Okoboji Badge Magentic Mould Round 44mm

SPECIFICATIONS

PRODUCT VIDEO

PRODUCT DESCRIPTION

The Badge Magnetic Mould Round 44mm represents an essential production tool for India’s thriving badge manufacturing industry, offering the perfect balance between compact size and functional design space. This precision-engineered circular mould creates standard 44mm diameter badges that serve as the industry benchmark for promotional items, corporate identification, and event credentials across the Indian market. The magnetic mounting technology transforms traditional badge production by eliminating time-consuming mould changes and enabling seamless transitions between different badge formats during production runs.

Manufactured using premium chrome-plated steel, this magnetic mould ensures exceptional dimensional accuracy and surface quality essential for professional badge production. The chrome plating delivers superior corrosion resistance and non-stick properties that guarantee clean badge release whilst maintaining precise tolerances throughout extended manufacturing cycles. Indian badge producers, promotional merchandise companies, school suppliers, and corporate gift manufacturers will find this 44mm round format ideal for creating cost-effective badges that meet the diverse requirements of educational institutions, small businesses, political campaigns, and promotional events throughout the Indian subcontinent.

Upgrade Your Experience

Okoboji Badge Magentic Mould Round 58mm

Okoboji Badge Magentic Mould Square 55x55mm

Okoboji Die Cutter for Badge Round 75mm

Okoboji Die Cutter for Badge Square 55x55mm

Okoboji Punch for Badge Magnetic MA05

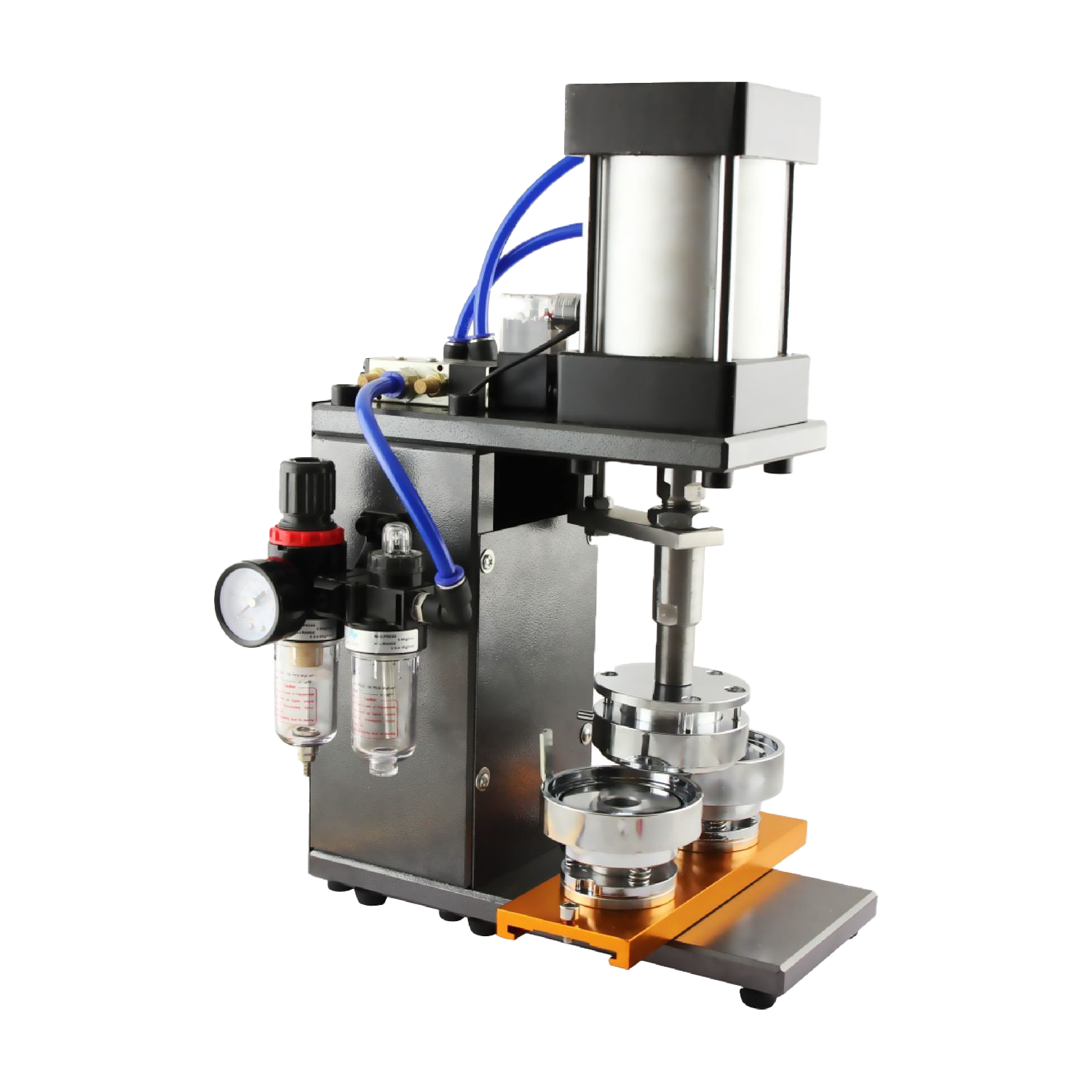

Okoboji Punch for Badge Pneumatic MAQ

Okoboji Punch for Badge Slide MA01

Okoboji Punch for Badge Slide MA03

KEY FEATURES

- Premium chrome-plated steel construction ensures long-lasting durability and exceptional corrosion resistance for reliable performance in Indian manufacturing conditions.

- Magnetic mounting system provides tool-free mould changes in under 25 seconds, dramatically improving production efficiency and reducing operational downtime.

- Standard 44mm diameter creates versatile round badges perfect for schools, small businesses, promotional campaigns, and corporate events across India.

- Universal compatibility with MA05, MA02, and MAQ badge machines ensures seamless integration with popular Indian badge-making equipment and existing workflows.

- Professional chrome finish provides smooth badge release properties whilst maintaining dimensional accuracy across thousands of production cycles.

- Compact round design offers optimal cost-effectiveness for high-volume production of standard promotional and identification badges.

- Industrial-grade manufacturing quality ensures consistent output meeting professional standards expected by Indian educational and corporate clients.

- Fast-track magnetic operation enables rapid production setup changes for efficient multi-size badge manufacturing operations.

FREQUENTLY ASKED QUESTIONS

Why is the 44mm round size particularly popular in the Indian badge market?

The 44mm diameter provides the ideal balance between sufficient space for clear logo and text presentation whilst remaining compact enough for comfortable daily wear in professional environments.

How does the magnetic system improve safety and efficiency in badge production operations?

Magnetic mounting eliminates the need for tools and reduces repetitive motions, improving operator safety whilst dramatically reducing mould changeover time and increasing production throughput.

What design considerations work best with this round 44mm badge format?

Circular designs, centered logos, curved text arrangements, and balanced layouts work exceptionally well with the round format, creating visually appealing and professional badges.

Can this Okoboji mould maintain precision during high-speed production runs?

Yes, the precision-engineered magnetic mounting system and robust steel construction ensure consistent alignment and badge quality even during intensive production campaigns.

What badge backing options work effectively with this round magnetic mould?

The mould accommodates various backing systems including pin fasteners, magnetic backs, clip attachments, and adhesive mountings commonly used in Indian badge applications.

How does chrome plating improve the mould's performance and longevity?

Chrome plating provides superior corrosion resistance, reduces friction during operation, maintains smooth surface finish, and significantly extends the mould's operational life.

What production volumes can this mould handle effectively for commercial badge manufacturing?

This mould is designed for high-volume commercial production and can reliably handle thousands of badge cycles whilst maintaining consistent quality and performance.

Does Okoboji provide replacement parts or refurbishment services for magnetic moulds?

Okoboji offers comprehensive after-sales support including maintenance guidance, replacement parts availability, and refurbishment services to maximise mould life.

How does this round mould compare to oval or square alternatives for badge applications?

Round badges offer classic appeal, universal acceptance, and work particularly well for corporate identification, whilst oval and square formats provide different aesthetic options.

What quality control procedures ensure consistent badge production with this round mould?

Strict manufacturing tolerances, precision machining, comprehensive testing, and quality assurance protocols guarantee reliable badge formation and professional results throughout the mould's service life.

Customers also bought

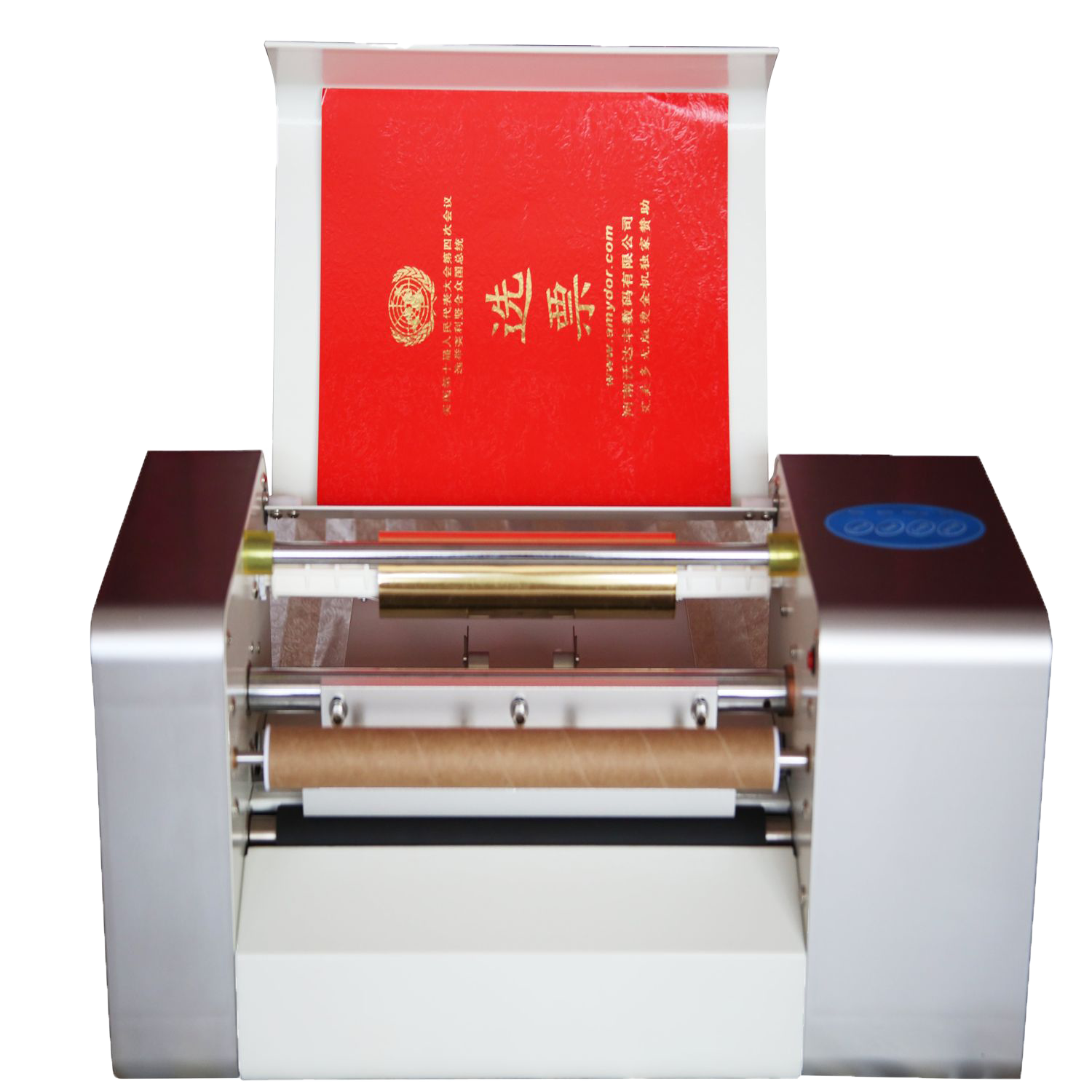

Okoboji Digital Foil Printer 350mm 360A

Okoboji Gluing Machine Hot and Cold 700mm/27.55" GM700

Okoboji PVC Tubebind Automatic TBA