Okoboji Wiro Binder Electric DW600

SPECIFICATIONS

PRODUCT VIDEO

PRODUCT DESCRIPTION

The Okoboji Wiro Binder Electric DW600 represents a perfect fusion of German precision engineering and manufacturing excellence, designed specifically for modern Indian offices and businesses requiring professional document binding solutions. This robust electric wiro binding machine transforms ordinary documents into professionally bound presentations, reports, and manuals with exceptional ease and consistency. The DW600 eliminates the labour-intensive manual punching process by delivering automated precision that ensures uniform hole spacing and clean, precise perforations every time.

This versatile binding solution addresses the growing demand in Indian corporate environments for efficient document management systems that enhance presentation quality whilst reducing operational time. Whether you’re preparing quarterly reports for board meetings, creating training manuals for employee development, or producing client presentations that reflect your company’s commitment to quality, the Okoboji DW600 delivers the professional finish that distinguishes your business in competitive markets. The machine’s intelligent design incorporates user-friendly controls that make professional binding accessible to staff across all technical skill levels.

Upgrade Your Experience

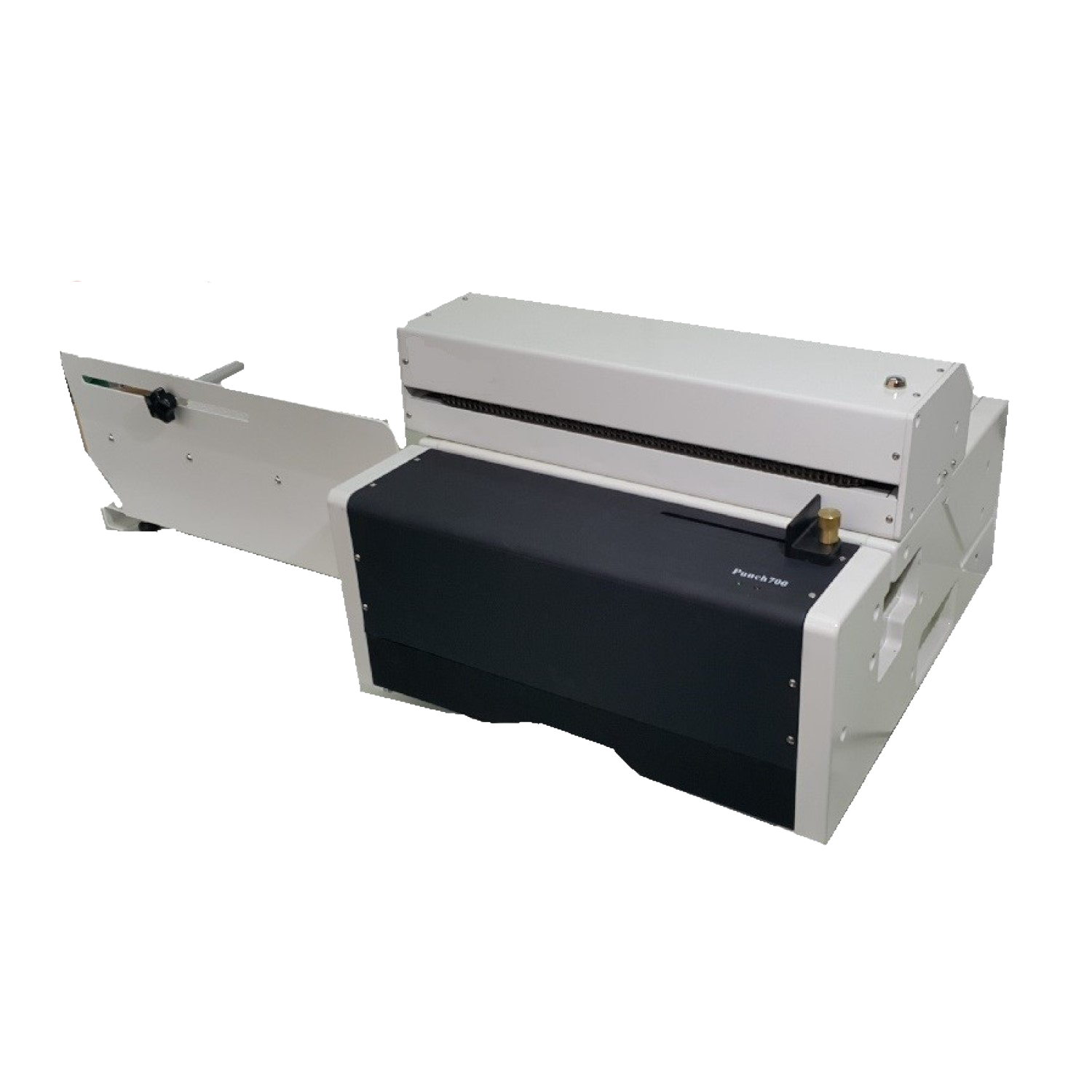

Okoboji Wiro Binder Electric Punch 700

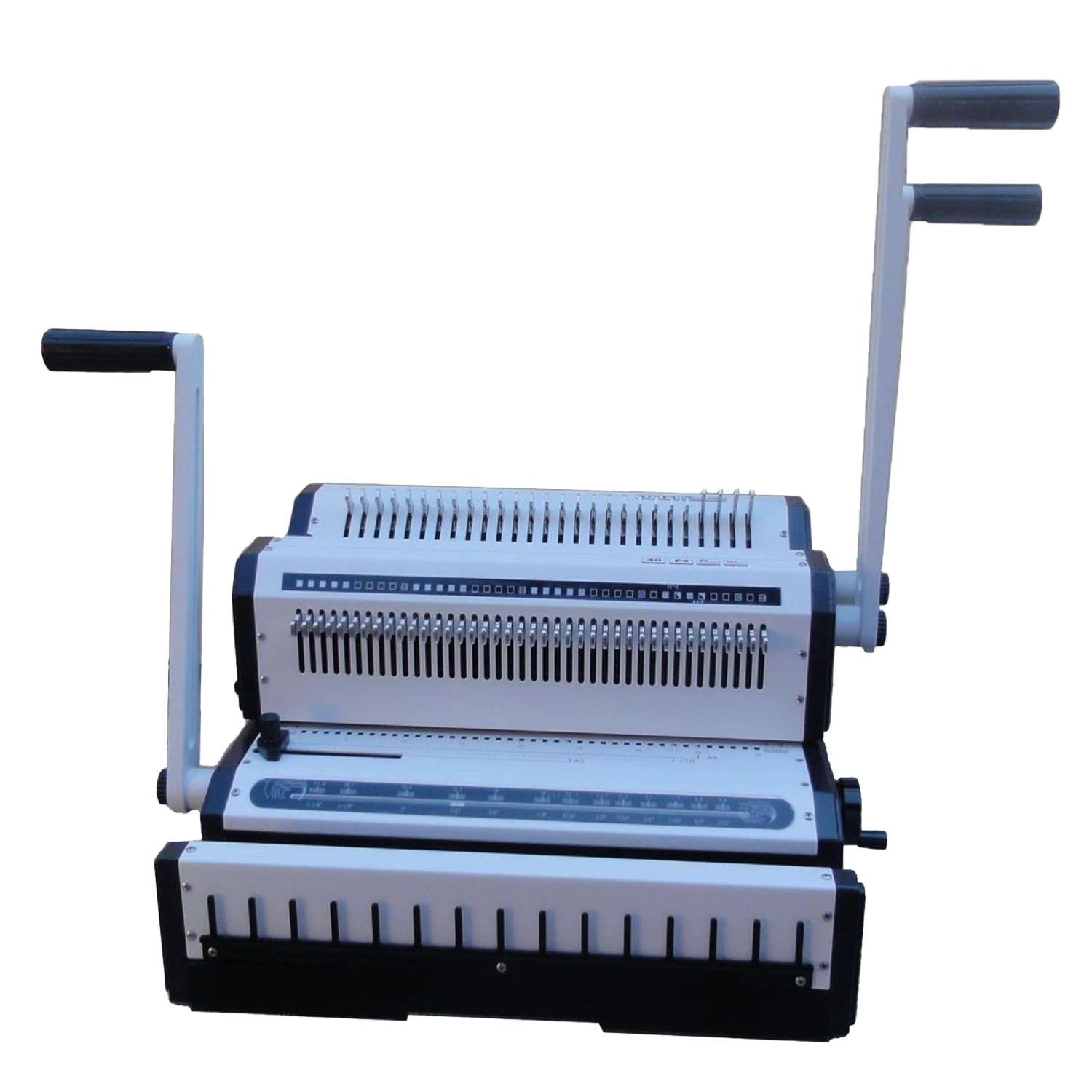

Okoboji Wiro Binder Punch W25A 3:1

Okoboji Wiro Binder Punch WW2500

Okoboji Wiro Binder W20 A4

KEY FEATURES

- Electric automation eliminates manual labour whilst delivering consistent professional results for high-volume document binding requirements in busy Indian offices.

- 25-sheet punching capacity handles substantial document volumes efficiently, reducing processing time and increasing workplace productivity significantly.

- Adjustable margin settings of 2.5mm, 4.5mm, and 6.5mm provide precise customisation for different document types and professional formatting standards.

- F4 paper size compatibility ensures seamless integration with standard Indian office paper formats and existing document workflows.

- Dual voltage operation (240V/110V, 50/60Hz) offers flexible installation options suitable for various Indian electrical configurations and international compatibility.

- Sturdy construction with 31.8kg weight provides exceptional stability during operation whilst maintaining compact 430x450x200mm footprint for space-efficient placement.

- Disengageable movable cutters allow selective hole punching for shorter documents, enhancing versatility and reducing waste in diverse applications.

FREQUENTLY ASKED QUESTIONS

What types of documents work best with the Okoboji DW600 wiro binding machine?

The DW600 excels with corporate reports, training manuals, presentations, calendars, notebooks, and academic materials requiring professional binding that allows 360-degree page rotation and flat-lay capability.

How does the electric operation improve efficiency compared to manual binding machines?

Electric operation reduces punching time to 1.5 seconds per cycle, eliminates physical strain, ensures consistent hole spacing, and allows operators to process up to 24,000 sheets per hour depending on workflow organisation.

Which hole pitch configuration should I choose for different document types?

Use NO.2 (27pin) for standard office documents, NO.4 (40pin) for thicker reports and manuals, and NO.11/NO.12 (37+1pin) for calendars and speciality applications requiring specific wire loop spacing.

What maintenance procedures keep the Okoboji DW600 operating at peak performance?

Regular cleaning of punch waste, monthly lubrication of moving parts, periodic inspection of cutting dies, and annual professional servicing ensure optimal performance and extend machine lifespan significantly.

How do I determine the correct margin setting for my documents?

Use 2.5mm for tight binding of thin documents, 4.5mm for standard office papers and reports, and 6.5mm for thick documents or when additional white space improves document appearance.

Does Okoboji provide technical support and spare parts availability in India?

Yes, Okoboji maintains comprehensive technical support through authorised service centres across major Indian cities, with genuine spare parts readily available and trained technicians for prompt service assistance.

Can this machine handle different paper weights and cardstock materials?

The DW600 efficiently processes standard 70-80gsm office paper, heavier cardstock up to 200gsm, and laminated covers, making it versatile for diverse document binding requirements in professional environments.

What safety features protect operators during high-volume binding operations?

Built-in safety mechanisms include automatic power cutoff, protective guards around cutting areas, stable base design preventing tip-over, and emergency stop functionality for operator protection during extended use.

How does wiro binding compare to comb binding for professional document presentation?

Wiro binding offers superior durability, 360-degree page rotation, flat-lay capability, professional appearance, and resistance to damage, making it ideal for documents requiring frequent handling and reference.

What installation requirements and space considerations apply to the DW600?

The machine requires stable table surface supporting 35kg, access to appropriate electrical supply, 1 metre clearance for operation, adequate lighting, and proper ventilation for optimal performance and safety.

Customers also bought

Okoboji Creasing and Perforation Rotary Electric A3

Okoboji Paper Cutter A4 Metal Body

Okoboji Perfect Binder A3 Side Glue