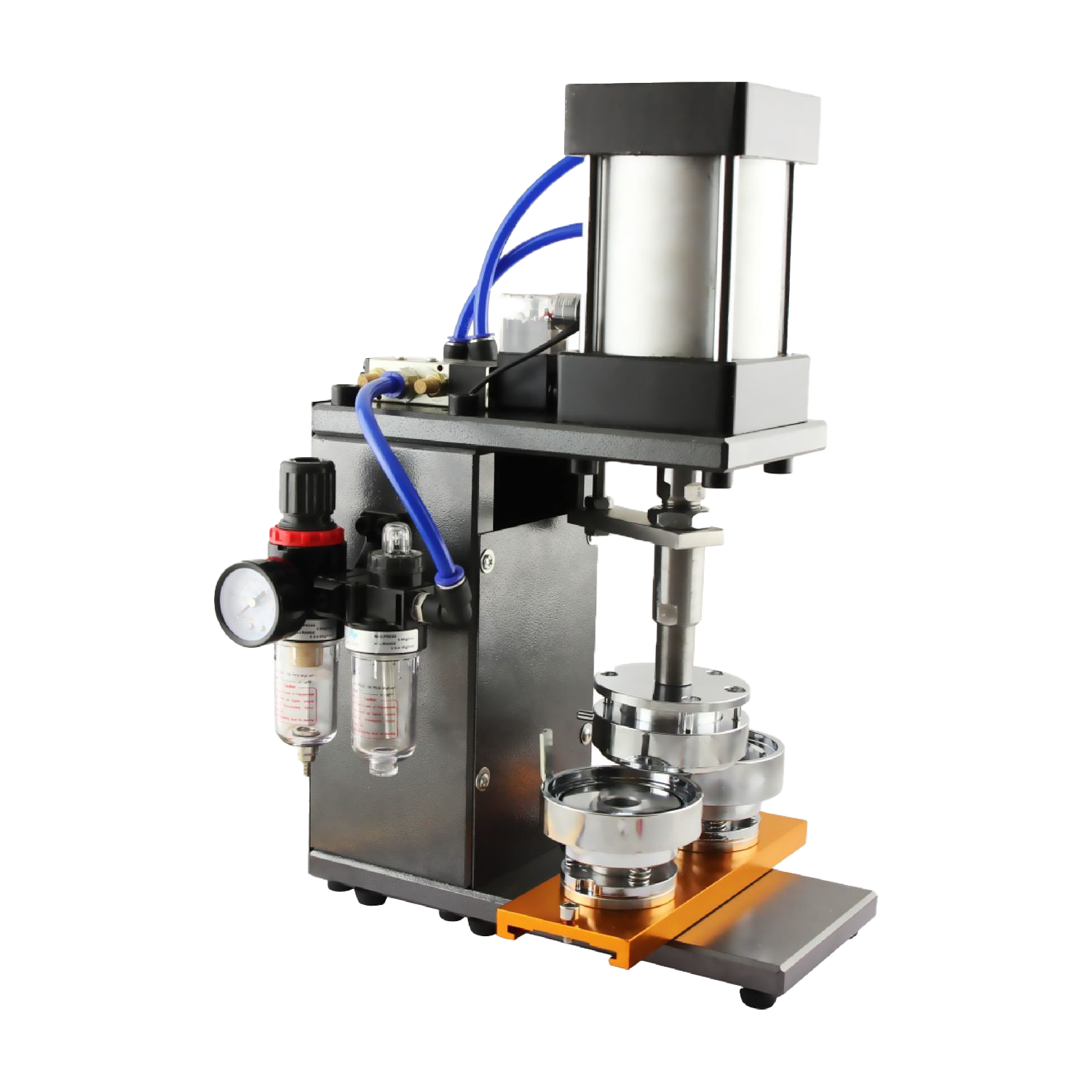

Okoboji Badge Slide Mould Round 58mm

SPECIFICATIONS

PRODUCT VIDEO

PRODUCT DESCRIPTION

The Okoboji Badge Slide Mould Round 58mm represents the pinnacle of large-format badge manufacturing technology, combining substantial 58mm dimensions with advanced slide plate engineering to create impressive badges that command attention in professional environments. This expertly crafted chrome plated steel mould utilises innovative plastic slide plate technology to deliver exceptional performance, enabling smooth, efficient operation that dramatically improves production workflows. The expanded round format provides generous space for detailed corporate branding, comprehensive employee information, or striking promotional graphics whilst maintaining the precision and reliability that characterise professional badge manufacturing.

Engineered specifically for compatibility with MA01 and MA03 badge punch machines, this mould addresses the growing demand for larger, more impactful badges in India’s corporate and promotional markets. The revolutionary plastic slide plate system transforms traditional production constraints into streamlined operations, enabling fast track changeovers and consistent quality throughout extended manufacturing campaigns. Whether creating executive identification badges, premium promotional materials for major corporate events, or distinctive commemorative items, this professional-grade mould delivers outstanding results that showcase Okoboji’s commitment to innovation and customer success in the competitive Indian badge manufacturing industry.

Upgrade Your Experience

Okoboji Badge Magentic Mould Oval 57x45mm

Okoboji Badge Slide Mould Round 44mm

Okoboji Die Cutter for Badge Oval 57x45mm

Okoboji Die Cutter for Badge Round 37mm

Okoboji Die Cutter for Badge Square 35x35mm

Okoboji Punch for Badge Magnetic MA05

Okoboji Punch for Badge Pneumatic MAQ

Okoboji Punch for Badge Slide MA03

KEY FEATURES

- Large 58mm round format provides generous space for detailed corporate logos, comprehensive employee information, and impactful promotional messaging.

- Premium chrome plated steel construction ensures exceptional durability and maintains pristine appearance throughout demanding commercial production environments.

- Advanced plastic slide plate system enables fast track operation with smooth, effortless mould changes that maximise production efficiency significantly.

- Precision engineering guarantees perfect large round badge formation with consistent dimensions and professional finish quality throughout extended campaigns.

- Universal compatibility with MA01 and MA03 badge punch machines provides maximum production flexibility and optimal equipment utilisation for diverse operations.

- Okoboji's proven manufacturing excellence delivers reliable, high-performance tooling that gives Indian badge producers decisive competitive advantages in premium markets.

- Innovative slide track technology reduces operator effort and enables rapid changeovers between different large badge designs during intensive production.

- Professional-grade construction supports high-volume commercial badge production with quality standards that meet demanding corporate client requirements.

FREQUENTLY ASKED QUESTIONS

What advantages does the larger 58mm size offer for professional badge applications?

The expanded dimensions provide significantly more design space for detailed logos, comprehensive text information, photographic elements, and complex graphics whilst maintaining excellent readability and visual impact.

How does the plastic slide plate system enhance large badge production efficiency?

The smooth slide operation eliminates friction and resistance common with larger moulds, enabling effortless changeovers and reducing operator fatigue during extended production runs.

What types of premium applications work best with this 58mm round slide mould?

This size is ideal for executive identification badges, security access credentials, premium promotional materials, conference name badges, and high-end corporate recognition items.

Can this Okoboji slide mould maintain precision during intensive large badge production?

Yes, the precision-engineered construction and robust slide system ensure consistent badge formation with uniform dimensions throughout demanding commercial production campaigns.

What advanced badge materials are compatible with this large slide mould system?

The mould accommodates high-resolution prints, security laminates, holographic elements, magnetic strips, and other advanced features used in premium badge applications.

How does the slide track operation ensure accuracy during large badge manufacturing?

The precision-machined slide track provides consistent positioning and secure mounting that eliminates the alignment variations common with traditional mounting systems.

What specialised maintenance procedures are recommended for this large slide mould?

Regular cleaning of slide tracks, lubrication of moving components, and periodic inspection of plastic plate condition will ensure optimal performance and extended operational life.

Does Okoboji provide technical support for optimising large-format slide badge production?

Okoboji offers comprehensive assistance including production guidance, maintenance recommendations, and troubleshooting support specifically for large-format badge manufacturing applications.

How does this slide mould's performance compare to magnetic alternatives for large badge production?

Slide systems offer smoother operation, reduced mechanical stress, and more consistent positioning particularly advantageous for larger, heavier badge materials and high-volume production.

What quality assurance measures ensure consistent large badge production with this slide mould?

Strict manufacturing tolerances, precision machining processes, comprehensive testing protocols, and continuous quality monitoring guarantee reliable large badge formation and professional results.

Customers also bought

Okoboji Cold Laminator Elec Pneumatic 63" 1600mm

Okoboji Paper Cutter Digital Electric 490mm LCD

Okoboji Wiro Binder HD W20A A4