Okoboji Badge Magentic Mould Round 58mm

SPECIFICATIONS

PRODUCT VIDEO

PRODUCT DESCRIPTION

The Badge Magnetic Mould Round 58mm delivers professional-grade manufacturing capability for India’s expanding promotional products and corporate identification market. This precision-engineered circular mould produces large-format 58mm diameter badges that provide generous design space for detailed corporate branding, comprehensive information display, and sophisticated visual presentations required by premium badge applications. The advanced magnetic mounting system revolutionises production efficiency by enabling instantaneous mould changes without tools, significantly reducing setup time and maximising productive capacity during multi-format badge manufacturing operations.

Constructed from superior chrome-plated steel, this magnetic mould ensures exceptional durability, corrosion resistance, and dimensional stability essential for high-volume badge production environments. The premium chrome finish provides smooth, non-stick surface properties that guarantee clean badge release whilst maintaining precise tolerances throughout extended manufacturing cycles. Indian badge manufacturers, corporate suppliers, conference organisers, and premium promotional merchandise producers will find this larger 58mm format perfectly suited for executive badges, detailed identification credentials, premium promotional items, and sophisticated branding applications that demand both visual impact and professional presentation quality.

Upgrade Your Experience

Okoboji Badge Magentic Mould Oval 57x45mm

Okoboji Badge Slide Mould Round 25mm

Okoboji Badge Slide Mould Round 58mm

Okoboji Die Cutter for Badge Round 58mm

Okoboji Die Cutter for Badge Square 35x35mm

Okoboji Punch for Badge Magnetic MA05

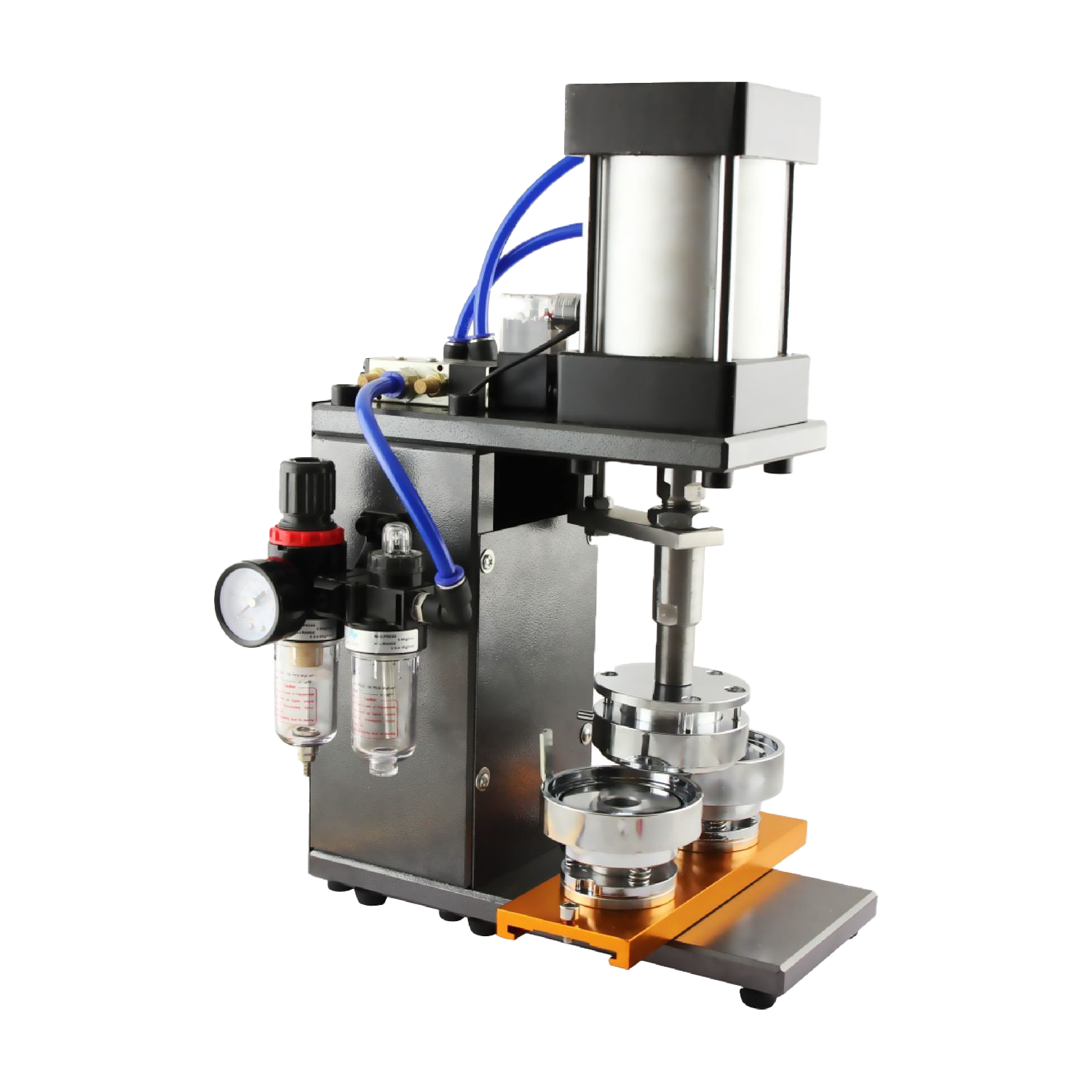

Okoboji Punch for Badge Pneumatic MAQ

Okoboji Punch for Badge Slide MA01

KEY FEATURES

- Superior chrome-plated steel construction provides exceptional durability and corrosion resistance for demanding Indian manufacturing environments and continuous production operations.

- Advanced magnetic mounting system enables tool-free mould changes in seconds, maximising production efficiency and reducing operational costs for multi-format badge production.

- Large 58mm diameter accommodates detailed corporate logos, comprehensive text information, and sophisticated design elements for premium badge applications.

- Complete compatibility with MA05, MA02, and MAQ badge-making machines ensures seamless integration with established Indian production equipment and existing workflows.

- Professional chrome finish guarantees smooth badge release properties whilst maintaining dimensional precision across extended high-volume production cycles.

- Large format design ideal for executive identification, conference badges, premium promotional merchandise, and detailed corporate branding applications.

- Industrial-grade manufacturing standards ensure consistent quality output meeting international badge production requirements and Indian professional standards.

- Fast-track magnetic operation reduces training requirements and enables rapid production changeovers for efficient multi-size badge manufacturing operations.

FREQUENTLY ASKED QUESTIONS

What advantages does the larger 58mm size offer for professional badge applications?

The 58mm diameter provides significantly more design space for detailed logos, comprehensive text information, photographic elements, and complex graphics whilst maintaining excellent readability and visual impact.

How does this magnetic mould improve production efficiency in large-scale badge manufacturing?

The magnetic system eliminates tool requirements and reduces changeover time to seconds, enabling rapid production of different badge designs and significantly increasing overall throughput.

What types of professional applications work best with this 58mm round format?

This size is ideal for executive identification badges, security access badges, trade show promotional materials, conference name badges, and premium corporate recognition items.

Can this Okoboji mould handle the precision requirements of high-end corporate badge production?

Yes, the precision-engineered construction and chrome plated finish ensure consistent quality and professional appearance that meets the demanding standards of premium corporate clients.

What badge materials and finishes are compatible with this large magnetic mould?

The mould works excellently with all professional badge materials including high-resolution prints, laminated graphics, metallic foils, security features, and protective coatings.

How does the magnetic mounting system ensure accuracy during intensive production runs?

Precision-machined magnetic contact points provide secure, repeatable positioning that eliminates the alignment variations and quality issues associated with traditional mounting systems.

What maintenance procedures maximise the operational life of this chrome plated mould?

Regular cleaning with appropriate solvents, maintaining debris-free magnetic surfaces, and periodic inspection of chrome condition will ensure optimal performance and extended service life.

Does Okoboji provide technical support for optimising large-format badge production?

Okoboji offers comprehensive technical assistance including production optimisation guidance, troubleshooting support, and operational training to maximise customer success.

How does this mould's durability compare to imported alternatives in the Indian market?

Okoboji's premium materials, precision manufacturing, and rigorous quality control deliver superior durability and performance compared to many imported alternatives.

What quality assurance measures ensure consistent large badge production with this mould?

Strict manufacturing tolerances, precision machining processes, comprehensive testing protocols, and continuous quality monitoring guarantee reliable badge formation and professional results.

Customers also bought

Okoboji Glue Binding Machine B40M

Okoboji Paper Half Cutting 600mm HC600

Okoboji Paper Ream Cutter 858 A3