demands and customer specifications efficiently.

What makes this machine specifically suitable for bag making applications?

Bag manufacturing often requires multiple eyelets in precise patterns, making the 4-head capability ideal. The pneumatic power handles varying fabric thicknesses consistently, whilst the size range covers most bag eyelet requirements, making this Okoboji machine perfect for textile manufacturers.

What air pressure requirements does this pneumatic system need?

The machine requires 5-6 MPa air pressure for optimal operation. Most industrial facilities can accommodate this requirement, though businesses may need to upgrade compressed air systems to ensure consistent pressure for reliable Okoboji machine performance.

How does the 60 strokes per minute speed translate to actual production output?

With maximum 4-head operation, this Okoboji machine can potentially install 240 eyelets per minute, representing exceptional productivity for industrial applications. Actual output depends on material handling, setup requirements, and operator efficiency throughout production runs.

What training and skills are required for operating this advanced pneumatic machine?

Operators need training in pneumatic systems, safety procedures, eyelet size changeovers, and quality control procedures. The advanced nature of this Okoboji machine requires skilled technicians familiar with industrial pneumatic equipment and precision manufacturing requirements.

How does the Easy Make-Ready feature impact production efficiency?

Quick changeover capability minimises downtime between different eyelet sizes and configurations, maintaining high productivity even with diverse production requirements. This Okoboji feature is crucial for manufacturers handling multiple product lines or custom orders.

What maintenance requirements does this industrial pneumatic machine have?

Regular maintenance includes daily lubrication, weekly air system inspection, periodic pneumatic component servicing, and scheduled professional maintenance. The industrial design requires systematic maintenance to ensure reliable operation throughout demanding production schedules for this Okoboji system.

How does this machine integrate into existing industrial manufacturing workflows?

Standard 220V electrical connection and industrial pneumatic requirements enable integration into most manufacturing facilities. The substantial 120kg weight requires proper installation planning, but the productivity benefits make this Okoboji machine valuable for high-volume manufacturing operations.

Customers also bought

Okoboji Paper Creaser Automatic W auto pickup K330C

Okoboji Paper Cutter Digital Electric 490mm LCD

Okoboji Paper Cutter Digital Hydraulic 680mm