Okoboji Eyelet Manual Single Head Foot Pedal 5.5mm DJJ4

SPECIFICATIONS

PRODUCT VIDEO

PRODUCT DESCRIPTION

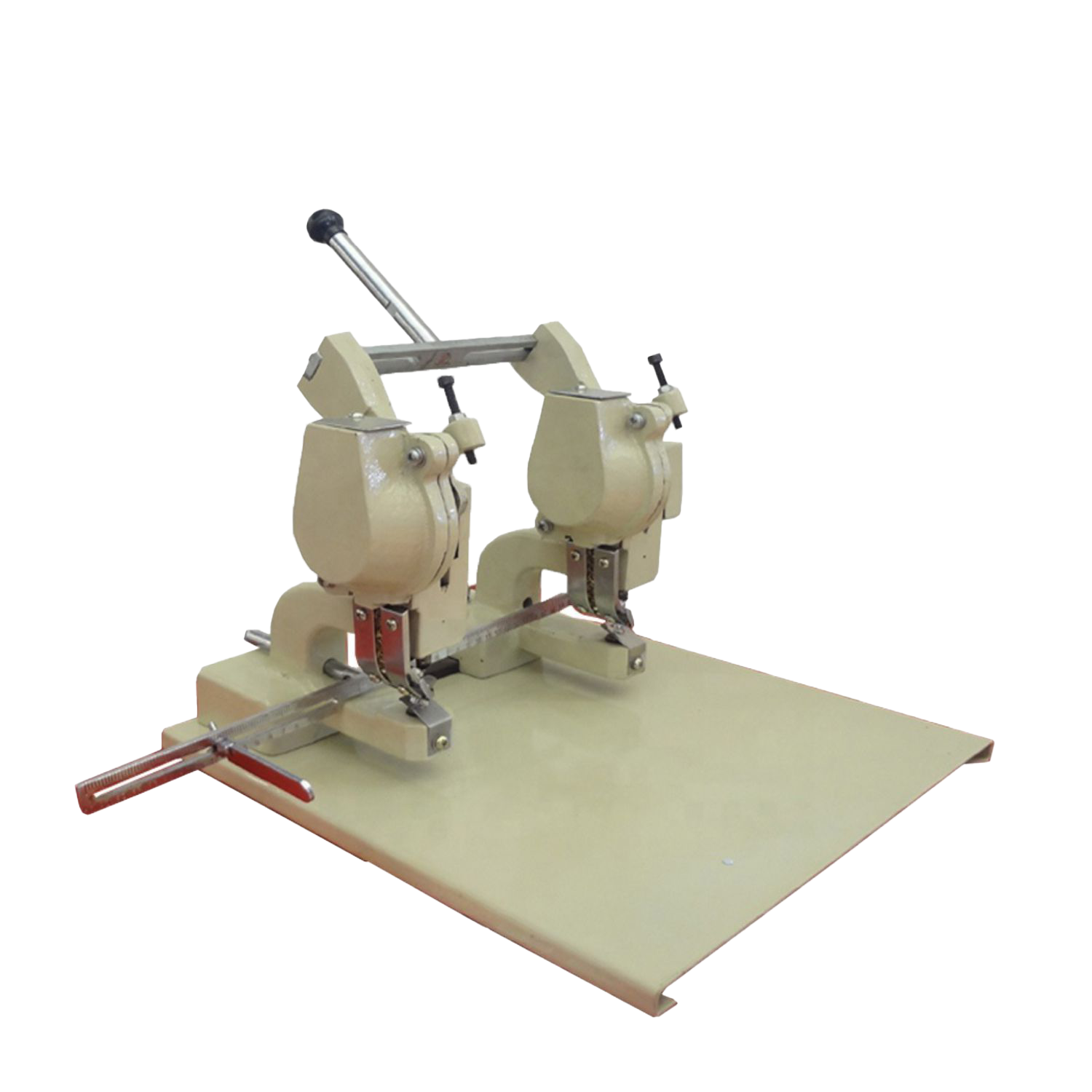

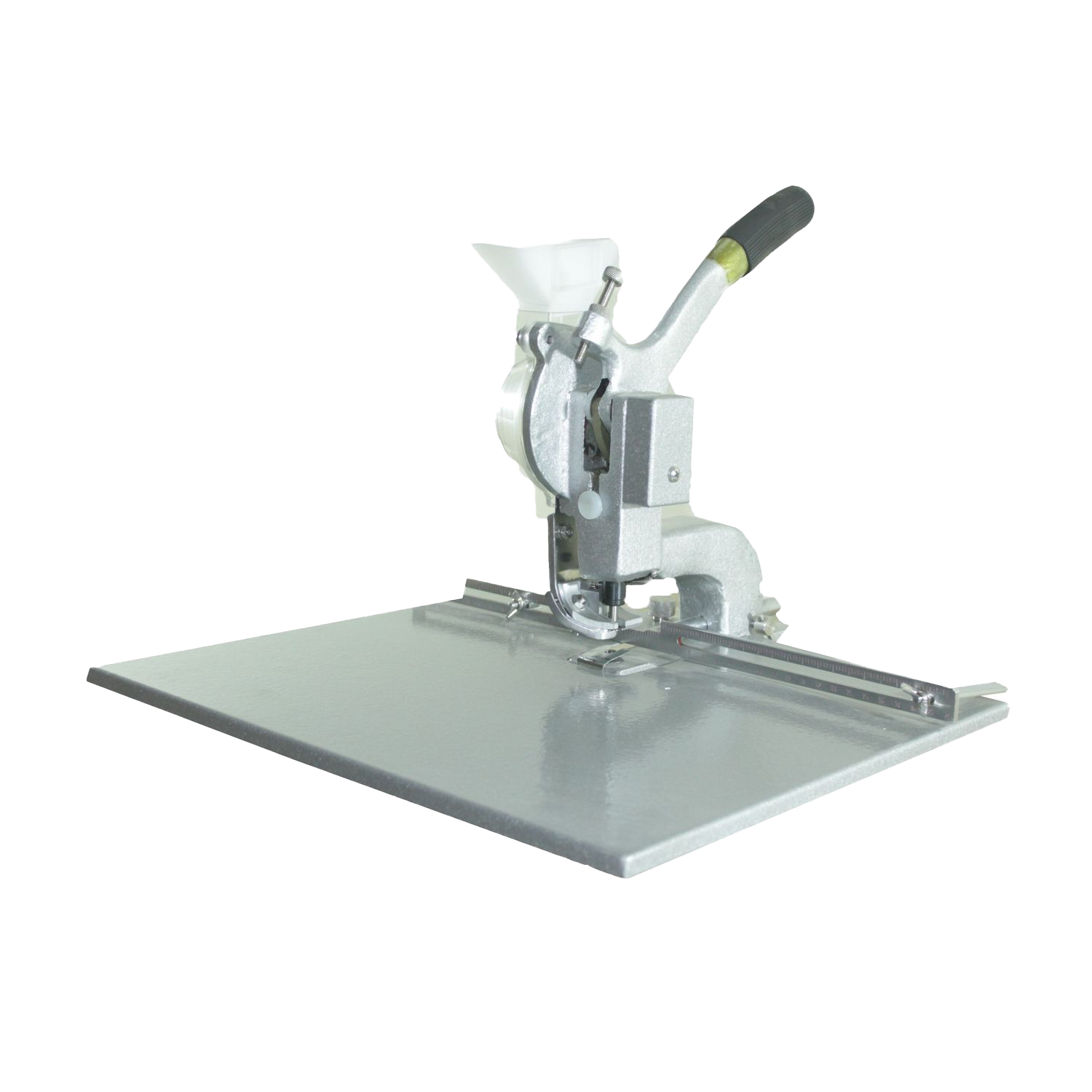

The Okoboji Manual Single Head Foot Pedal 5.5mm DJJ4 represents the perfect synthesis of precision, control, and ergonomic efficiency in single-head manual eyelet technology. This machine demonstrates how focused engineering can create a tool that excels in applications where quality and operator comfort are paramount, providing professional-grade results whilst maintaining the operational advantages that make manual systems invaluable for precision work.

This Okoboji machine excels in environments where precision takes precedence over maximum speed, such as custom leather work, prototype development, repair services, or specialised manufacturing where each eyelet must be perfectly positioned. The combination of stand-mounted stability with foot pedal operation creates an optimal working environment for sustained precision work, whilst the manual operation ensures complete operator control over pressure, timing, and positioning.

The foot pedal operation fundamentally transforms the manual eyeleting experience by freeing both hands for precise material positioning and manipulation. This ergonomic advantage becomes particularly crucial when working with delicate materials, complex positioning requirements, or applications demanding exact eyelet placement. The single-head design provides operators with complete control over each eyelet installation, enabling the precise adjustments and careful positioning that quality-focused applications require.

Upgrade Your Experience

Okoboji Eyelet Desktop Manual DT

Okoboji Eyelet Electric 5.5mm Single Head

Okoboji Eyelet Manual Dual Head 5.5mm DJS4

Okoboji Eyelet Manual Single Head 4mm DJC4 4mm

KEY FEATURES

- Precision Single Head Design : Focused single-head configuration provides complete operator control over each eyelet installation, enabling precise positioning and pressure adjustment that makes this Okoboji machine ideal for quality-focused applications requiring exact eyelet placement.

- Ergonomic Foot Pedal Control : Professional foot pedal operation keeps both hands free for precise material handling and positioning, significantly reducing operator fatigue whilst improving accuracy during extended production periods requiring sustained precision and quality.

- Professional 5.5mm Capability : Optimised for the versatile 5.5mm eyelet size that provides excellent holding strength for diverse applications, making this Okoboji machine suitable for leather goods, textiles, repairs, and specialised manufacturing across multiple industries.

- High-Speed Manual Performance : Achieves impressive 80 eyelets per minute capability through efficient foot pedal operation and streamlined single-head design, providing excellent productivity for precision work whilst maintaining complete operator control over quality standards.

- Stand-Mounted Stability : Robust stand construction provides stable platform for precise work, whilst ergonomic height ensures comfortable operation during extended periods, making this Okoboji machine ideal for professional workshops requiring sustained precision capability.

- Versatile Material Compatibility : Handles paper and PVC materials up to 5mm thickness plus leather and cloth materials up to 3mm thickness, providing flexibility for diverse precision applications requiring reliable 5.5mm eyelet installation.

- Power-Independent Precision : Manual operation eliminates electrical dependency whilst maintaining professional capability, making this Okoboji machine perfect for precision work in locations with power constraints or for businesses prioritising operational cost control.

- Automatic Drop Feed Efficiency : Streamlined eyelet feeding system maintains smooth operation whilst operators focus on precise positioning, ensuring consistent workflow during precision manual work without compromising attention to quality details.

FREQUENTLY ASKED QUESTIONS

What makes this single head foot pedal machine ideal for precision work?

The single-head design provides complete control over each eyelet, whilst foot pedal operation keeps hands free for precise positioning. This Okoboji combination enables exact placement and pressure control essential for quality-focused applications requiring perfect eyelet installation.

How does the stand-mounted design benefit precision operations?

The stand provides stable platform for accurate work whilst positioning the machine at optimal ergonomic height. This stability is crucial for precision positioning, making this Okoboji machine ideal for detailed work requiring sustained accuracy and operator comfort.

What applications benefit most from this precise manual operation?

Custom leather work, prototype development, repair services, high-end manufacturing, and specialised applications where each eyelet placement is critical. This Okoboji machine excels where quality and precision matter more than maximum production speed.

How does foot pedal operation improve quality compared to hand operation?

Foot control allows both hands to focus entirely on material positioning and alignment, significantly improving precision. This Okoboji design enables operators to make fine adjustments while maintaining complete control over the eyeleting process timing.

What material handling capabilities does this precision machine offer?

Handles paper and PVC up to 5mm thickness, leather and cloth up to 3mm thickness. The precise control makes this Okoboji machine particularly effective with delicate materials requiring careful handling and exact eyelet positioning.

How does the 80 eyelets per minute speed benefit precision work?

This speed provides excellent productivity for precision applications, allowing operators to maintain quality standards whilst achieving reasonable throughput. The Okoboji foot pedal design enables sustained speed without compromising accuracy or operator comfort.

What workspace requirements does this stand-mounted precision machine need?

Requires floor space for comfortable operator movement around the machine with adequate clearance for foot pedal operation. The professional design integrates efficiently into precision workshop layouts whilst maintaining ergonomic operator positioning.

Is this machine suitable for businesses specialising in custom work?

Absolutely ideal for custom applications requiring precise eyelet placement, variable materials, and quality-focused results. This Okoboji machine provides the control and precision essential for custom manufacturing, repairs, and specialised production requirements.

What training helps operators maximise this machine's precision capabilities?

Training focuses on foot pedal coordination, material positioning techniques, pressure control, and quality assessment procedures. The manual precision nature makes this Okoboji machine ideal for developing skilled operators capable of high-quality work.

How does this machine compare to dual head alternatives for precision applications?

Single head operation provides superior control and precision for detailed work where each eyelet requires individual attention. This Okoboji design prioritises quality over speed, making it ideal for applications where precision matters more than maximum productivity.

Customers also bought

Okoboji Creasing Machine Automatic 12.5" ACM12

Okoboji Handheld Punch Single T35

Okoboji Hole Punch Electric Drill 3 Head HD WYWB830