Okoboji Punch for Badge Magnetic MA05

SPECIFICATIONS

PRODUCT VIDEO

PRODUCT DESCRIPTION

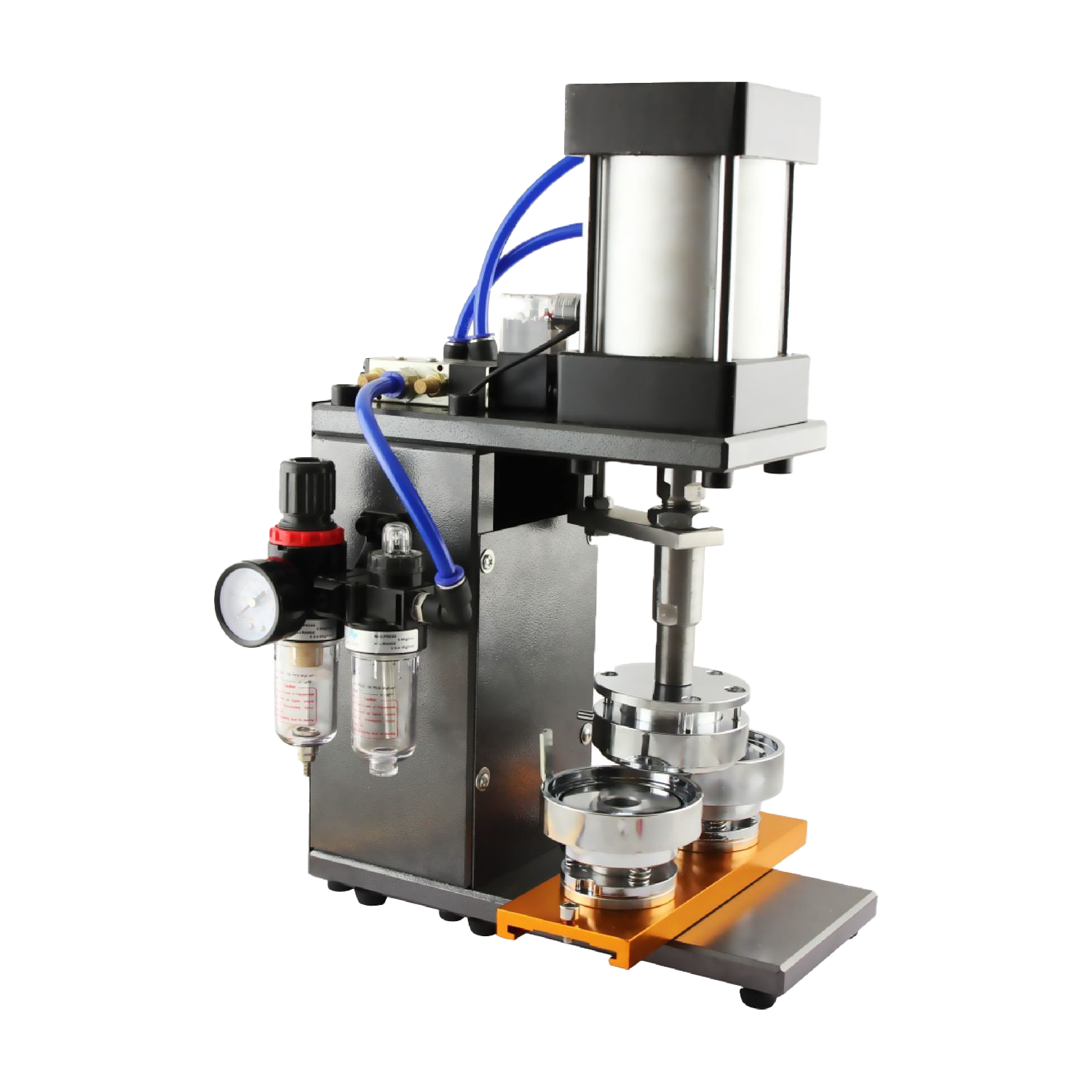

The Okoboji Punch for Badge Magnetic MA05 represents the pinnacle of professional badge manufacturing technology, specifically engineered to work seamlessly with magnetic mould systems to deliver exceptional production efficiency and consistent quality. This advanced badge punch machine combines robust mechanical engineering with innovative magnetic mould compatibility to create a comprehensive badge production solution that meets the demanding requirements of India’s commercial badge manufacturing industry. The MA05 system transforms traditional badge production workflows by utilising chrome plated steel magnetic moulds that enable lightning-fast changeovers and consistent alignment throughout extended production runs.

Designed for compatibility with MA05, MA02, and MAQ magnetic mould systems, this versatile punch machine accommodates diverse badge production requirements whilst maintaining the precision and reliability essential for professional applications. The magnetic mould technology eliminates time-consuming manual adjustments and ensures perfect alignment with every operation, dramatically improving production efficiency compared to traditional mounting systems. Whether producing corporate identification badges, promotional materials for marketing campaigns, or commemorative items for special events, this professional-grade punch machine delivers outstanding results that demonstrate Okoboji’s commitment to innovation and customer success in India’s competitive badge manufacturing marketplace.

Upgrade Your Experience

Okoboji Badge Magentic Mould Round 75mm

Okoboji Badge Magentic Mould Square 55x55mm

Okoboji Badge Slide Mould Round 25mm

Okoboji Die Cutter for Badge Oval 57x45mm

Okoboji Die Cutter for Badge Round 37mm

Okoboji Die Cutter for Badge Square 35x35mm

Okoboji Punch for Badge Pneumatic MAQ

Okoboji Punch for Badge Slide MA03

KEY FEATURES

- Advanced magnetic mould compatibility with MA05, MA02, and MAQ systems provides maximum production flexibility and universal mould interchangeability.

- Chrome plated steel magnetic mould technology enables fast track operation with lightning-quick mould changes that dramatically improve production efficiency.

- Professional-grade mechanical construction ensures exceptional durability and maintains consistent performance throughout intensive commercial production environments.

- Precision-engineered punch mechanism guarantees accurate badge formation with uniform quality and professional finish standards throughout extended production campaigns.

- Universal magnetic mould compatibility accommodates badge sizes up to 75mm, providing versatility for diverse badge production requirements and applications.

- Okoboji's proven manufacturing excellence delivers reliable, high-performance badge production equipment that gives Indian manufacturers competitive advantages in professional markets.

- Fast track operation capability enables rapid production changeovers between different badge designs, supporting efficient workflow management for commercial applications.

- Robust construction supports high-volume commercial badge production with minimal maintenance requirements and consistent quality over extended operational periods.

FREQUENTLY ASKED QUESTIONS

What makes the magnetic mould system superior to traditional badge punch mounting methods?

Magnetic mounting eliminates manual adjustments, provides instant mould changes, ensures perfect alignment every time, and dramatically reduces production downtime compared to screw-type mounting systems.

Which badge mould sizes are compatible with the MA05 magnetic punch system?

The MA05 system accommodates all magnetic badge moulds from 25 to 75mm diameter, including round, oval, and square formats, providing comprehensive production flexibility.

How does the fast track operation improve commercial badge production efficiency?

Fast track operation enables mould changes in seconds rather than minutes, allowing rapid production of different badge designs and significantly increasing overall throughput.

What production volumes can this magnetic punch system handle for commercial manufacturing?

The robust construction supports intensive commercial production with capability for thousands of badge cycles whilst maintaining consistent quality and performance.

Can this Okoboji punch machine handle different badge materials and thicknesses effectively?

Yes, the precision-engineered mechanism accommodates various badge materials including papers, plastics, laminates, and specialty substrates within appropriate thickness ranges.

How does the chrome plated steel construction benefit long-term operation and maintenance?

Chrome plating provides corrosion resistance, reduces friction, maintains smooth operation, and significantly extends equipment life even under intensive production schedules.

What training is required for operators to use this magnetic badge punch system effectively?

The intuitive magnetic mould system and fast track operation make training straightforward, with most operators becoming proficient quickly due to the simplified changeover process.

Does Okoboji provide technical support and maintenance guidance for the MA05 punch system?

Okoboji offers comprehensive technical support including operational training, maintenance recommendations, troubleshooting assistance, and parts availability for optimal performance.

How does this magnetic punch system compare to pneumatic alternatives for production efficiency?

While pneumatic systems offer automation, the magnetic system provides excellent manual control, lower maintenance requirements, and cost-effective operation ideal for many applications.

What quality control measures ensure consistent badge production with this magnetic punch system?

Precision manufacturing, magnetic alignment consistency, robust construction, and comprehensive testing guarantee reliable badge formation and professional results throughout production.

Customers also bought

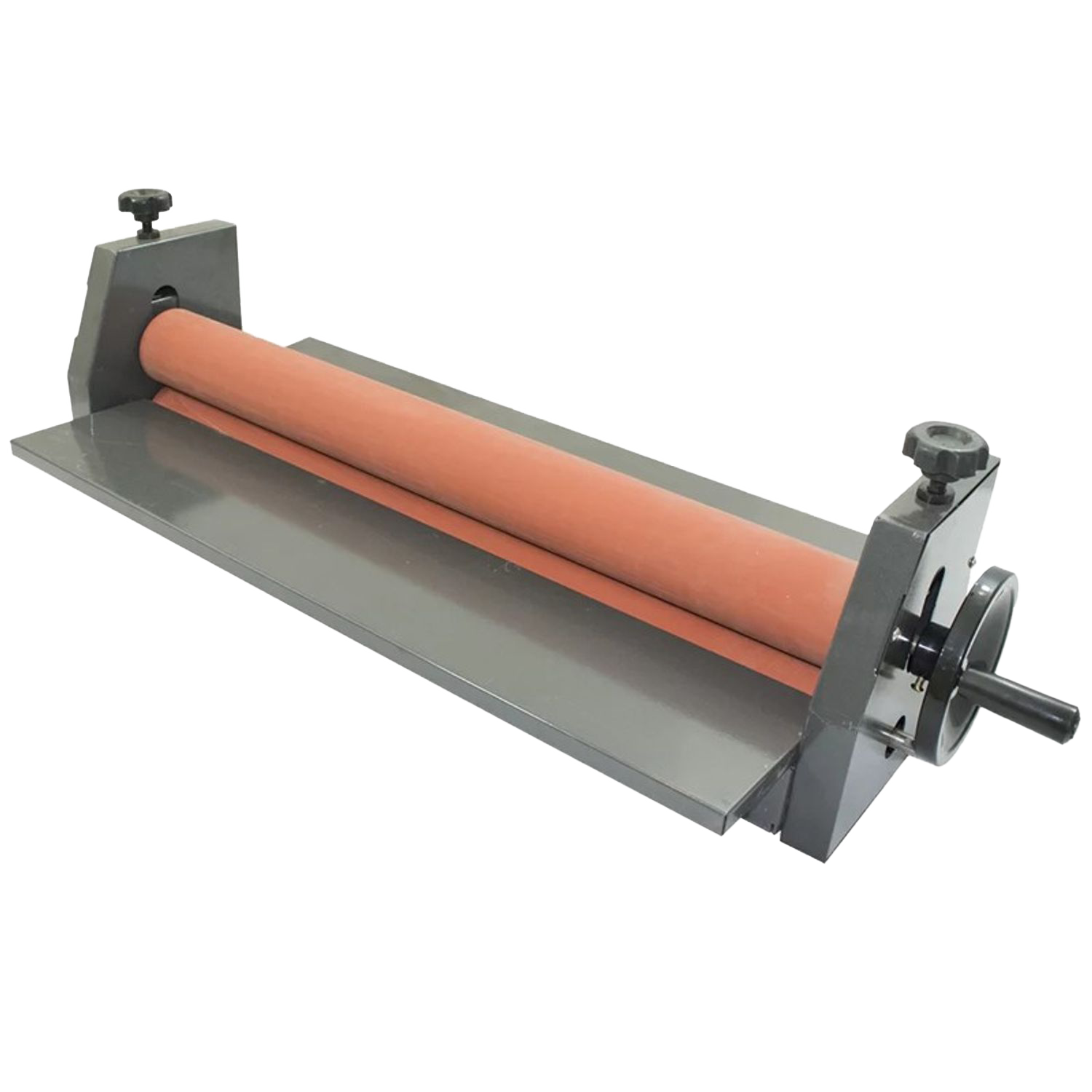

Okoboji Cold Laminator Desktop LBS1000

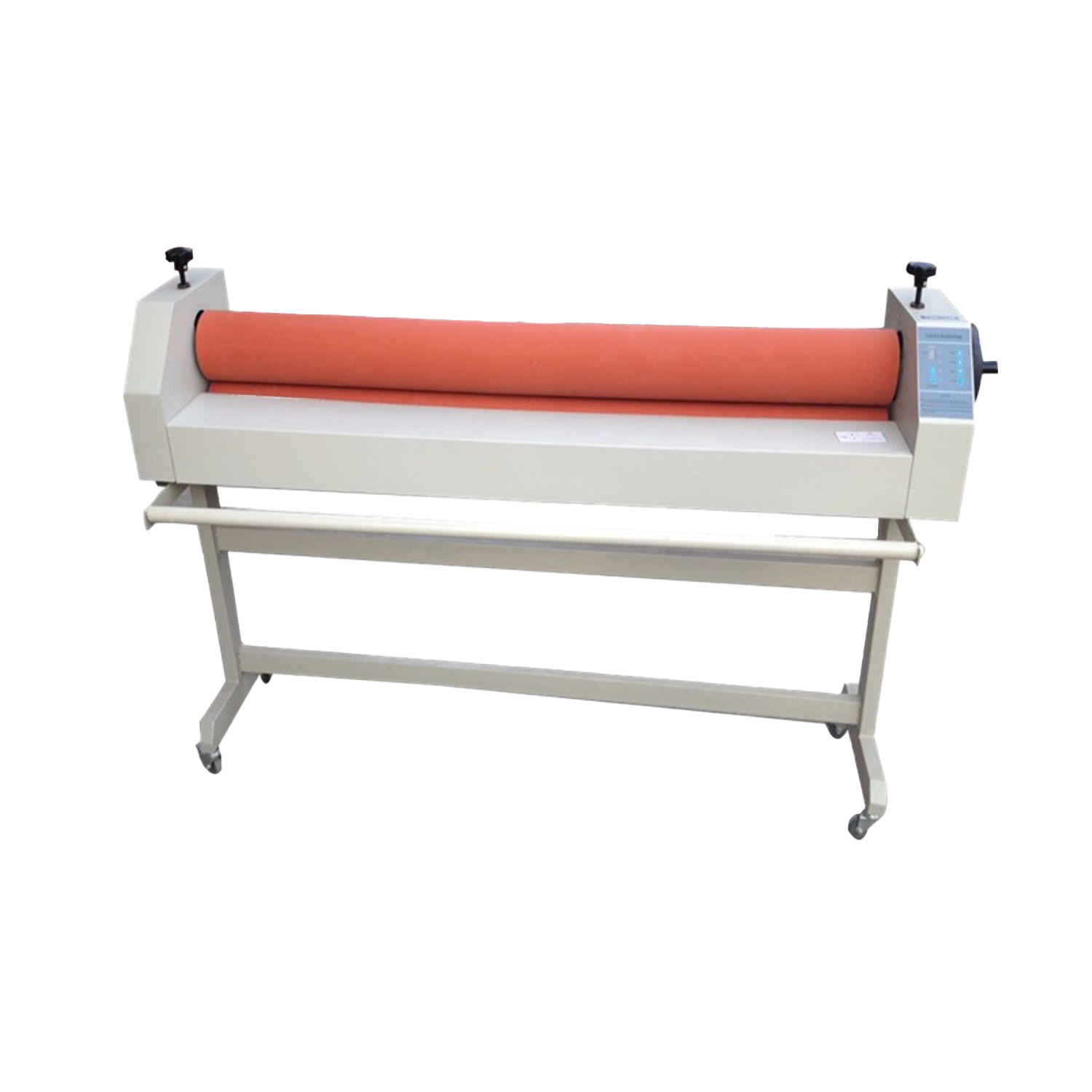

Okoboji Cold Laminator Electric 650mm

Okoboji Handheld Corner Cutter All in One CC085