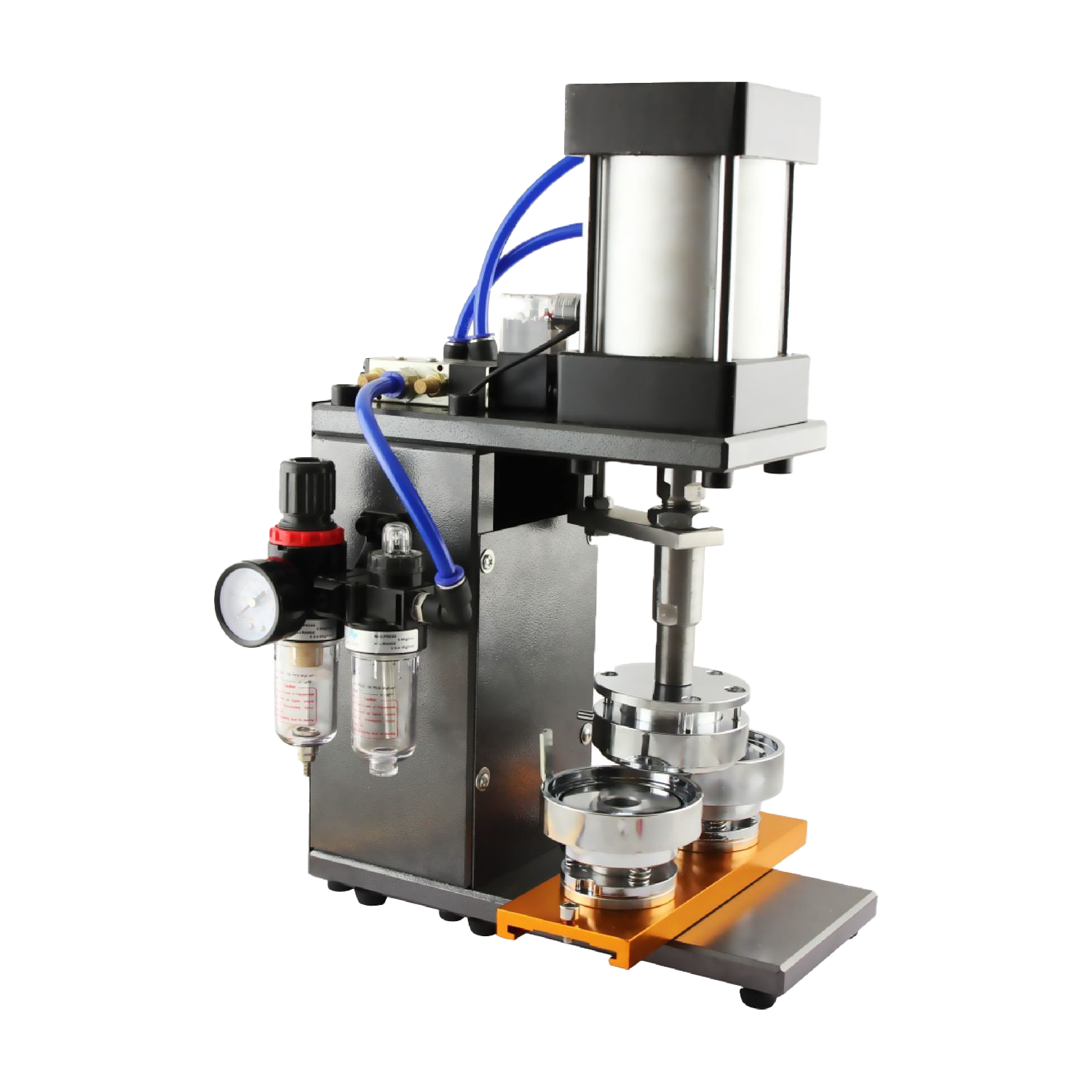

Okoboji Punch for Badge Slide MA01

SPECIFICATIONS

PRODUCT VIDEO

PRODUCT DESCRIPTION

The Okoboji Punch for Badge Slide MA01 introduces innovative slide technology to professional badge manufacturing, combining chrome plated steel construction with advanced plastic slide plate systems to deliver exceptional efficiency and precision in badge production. This expertly engineered slide badge punch machine represents a significant advancement in badge manufacturing technology, utilising innovative slide track operation that enables smooth, fast mould changes whilst maintaining the accuracy and reliability essential for commercial production environments. The MA01 system transforms traditional badge production workflows by providing effortless mould changeovers that dramatically improve production efficiency.

Specifically designed for compatibility with MA01 and MA03 slide mould systems, this versatile punch machine accommodates diverse badge production requirements whilst maintaining exceptional precision and finish quality. The innovative plastic slide plate technology provides smooth, friction-free operation that reduces wear and ensures consistent positioning throughout extended production runs. Whether producing corporate identification badges, promotional materials for marketing campaigns, or custom badges for special events, this professional-grade slide punch machine delivers outstanding results that showcase Okoboji’s commitment to engineering innovation and customer satisfaction in India’s competitive badge manufacturing industry.

Upgrade Your Experience

Okoboji Badge Magentic Mould Oval 39x31mm

Okoboji Badge Magentic Mould Round 44mm

Okoboji Badge Slide Mould Round 37mm

Okoboji Die Cutter for Badge Round 25mm

Okoboji Die Cutter for Badge Round 75mm

Okoboji Die Cutter for Badge Square 35x35mm

Okoboji Punch for Badge Magnetic MA05

Okoboji Punch for Badge Pneumatic MAQ

KEY FEATURES

- Advanced chrome plated steel construction with plastic slide plate technology provides smooth, efficient operation and exceptional durability for commercial applications.

- Innovative slide track operation enables fast, effortless mould changes that dramatically improve production efficiency compared to traditional mounting systems.

- Universal compatibility with MA01 and MA03 slide mould systems provides maximum production flexibility and comprehensive mould interchangeability options.

- Precision-engineered slide mechanism guarantees accurate badge formation with consistent positioning and professional finish quality throughout extended production campaigns.

- Professional-grade construction ensures reliable performance throughout intensive commercial production environments whilst minimising maintenance requirements significantly.

- Okoboji's proven manufacturing excellence delivers innovative slide technology that gives Indian badge manufacturers competitive advantages in efficient production markets.

- Plastic slide plate system reduces friction and wear whilst providing smooth operation that extends equipment life and maintains consistent performance.

- Robust mechanical design supports high-volume commercial badge production with fast track operation capability ideal for demanding production schedules.

FREQUENTLY ASKED QUESTIONS

What advantages does the slide track system offer compared to traditional badge punch mounting methods?

The slide track system provides smooth, effortless mould changes, reduces operator fatigue, ensures consistent positioning, and dramatically improves production efficiency through faster changeovers.

How does the plastic slide plate technology enhance badge production operations?

Plastic slide plates provide friction-free operation, reduce wear on components, ensure smooth mould movements, and extend equipment life whilst maintaining consistent performance.

Which slide mould types are compatible with the MA01 badge punch system?

The MA01 system is compatible with all MA01 and MA03 slide moulds, accommodating various badge sizes and formats whilst providing comprehensive production flexibility.

Can this Okoboji slide punch machine handle high-volume commercial badge production effectively?

Yes, the robust construction and efficient slide track operation support intensive commercial production whilst maintaining consistent quality and performance standards.

What maintenance procedures ensure optimal performance of the slide track system?

Regular cleaning of slide tracks, appropriate lubrication of moving components, and periodic inspection of plastic slide plates ensure optimal performance and extended operational life.

How does the chrome plated steel construction benefit slide system operation and longevity?

Chrome plating provides corrosion resistance, reduces friction, maintains smooth operation, and significantly extends equipment life even under intensive production conditions.

What training is required for operators to use the MA01 slide badge punch effectively?

No,the intuitive slide track operation simplifies training, with operators quickly learning efficient mould changeover techniques and proper operation procedures.

Does Okoboji provide technical support and parts availability for the MA01 slide system?

Yes,Okoboji offers comprehensive technical support including maintenance guidance, troubleshooting assistance, parts availability, and operational recommendations for optimal performance.

How does the slide system compare to magnetic alternatives for production efficiency and ease of use?

Slide systems offer smooth mechanical operation, reduced complexity, excellent control, and cost-effective maintenance whilst providing reliable production efficiency.

What quality control measures ensure consistent badge production with the MA01 slide punch system?

Precision manufacturing, consistent slide track operation, robust construction, and comprehensive testing guarantee reliable badge formation and professional results throughout production.

Customers also bought

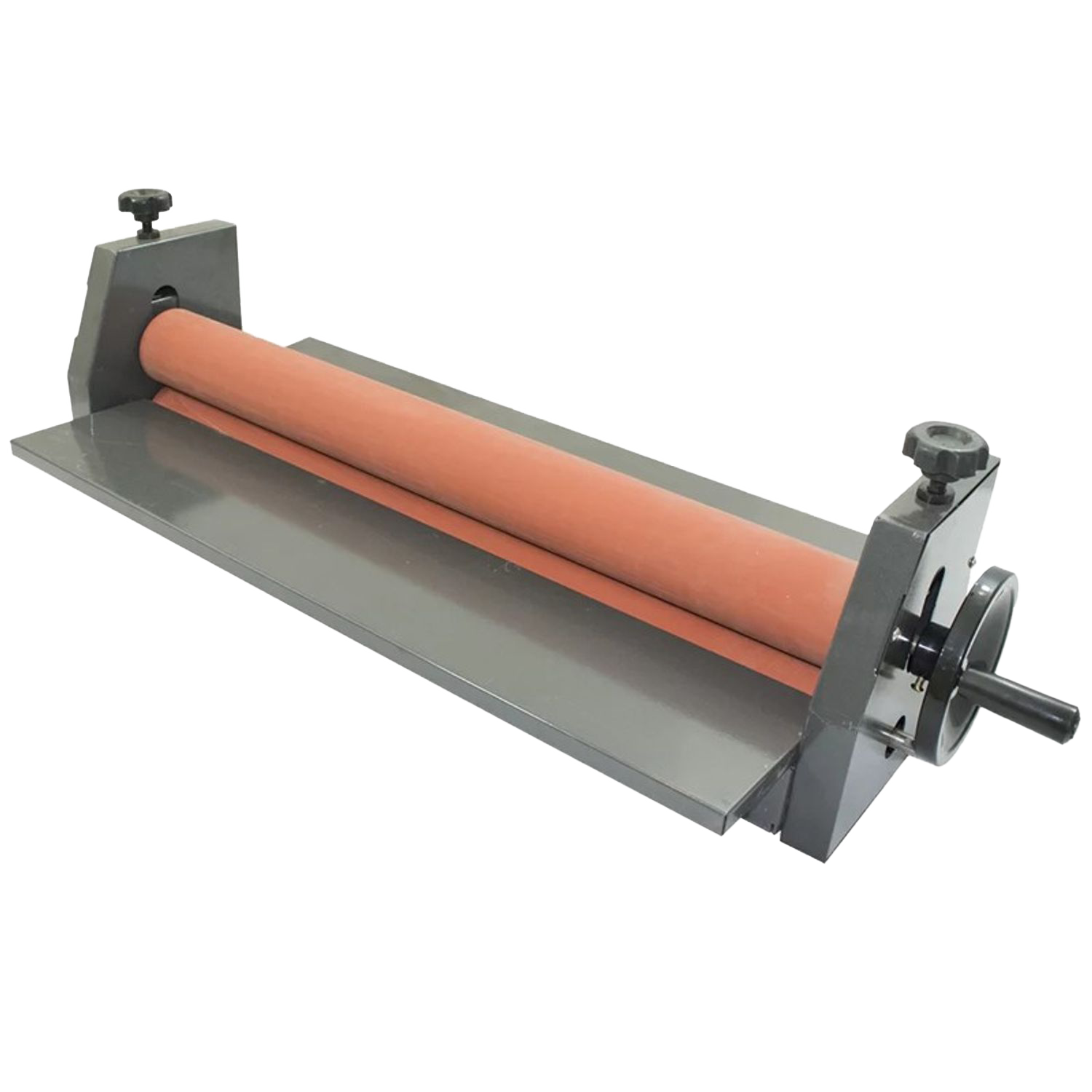

Okoboji Cold Laminator Desktop LBS1000

Okoboji Corner Cutter Manual Desktop M100

Okoboji Paper Cutter B4 Metal Body