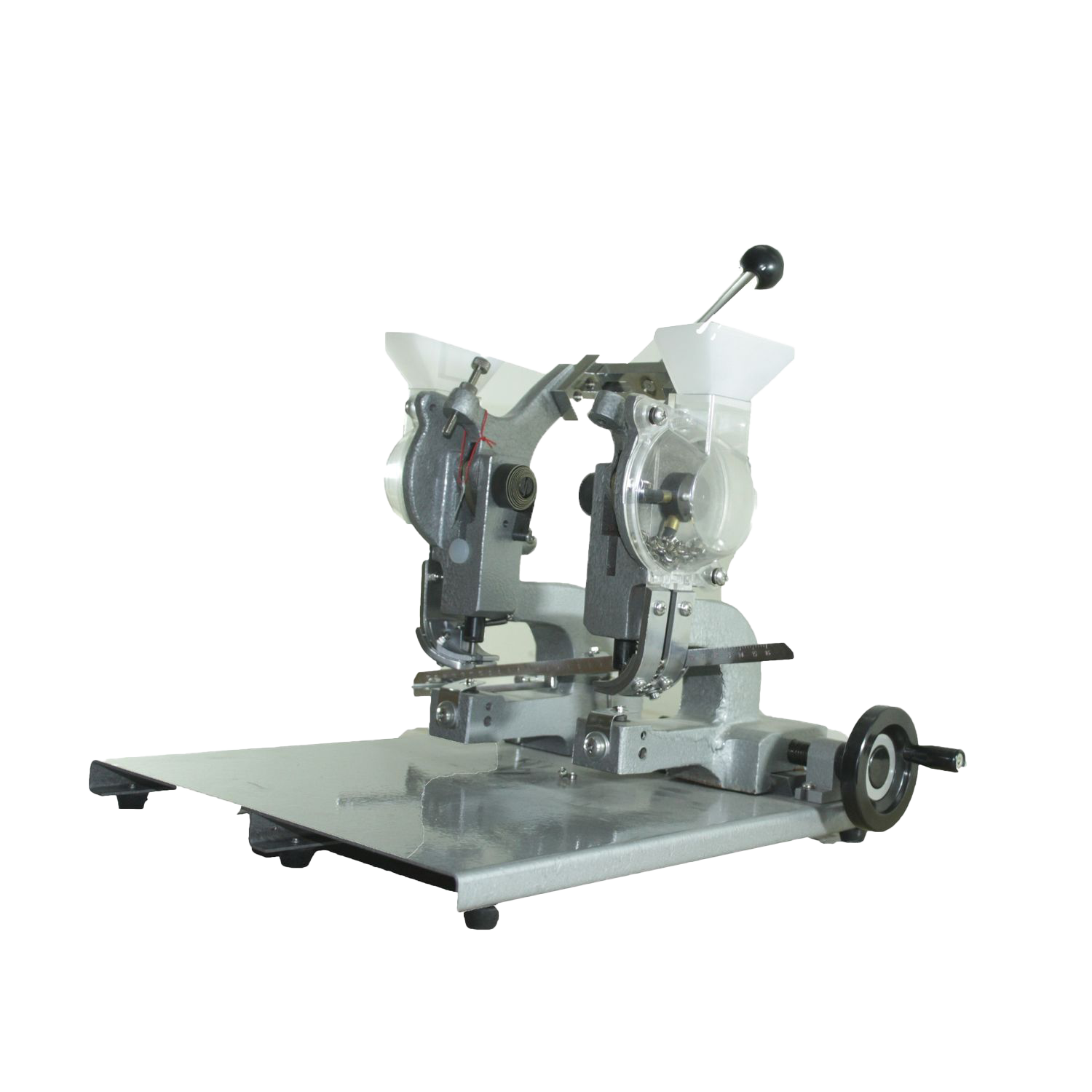

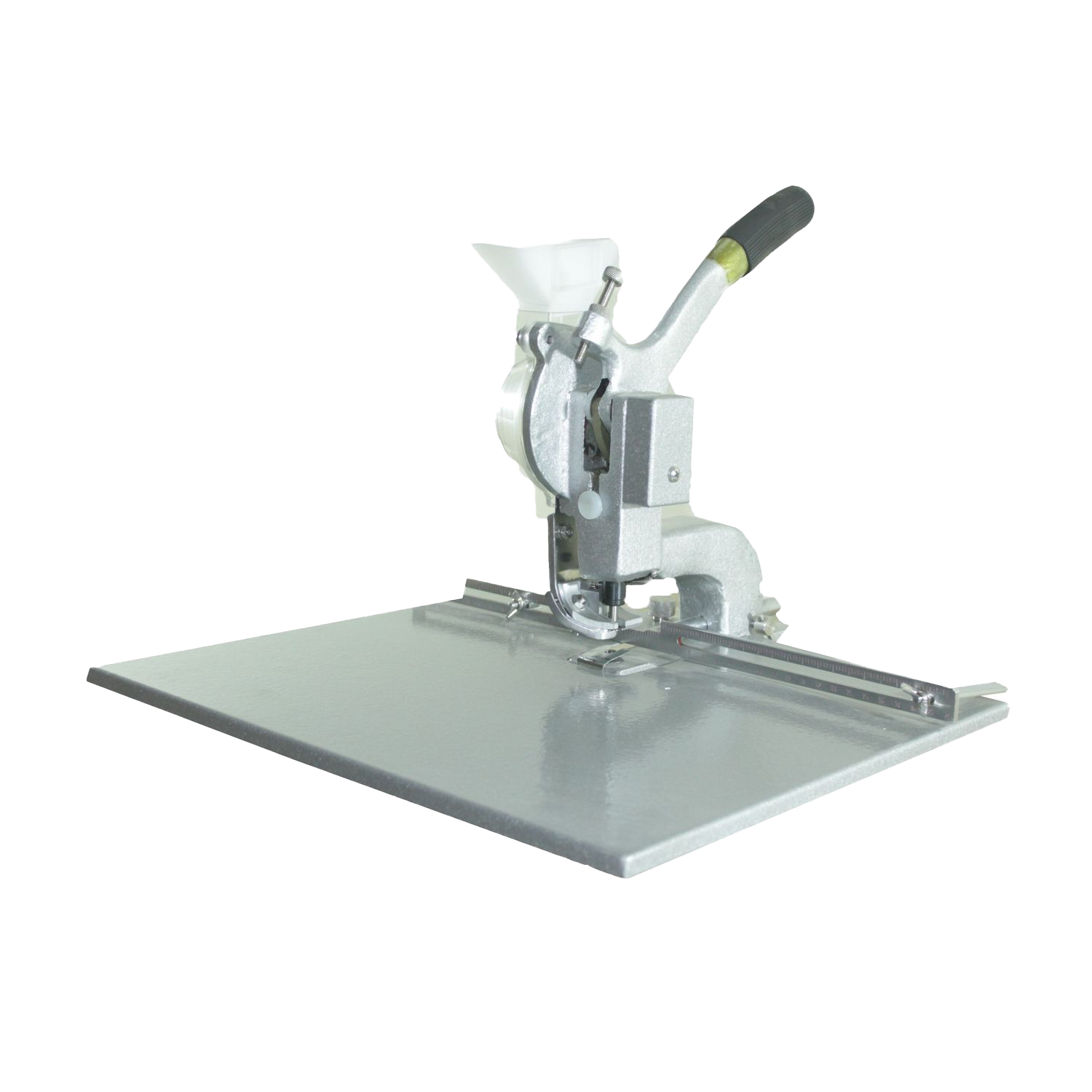

Okoboji Eyelet Electric 5.5mm Single Head

SPECIFICATIONS

PRODUCT VIDEO

PRODUCT DESCRIPTION

The Okoboji Electric 5.5mm Single Head Eyelet Machine delivers exceptional performance and reliability for businesses requiring precise, high-speed eyeleting operations in a compact, cost-effective solution. This machine represents the perfect balance between advanced electric operation and practical single-head functionality, making it particularly suitable for small to medium-scale manufacturing environments where efficiency and quality are paramount.

Powered by a robust 1/4 horsepower electric motor, this Okoboji machine ensures consistent operation throughout demanding production schedules whilst maintaining the precision required for professional-grade eyelet installation. The single-head design provides excellent value for businesses that need reliable eyeleting capabilities without the complexity of multi-head systems, making it an ideal entry point for companies looking to upgrade from manual operations.

Indian manufacturers appreciate this machine’s versatility in handling both paper and PVC materials up to 5mm thickness, as well as leather and cloth materials up to 5mm thickness. The consistent 80 eyelets per minute speed ensures productivity levels that can significantly improve manufacturing throughput whilst reducing labour costs and enhancing product quality standards across diverse applications.

Upgrade Your Experience

Okoboji Eyelet Desktop Manual DT

Okoboji Eyelet Manual 2 Head Foot Pedal EPDM2

Okoboji Eyelet Manual Dual Head 4mm DJS4 4mm

Okoboji Eyelet Manual Single Head 4mm DJC4 4mm

KEY FEATURES

- Reliable 1/4HP Electric Motor : Okoboji's precision-engineered quarter horsepower motor provides consistent power delivery for sustained high-speed operation, ensuring reliable performance throughout demanding production schedules with minimal maintenance requirements.

- Versatile Material Handling : Accommodates both paper and PVC materials up to 5mm thickness providing exceptional flexibility for diverse manufacturing applications across multiple industries.

- High-Speed Consistent Operation : Delivers precise 80 eyelets per minute speed with electric reliability, ensuring predictable production rates that help businesses meet tight deadlines whilst maintaining consistent quality standards.

- Single Head Efficiency : Streamlined single-head design offers excellent performance-to-cost ratio, making this Okoboji machine ideal for businesses requiring reliable eyeleting without the complexity and expense of multi-head systems.

- Compact Industrial Design : Space-efficient footprint allows easy integration into existing workshop layouts whilst providing full industrial-grade capability, making it perfect for businesses with limited floor space requirements.

- Electric Operation Advantages : Eliminates the need for compressed air systems or manual operation, providing consistent speed control, reduced noise levels, and lower long-term operational costs compared to alternative power systems.

- Professional Quality Output : Ensures consistently clean, precise eyelet installations that meet stringent quality standards, enhancing product appearance and durability for customer satisfaction across diverse applications.

- Cost-Effective Investment : Okoboji's single head electric system provides excellent return on investment for small to medium-scale operations, offering electric advantages at an accessible price point for growing businesses.

- Comprehensive technical support and spare parts availability across India by Okoboji Global Pvt Ltd ensures minimal downtime and sustained operational efficiency for customers.

- Customizable Railing solutions featuring interchangeable railings and precisely positioned eyelets, tailored to meet the distinct requirements of your enterprise ensuring optimal functionality and versatility.

FREQUENTLY ASKED QUESTIONS

What are the main advantages of the Okoboji Electric Single Head machine over manual alternatives?

The electric operation provides consistent 80 eyelets per minute speed compared to variable manual speeds, eliminates operator fatigue, ensures uniform eyelet quality, and reduces labour costs. Okoboji's electric system also offers precise speed control and reliable long-term operation.

Which industries benefit most from this Okoboji single head electric eyelet machine?

This machine is perfect for footwear manufacturers, bag makers, textile producers, packaging companies, and small-scale leather goods manufacturers. The 5mm thickness capability makes it ideal for Indian businesses working with diverse materials across multiple applications.

How does the 1/4HP motor perform compared to higher power alternatives?

Okoboji's 1/4HP motor provides optimal power for single head operation, ensuring adequate force for clean eyelet installation whilst maintaining energy efficiency. This power rating is specifically chosen to balance performance with operational costs for small to medium-scale operations.

What maintenance schedule does this Okoboji electric machine require?

Daily cleaning and weekly lubrication of moving parts are recommended. Monthly electrical connection inspections and quarterly motor maintenance ensure optimal performance. Okoboji provides detailed maintenance guidelines to maximise machine lifespan and reliability.

Can this machine handle heavy-duty continuous operation?

Yes, the robust 1/4HP motor and industrial-grade construction enable continuous operation for standard 8-10 hour shifts. The electric system provides consistent performance without the fatigue issues associated with manual operation, making it suitable for sustained production requirements.

What electrical requirements are needed for installation?

The machine requires standard 220V AC, 50Hz power supply with 750W capacity. Most Indian industrial electrical systems can accommodate this requirement without modifications. Okoboji recommends dedicated electrical connection for optimal performance and safety.

How does this single head machine compare to dual head alternatives in terms of productivity?

While dual head machines offer doubled output, this Okoboji single head system provides excellent value for businesses with moderate production requirements. The lower initial investment and reduced complexity make it ideal for companies prioritising cost-effectiveness over maximum speed.

What training is required for operators to use this Okoboji electric machine?

Basic training typically requires 1-2 days covering electric controls, material handling, safety procedures, and routine maintenance. The intuitive electric operation makes this Okoboji machine easier to learn compared to more complex alternatives.

Is this machine suitable for prototype development and small batch production?

Absolutely. The single head design and electric control make it perfect for small batches, prototype work, and custom applications. Okoboji's machine offers the precision and reliability needed for high-quality prototype development and specialty manufacturing.

What technical support does Okoboji provide for this electric machine?

Okoboji offers comprehensive support including installation guidance, operator training, troubleshooting assistance, spare parts supply, and regular maintenance services. Our India-based service network ensures prompt response to any technical requirements or operational questions.

Customers also bought

Okoboji Digital Foil Printer 250 X 350mm Automatic 3025XY

Okoboji Digital Foil Printer 57 X 250mm X axis 8025

Okoboji Hot Stamping 12" X 15.74" 3T Presure HD 3040 3T