Okoboji Eyelet Electric 5.5mm Dual Head

SPECIFICATIONS

PRODUCT VIDEO

PRODUCT DESCRIPTION

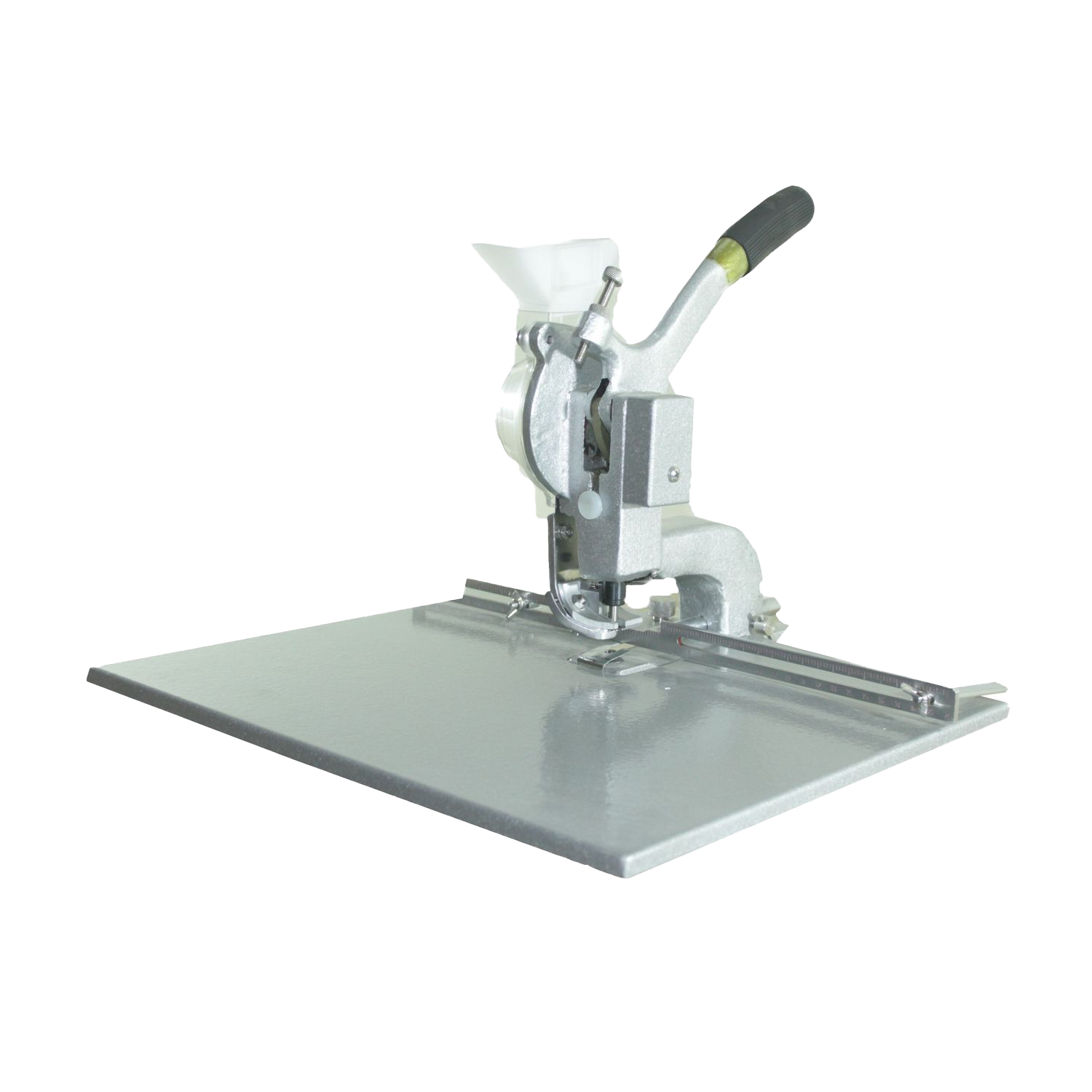

The Okoboji Electric Eyelet Machine 5.5mm Dual Head represents the pinnacle of industrial eyeleting technology, designed specifically for high-volume production environments across India’s manufacturing sector. This professional-grade machine combines precision engineering with robust construction to deliver consistent, reliable performance for garment manufacturers, leather goods producers, and industrial fabric processing units.

With its dual head configuration, this Okoboji machine significantly increases productivity by allowing simultaneous eyeleting operations, making it ideal for large-scale production runs in textile mills, shoe manufacturing units, and tarpaulin production facilities. The 5.5mm eyelet capacity accommodates a wide range of industrial applications, from heavy-duty canvas and leather work to precision garment finishing, ensuring versatility across multiple industries.

The advanced electric motor system provides consistent power delivery, whilst the adjustable settings allow operators to fine-tune the machine for different material thicknesses and eyelet types. This Okoboji eyelet machine stands as a testament to modern manufacturing efficiency, reducing labour costs whilst maintaining the highest quality standards demanded by Indian industrial applications.

Upgrade Your Experience

Okoboji Eyelet Electric 5.5mm Single Head

Okoboji Eyelet Manual 2 Head Foot Pedal EPDM2

Okoboji Eyelet Manual Single Head 4mm DJC4 4mm

Okoboji Eyelet Pneumatic 4 Head Punch EPNQ4

KEY FEATURES

- High-speed dual head operation delivers exceptional productivity with 80 eyelets per minute capacity, significantly reducing production time for large-scale manufacturing operations.

- Versatile material compatibility handles paper and PVC up to 5mm thickness making it perfect for diverse industrial applications.

- Robust electric motor system ensures consistent performance and reliability, engineered specifically for the demanding requirements of Indian manufacturing environments.

- Precision dual eyeleting and punching function provides professional-grade results with adjustable settings for optimal performance across different materials and eyelet sizes.

- Okoboji's proven engineering excellence guarantees long-lasting durability and minimal maintenance requirements, maximising return on investment for industrial users.

- Advanced safety features and user-friendly controls ensure operator safety whilst maintaining high productivity levels throughout extended production shifts.

- Professional-grade construction with industrial components designed to withstand continuous heavy-duty use in demanding manufacturing environments.

- Comprehensive technical support and spare parts availability across India by Okoboji Global Pvt Ltd ensures minimal downtime and sustained operational efficiency for customers.

- Customizable Railing solutions featuring interchangeable railings and precisely positioned eyelets, tailored to meet the distinct requirements of your enterprise ensuring optimal functionality and versatility.

FREQUENTLY ASKED QUESTIONS

What materials can the Okoboji Electric 5.5mm Dual Head machine handle effectively?

This versatile Okoboji machine accommodates paper and PVC materials up to 5mm thickness . It's ideal for footwear, bags, curtains, banners, packaging, and textile applications commonly used in Indian manufacturing.

How does the dual head technology improve production efficiency compared to single head machines?

Okoboji's dual head design doubles productivity by enabling simultaneous eyeleting operations. This means you can complete twice the work in the same timeframe, significantly reducing labour costs and improving delivery schedules for your business.

What power requirements does this Okoboji electric eyelet machine need?

The machine operates on standard 220V AC, 50Hz power supply with approximately 1500W consumption. This makes it suitable for most Indian industrial electrical systems without requiring special power arrangements or additional infrastructure investments.

How often does the Okoboji dual head eyelet machine require maintenance?

Regular maintenance includes daily cleaning, weekly lubrication of moving parts, and monthly inspection of electrical connections. Okoboji recommends professional servicing every 6 months to ensure optimal performance and extend machine lifespan significantly.

Can this machine handle different eyelet sizes for various applications?

Yes, the Okoboji system accommodates eyelet sizes ranging from 3mm to 5.5mm diameter. Simply change the appropriate dies and adjust settings to switch between different eyelet sizes for diverse product requirements.

What training is required for operators to use this Okoboji machine safely?

Basic operator training typically requires 2-3 days covering safety procedures, material handling, machine settings, and troubleshooting. Okoboji provides comprehensive operation manuals and recommends certified technician training for optimal results.

How does this electric machine compare to pneumatic eyelet machines in terms of performance?

Electric operation provides consistent performance without requiring compressed air systems, reducing infrastructure costs. The Okoboji electric system offers precise speed control, lower noise levels, and reduced energy consumption compared to pneumatic alternatives.

What safety features are included with the Okoboji dual head eyelet machine?

Safety features include emergency stop buttons, protective guards around moving parts, overload protection, and safety interlocks. Okoboji prioritises operator safety with comprehensive protection systems meeting industrial safety standards.

Can this machine be integrated into existing production lines?

The Okoboji dual head machine's compact design and standard dimensions allow easy integration into existing workflows. Its electric operation and adjustable height make it compatible with most production line configurations.

What technical support does Okoboji provide after purchase?

Okoboji offers comprehensive technical support including installation assistance, operator training, spare parts availability, and prompt service response. Our India-based service network ensures quick resolution of any technical issues or maintenance requirements.

Customers also bought

Okoboji Creasing Machine Automatic 12.5" ACM12

Okoboji Digital Foil Printer 57 X 250mm X axis 8025

Okoboji Paper Creaser Automatic W auto pickup K330C