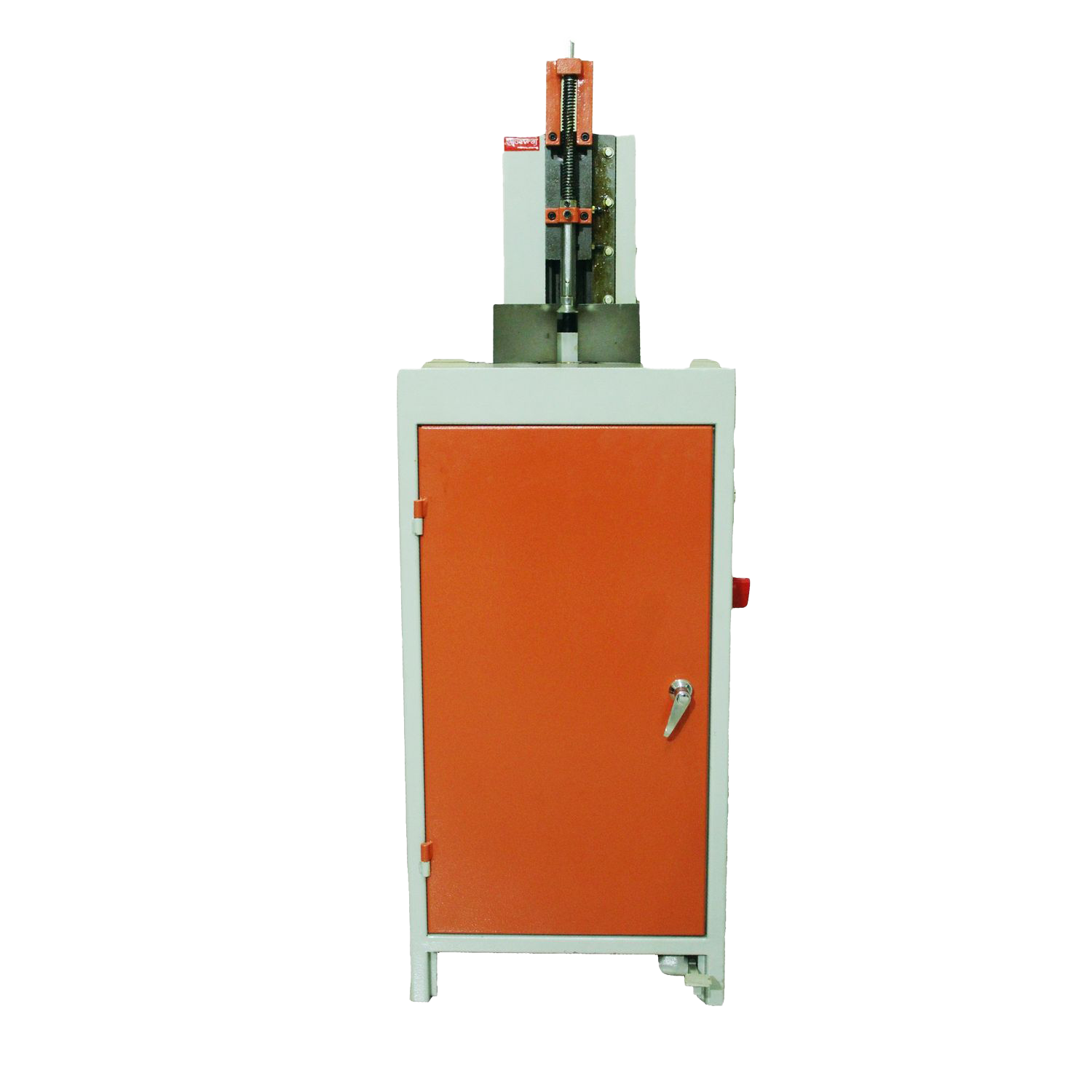

Okoboji Corner Cutter 7 Dye Pneumatic

SPECIFICATIONS

PRODUCT VIDEO

PRODUCT DESCRIPTION

The Okoboji Corner Cutter 7 Die Pneumatic represents an exceptional combination of pneumatic power and comprehensive die versatility, featuring the most extensive die selection available in pneumatic corner cutting technology. This advanced air-powered corner cutter incorporates seven interchangeable dies that provide unparalleled flexibility for addressing diverse customer requirements and specialised project specifications. The comprehensive die system enables businesses to tackle virtually any corner cutting application whilst maintaining the superior cutting force and reliability that characterises pneumatic operation.

The seven-die configuration distinguishes this pneumatic corner cutter as the most versatile option in the Okoboji pneumatic lineup, enabling operators to address diverse radius specifications, specialty cutting requirements, and custom applications within a single machine investment. This extensive die selection eliminates the need for multiple corner cutting machines whilst providing the operational flexibility essential for businesses serving diverse customer bases with varied corner cutting requirements.

This versatile pneumatic corner cutter serves businesses requiring comprehensive corner cutting capabilities with the superior power and reliability of pneumatic operation. Commercial printing houses, packaging manufacturers, custom document services, and specialised manufacturing operations benefit significantly from the combination of pneumatic power and extensive die selection offered by this advanced Okoboji system.

Upgrade Your Experience

Okoboji Corner Cutter Electric DT WH08

Okoboji Corner Cutter Electric Heavy Duty Orange

Okoboji Corner Cutter Manual S100

Okoboji Corner Cutter Pneumatic Dual Head HD

KEY FEATURES

- Comprehensive seven-die system provides the most extensive corner cutting versatility available in pneumatic technology, enabling operators to address virtually any customer requirement within single machine investment.

- Advanced pneumatic operation delivers superior cutting force and consistency compared to electric alternatives, particularly advantageous for demanding materials and high-volume commercial applications.

- Professional 80mm cutting capacity accommodates thick materials and challenging substrates whilst maintaining precision results throughout intensive daily usage patterns typical in commercial environments.

- Heavy-duty stand-alone construction incorporates reinforced components designed for demanding commercial applications requiring exceptional reliability and extended operational lifespan.

- Enhanced R8-R12 knife range optimises performance across diverse applications whilst providing comprehensive coverage for commercial corner cutting requirements in professional Okoboji operations.

- Pneumatic system eliminates motor noise, reduces electrical complexity, and provides consistent cutting force independent of electrical supply variations, enhancing operational reliability and workplace comfort.

- Rapid die change capability enables quick transitions between different corner specifications, minimising downtime and maximising productivity for businesses serving diverse customer requirements.

- Cost-effective pneumatic operation reduces maintenance requirements compared to electric alternatives whilst providing superior cutting force and operational flexibility for demanding commercial applications.

FREQUENTLY ASKED QUESTIONS

What specific die configurations are included in the seven-die pneumatic system?

The comprehensive seven-die system includes multiple radius specifications within the R3-R10 range plus specialty cutting options, providing extensive versatility for addressing diverse commercial corner cutting requirements.

How does the seven-die system enhance business opportunities compared to limited-die alternatives?

The extensive die selection enables businesses to serve diverse customer bases, tackle specialty projects, and differentiate services whilst maintaining pneumatic power advantages, expanding market opportunities.

What air compressor specifications ensure optimal performance for seven-die pneumatic operation?

The system requires 6-8 bar air pressure with 4-6 CFM capacity, standard specifications available in most commercial workshops, ensuring reliable operation across all die configurations.

How quickly can operators change between different dies during production runs?

The quick-change die system enables transitions between different corner specifications in under 45 seconds, minimising production downtime and maximising operational efficiency for diverse projects.

What maintenance procedures apply to multi-die pneumatic corner cutting equipment?

Regular air system maintenance, die inspection and cleaning, lubrication point servicing, and periodic calibration ensure optimal performance across all seven die configurations.

Does the extensive die system affect cutting speed or operational efficiency?

The 56 cuts per minute speed maintains consistent productivity across all die configurations whilst the quick-change system minimises transition time, ensuring efficient operation for diverse applications.

What training considerations apply to operating seven-die pneumatic corner cutting equipment?

Comprehensive training covers die selection procedures, pneumatic system operation, quick-change techniques, and application-specific methods for maximising the versatility of seven-die capabilities.

How does pneumatic operation benefit businesses requiring diverse corner cutting capabilities?

Pneumatic systems provide consistent cutting force across all die configurations, superior performance with challenging materials, and reliable operation essential for businesses serving diverse customer requirements.

What types of projects benefit most from comprehensive seven-die corner cutting capabilities?

Custom packaging, specialty document preparation, varied commercial printing, architectural applications, and diverse manufacturing projects benefit from the extensive versatility of seven-die systems.

How does this model compare to electric alternatives for businesses requiring extensive die versatility?

The pneumatic system provides superior cutting force, consistent performance across diverse applications, reduced maintenance complexity, and operational reliability essential for businesses requiring comprehensive corner cutting capabilities.

Customers also bought

Okoboji Paper Creaser Automatic 13" 330mm ACM13

Okoboji Paper Creasing, Perforation Manual 460 2in1

Okoboji Paper Cutter Digital Electric 490mm