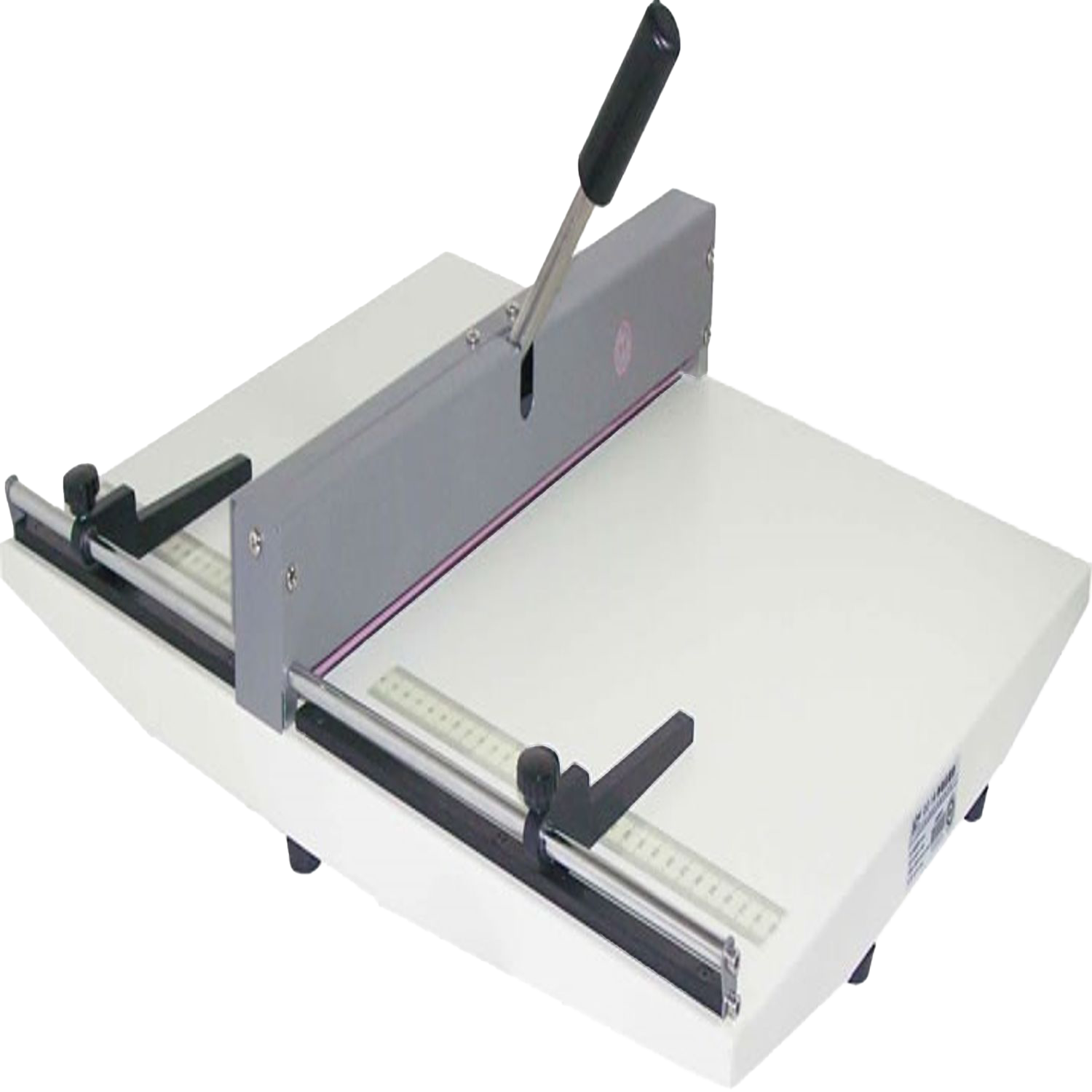

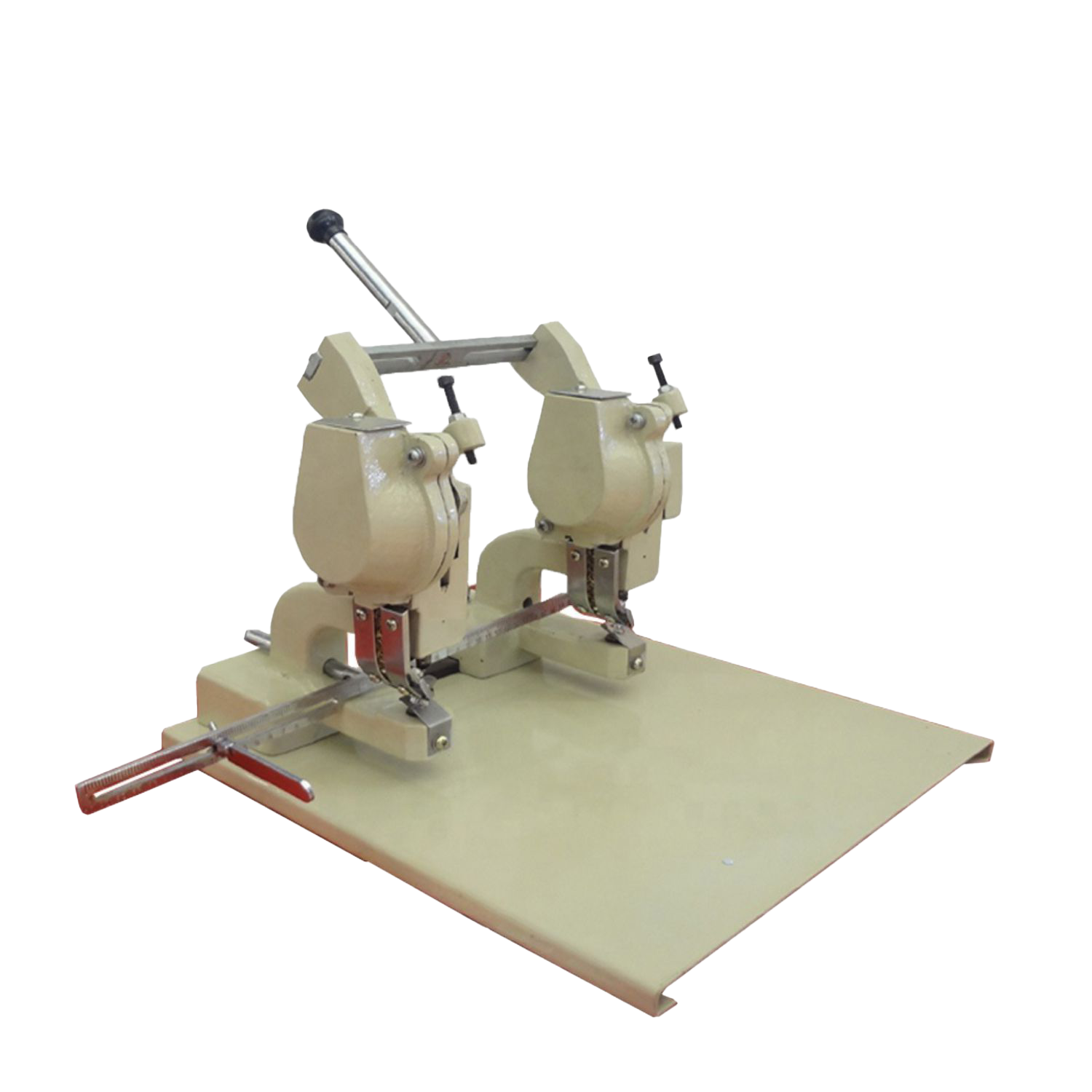

Okoboji Eyelet Manual Single Head 5.5mm DJC4

SPECIFICATIONS

PRODUCT VIDEO

PRODUCT DESCRIPTION

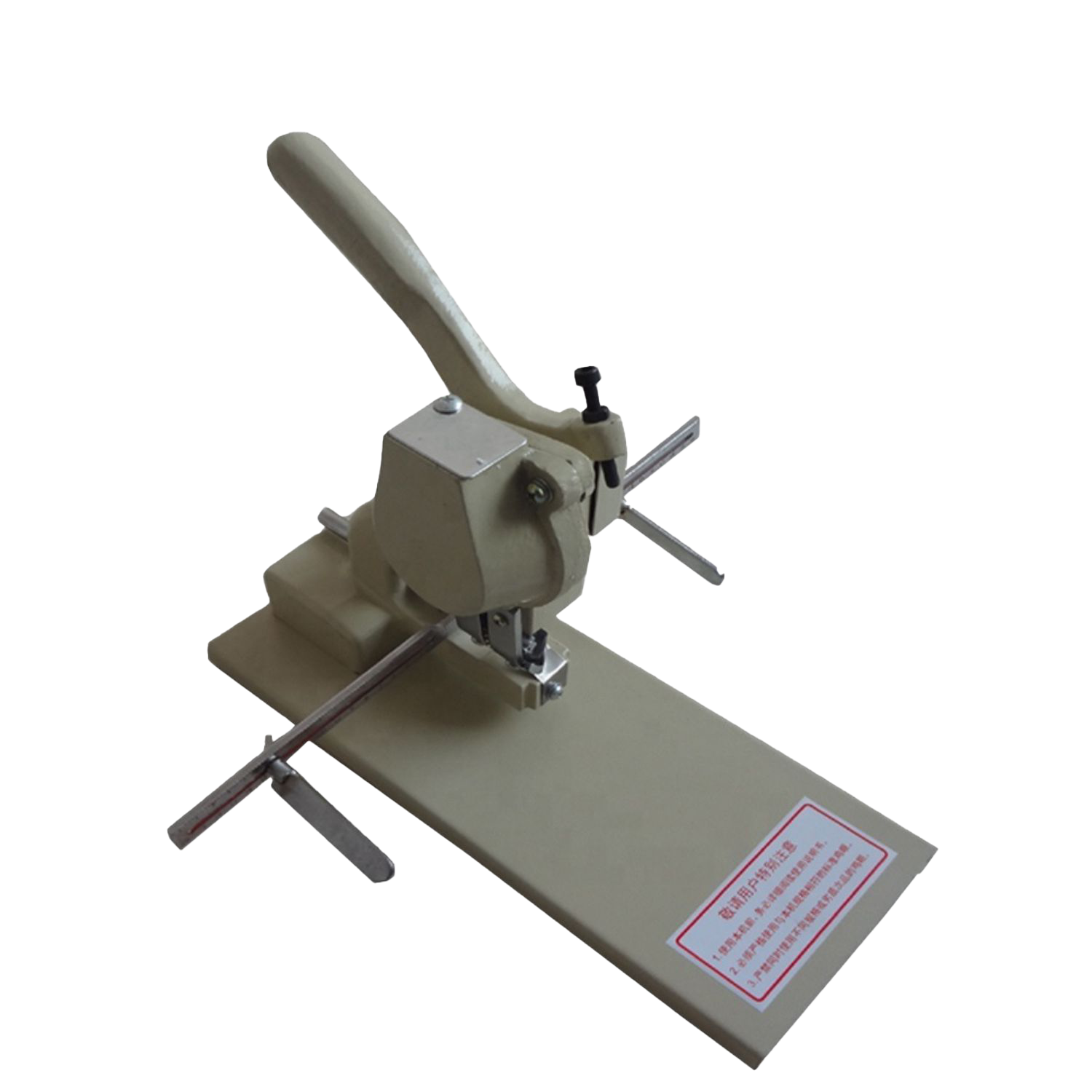

The Okoboji Manual Single Head 5.5mm DJC4 Eyelet Machine combines the precision of single-head operation with the versatility of larger 5.5mm eyelet capability, delivering exceptional performance for businesses requiring professional-grade manual eyeleting in a compact, controllable format. This machine represents the ideal solution for workshops and manufacturers who need the strength and durability of larger eyelets whilst maintaining the precise control and cost-effectiveness that manual operation provides.

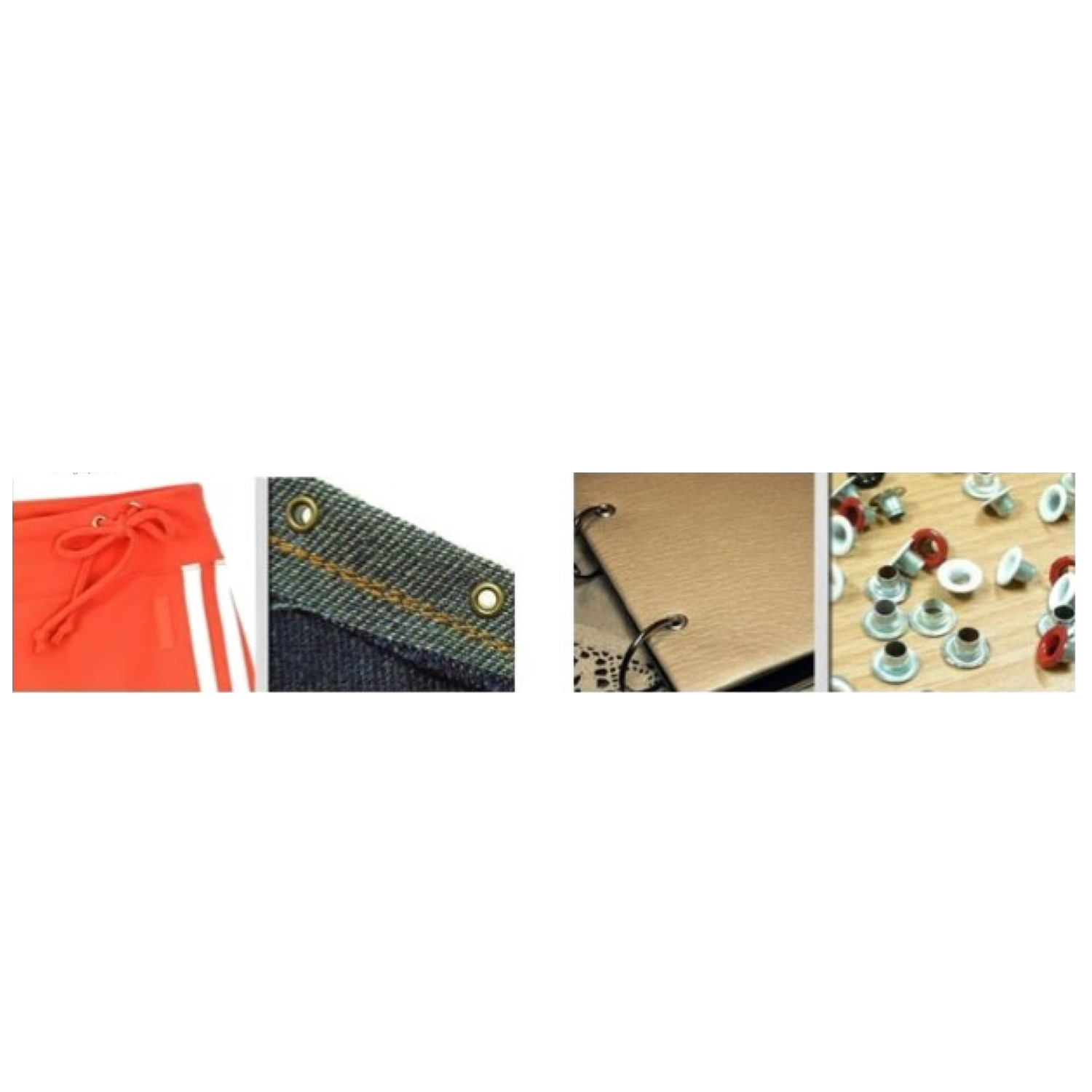

Engineered for applications where 5.5mm eyelets provide optimal strength-to-size ratio, this Okoboji machine excels in medium-duty applications including leather goods, canvas work, moderate-weight textiles, and industrial applications where larger eyelets are necessary for durability but where the complexity of multi-head systems is unnecessary. The desktop design ensures easy integration into existing workshop configurations whilst the manual operation provides the precise control valued by skilled operators.

The combination of 5.5mm capability with single-head simplicity makes this Okoboji system particularly attractive for businesses transitioning from smaller eyelet sizes or for operations requiring the flexibility to handle diverse applications without the infrastructure requirements of electric or pneumatic alternatives. The robust construction ensures reliable performance throughout demanding manual operation whilst maintaining the operational cost advantages that manual systems provide.

Upgrade Your Experience

Okoboji Eyelet Electric 5.5mm Dual Head

Okoboji Eyelet Manual 2 Head Foot Pedal EPDM2

Okoboji Eyelet Manual Dual Head 5.5mm DJS4

Okoboji Eyelet Pneumatic 4 Head Punch EPNQ4

KEY FEATURES

- 5.5mm Large Eyelet Precision : Okoboji's 5.5mm capability provides superior holding strength compared to smaller eyelets, making this machine ideal for canvas work, leather goods, and applications requiring robust eyelet connections with precise manual control.

- Professional Desktop Design : Compact desktop configuration fits efficiently into workshop environments whilst providing full 5.5mm capability, making this Okoboji machine perfect for professional workshops with space constraints.

- Flexible Working Range : Adjustable vertical travel from 60-165mm with 80-130mm hold setting range accommodates diverse material thicknesses, providing versatility for varied applications requiring larger eyelet sizes.

- Manual Control Excellence : Hand-operated mechanism provides superior control over eyeleting pressure and positioning, enabling consistent high-quality results and making this Okoboji system ideal for precision manual work.

- Automatic Drop Feed System : Efficient 5.5mm eyelet feeding system maintains smooth operation whilst operators focus on material positioning, ensuring consistent workflow throughout manual production processes.

- 3mm Binding Capacity : Handles materials up to 3mm thickness, accommodating most manual applications including leather, heavy canvas, and multiple fabric layers commonly used in quality manufacturing.

- Cost-Effective Manual Operation : Eliminates power requirements whilst delivering professional-grade 5.5mm eyelet installation, making this Okoboji machine an excellent investment for quality-focused businesses prioritising operational cost control.

- Single Head Reliability : Streamlined single-head design reduces mechanical complexity whilst maintaining precision and reliability, ensuring consistent performance throughout demanding manual production requirements.

FREQUENTLY ASKED QUESTIONS

What applications benefit most from 5.5mm eyelets in a single head manual machine?

This Okoboji machine is ideal for leather goods, canvas bags, moderate-weight tarpaulins, and applications where larger eyelets provide better durability than 4mm options but where dual-head complexity isn't required for production volumes.

How does the manual control benefit precision work with 5.5mm eyelets?

Manual operation allows operators to adjust pressure precisely for each material type and thickness, ensuring optimal 5.5mm eyelet installation without over-compression or under-setting that can occur with automated systems.

What material thickness range can this Okoboji desktop machine handle?

The machine accommodates materials up to 3mm thickness with adjustable travel from 60-165mm, covering most manual applications including heavy leather, canvas, and multiple fabric layers requiring 5.5mm eyelets.

How does this single head model compare to dual head alternatives for precision work?

Single head operation provides superior control and precision for detailed work, making this Okoboji machine ideal for custom applications, prototyping, and quality-focused production where precision matters more than maximum speed.

What are the workspace requirements for this desktop Okoboji machine?

The compact desktop design requires minimal floor space whilst providing full 5.5mm capability, making it perfect for workshops where space efficiency is important but professional eyelet capability is required.

What maintenance schedule ensures optimal performance for this manual machine?

Weekly lubrication of moving parts, regular cleaning, and periodic inspection of the drop feed mechanism maintain optimal performance. The manual operation significantly reduces maintenance complexity compared to powered alternatives.

How does the automatic drop feed system work with manual operation?

The drop feed automatically positions 5.5mm eyelets for installation whilst operators control the manual pressing action, combining automation convenience with manual precision control in this Okoboji system.

Is this machine suitable for businesses upgrading from smaller eyelet capabilities?

Absolutely. This Okoboji machine provides an excellent upgrade path for businesses moving from 4mm to 5.5mm capabilities whilst maintaining the control and cost-effectiveness of manual operation.

What training is required for operators transitioning to this 5.5mm machine?

Training typically requires 2-3 days covering 5.5mm eyelet handling, material positioning for larger eyelets, pressure adjustment techniques, and maintenance procedures specific to this Okoboji system.

What support does Okoboji provide for manual single head machine users?

Okoboji offers comprehensive support including installation guidance, operator training, maintenance instruction, troubleshooting assistance, and spare parts supply tailored to the specific requirements of manual single head operations.

Customers also bought

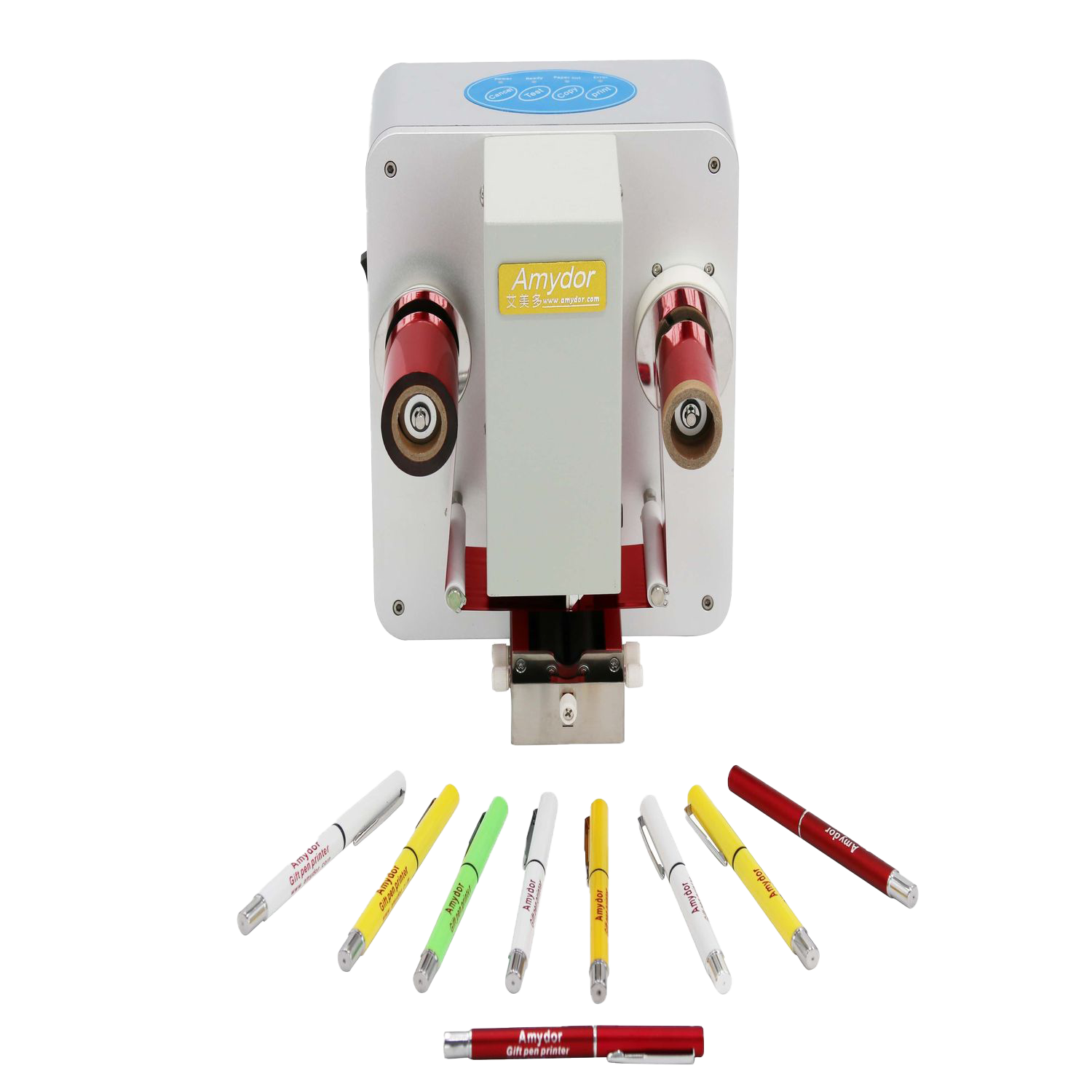

Okoboji Digital Foil Cylinder Printer 8-20mm 55Y

Okoboji Digital Foil Printer 350mm High Speed 360C

Okoboji Paper Creaser Automatic 13" 330mm ACM13