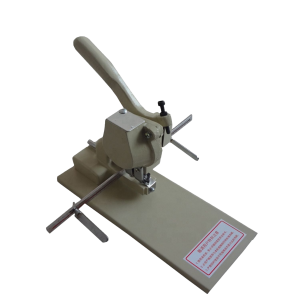

Okoboji Eyelet Desktop Manual DT

SPECIFICATIONS

PRODUCT VIDEO

PRODUCT DESCRIPTION

The Okoboji Desktop Manual DT represents the most accessible entry point into professional eyelet installation, designed specifically for small workshops, craft businesses, and entrepreneurs who need reliable 5.5mm eyelet capability in an ultra-compact, budget-friendly package. This machine demonstrates how sophisticated engineering can be distilled into an essential tool that delivers professional results without the complexity or cost of larger industrial systems.

Understanding that many businesses begin with modest requirements before scaling up, this Okoboji desktop model provides the foundation for quality eyelet work whilst remaining accessible to users with limited space and budget constraints. The manual operation teaches operators the fundamentals of proper eyelet installation, developing skills and understanding that prove valuable as businesses grow and potentially upgrade to more advanced systems.

The compact desktop design means this machine can fit into the smallest workshop spaces, making it perfect for home-based businesses, startup operations, or as a secondary machine for specialised applications. Despite its modest size and price point, this Okoboji system maintains the quality standards and precision engineering that ensure consistent, professional results across diverse applications requiring 5.5mm eyelets.

Upgrade Your Experience

Okoboji Eyelet Electric 5.5mm Single Head

Okoboji Eyelet Manual Dual Head 5.5mm DJS4

Okoboji Eyelet Manual Single Head 5.5mm DJC4

Okoboji Eyelet Manual Single Head Foot Pedal 5.5mm DJJ4

KEY FEATURES

- Ultra-Compact Desktop Design : This Okoboji machine fits easily on any workbench or table, requiring minimal space whilst providing full 5.5mm eyelet capability, making it perfect for small workshops, craft rooms, and space-constrained environments.

- Budget-Friendly Professional Quality : Engineered to deliver reliable professional results at an accessible price point, this Okoboji desktop model provides excellent value for startups, craft businesses, and operations requiring occasional eyelet installation.

- 5.5mm Versatile Capability : Handles the popular 5.5mm eyelet size that works well for diverse applications including small leather goods, craft projects, repairs, and light manufacturing, providing flexibility for varied business needs.

- Manual Operation Simplicity : Hand-operated mechanism requires no power source and minimal maintenance, making this Okoboji machine extremely reliable and cost-effective for businesses prioritising operational simplicity and low running costs.

- Lightweight Portable Construction : Easy to move and store when not in use, this desktop model can be transported between locations or stored efficiently, making it ideal for mobile services or shared workshop spaces.

- Learning-Friendly Design : Perfect for operators new to eyelet installation, this Okoboji machine teaches proper technique and builds understanding of eyelet mechanics, providing valuable foundation skills for business growth.

- Quick Setup Operation : Minimal assembly required with straightforward operation that gets users productive immediately, reducing downtime and enabling quick turnaround for customer projects or production requirements.

- Durable Entry-Level Construction : Built with quality materials to withstand regular use whilst maintaining affordability, ensuring this Okoboji desktop machine provides reliable service throughout business development stages.

FREQUENTLY ASKED QUESTIONS

Why is the 44mm round size particularly popular in the Indian badge market?

The 44mm diameter provides the ideal balance between sufficient space for clear logo and text presentation whilst remaining compact enough for comfortable daily wear in professional environments.

How does the magnetic system improve safety and efficiency in badge production operations?

Magnetic mounting eliminates the need for tools and reduces repetitive motions, improving operator safety whilst dramatically reducing mould changeover time and increasing production throughput.

What design considerations work best with this round 44mm badge format?

Circular designs, centered logos, curved text arrangements, and balanced layouts work exceptionally well with the round format, creating visually appealing and professional badges.

Can this Okoboji mould maintain precision during high-speed production runs?

Yes, the precision-engineered magnetic mounting system and robust steel construction ensure consistent alignment and badge quality even during intensive production campaigns.

What badge backing options work effectively with this round magnetic mould?

The mould accommodates various backing systems including pin fasteners, magnetic backs, clip attachments, and adhesive mountings commonly used in Indian badge applications.

How does chrome plating improve the mould's performance and longevity?

Chrome plating provides superior corrosion resistance, reduces friction during operation, maintains smooth surface finish, and significantly extends the mould's operational life.

What production volumes can this mould handle effectively for commercial badge manufacturing?

This mould is designed for high-volume commercial production and can reliably handle thousands of badge cycles whilst maintaining consistent quality and performance.

Does Okoboji provide replacement parts or refurbishment services for magnetic moulds?

Okoboji offers comprehensive after-sales support including maintenance guidance, replacement parts availability, and refurbishment services to maximise mould life.

How does this round mould compare to oval or square alternatives for badge applications?

Round badges offer classic appeal, universal acceptance, and work particularly well for corporate identification, whilst oval and square formats provide different aesthetic options.

What quality control procedures ensure consistent badge production with this round mould?

Strict manufacturing tolerances, precision machining, comprehensive testing, and quality assurance protocols guarantee reliable badge formation and professional results throughout the mould's service life.

Customers also bought

Okoboji Creasing and Perforation Rotary Electric A3

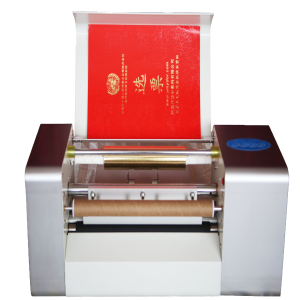

Okoboji Digital Foil Printer 350mm 360A

Okoboji Hole Punch Electric Drill 1 Head Orange