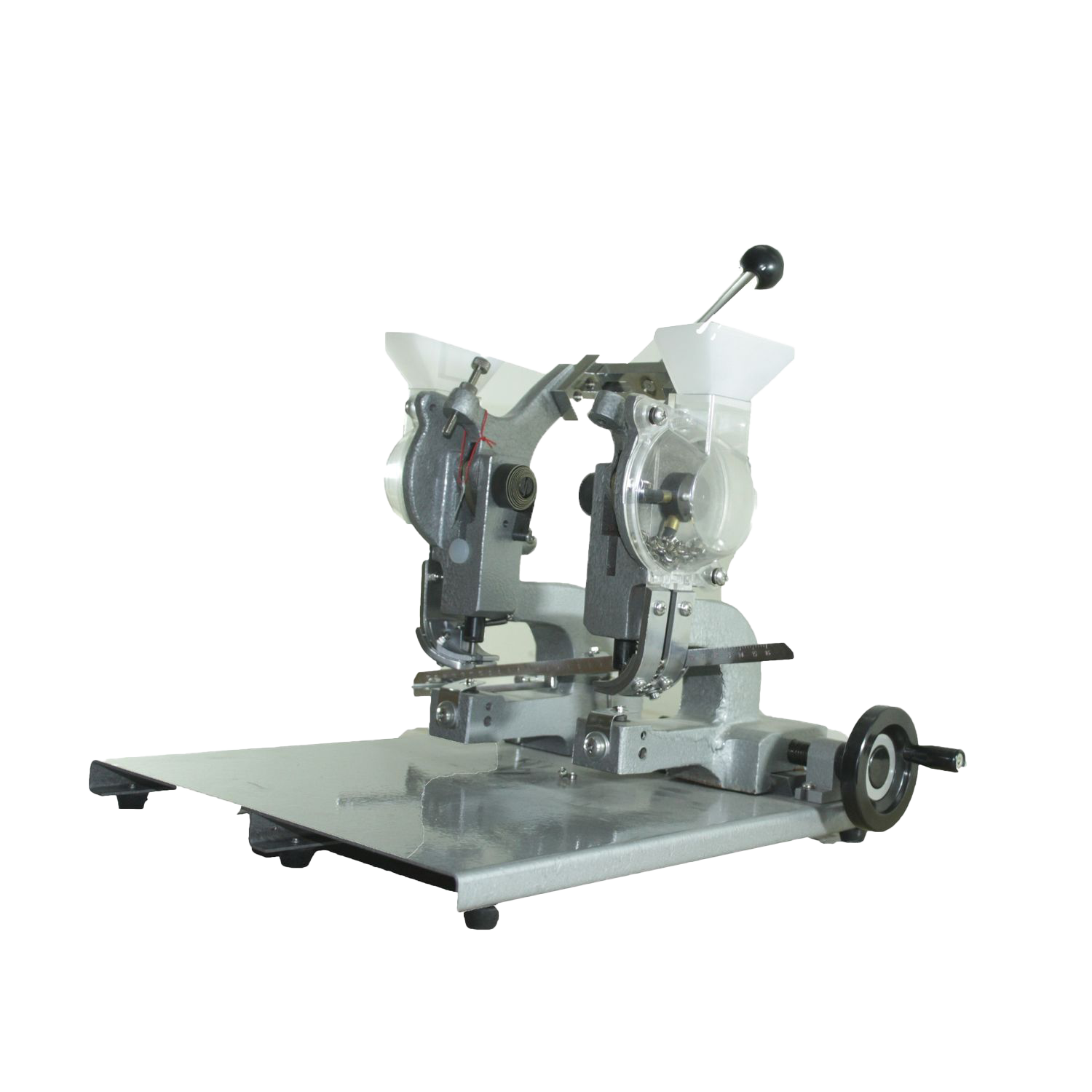

Okoboji Eyelet Manual 2 Head Foot Pedal EPDM2

SPECIFICATIONS

PRODUCT VIDEO

PRODUCT DESCRIPTION

The Okoboji Manual 2 Head Foot Pedal EPDM2 represents an intelligent evolution in manual eyelet technology, combining the productivity advantages of dual-head operation with the ergonomic benefits of foot pedal control. This machine demonstrates how thoughtful engineering can significantly improve operator efficiency and comfort whilst maintaining the cost-effectiveness and reliability that manual systems provide for growing businesses.

The foot pedal operation represents a crucial advancement in manual machine design, allowing operators to keep both hands free for precise material positioning and handling. This ergonomic advantage becomes particularly important during extended production runs, where proper material positioning directly impacts final product quality. The dual-head configuration means operators can achieve twice the productivity of single-head alternatives whilst maintaining the precise control that experienced craftspeople value.

Understanding that many businesses operate in environments where consistent power supply may be challenging or where operational costs must be carefully controlled, this Okoboji machine provides professional-grade capability without electrical dependency. The 5.5mm eyelet capacity handles the most commonly required eyelet size across diverse applications, whilst the 80 eyelets per minute capability ensures productivity levels that can satisfy demanding production schedules.

Upgrade Your Experience

Okoboji Eyelet Desktop Manual DT

Okoboji Eyelet Electric 5.5mm Single Head

Okoboji Eyelet Manual Dual Head 4mm DJS4 4mm

Okoboji Eyelet Pneumatic 4 Head Punch EPNQ4

KEY FEATURES

- Dual Head Productivity Enhancement : The innovative dual-head design enables simultaneous installation of two 5.5mm eyelets, effectively doubling output compared to single-head manual machines whilst maintaining the precision control that experienced operators value for quality work.

- Ergonomic Foot Pedal Operation : Foot-operated mechanism keeps both hands completely free for precise material positioning and handling, significantly improving accuracy and reducing operator fatigue during extended production periods whilst maintaining excellent control over the eyeleting process.

- High-Speed Manual Capability : Achieves impressive 80 eyelets per minute speed through efficient dual-head design and foot pedal operation, providing productivity levels that can satisfy demanding production schedules whilst maintaining manual operation advantages.

- Versatile Material Handling : Accommodates paper and PVC materials up to 5mm thickness plus leather and cloth materials up to 3mm thickness, providing flexibility for diverse manufacturing applications requiring reliable 5.5mm eyelet installation across multiple industries.

- Power-Independent Operation : Manual foot operation eliminates electrical power requirements, making this Okoboji machine ideal for locations with unreliable power supply, remote workshops, or businesses seeking to minimise operational energy costs whilst maintaining professional capability.

- 5.5mm Professional Standard : Optimised for the widely-used 5.5mm eyelet size that provides excellent holding strength for most applications, making this Okoboji machine suitable for leather goods, textiles, packaging, and diverse manufacturing requirements across multiple sectors.

- Automatic Drop Feed System : Efficient eyelet feeding mechanism maintains smooth operation whilst operators focus on material positioning, ensuring consistent workflow and reducing production interruptions during manual dual-head operation for sustained productivity.

- Cost-Effective Dual Production : Provides dual-head productivity benefits without the complexity and expense of powered alternatives, making this Okoboji machine an excellent investment for businesses seeking to improve efficiency whilst controlling operational costs.

FREQUENTLY ASKED QUESTIONS

How does foot pedal operation improve productivity compared to hand-operated alternatives?

Foot pedal operation keeps both hands free for precise material positioning, significantly improving accuracy and speed. This Okoboji design reduces operator fatigue and enables better workflow, particularly important during extended production runs requiring consistent quality.

What are the main advantages of dual-head configuration in manual operation?

The dual-head design doubles productivity by installing two eyelets simultaneously, making this Okoboji machine ideal for businesses needing higher output than single-head machines can provide whilst maintaining manual operation benefits like cost control and power independence.

How does the 80 eyelets per minute speed compare to other manual machines?

This speed represents excellent performance for manual operation, achieved through the efficient combination of dual-head design and foot pedal operation. The Okoboji EPDM2 provides productivity levels approaching powered machines whilst maintaining manual advantages.

What material thickness range can this foot pedal machine handle effectively?

The machine accommodates paper and PVC up to 5mm thickness, plus leather and cloth up to 3mm thickness. This range covers most common applications requiring 5.5mm eyelets, making this Okoboji machine versatile for diverse manufacturing needs.

What workspace requirements does this stand-mounted Okoboji machine need?

The stand-mounted design requires floor space for operator movement around the machine, plus clearance for foot pedal operation. The ergonomic design ensures comfortable standing operation whilst maintaining compact footprint for efficient workshop layout.

How does the automatic drop feed system work with foot operation?

The drop feed automatically positions eyelets for installation whilst the operator controls timing through foot pedal activation. This combination provides efficient eyelet handling whilst maintaining operator control over the installation process in this Okoboji system.

What training is required for operators using this dual-head foot pedal machine?

Training typically requires 2-3 days covering foot pedal coordination, dual-head operation techniques, material positioning, and safety procedures. The manual nature makes this Okoboji machine intuitive for operators familiar with manual machinery operation.

Is this machine suitable for businesses transitioning from single-head operation?

Excellent transition machine for businesses growing beyond single-head capacity but not yet ready for powered equipment. This Okoboji model provides significant productivity improvement whilst maintaining familiar manual operation principles and cost structures.

What maintenance schedule ensures optimal performance for this foot pedal machine?

Weekly lubrication of moving parts, regular cleaning of eyelet feed mechanism, and periodic inspection of foot pedal operation maintain optimal performance. The manual design significantly reduces maintenance complexity compared to powered alternatives for this Okoboji system.

How does this machine compare to powered alternatives for medium-scale production?

While powered machines offer higher speeds, this Okoboji manual system provides excellent productivity without electrical costs, maintenance complexity, or power dependency. It offers superior control for quality-focused applications requiring manual precision and operational cost control.

Customers also bought

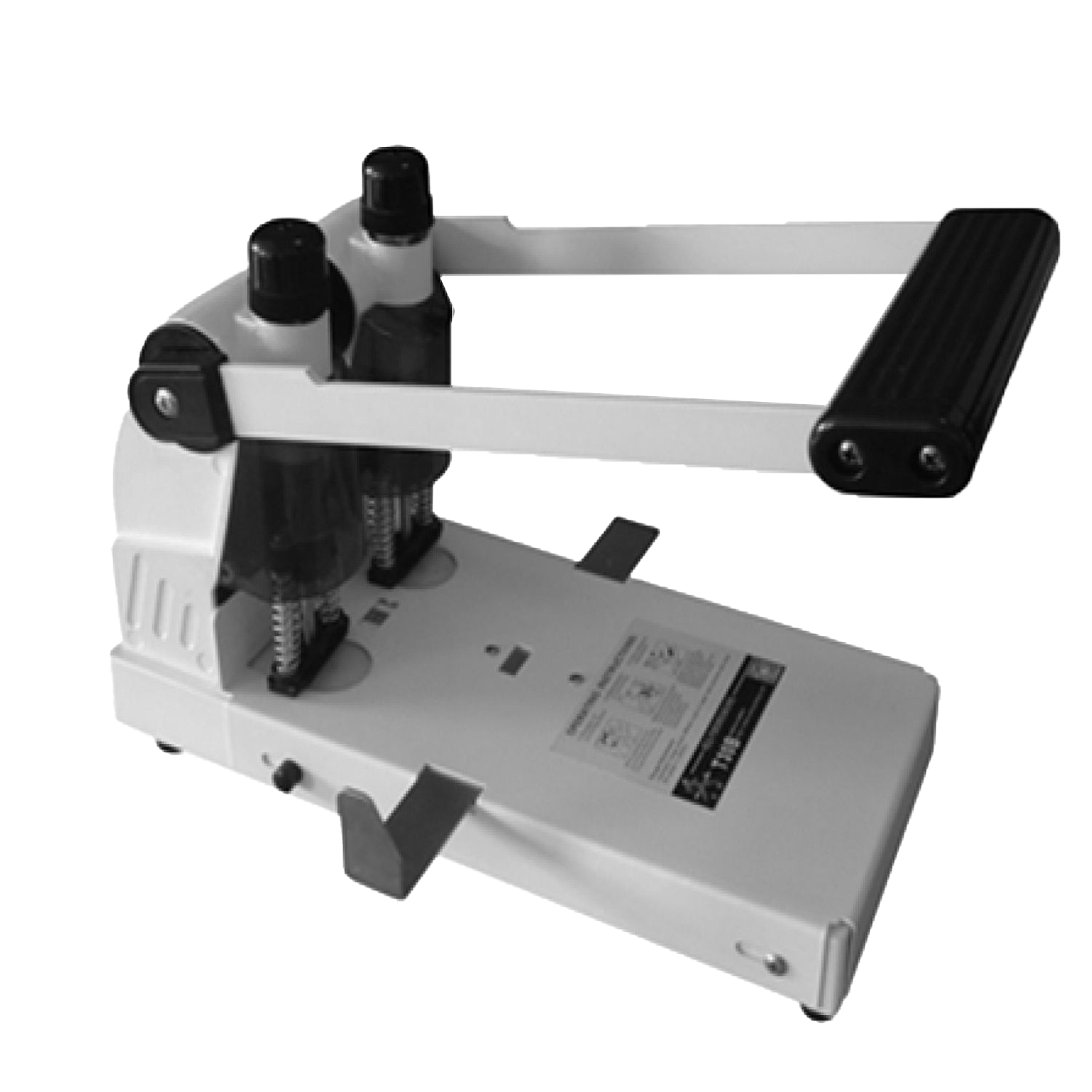

Okoboji Hole Punch Electric Drill 3 Hole Adj WYWB50B

Okoboji Hole Punch Manual 2 Head WYT30B

Okoboji Paper Cutter Digital Electric 720mm