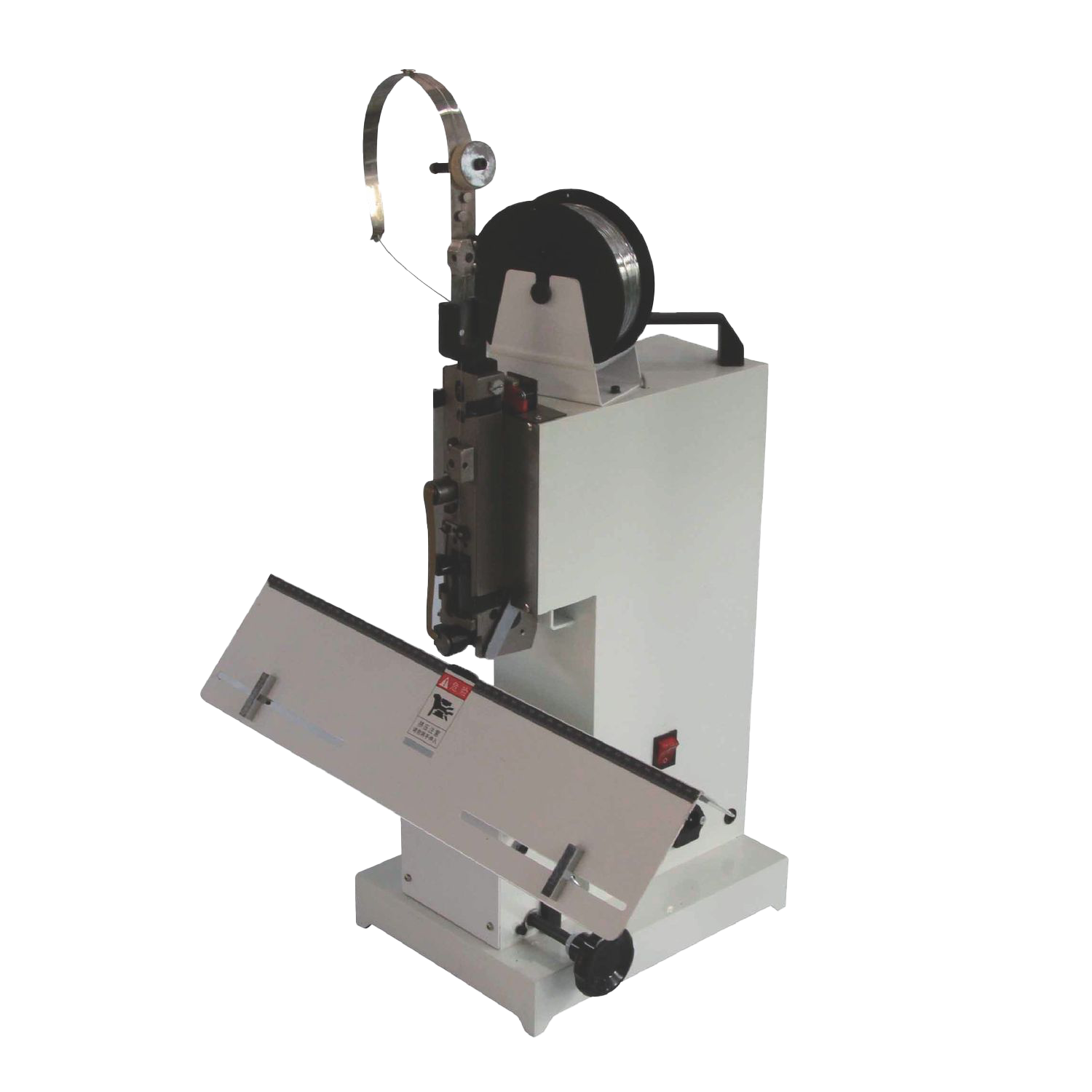

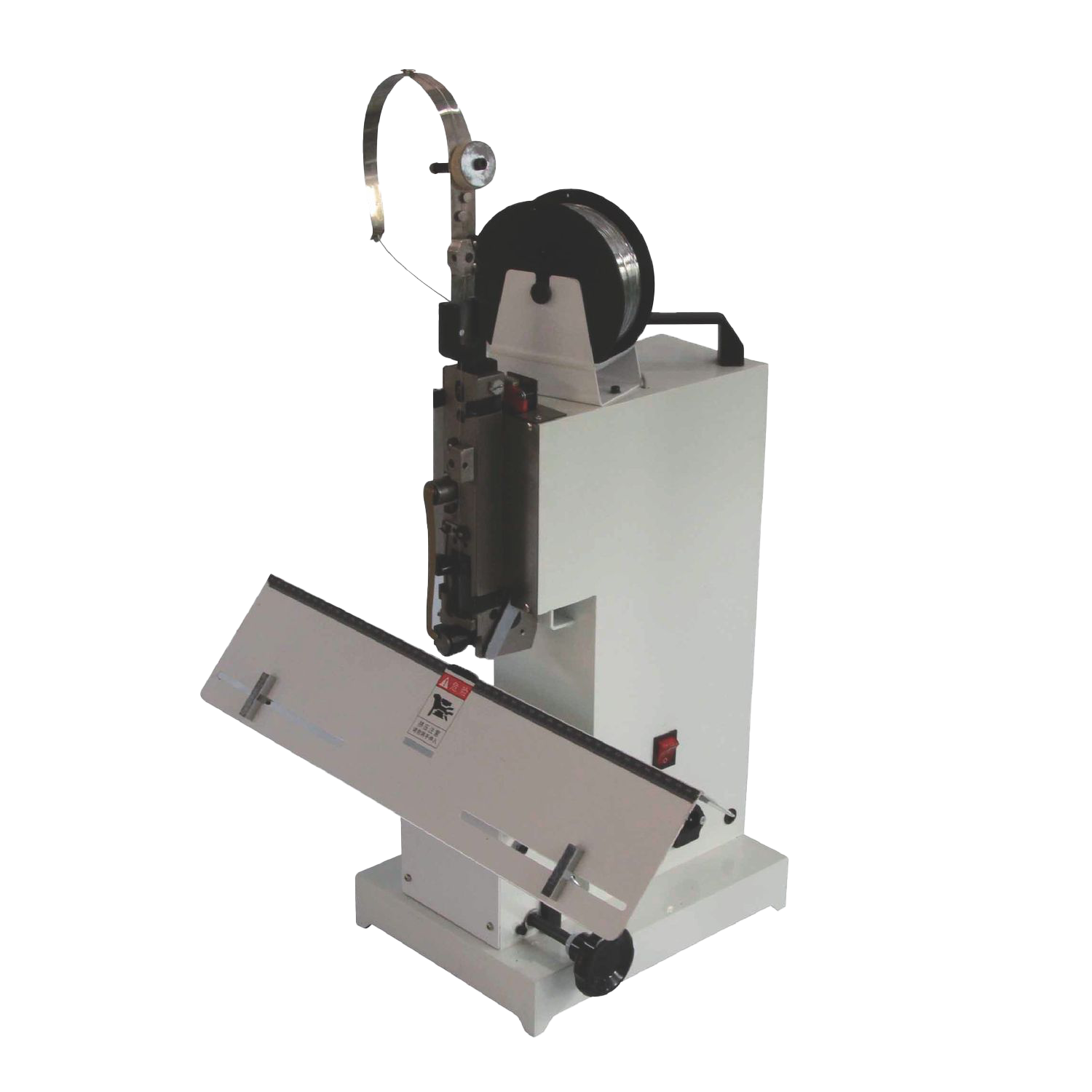

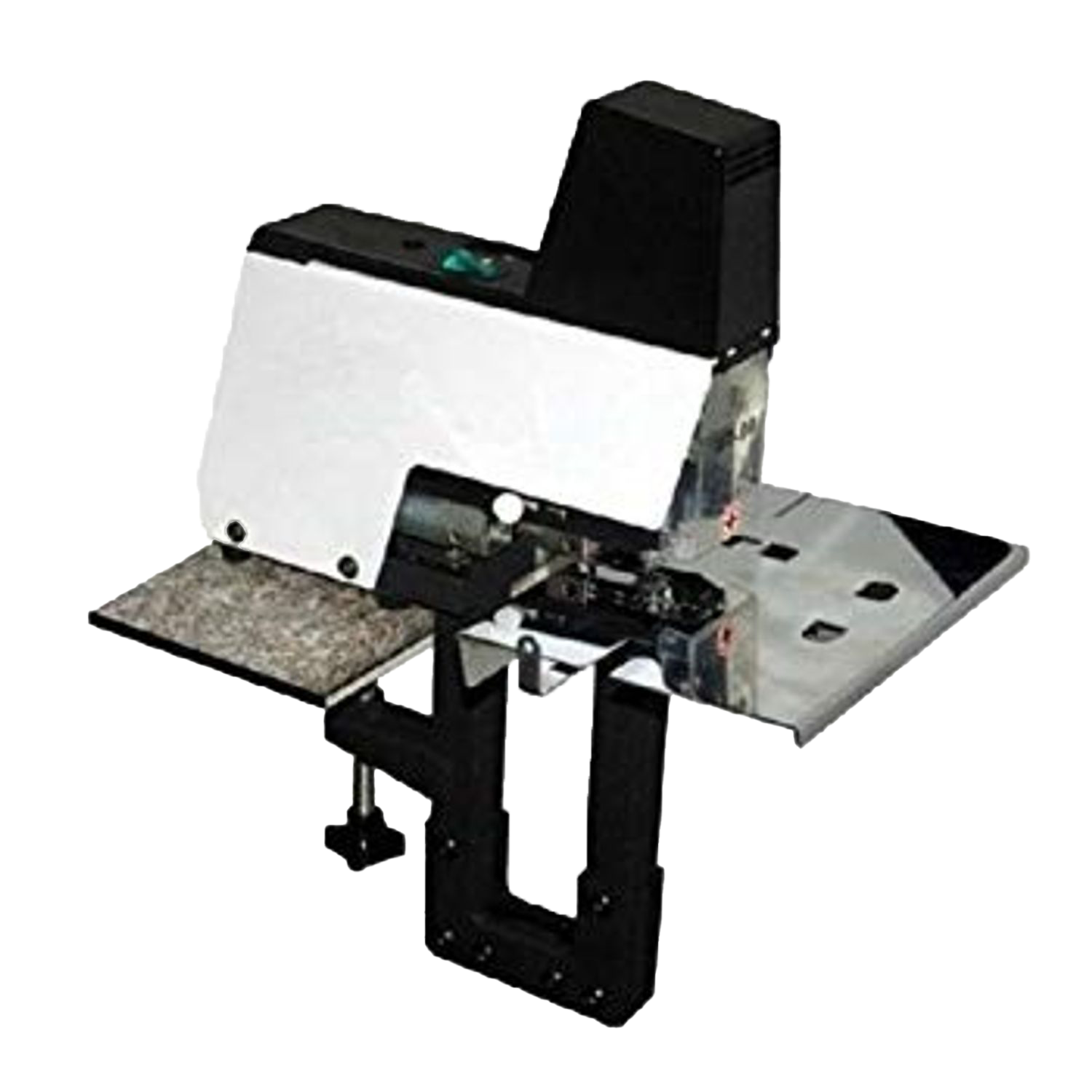

Okoboji Wire Stapler Single Head Desktop

SPECIFICATIONS

PRODUCT VIDEO

PRODUCT DESCRIPTION

The Okoboji Wire Stapler Single Head Desktop represents a pinnacle of efficiency in modern office automation, specifically engineered for Indian businesses requiring high-volume document binding solutions. This professional-grade electric stapler transforms time-consuming manual binding tasks into effortless automated processes, delivering consistent stapling performance at speeds of 300-600 bindings per hour. Unlike traditional manual staplers that cause hand fatigue and inconsistent results, this Okoboji desktop unit utilises advanced M2000 head technology to ensure uniform staple placement across documents ranging from thin papers to substantial materials up to 6mm thickness.

Perfect for printing houses, publishing companies, educational institutions, and corporate offices across India, this stapler accommodates the demanding workflow requirements of contemporary business environments. The robust 25-watt motor provides reliable power for continuous operation, whilst the versatile voltage compatibility (110/220V, 50/60Hz) ensures seamless integration into any Indian office setup. Whether you’re preparing training manuals, binding reports, creating booklets, or processing large volumes of documentation, the Okoboji Wire Stapler delivers professional results that enhance productivity and maintain document presentation standards.

The substantial 25kg construction ensures exceptional stability during operation, eliminating movement and vibration that can compromise stapling precision. This desktop stapler is particularly valuable for businesses transitioning from labour-intensive manual processes to streamlined automated solutions, offering immediate improvements in processing speed, consistency, and operator comfort whilst reducing repetitive strain injuries commonly associated with high-volume manual stapling tasks.

Upgrade Your Experience

Okoboji Perfect Binder A3

Okoboji PVC Tubebind Automatic TBA

Okoboji Stapler Electric Table Attachable

Okoboji Wire Stapler Single Head Heavy Duty SSWSHD09

KEY FEATURES

- High-speed automated binding capability processing 300-600 documents per hour, significantly reducing manual labour costs and increasing office productivity for Indian businesses.

- Versatile thickness accommodation from 0.2mm to 6mm allows binding of diverse materials including thin papers, card stock, and multi-page documents in a single efficient operation.

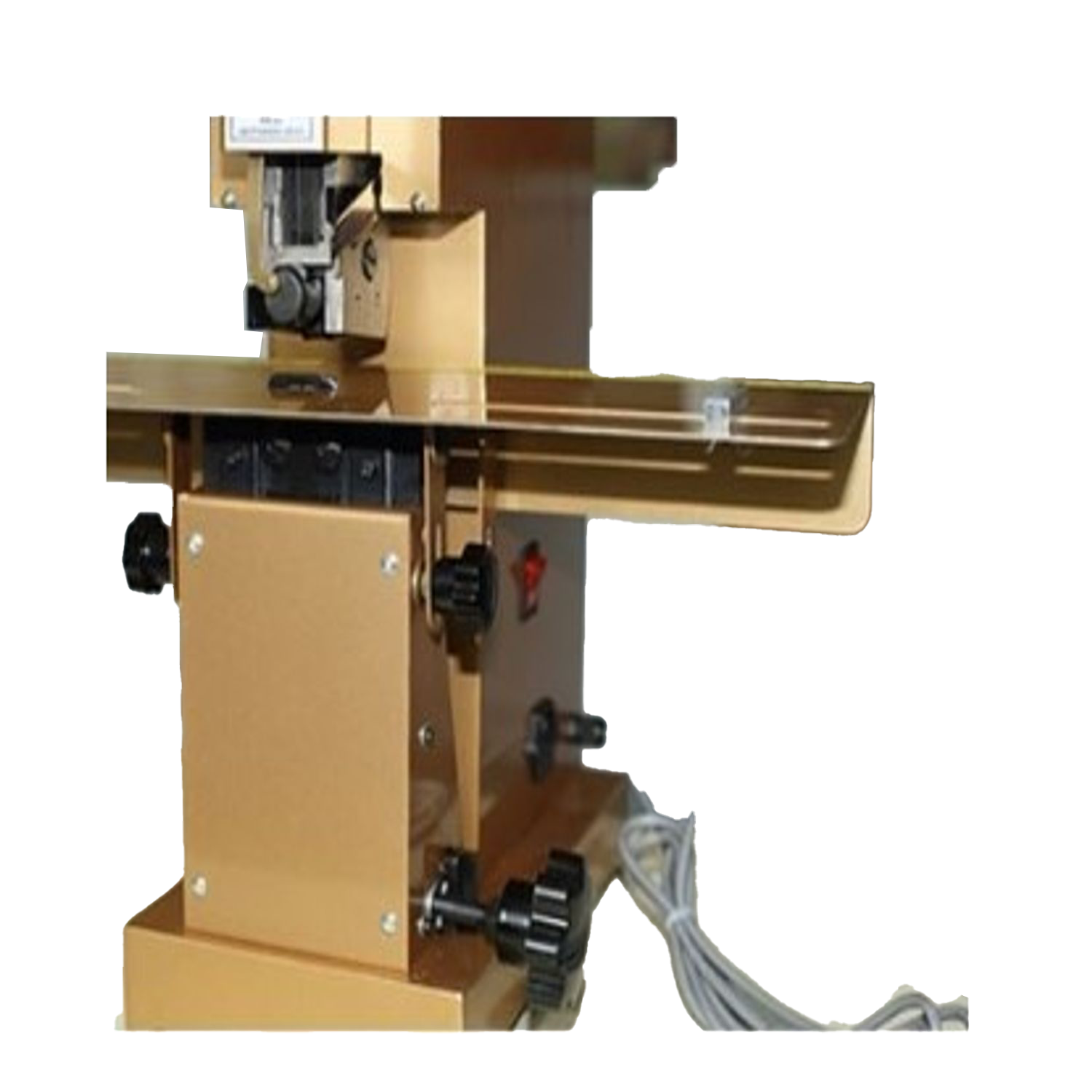

- Professional M2000 binding head technology delivers consistent staple placement and penetration, ensuring reliable document binding quality that meets commercial publishing standards.

- Robust 25-watt motor provides sustained power for continuous operation in demanding office environments, making this Okoboji stapler ideal for high-volume binding applications.

- Universal voltage compatibility (110/220V, 50/60Hz) ensures seamless installation in any Indian office electrical system without requiring additional transformers or modifications.

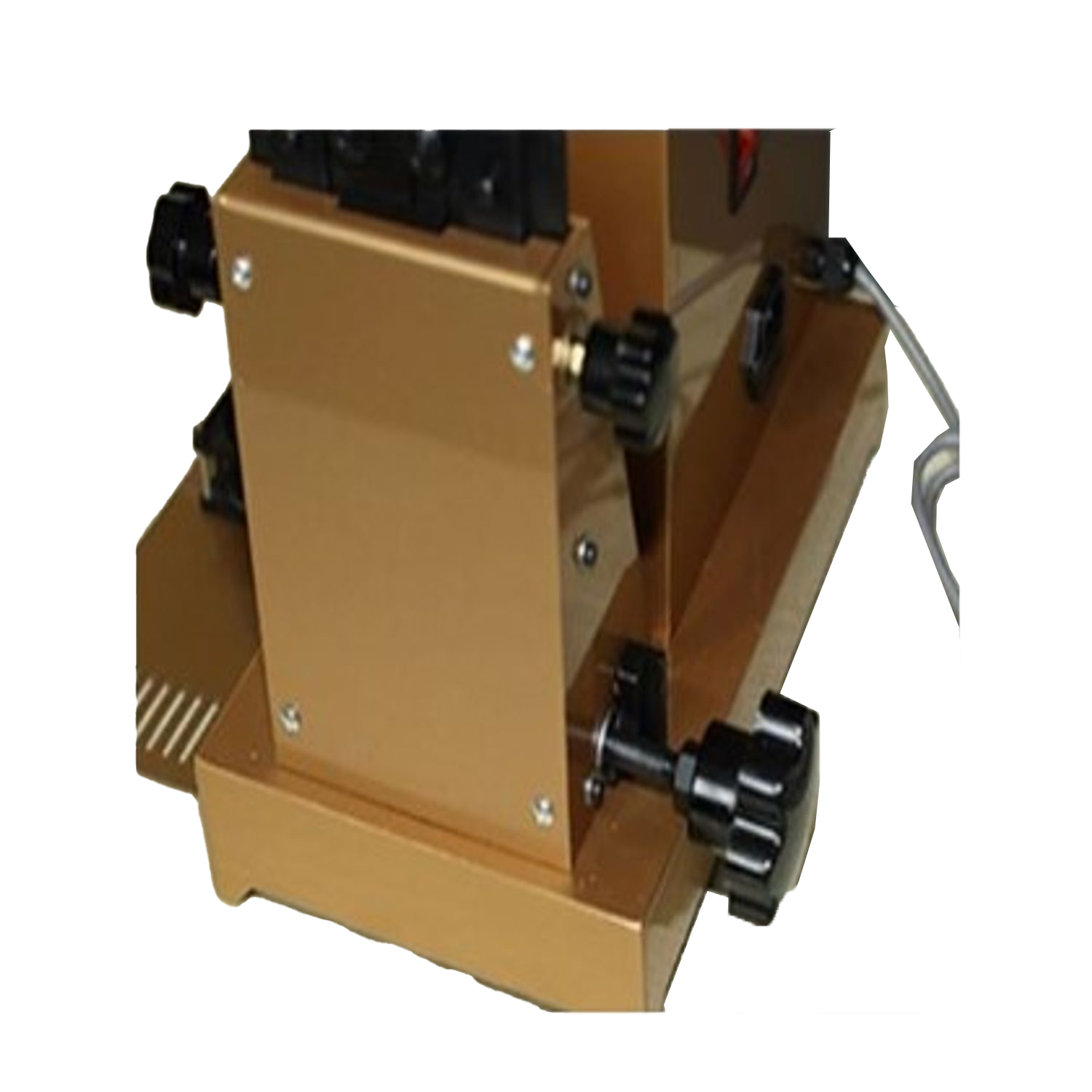

- Heavy-duty 25kg construction provides exceptional operational stability, eliminating vibration and movement during high-speed binding cycles for precise staple placement.

- Standard 25# stitching wire compatibility (0.5-0.6mm diameter) ensures easy availability of consumables across India whilst maintaining optimal binding strength and reliability.

- Compact desktop design maximises workspace efficiency whilst providing professional-grade binding capabilities that rival larger industrial machines offered by Okoboji.

FREQUENTLY ASKED QUESTIONS

What types of materials can the Okoboji Wire Stapler Single Head Desktop effectively bind?

This versatile stapler handles papers from 0.2mm to 6mm thickness, including standard office papers, card stock, thin cardboard, multi-page reports, booklets, calendars, and training materials commonly used in Indian offices and educational institutions.

How does the 300-600 binding speed specification translate to actual workplace productivity?

The Okoboji stapler can complete 5-10 bindings per minute, allowing a single operator to process substantial document volumes efficiently, reducing labour costs and eliminating the physical strain associated with manual stapling operations.

Is the 25# stitching wire readily available in Indian markets, and what are the ongoing operational costs?

Yes, 25# stitching wire (0.5-0.6mm diameter) is widely available across India through stationery suppliers and online marketplaces, ensuring consistent supply and competitive pricing for ongoing operations.

What maintenance procedures are required to ensure optimal performance and longevity of this Okoboji stapler?

Regular cleaning of the wire feed mechanism, periodic lubrication of moving parts with light machine oil, checking electrical connections, and ensuring proper wire loading alignment will maintain peak performance and extend operational life.

Can this desktop stapler integrate with existing office workflows and space constraints in Indian offices?

The compact desktop design fits standard office furniture whilst the 25kg stable base prevents movement during operation, making it suitable for both dedicated binding stations and shared workspace environments.

What safety considerations and training requirements apply when operating this electric stapler?

Operators should receive basic training on proper wire loading, material positioning, emergency shut-off procedures, and electrical safety protocols to ensure safe operation in compliance with Indian workplace safety standards.

How does the M2000 binding head technology compare to alternative binding methods available in the Indian market?

The M2000 head provides superior consistency and penetration compared to manual staplers, whilst offering faster processing than traditional spiral binding methods, making it ideal for high-volume commercial applications.

What troubleshooting steps can resolve common operational issues with this Okoboji wire stapler?

Common issues include checking power connections, clearing wire jams by opening the feed mechanism, ensuring proper wire alignment, verifying material thickness compatibility, and cleaning debris from the binding head area.

Is technical support and spare parts availability reliable for Okoboji products in India?

Okoboji maintains comprehensive support networks across India, providing technical assistance, genuine spare parts, and service documentation to ensure minimal downtime and optimal equipment performance.

What return on investment can Indian businesses expect when upgrading from manual to this automated stapling solution?

Businesses typically recover their investment within 6-12 months through reduced labour costs, increased processing speed, improved binding quality, and eliminated repetitive strain injuries associated with manual stapling operations.

Customers also bought

Okoboji Corner Cutter Electric DT W Cover WH08C

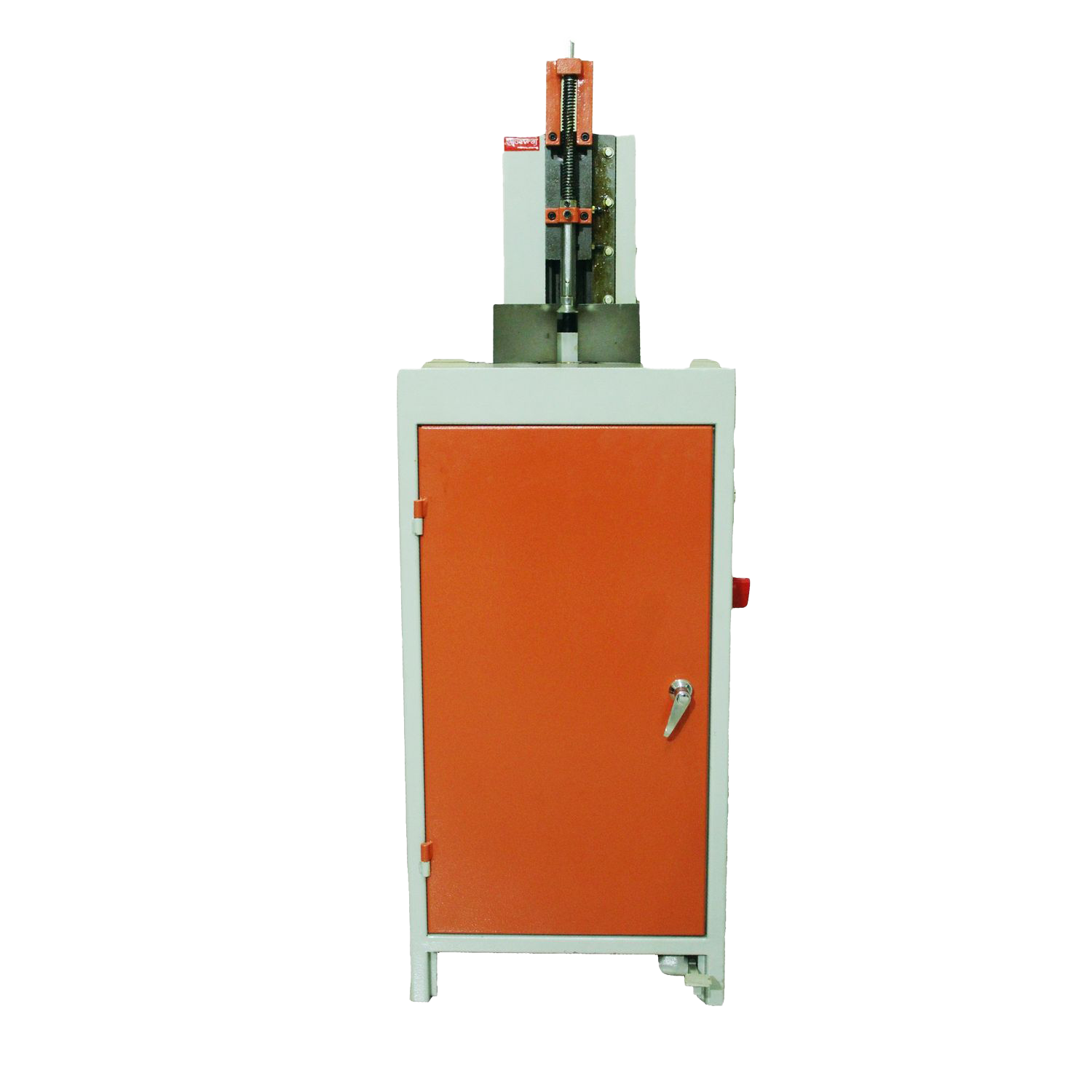

Okoboji Corner Cutter Electric Heavy Duty Orange

Okoboji Corner Cutter Electric Super HD Back Motor Grey