Okoboji Badge Slide Mould Round 75mm

SPECIFICATIONS

PRODUCT VIDEO

PRODUCT DESCRIPTION

The Okoboji Badge Slide Mould Round 75mm represents the ultimate in large-format badge manufacturing technology, combining impressive 75mm dimensions with cutting-edge plastic slide plate engineering to create commanding badges that make powerful statements in professional and promotional applications. This masterfully engineered chrome plated steel mould utilises advanced slide technology to deliver exceptional performance whilst enabling smooth, efficient operation that transforms ambitious badge design concepts into reality. The substantial round format provides maximum space for sophisticated corporate branding, detailed employee credentials, or striking promotional graphics that create memorable impressions and reinforce brand identity effectively.

Specifically designed for compatibility with MA01 and MA03 badge punch machines, this premium mould addresses the most demanding requirements of India’s prestigious badge manufacturing markets. The revolutionary plastic slide plate system eliminates traditional production constraints whilst ensuring flawless operation and consistent quality throughout extended manufacturing campaigns. Whether creating distinguished executive identification badges, impactful promotional materials for major corporate events, or exclusive commemorative items for landmark occasions, this professional-grade mould delivers extraordinary results that exemplify the quality and innovation that establish Okoboji as the premier choice for discerning badge manufacturers throughout India.

Upgrade Your Experience

Okoboji Badge Magentic Mould Oval 57x45mm

Okoboji Badge Magentic Mould Round 58mm

Okoboji Die Cutter for Badge Round 75mm

Okoboji Die Cutter for Badge Square 55x55mm

Okoboji Punch for Badge Magnetic MA05

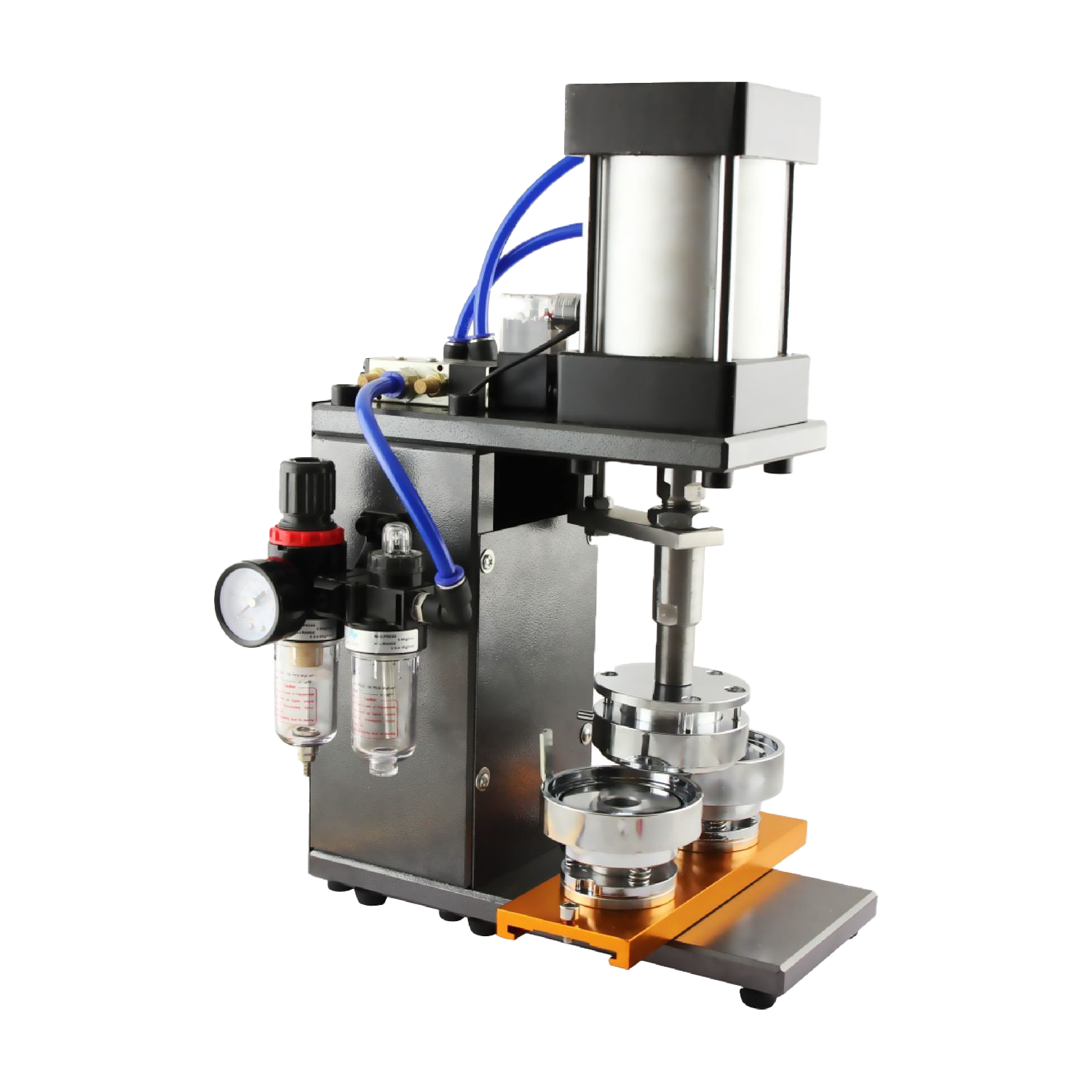

Okoboji Punch for Badge Pneumatic MAQ

Okoboji Punch for Badge Slide MA01

Okoboji Punch for Badge Slide MA03

KEY FEATURES

- Extra-large 75mm round format provides maximum space for sophisticated corporate logos, detailed employee credentials, and impactful promotional messaging.

- Premium chrome plated steel construction ensures exceptional durability and maintains pristine appearance throughout the most demanding commercial production environments.

- Revolutionary plastic slide plate system enables instantaneous operation with smooth, effortless mould changes that maximise production efficiency dramatically.

- Precision engineering guarantees perfect extra-large round badge formation with consistent dimensions and professional finish quality throughout extended campaigns.

- Universal compatibility with MA01 and MA03 badge punch machines provides maximum production flexibility and optimal equipment utilisation for diverse applications.

- Okoboji's proven manufacturing excellence delivers reliable, high-performance tooling that gives Indian badge producers decisive competitive advantages in premium markets.

- Advanced slide track technology minimises operator effort and enables rapid changeovers between different extra-large badge designs during intensive production.

- Professional-grade construction supports high-volume commercial badge production with quality standards that exceed demanding corporate client expectations consistently.

FREQUENTLY ASKED QUESTIONS

What premium applications justify the investment in this extra-large 75mm slide mould?

The 75mm format is ideal for executive identification badges, VIP access credentials, premium promotional materials, commemorative awards, and high-end corporate recognition items requiring maximum visual impact.

How does the plastic slide plate system benefit extra-large badge production operations?

The smooth slide operation eliminates the mechanical stress and positioning challenges common with extra-large moulds, ensuring consistent quality and reducing operator fatigue during extended production.

What design possibilities does the 75mm round format offer over smaller badge sizes?

The expanded space allows for photographic elements, detailed security features, complex multi-colour designs, comprehensive text information, and sophisticated branding elements.

Can this Okoboji slide mould maintain precision during intensive extra-large badge production?

Yes, the precision-engineered construction and robust slide system ensure consistent badge formation with uniform dimensions throughout the most demanding commercial production requirements.

What advanced badge materials and security features are compatible with this large slide mould?

The mould accommodates high-resolution photography, holographic elements, security laminates, RFID components, magnetic strips, and other advanced features used in premium badge applications.

How does the slide track operation ensure consistent quality during extra-large badge manufacturing?

The precision-machined slide track provides secure, repeatable positioning that eliminates the positioning variations and quality issues associated with traditional mounting systems.

What specialised maintenance procedures are recommended for this premium extra-large slide mould?

Regular cleaning with professional-grade solvents, lubrication of slide components, and periodic inspection of track condition will ensure optimal performance and extended operational life.

Does Okoboji provide specialised support for extra-large format slide badge production applications?

Okoboji offers comprehensive technical support including design consultation, production optimisation guidance, and specialised training for extra-large format badge manufacturing.

How does this slide mould's performance compare to international alternatives for premium badge production?

Okoboji's precision manufacturing and quality control meet international standards whilst providing better value and local support compared to imported alternatives.

What quality control measures ensure consistent extra-large badge production with this premium slide mould?

Strict manufacturing tolerances, precision machining processes, comprehensive testing protocols, and rigorous quality assurance guarantee reliable performance and professional results consistently.

Customers also bought

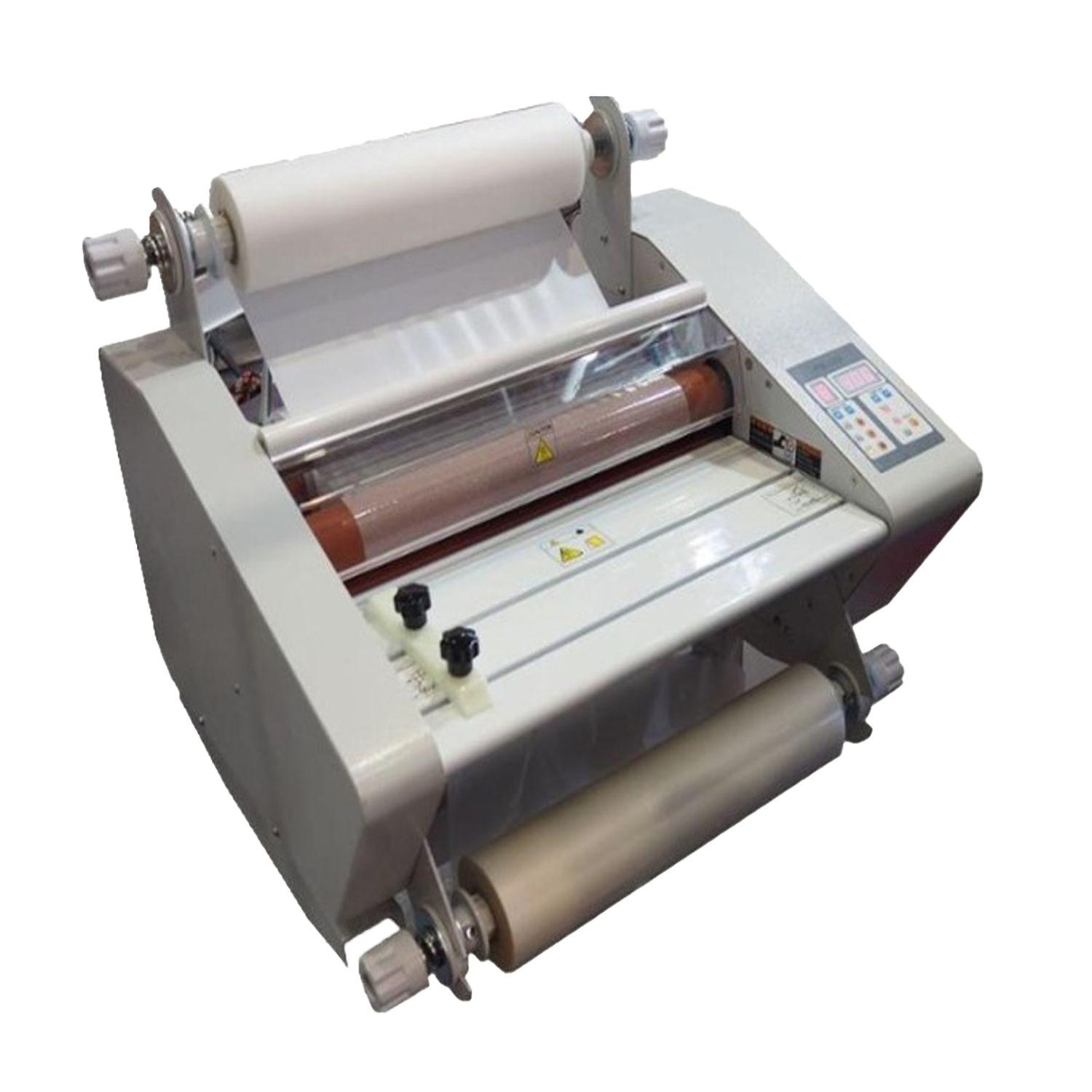

Okoboji Cold Laminator Desktop LBS1000

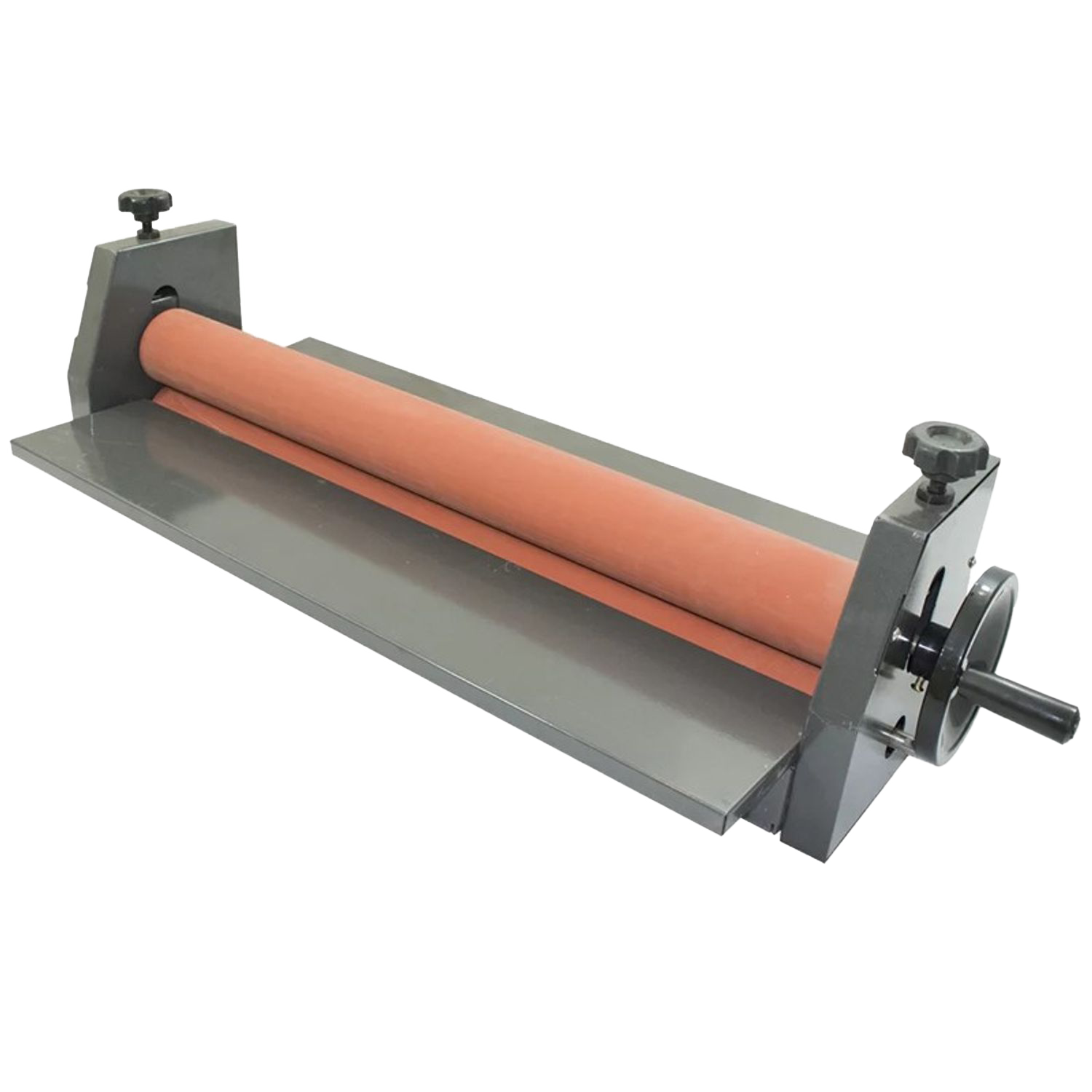

Okoboji Corner Cutter Manual S100

Okoboji Okoboji Thermal Roll Laminator FM360 360mm