Okoboji Wiro & Spiral Binder SW2500

SPECIFICATIONS

PRODUCT VIDEO

PRODUCT DESCRIPTION

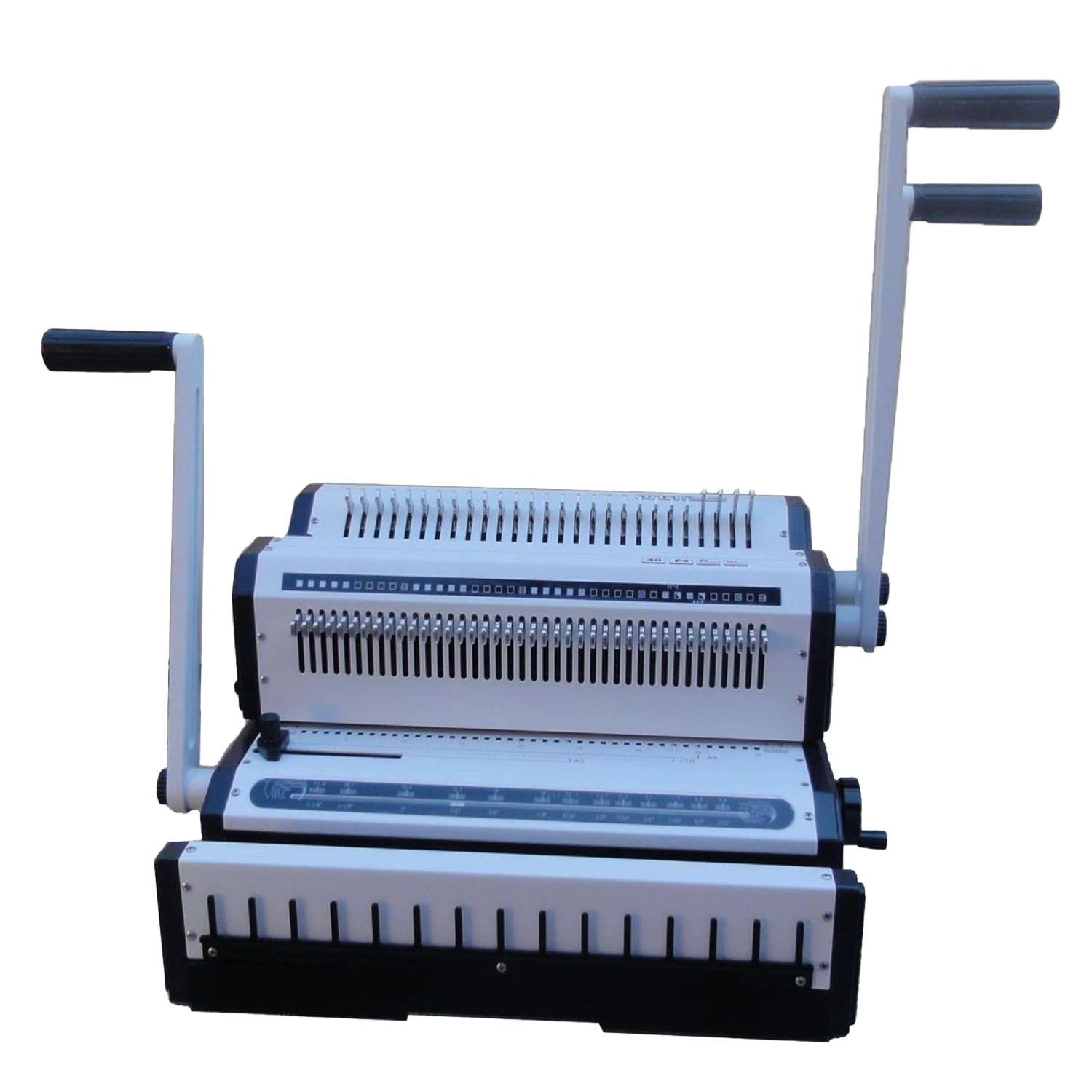

The Okoboji Wiro & Spiral Binder SW2500 represents the ultimate convergence of binding technologies, ingeniously engineered to deliver both wire binding and spiral binding capabilities within a single, sophisticated machine platform that revolutionises document binding operations for Indian businesses and institutions seeking maximum versatility and operational efficiency. This groundbreaking dual-purpose binding system addresses the diverse and evolving binding requirements of modern organisations by eliminating the substantial investment and workspace requirements associated with maintaining separate binding machines for different document types and aesthetic preferences. The machine’s innovative design philosophy centres on maximising operational flexibility whilst maintaining the precision engineering, build quality, and reliability that characterise professional-grade binding equipment used in demanding commercial environments.

Understanding the strategic advantages of dual-purpose binding capability becomes essential when considering the comprehensive document production requirements typical of modern business operations. The SW2500’s unique ability to seamlessly accommodate both wire binding for professional reports requiring lay-flat functionality and spiral binding for notebooks, calendars, and educational materials provides organisations with unprecedented flexibility in document presentation and binding aesthetics. This versatility proves particularly valuable for businesses serving diverse clientele, educational institutions with varying academic material requirements, commercial printing operations offering comprehensive binding services, and corporate environments where different departments require different binding solutions for their specific document types and presentation standards.

The SW2500 particularly excels in environments where binding requirements vary significantly and where operational efficiency, space utilisation, and cost-effectiveness directly impact business productivity and profitability. Commercial printing operations serving diverse customer bases, corporate offices handling multiple document types across different departments, educational institutions with varying academic and administrative material requirements, training centres developing different course formats and materials, and professional service providers creating materials for multiple client types all benefit tremendously from the machine’s dual-purpose capability. The machine’s substantial F4 format compatibility, impressive variable binding capacity ranging from 140 to 500 sheets depending on binding method selected, and robust 28.5kg construction establish it as an indispensable tool for organisations seeking comprehensive binding solutions that deliver professional results across diverse applications whilst maximising workspace efficiency and investment value.

Upgrade Your Experience

Okoboji Wiro Binder Electric DW600

Okoboji Wiro Binder HD W20A A4

Okoboji Wiro Binder Punch W25A 2:1

Okoboji Wiro Binder Punch WW2500

KEY FEATURES

- Revolutionary Dual-Binding Technology : Unique 2-in-1 capability accommodates both wire binding and spiral binding within a single machine, eliminating the need for multiple binding systems and providing exceptional versatility for diverse document requirements.

- Enhanced F4 Format Support : Accommodates documents up to F4 size (below 330mm width), supporting larger format binding projects including oversized reports, calendars, portfolios, and commercial printing applications beyond standard A4 limitations.

- Variable Binding Capacity System : Supports 140-sheet capacity for wire binding applications and 500-sheet capacity for spiral binding projects, providing flexibility for various document thicknesses and binding strength requirements across different applications.

- Comprehensive 25-Sheet Punching Capacity : Efficiently processes substantial document thickness with precision hole placement across both binding methods, enabling professional binding of comprehensive reports, manuals, and complex presentations.

- Extensive Die Configuration Options : Features comprehensive hole pattern varieties including 24-pin, 40-pin, 54-pin, and 56-pin configurations, ensuring compatibility with virtually any wire or spiral binding specification and supply standard available in the Indian market.

- Professional Adjustable Margin System : Precision margin settings (2.5mm, 4.5mm, 6.5mm) accommodate different document types and binding requirements, ensuring optimal hole placement and professional binding alignment across both wire and spiral configurations.

- Heavy-Duty Construction Design : Robust 28.5kg weight and premium engineering provide exceptional stability and durability for intensive commercial use, making it a reliable long-term investment for Okoboji customers requiring professional-grade equipment.

- Complete Movable Cutter System : All-disengageable cutter configuration enables binding of various document sizes and formats, providing maximum flexibility for custom binding applications and non-standard document dimensions across both binding methods.

FREQUENTLY ASKED QUESTIONS

What makes the Okoboji SW2500 unique compared to single-purpose binding machines?

The SW2500's revolutionary 2-in-1 capability accommodates both wire binding and spiral binding in a single machine, eliminating the need for multiple binding systems and providing exceptional versatility for diverse document binding requirements and aesthetic preferences.

How does the variable binding capacity benefit different binding applications?

The machine supports up to 500 sheets for spiral binding applications and 140 sheets for wire binding, providing flexibility for various document types from thick notebooks and calendars to professional reports and presentations.

What professional advantages does F4 format capability provide for binding operations?

F4 format support accommodates larger documents, oversized reports, calendars, portfolios, and commercial printing projects that exceed standard A4 limitations, providing expanded binding possibilities for diverse business applications and client requirements.

Can this machine handle both standard and custom document sizes effectively?

Yes, the complete movable cutter system with all-disengageable configuration enables binding of various document sizes and formats across both wire and spiral binding methods, providing maximum flexibility for custom applications.

What die configurations does the SW2500 accommodate for different binding requirements?

The machine features comprehensive die options including 24-pin, 40-pin, 54-pin, and 56-pin configurations, ensuring compatibility with virtually any wire or spiral binding specification and supply standard available in the market.

How does dual-purpose capability benefit commercial printing and office operations?

Dual-purpose capability enables businesses to handle diverse binding requirements without multiple machines, providing cost efficiency, space savings, and operational flexibility for organisations with varying document binding needs and client requirements.

Is the SW2500 suitable for educational institutions with diverse material requirements?

Absolutely, the machine's ability to create both wire-bound academic reports and spiral-bound notebooks, course materials, and calendars makes it ideal for educational environments with diverse binding requirements and varying presentation standards.

What training is required for operators to effectively use both binding methods?

Okoboji provides comprehensive training covering both wire and spiral binding techniques, die selection, optimal binding practices, and machine maintenance to ensure operators achieve optimal results across all binding applications.

How do the adjustable margin settings accommodate different binding methods?

The precision margin settings (2.5mm, 4.5mm, 6.5mm) work effectively with both wire and spiral binding configurations, ensuring optimal hole placement and professional binding alignment regardless of the selected binding method.

What ongoing support does Okoboji provide for dual-purpose binding operations?

Okoboji offers comprehensive technical support, die configuration guidance, binding optimization assistance, supply recommendations, and professional service to ensure optimal performance and maximum return on investment for dual-purpose binding operations.

Customers also bought

Okoboji Paper Creaser Automatic W auto pickup K330C

Okoboji Paper Half Cutting 600mm HC600

Okoboji Perfect Bind A3 60BR