Okoboji Badge Magentic Mould Square 35x35mm

SPECIFICATIONS

PRODUCT VIDEO

PRODUCT DESCRIPTION

The Badge Magnetic Mould Square 35x35mm introduces innovative geometric design possibilities to India’s dynamic badge manufacturing industry, offering a distinctive alternative to traditional round formats. This precision-engineered square mould creates compact 35x35mm badges that provide unique visual appeal and efficient design utilisation for modern corporate branding, contemporary promotional items, and stylish identification applications. The magnetic mounting system transforms production efficiency by eliminating complex mould change procedures and enabling seamless transitions between different badge formats during varied manufacturing requirements.

Constructed from premium chrome-plated steel, this magnetic mould delivers exceptional dimensional accuracy and surface quality essential for professional badge production operations. The chrome plating ensures superior corrosion resistance and non-stick properties that guarantee consistent badge release whilst maintaining precise tolerances throughout extended manufacturing cycles. Indian badge manufacturers, contemporary promotional companies, modern corporate suppliers, and innovative design-focused producers will appreciate how this square format offers fresh aesthetic possibilities whilst maintaining cost-effectiveness and production efficiency demanded by competitive market conditions across India’s evolving promotional products sector.

Upgrade Your Experience

Okoboji Badge Magentic Mould Oval 57x45mm

Okoboji Badge Slide Mould Round 25mm

Okoboji Badge Slide Mould Round 44mm

Okoboji Die Cutter for Badge Round 75mm

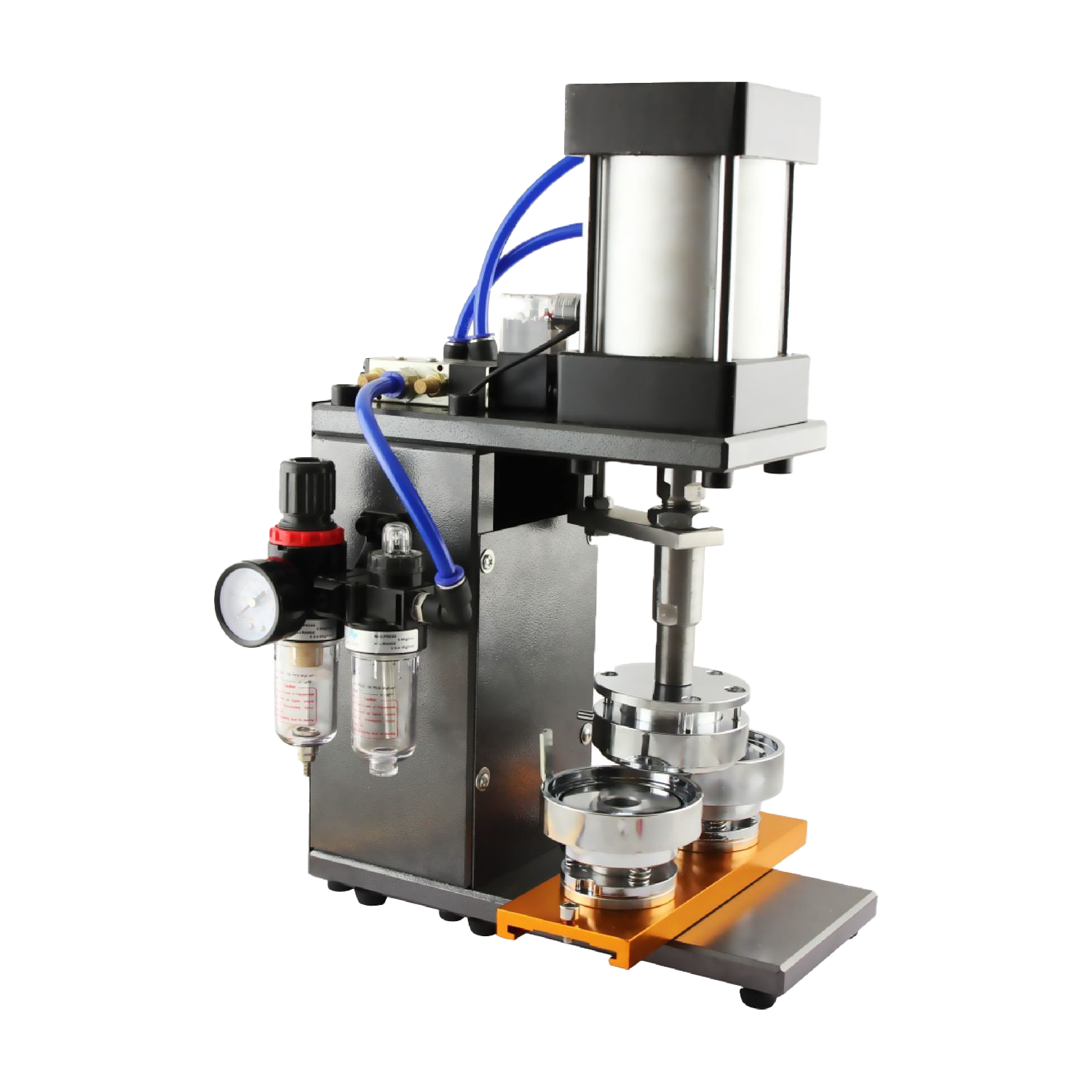

Okoboji Punch for Badge Magnetic MA05

Okoboji Punch for Badge Pneumatic MAQ

Okoboji Punch for Badge Slide MA01

Okoboji Punch for Badge Slide MA03

KEY FEATURES

- Premium chrome-plated steel construction ensures exceptional durability and superior corrosion resistance for reliable performance in Indian manufacturing environments.

- Advanced magnetic mounting system enables tool-free mould changes in seconds, dramatically improving production efficiency and reducing operational downtime during varied production runs.

- Distinctive 35x35mm square dimensions create modern, contemporary badge designs that stand out from traditional round formats for innovative branding applications.

- Complete compatibility with MA05, MA02, and MAQ badge-making machines ensures seamless integration with popular Indian badge production equipment and existing workflows.

- Professional chrome finish provides optimal badge release properties whilst maintaining dimensional precision across thousands of production cycles.

- Compact square design offers efficient material utilisation and cost-effective production for modern promotional campaigns and contemporary corporate applications.

- Industrial-grade manufacturing quality ensures consistent output meeting professional standards expected by innovative Indian corporate and educational clients.

- Fast-track magnetic operation reduces setup complexity and enables rapid production changeovers for efficient multi-format badge manufacturing operations.

FREQUENTLY ASKED QUESTIONS

What advantages does the square format offer over traditional round badge designs?

Square badges provide distinctive geometric appeal, modern aesthetic, efficient use of design space, better text alignment options, and contemporary appearance that differentiates brands effectively.

How does this compact 35x35mm size benefit specific badge applications?

The compact dimensions are ideal for minimalist designs, modern corporate identification, security badges, membership cards, and applications requiring subtle, professional appearance.

Can this Okoboji magnetic mould handle precision requirements for detailed square badge designs?

Yes, the precision-engineered construction ensures consistent square formation with sharp corners and uniform dimensions essential for professional square badge production.

What design considerations work best with the square 35x35mm format?

Geometric layouts, centered logos, grid-based designs, modern typography, and minimalist aesthetics work exceptionally well with the square format's contemporary appeal.

How does the magnetic system improve efficiency in square badge production operations?

Magnetic mounting eliminates alignment challenges common with square formats, ensuring consistent corner positioning and reducing setup time between different badge designs.

What badge materials are most compatible with this square magnetic mould?

The mould works excellently with all standard badge materials including paper substrates, plastic films, security laminates, and protective coatings used in professional badge manufacturing.

How does chrome plating enhance the mould's performance for precision square badge production?

Chrome plating provides smooth release properties, reduces friction during square badge formation, maintains dimensional accuracy, and extends operational life significantly.

Does Okoboji provide design guidance for optimising square badge layouts and aesthetics?

Okoboji offers technical support including design recommendations, layout optimisation guidance, and aesthetic consultation for square badge applications.

What production volumes can this square mould handle for commercial badge manufacturing?

This mould is designed for high-volume commercial production and can reliably handle thousands of square badge cycles whilst maintaining consistent quality.

How does this square mould's quality compare to imported alternatives in the Indian market?

Okoboji's precision manufacturing, quality materials, and rigorous testing deliver superior performance and reliability compared to many imported square badge moulds.

Customers also bought

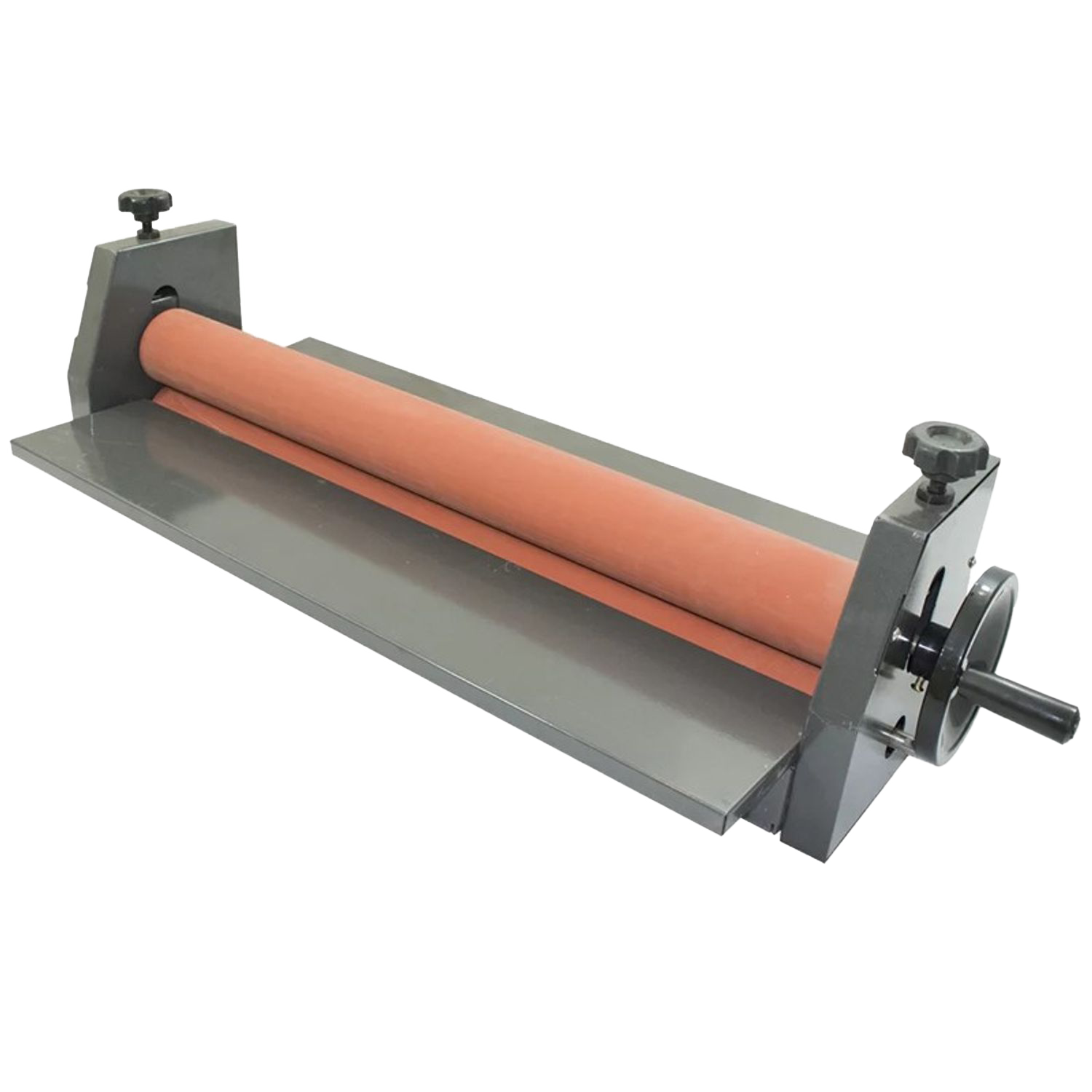

Okoboji Cold Laminator Desktop LBS1000

Okoboji Corner Cutter Electric DT W Cover WH08C

Okoboji ID Card Fusing A6 20