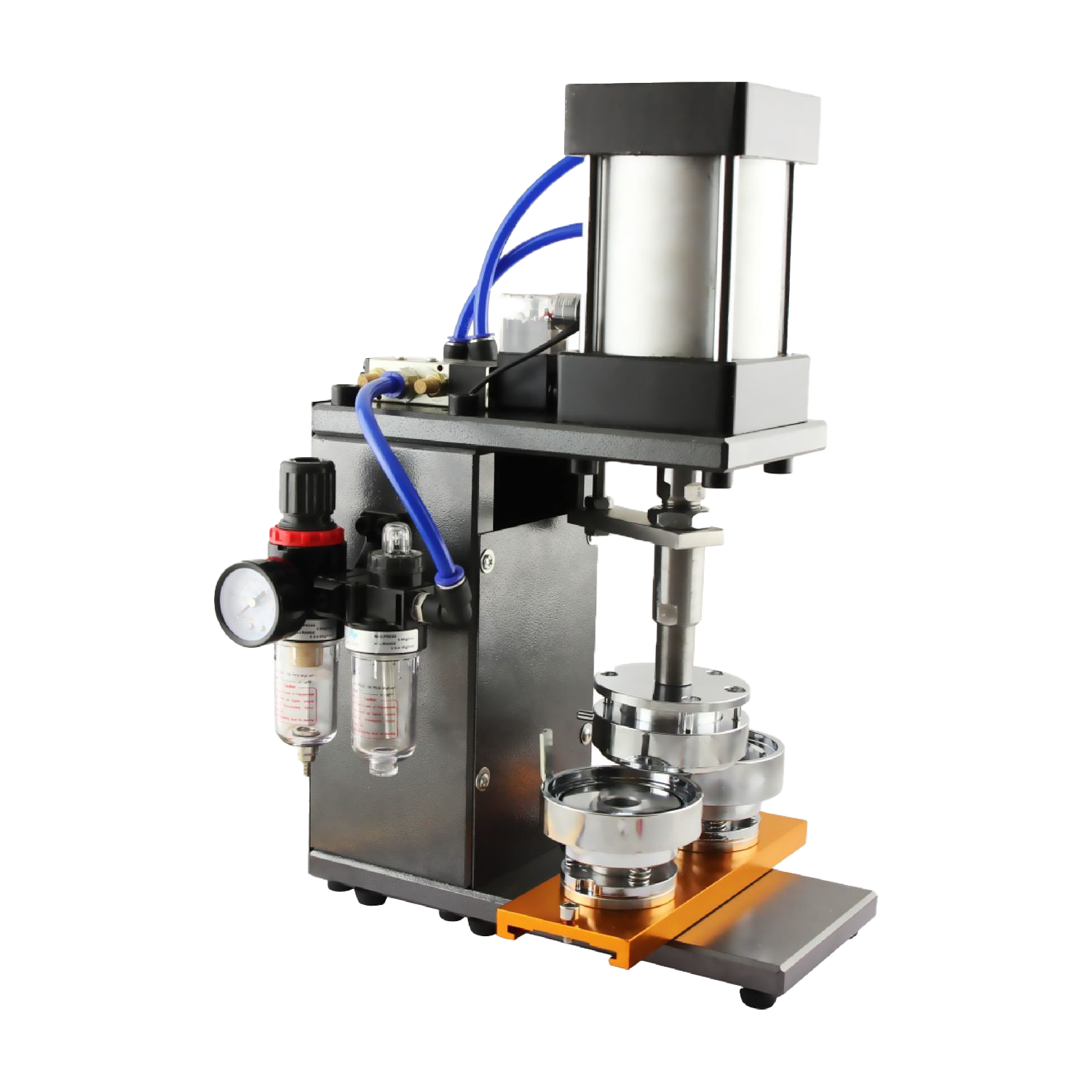

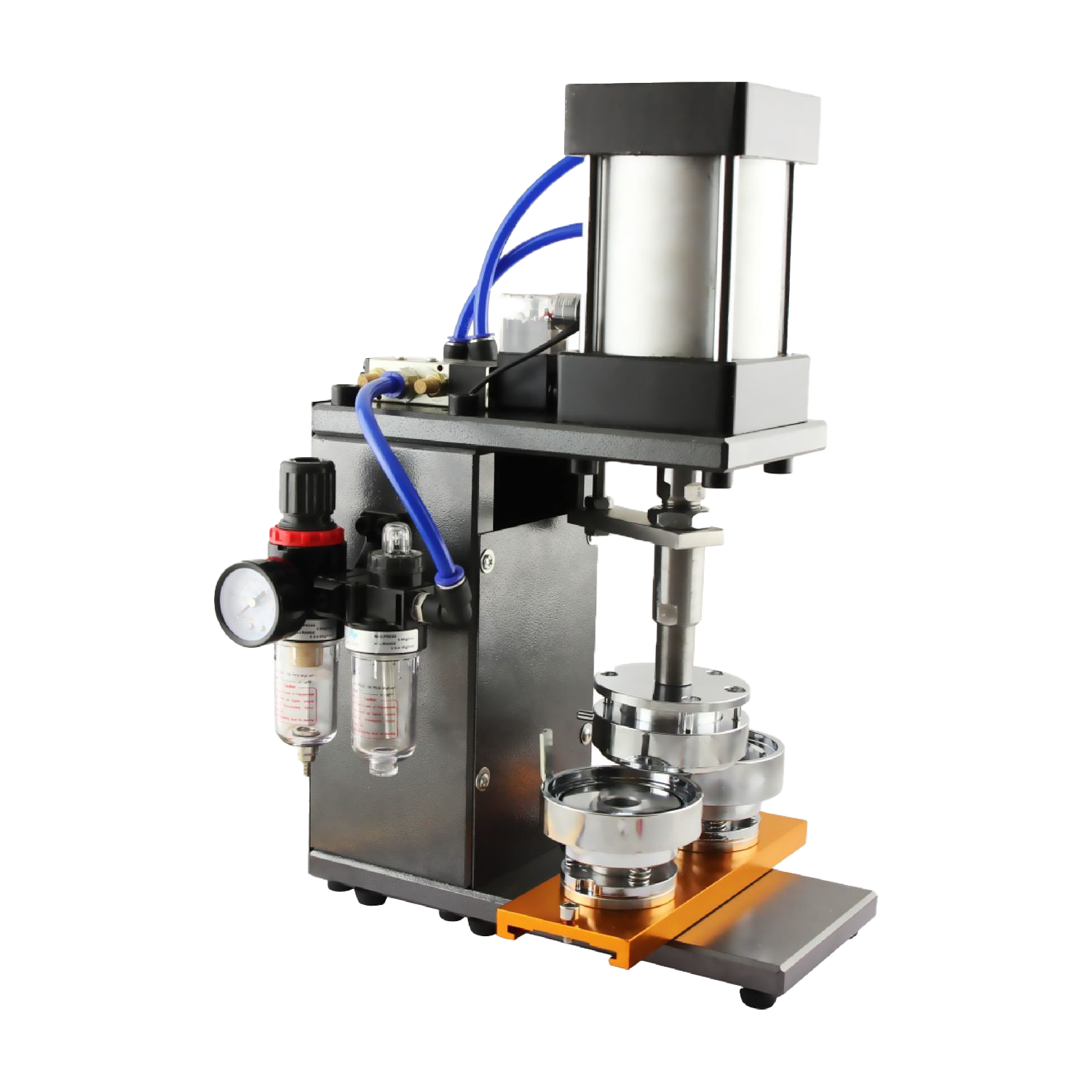

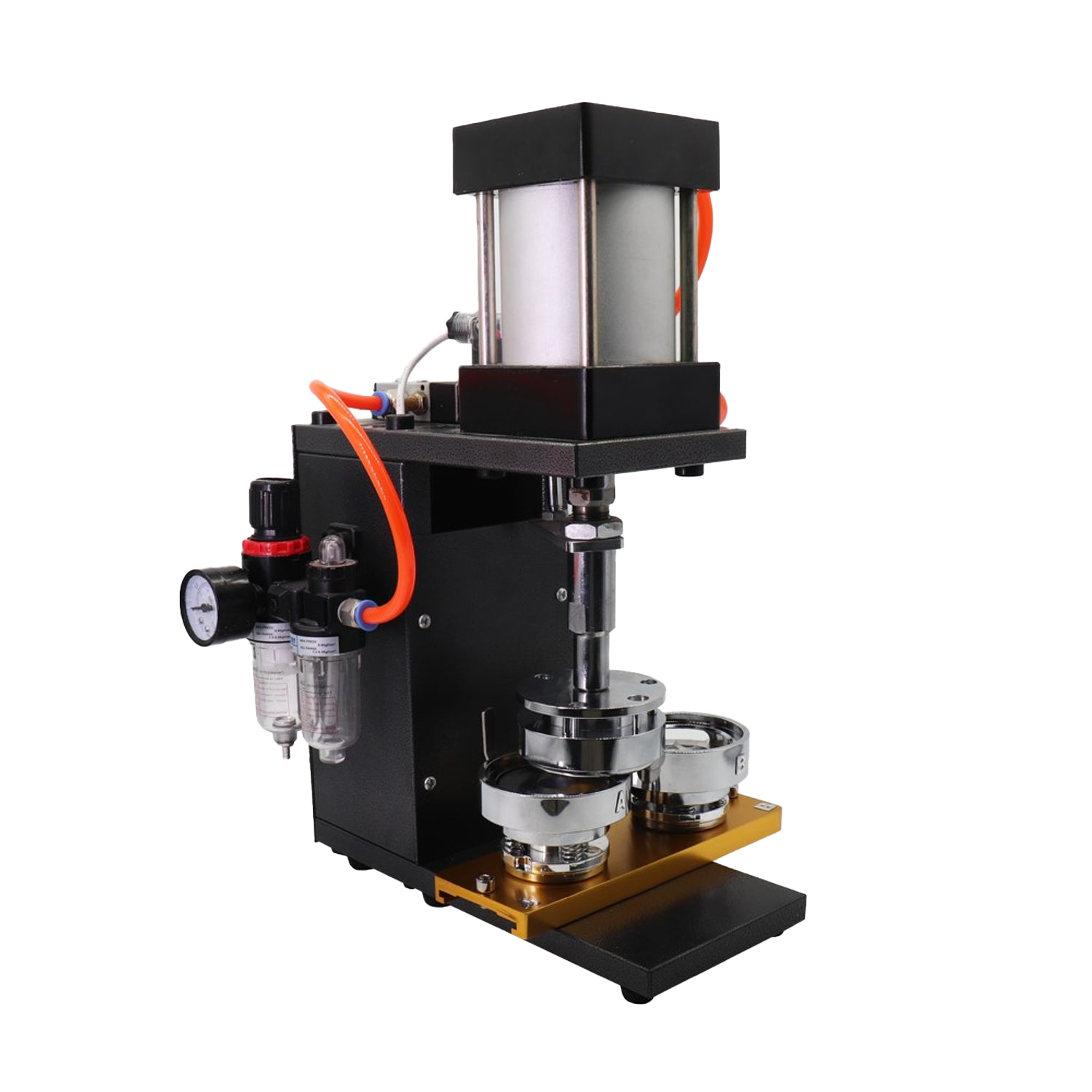

Okoboji Punch for Badge Pneumatic MAQ

SPECIFICATIONS

PRODUCT VIDEO

PRODUCT DESCRIPTION

The Okoboji Punch for Badge Pneumatic MAQ represents the ultimate in automated badge manufacturing technology, combining advanced pneumatic engineering with high-speed production capabilities to deliver exceptional efficiency for India’s most demanding commercial badge production environments. This state-of-the-art automatic pneumatic machine revolutionises badge manufacturing workflows by eliminating manual operation whilst maintaining the precision and quality standards that characterise professional badge production. With an impressive production capacity of 400-500 pieces per hour, the MAQ system addresses the requirements of high-volume manufacturers who demand reliability, speed, and consistent quality.

Engineered for compatibility with badge moulds of all sizes up to 75mm, this versatile pneumatic punch machine accommodates diverse production requirements whilst maintaining exceptional precision and finish quality. The innovative pneumatic operation eliminates operator fatigue and ensures consistent pressure application throughout extended production runs, making it the ideal solution for large-scale commercial badge manufacturing. The system operates without requiring electrical power, relying solely on pneumatic pressure to deliver reliable, efficient operation that reduces energy costs whilst maximising productivity and maintaining environmental sustainability in modern manufacturing operations.

Upgrade Your Experience

Okoboji Badge Magentic Mould Oval 57x45mm

Okoboji Badge Magentic Mould Square 35x35mm

Okoboji Badge Slide Mould Round 37mm

Okoboji Die Cutter for Badge Round 50mm

Okoboji Die Cutter for Badge Round 75mm

Okoboji Punch for Badge Magnetic MA05

Okoboji Punch for Badge Slide MA01

KEY FEATURES

- High-speed automatic pneumatic operation delivers impressive production capacity of 400-500 pieces per hour for demanding commercial applications.

- Universal mould compatibility accommodates badge moulds of all sizes up to 75mm, providing comprehensive production flexibility for diverse badge requirements.

- Advanced pneumatic technology eliminates manual operation and operator fatigue whilst maintaining consistent pressure and quality throughout production runs.

- Energy-efficient operation requires no electrical power, relying solely on pneumatic pressure to deliver cost-effective and environmentally sustainable manufacturing.

- Professional-grade construction ensures exceptional durability and maintains reliable performance throughout intensive high-volume commercial production environments.

- Okoboji's proven engineering excellence delivers cutting-edge automation technology that gives Indian manufacturers decisive competitive advantages in high-speed markets.

- Consistent pressure application ensures uniform badge quality and professional finish standards regardless of production volume or operator experience.

- Robust pneumatic system supports continuous operation with minimal maintenance requirements and exceptional reliability over extended operational periods.

FREQUENTLY ASKED QUESTIONS

What production advantages does the pneumatic MAQ system offer over manual badge punch machines?

The pneumatic system delivers 400-500 pieces per hour, eliminates operator fatigue, ensures consistent pressure application, and provides automated operation ideal for high-volume production.

What air pressure requirements are needed to operate the MAQ pneumatic badge punch effectively?

The system requires standard workshop pneumatic pressure, typically supplied by industrial air compressors commonly used in manufacturing environments throughout India.

How does the universal mould compatibility benefit diverse badge production operations?

Compatibility with all mould sizes up to 75mm enables production of various badge formats without equipment changes, maximising production flexibility and equipment utilisation.

Can this Okoboji pneumatic system maintain quality consistency during high-speed production?

Yes, the pneumatic operation ensures consistent pressure application and precise timing that maintains uniform badge quality regardless of production speed or volume.

What maintenance procedures are required to keep the pneumatic MAQ system operating optimally?

Regular pneumatic system checks, lubrication of moving parts, air filter maintenance, and periodic inspection ensure optimal performance and extended operational life.

How does the energy efficiency of pneumatic operation compare to electric alternatives?

Pneumatic operation eliminates electrical consumption, reduces energy costs, provides environmentally sustainable manufacturing, and often proves more cost-effective for continuous production.

What training is required for operators to use this automatic pneumatic badge system?

The automated operation simplifies training requirements, with operators primarily needing to understand mould changes, material loading, and basic pneumatic system operation.

Does Okoboji provide installation and commissioning support for the MAQ pneumatic system?

Okoboji offers comprehensive installation support, operator training, commissioning assistance, and ongoing technical support to ensure optimal system performance.

How does the MAQ production capacity compare to other automated badge manufacturing systems?

The 400-500 pieces per hour capacity positions the MAQ as a high-efficiency system ideal for commercial production whilst maintaining excellent quality standards.

What quality assurance measures ensure consistent high-speed badge production with the pneumatic MAQ?

Precision pneumatic controls, consistent pressure application, robust construction, and comprehensive testing guarantee reliable high-speed production and professional results.

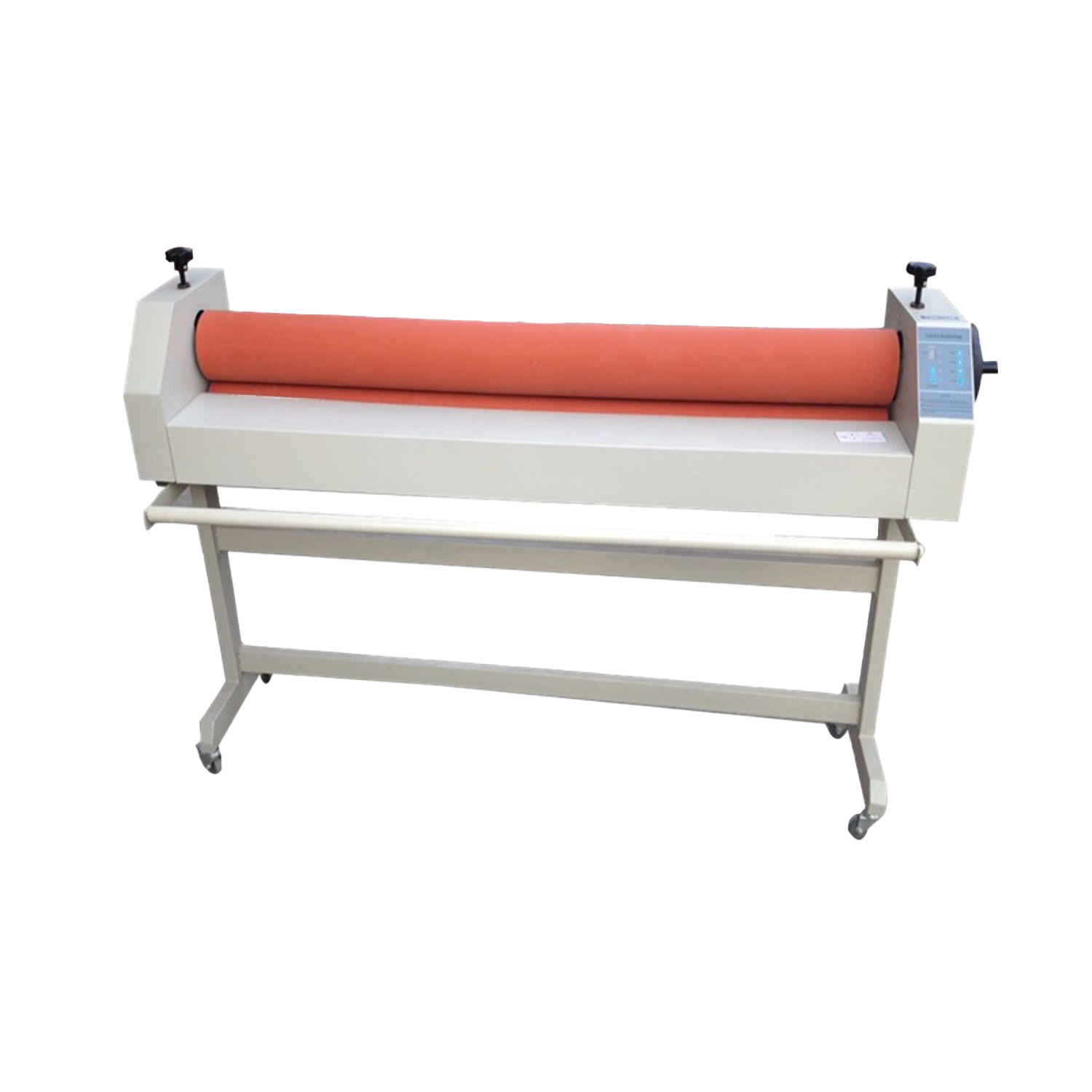

Customers also bought

Okoboji Cold Laminator Electric 650mm

Okoboji Corner Cutter Manual S100

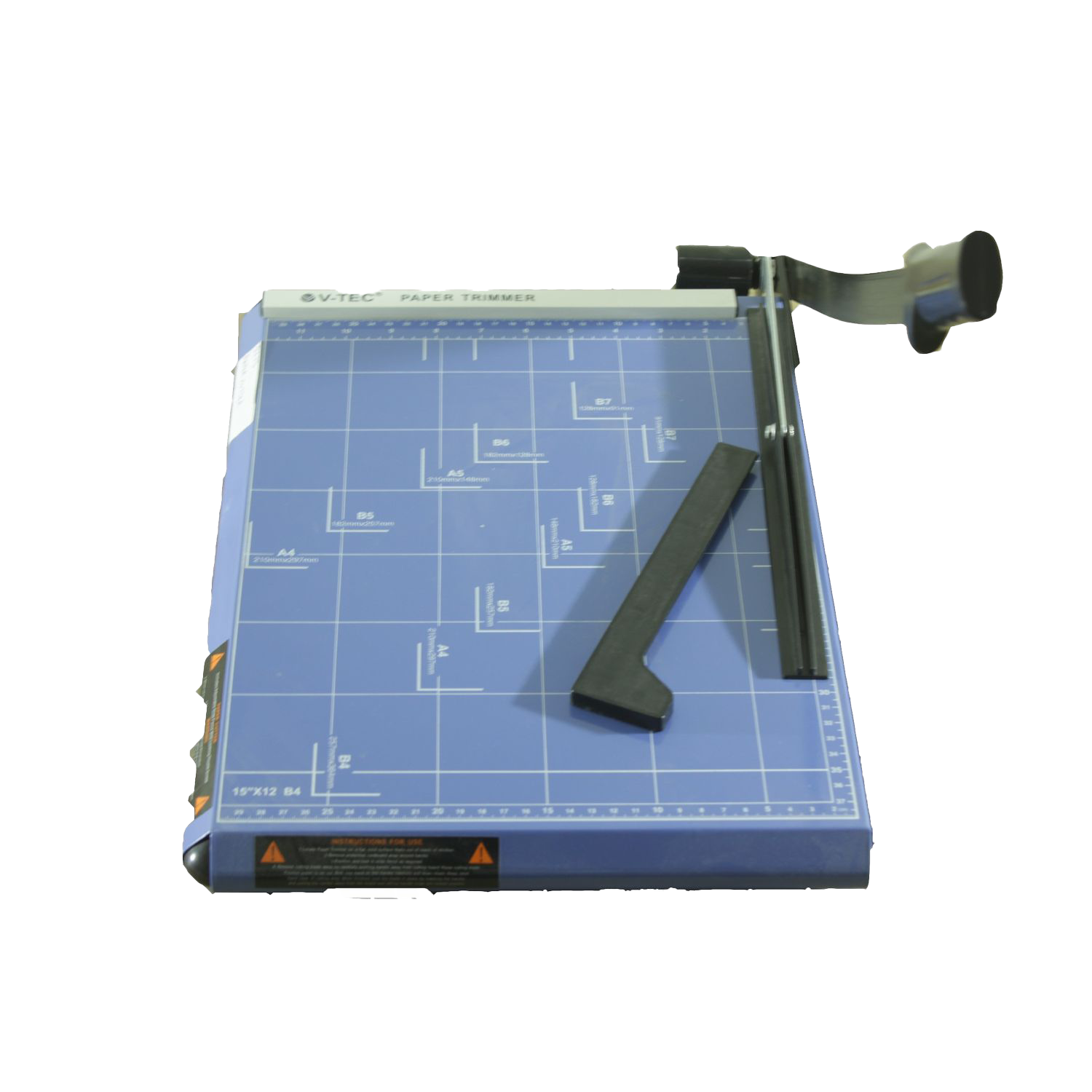

Okoboji Paper Cutter A3