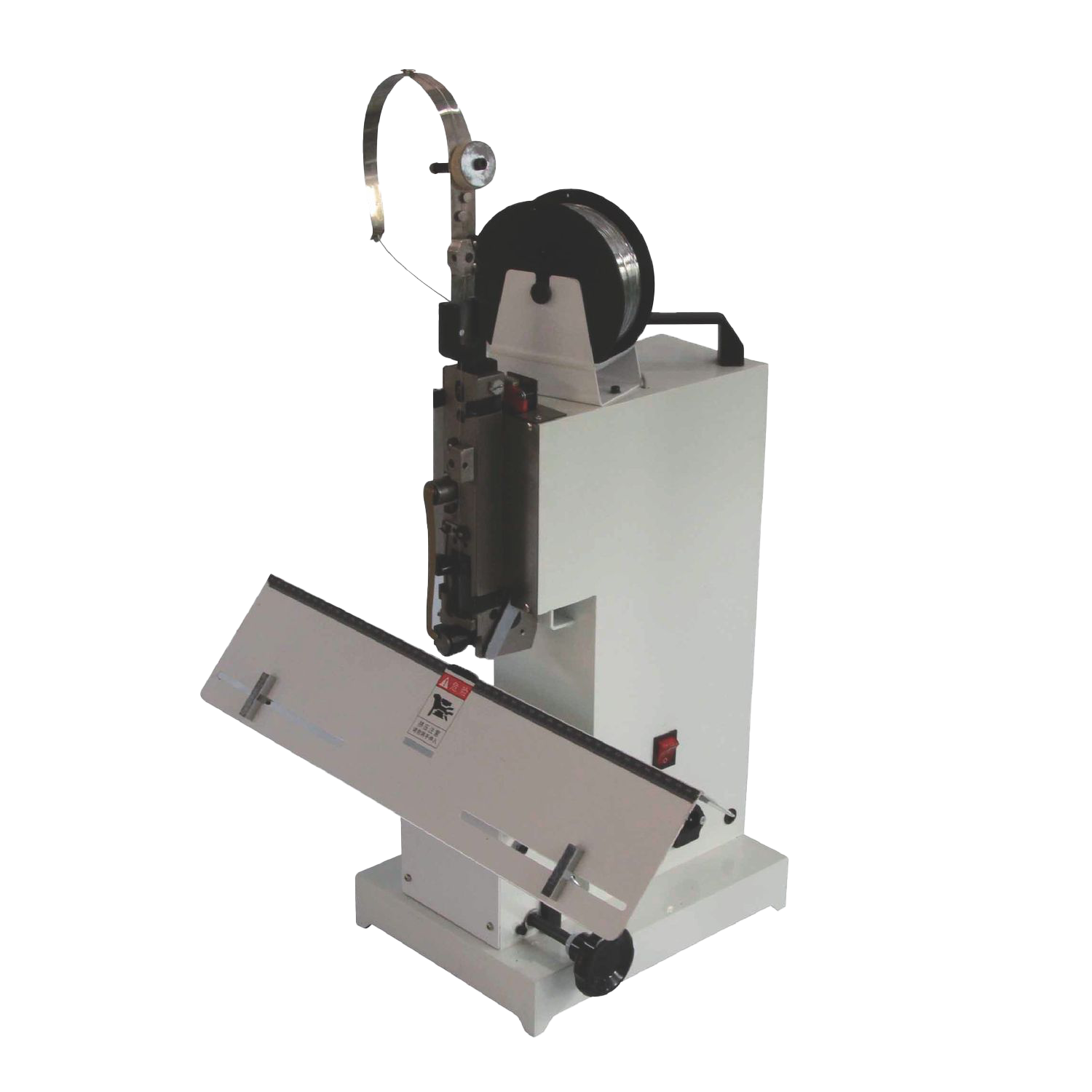

Okoboji Wire Stapler Single Head Heavy Duty SSWSHD09

SPECIFICATIONS

PRODUCT VIDEO

PRODUCT DESCRIPTION

The Okoboji Wire Stapler Single Head Heavy Duty SSWSHD09 represents the pinnacle of industrial-grade binding technology, specifically engineered for demanding commercial and manufacturing environments across India. This exceptional heavy-duty stapler delivers uncompromising performance with binding speeds of 300-600 operations per hour, making it the preferred choice for high-volume production facilities, large-scale printing operations, and industrial packaging applications where reliability and consistent output are paramount. Built to withstand the rigorous demands of continuous operation, this Okoboji model incorporates advanced binding head technology that ensures precise staple placement and superior penetration across diverse materials.

Designed for professional applications requiring exceptional durability and performance, this heavy-duty stapler accommodates binding thickness from 0.2mm to 6mm, enabling versatile material processing from delicate papers to substantial cardboard and packaging materials. The robust construction and industrial-grade components make it particularly suitable for manufacturing environments, large printing houses, packaging operations, and commercial binding services where equipment downtime directly impacts productivity and profitability. Unlike standard office staplers, the SSWSHD09 model features enhanced mechanisms designed to handle extended operation cycles without performance degradation.

The utilisation of 25# stitching wire (0.5-0.6mm diameter) ensures optimal binding strength and reliability whilst maintaining compatibility with readily available consumables across Indian industrial supply chains. Whether you’re operating a commercial printing facility, managing a large-scale packaging operation, or running an industrial binding service, this Okoboji heavy-duty stapler delivers the consistent, professional-grade performance required to meet demanding production schedules whilst maintaining the highest quality standards expected in competitive Indian markets.

Upgrade Your Experience

Okoboji Glue Binding Machine B40F

Okoboji PVC Tubebind Automatic TBA

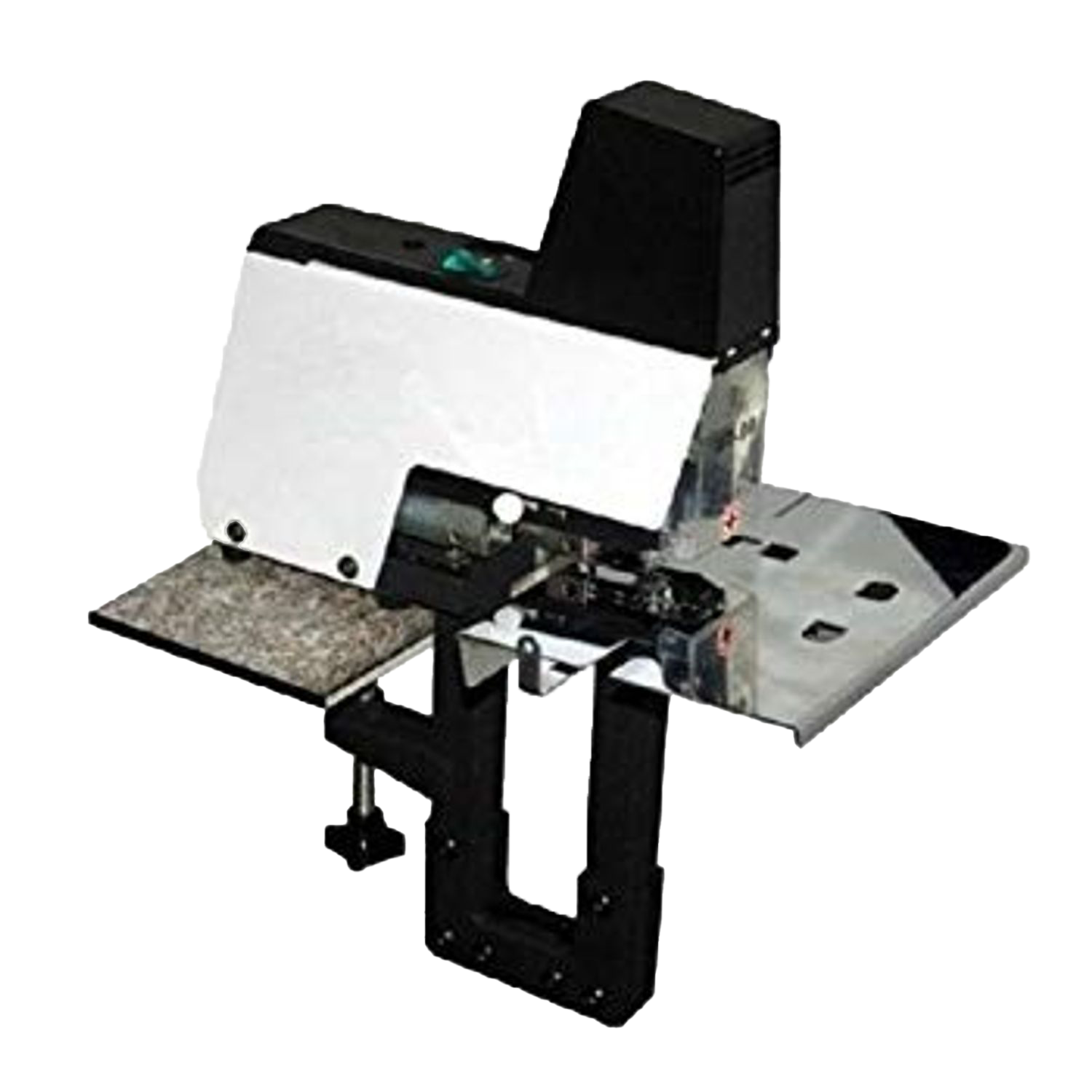

Okoboji Stapler Electric Table Attachable

Okoboji Wire Stapler Single Head Desktop

KEY FEATURES

- Industrial-grade heavy-duty construction engineered for continuous operation in demanding commercial and manufacturing environments across India.

- High-performance binding speed of 300-600 operations per hour maximises production efficiency and meets demanding industrial workflow requirements.

- Versatile material compatibility handles binding thickness from 0.2mm to 6mm, accommodating diverse applications from packaging to commercial printing operations.

- Advanced M2000 binding head technology ensures consistent staple placement and superior penetration quality required for professional industrial applications.

- Robust mechanical design withstands extended operation cycles without performance degradation, providing reliable service in high-volume production environments.

- Multiple #21-#26 stitching wire compatibility ensures easy consumable availability and cost-effective operation across Indian industrial supply networks.

- Professional-grade components deliver exceptional durability and longevity, reducing maintenance requirements and operational downtime for Okoboji customers.

- Heavy-duty model designation SSWSHD09 signifies enhanced specifications and performance capabilities specifically designed for industrial and commercial applications requiring superior binding solutions.

FREQUENTLY ASKED QUESTIONS

What industrial applications and environments are best suited for the Okoboji SSWSHD09 heavy-duty wire stapler?

This model excels in commercial printing facilities, packaging operations, large-scale binding services, manufacturing environments, industrial document processing, and high-volume production facilities requiring continuous, reliable binding performance.

How does the heavy-duty construction differ from standard staplers in terms of durability and operational lifespan?

The SSWSHD09 features reinforced mechanisms, industrial-grade components, and enhanced motor specifications designed for extended operation cycles, typically lasting 3-5 times longer than standard office staplers under demanding conditions.

Are there specific training requirements or safety protocols for operating this heavy-duty Okoboji stapler in industrial environments?

Operators should receive training on proper material positioning, safety procedures, emergency shut-off protocols, maintenance schedules, and compliance with Indian industrial safety standards to ensure safe, efficient operation.

What maintenance schedules and procedures are recommended to maximise the operational lifespan of this industrial stapler?

Regular lubrication of moving parts, weekly cleaning of wire feed mechanisms, monthly inspection of electrical connections, proper wire storage, and adherence to manufacturer maintenance guidelines will optimise performance and longevity.

How does the binding speed of 300-600 operations per hour impact overall production efficiency in commercial environments?

This speed capability allows processing of 5-10 items per minute, significantly increasing throughput compared to manual alternatives, reducing labour costs, and meeting demanding production schedules in competitive markets.

Is the 25# stitching wire specification readily available through Indian industrial supply chains?

Yes, 25# wire (0.5-0.6mm diameter) is standard industrial specification available through wholesale suppliers, industrial distributors, and Okoboji service networks across major Indian manufacturing centres.

What troubleshooting procedures can minimise downtime when operational issues occur with this heavy-duty stapler?

Standard procedures include checking wire feed alignment, clearing mechanism jams, verifying power connections, inspecting for worn components, and following systematic diagnostic protocols to quickly identify and resolve issues.

How does the 0.2-6mm binding thickness capability accommodate diverse industrial packaging and binding requirements?

This range covers applications from thin document binding to heavy cardboard packaging, enabling versatile use across multiple production lines and reducing the need for multiple specialized binding equipment.

What return on investment can Indian industrial operations expect when implementing this Okoboji heavy-duty binding solution?

Industrial facilities typically achieve ROI within 4-8 months through increased production speed, reduced labour requirements, improved binding quality, decreased maintenance costs, and enhanced operational reliability compared to manual or lower-grade alternatives.

Customers also bought

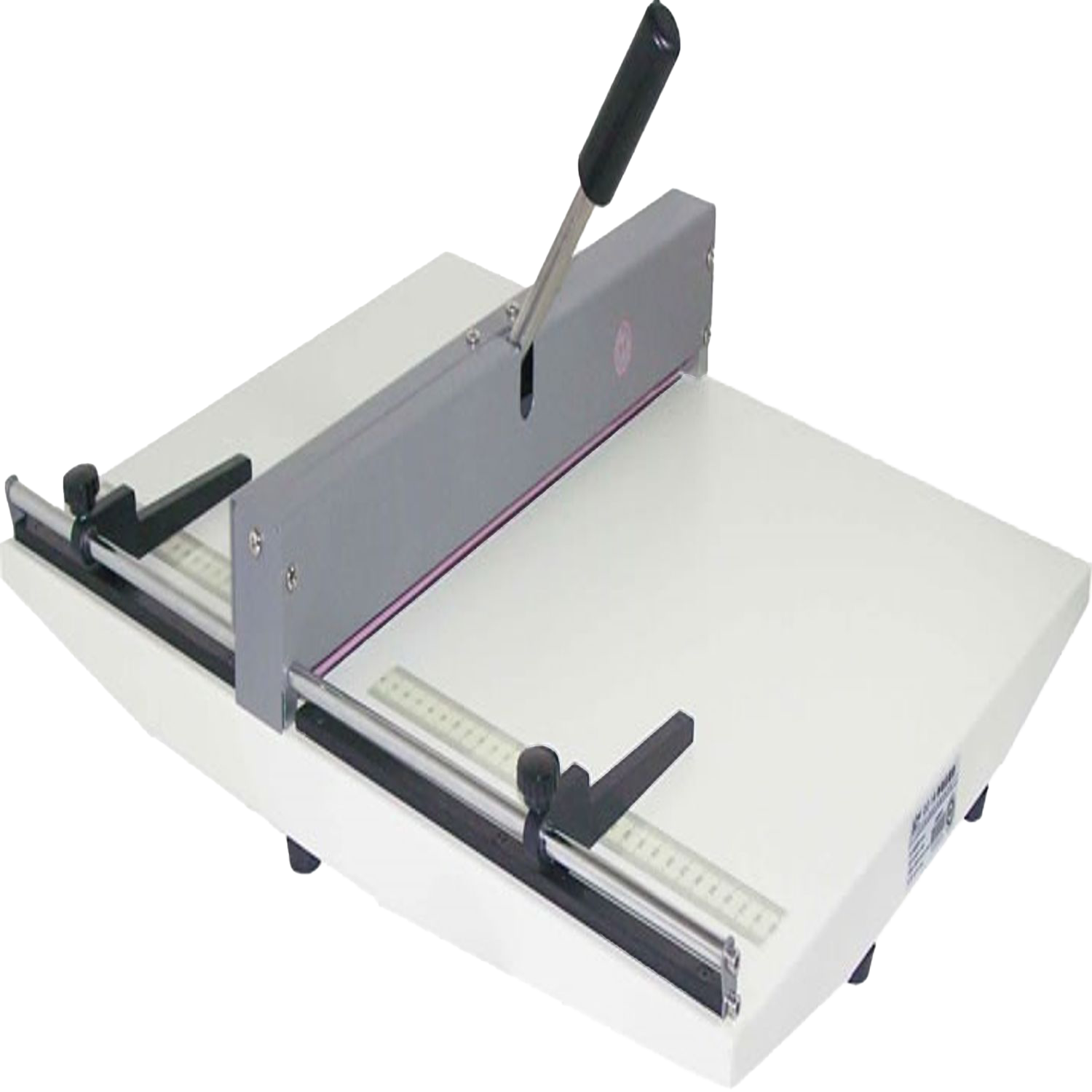

Okoboji Paper Creaser Automatic 13" 330mm ACM13

Okoboji Paper Creaser Manual A3 Size H460

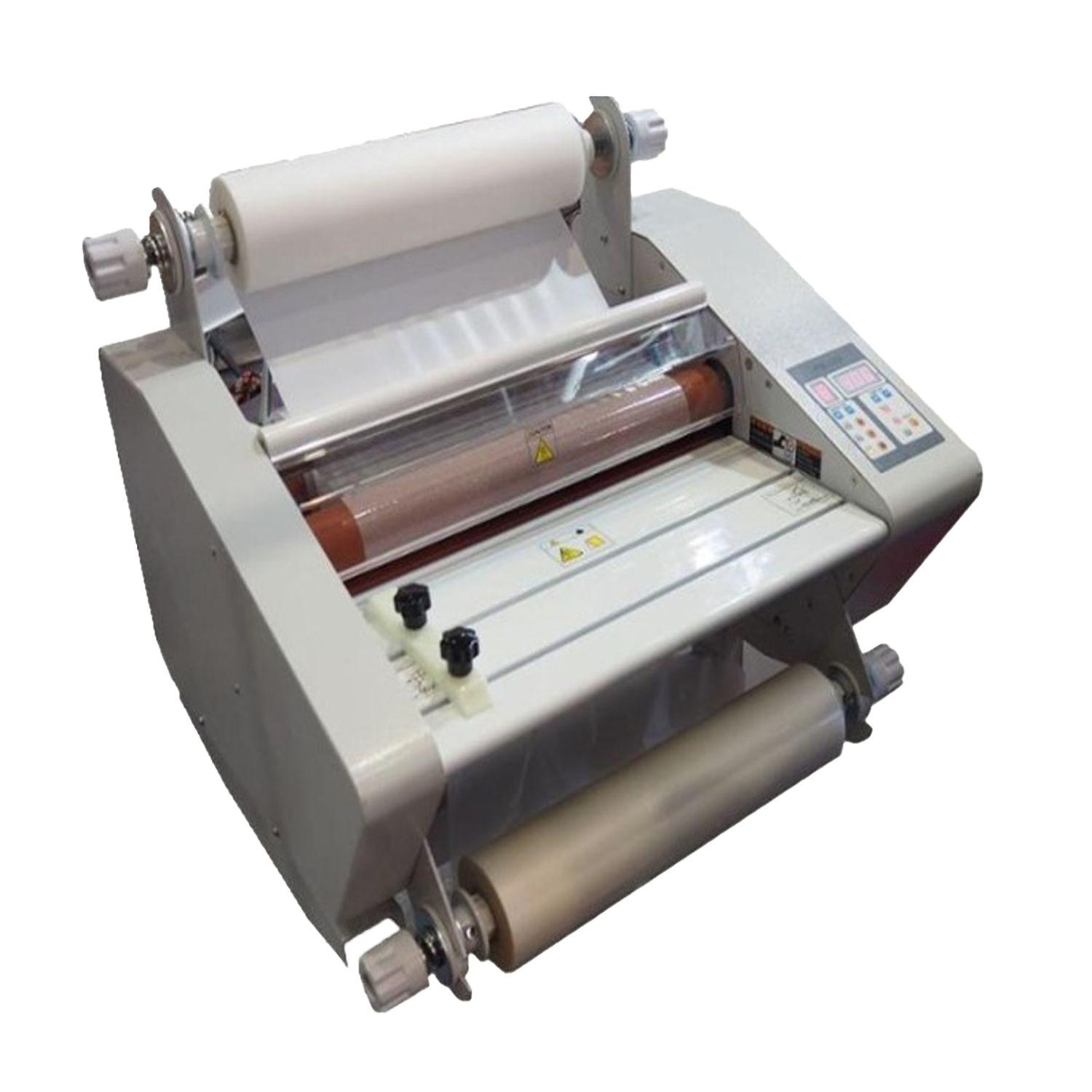

Okoboji Thermal Roll Laminator 358