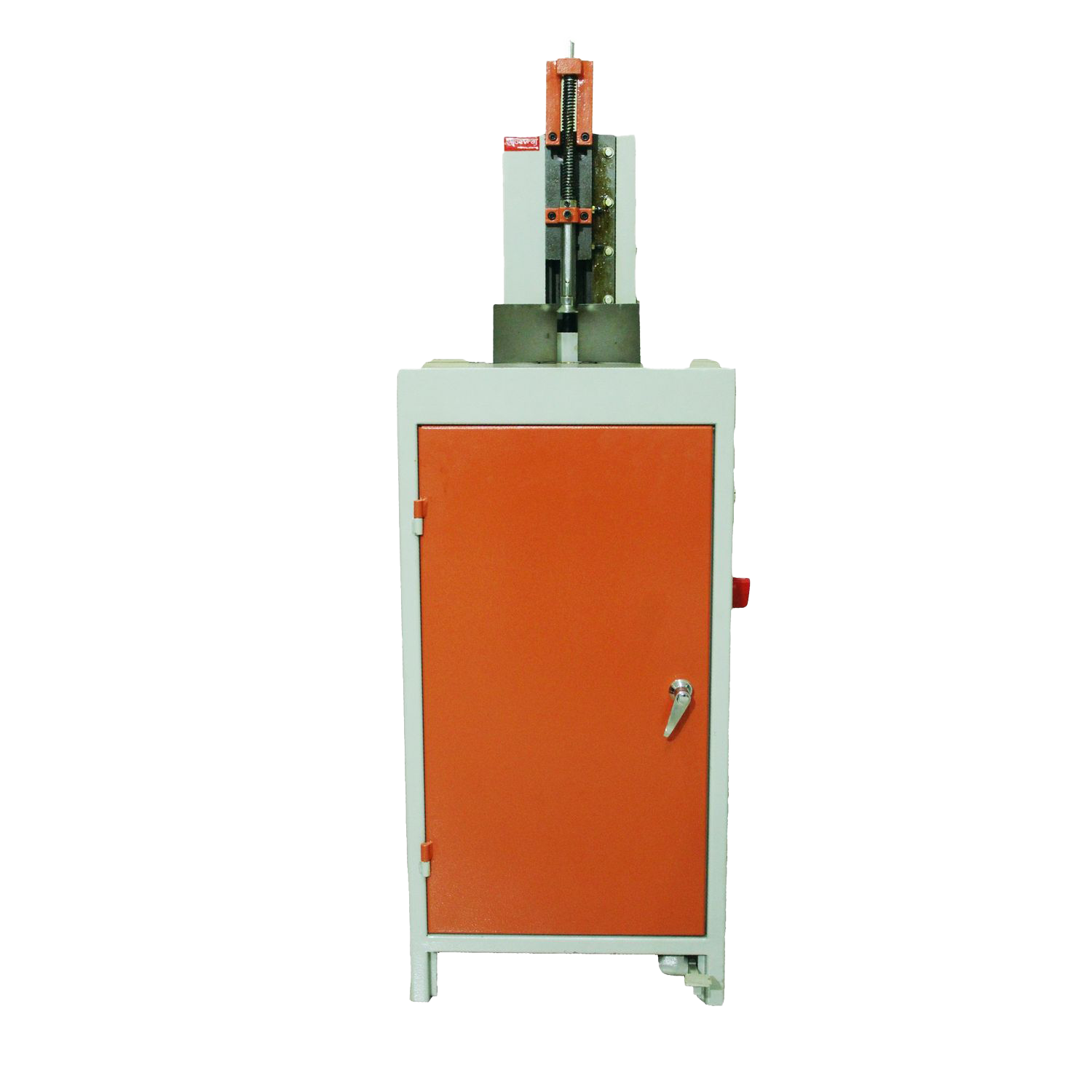

Okoboji Corner Cutter Pneumatic Dual Head HD

SPECIFICATIONS

PRODUCT VIDEO

PRODUCT DESCRIPTION

The Okoboji Corner Cutter Pneumatic Dual Head HD represents the pinnacle of air-powered corner cutting technology, featuring an innovative dual-head configuration that revolutionises productivity and operational efficiency in high-volume commercial applications. This advanced pneumatic corner cutter incorporates sophisticated air-powered systems that deliver exceptional cutting force, precision, and speed whilst maintaining the reliability and consistency demanded by intensive commercial operations. The dual-head design enables simultaneous cutting operations, effectively doubling productivity compared to single-head alternatives.

The heavy-duty pneumatic system provides superior cutting force and consistency compared to electric alternatives, particularly when processing challenging materials or maintaining continuous operation throughout demanding production schedules. This pneumatic corner cutter eliminates the motor noise and electrical complexity associated with electric systems whilst delivering enhanced cutting power and operational flexibility. The dual-head configuration optimises workspace efficiency by enabling operators to process multiple pieces simultaneously or maintain continuous operation through alternating head usage.

This premium pneumatic corner cutter serves high-volume commercial operations requiring maximum productivity, superior cutting force, and exceptional reliability. Industries such as large-scale packaging, commercial printing houses, industrial document preparation, and high-throughput manufacturing facilities benefit significantly from the enhanced capabilities and productivity advantages offered by this flagship Okoboji pneumatic system.

Upgrade Your Experience

Okoboji Corner Cutter Electric DT W Cover WH08C

Okoboji Corner Cutter Electric Heavy Duty Orange

Okoboji Corner Cutter Electric Super HD Back Motor Grey

Okoboji Manual Hand Held Corner Cutter

KEY FEATURES

- Revolutionary dual-head configuration enables simultaneous cutting operations, effectively doubling productivity compared to single-head corner cutters whilst maintaining precision cutting results throughout intensive commercial applications.

- Advanced pneumatic system delivers superior cutting force and consistency compared to electric alternatives, particularly advantageous when processing challenging materials or maintaining continuous high-volume operation.

- Heavy-duty construction incorporates reinforced components and premium materials designed for the most demanding commercial applications requiring exceptional reliability and extended operational lifespan.

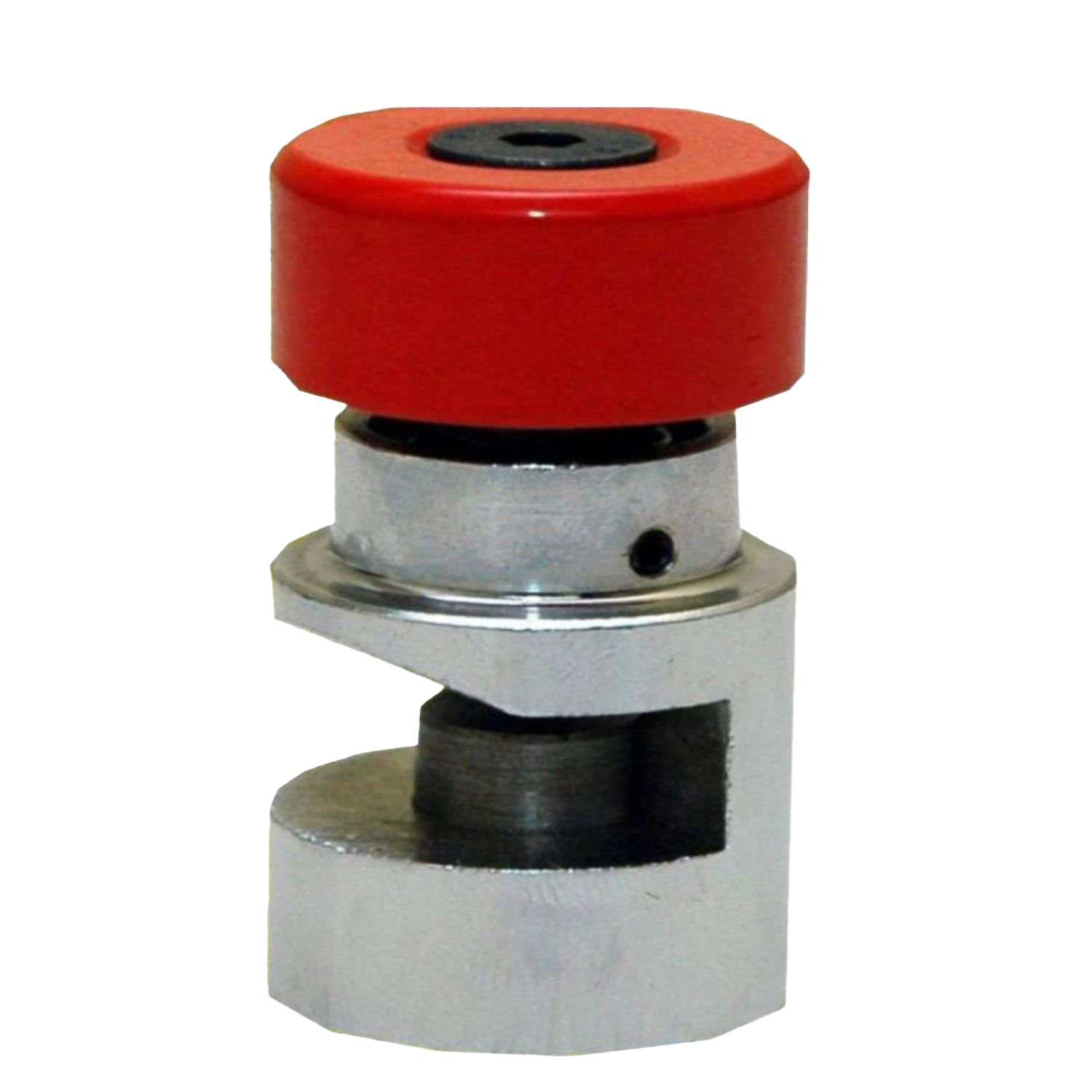

- Professional 80mm cutting capacity accommodates thick materials and challenging substrates whilst maintaining precision results throughout intensive daily usage patterns typical in commercial environments.

- Enhanced cutting speed capability maintains high productivity levels whilst accommodating the sophisticated dual-head operation system, ensuring efficient operation for high-volume Okoboji corner cutting applications.

- Pneumatic operation eliminates motor noise, reduces electrical complexity, and provides consistent cutting force independent of electrical supply variations, enhancing operational reliability and workplace comfort.

- Stand-alone design with optimised dual-head configuration provides exceptional workspace efficiency whilst maintaining superior stability during high-speed operation in professional environments.

- Advanced air-powered systems reduce maintenance requirements compared to electric alternatives whilst providing superior cutting force and operational flexibility for demanding commercial applications.

FREQUENTLY ASKED QUESTIONS

What advantages does the dual-head configuration provide over single-head corner cutters?

The Okoboji dual-head system enables simultaneous cutting operations, effectively doubling productivity whilst maintaining precision results, making it ideal for high-volume commercial applications requiring maximum efficiency.

What air compressor specifications are required for optimal pneumatic operation?

The pneumatic system requires 6-8 bar air pressure with 8-12 CFM capacity to operate both heads simultaneously, typical specifications available in most commercial workshop environments.

How does pneumatic operation compare to electric corner cutters for commercial applications?

Pneumatic operation provides superior cutting force, consistent performance independent of electrical variations, reduced noise levels, and simplified maintenance whilst eliminating motor-related issues common in electric systems.

What maintenance procedures apply specifically to dual-head pneumatic corner cutting equipment?

Regular air filter cleaning, moisture trap drainage, lubrication point servicing, and periodic head calibration ensure optimal performance for dual-head pneumatic corner cutting systems.

Can both heads operate independently, and what flexibility does this provide?

Yes, each head operates independently, enabling operators to use different cutting configurations simultaneously, maintain continuous operation through alternating usage, or focus both heads for maximum productivity.

What installation requirements apply to heavy-duty pneumatic corner cutting equipment?

Installation requires adequate compressed air supply, stable foundation for 120kg weight, proper air line connections, and sufficient workspace clearance for dual-head operation and maintenance access.

How does the 56 cuts per minute rate apply to dual-head operation?

Each head maintains 56 cuts per minute capability, providing combined productivity of up to 112 cuts per minute when both heads operate simultaneously, significantly enhancing commercial operation efficiency.

What types of businesses justify the investment in dual-head pneumatic corner cutting equipment?

High-volume printing houses, large packaging manufacturers, commercial bookbinders, and industrial document preparation facilities requiring maximum productivity benefit most from dual-head pneumatic capabilities.

Does the pneumatic system provide advantages for processing challenging materials?

Yes, pneumatic systems deliver superior cutting force and consistency, particularly advantageous for thick materials, laminated substrates, and challenging applications that strain electric motor systems.

What technical support is available for advanced pneumatic corner cutting equipment?

Okoboji provides comprehensive technical support including installation guidance, operator training, maintenance scheduling, compressed air system optimization, and priority service response for pneumatic equipment.

Customers also bought

Okoboji Digital Foil Printer 350mm High Speed 360C

Okoboji Hot Stamping 12" X 15.74" 3040 800KG

Okoboji Paper Cutter Digital Hydraulic 520mm