Okoboji Die Cutter for Badge Round 25mm

SPECIFICATIONS

PRODUCT VIDEO

PRODUCT DESCRIPTION

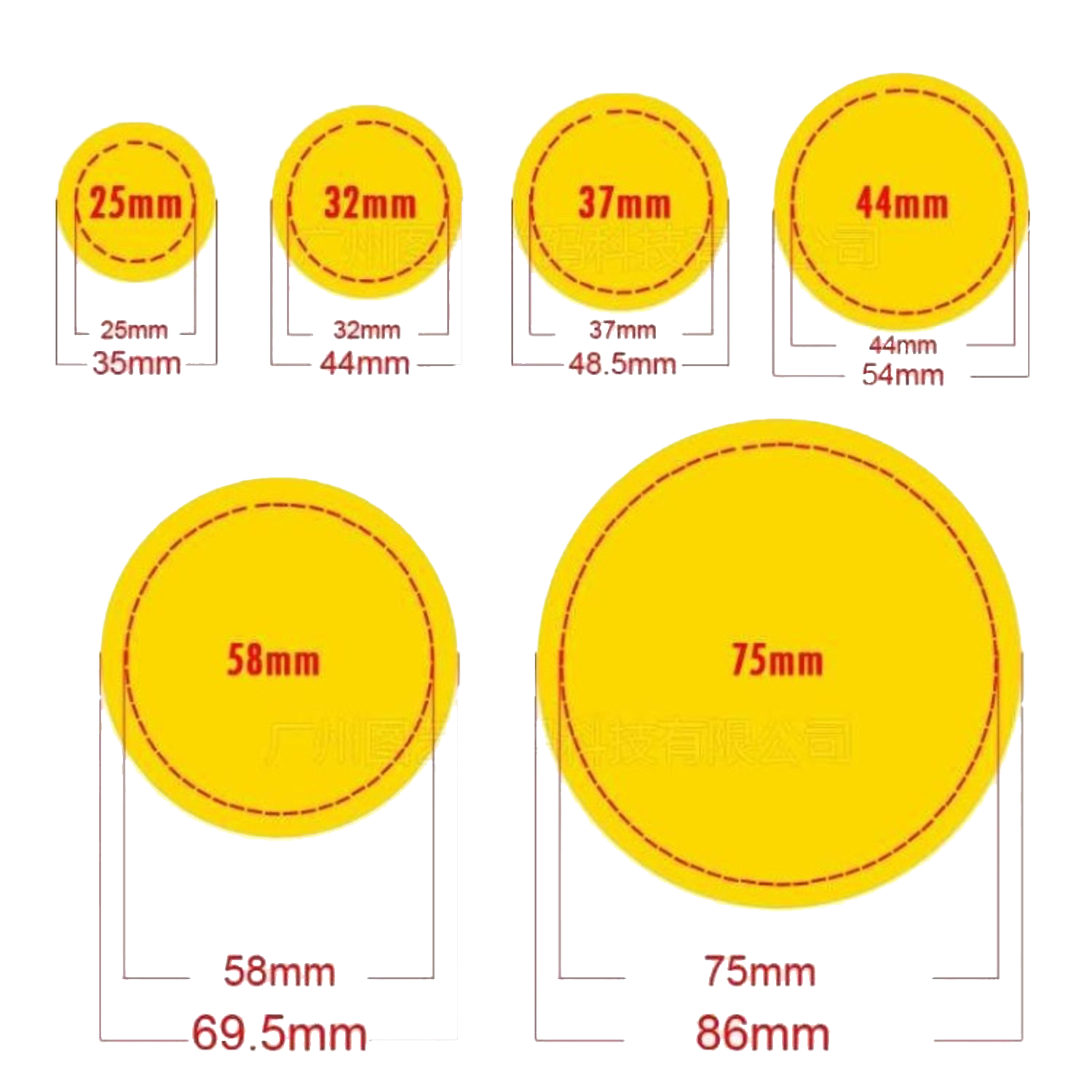

The Okoboji Die Cutter for Badge Round 25mm introduces precision compact badge cutting technology to India’s diverse identification and promotional badge industry, combining efficient small-format production with advanced manganese steel blade engineering to create discrete, professional badges that excel in specialised applications. This expertly engineered PVC die card cutter machine addresses the growing demand for smaller, more refined badge designs that provide subtle identification whilst maintaining high visual impact and professional appearance. The compact 25mm round format creates perfectly proportioned small badges ideal for minimalist corporate identification, security applications, membership credentials, or promotional items where understated elegance is paramount.

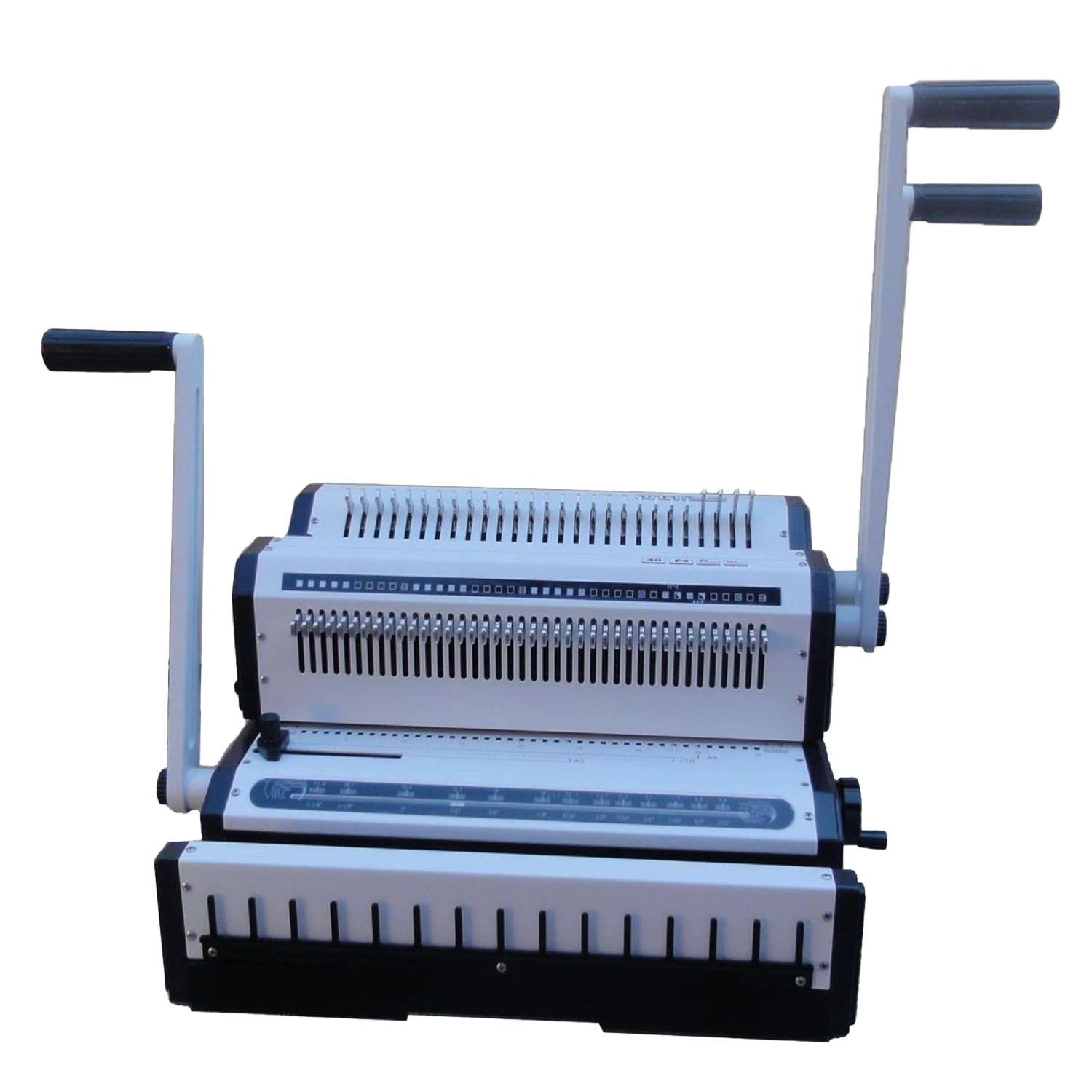

Specifically designed to accommodate materials ranging from 0.1mm to 1mm thickness with exceptional precision, this versatile die cutter handles everything from delicate specialty papers to robust PVC cards whilst maintaining clean cuts with professional edge quality. The robust steel body construction provides the stability necessary for precise small-format cutting operations whilst the premium manganese steel blade maintains its sharp edge throughout extended commercial use. Manual operation eliminates the complexity of automated systems whilst providing complete operator control over cutting parameters, making it the ideal choice for badge manufacturers seeking reliability, precision, and cost-effectiveness in compact badge production applications.

Upgrade Your Experience

Okoboji Badge Magentic Mould Oval 57x45mm

Okoboji Badge Slide Mould Round 44mm

Okoboji Die Cutter for Badge Oval 57x45mm

Okoboji Die Cutter for Badge Square 35x35mm

Okoboji Punch for Badge Magnetic MA05

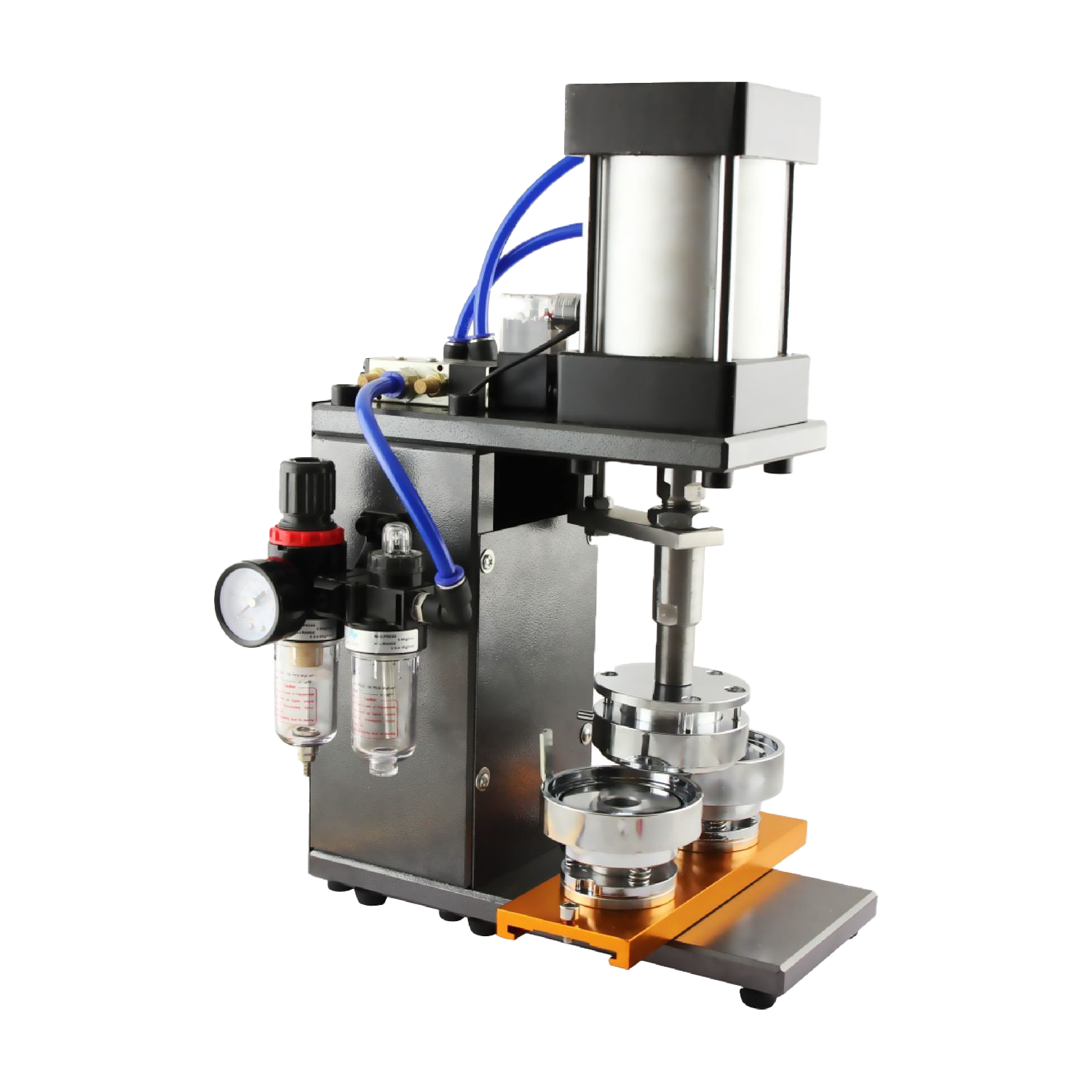

Okoboji Punch for Badge Pneumatic MAQ

Okoboji Punch for Badge Slide MA03

KEY FEATURES

- Compact 25mm round format creates discrete, professional badges perfect for minimalist identification, security applications, and subtle promotional uses.

- Premium steel body construction with manganese steel blade ensures exceptional durability and maintains sharp cutting performance throughout intensive small-format production.

- Versatile cutting capacity accommodates materials from 0.1mm to 1mm thickness, handling diverse substrates from delicate papers to robust PVC cards effectively.

- Manual operation provides complete operator control over cutting parameters, ensuring optimal results for small materials whilst eliminating complex automated mechanisms.

- Precision-engineered cutting system guarantees clean, accurate small round cuts with smooth edges and professional finish quality throughout extended production campaigns.

- Okoboji's proven manufacturing excellence delivers reliable, high-performance cutting tools that give Indian badge producers competitive advantages in specialised compact markets.

- Compact construction optimised for small format cutting provides efficient operation with minimal space requirements and fast cutting cycles.

- Professional-grade design provides dependable operation without electronic components, making it ideal for diverse production environments requiring discrete badge formats.

FREQUENTLY ASKED QUESTIONS

What advantages does the compact 25mm size offer for specialised badge applications?

The small format provides discrete identification perfect for security badges, membership credentials, minimalist corporate identification, and applications requiring subtle, professional appearance.

How does this small format die cutter ensure precision cutting despite the compact size?

The precision-engineered mechanism and robust construction provide exceptional accuracy whilst operator control ensures appropriate technique for small format materials.

What design considerations work best with the compact 25mm round format?

Simple logos, clear typography, focused messaging, and minimalist designs work exceptionally well with the compact format, creating elegant, professional small badges.

Can this Okoboji die cutter maintain cutting quality during high-volume small badge production?

Yes, the robust construction and premium blade technology ensure consistent cutting quality and professional results throughout demanding small-format production requirements.

What materials are most suitable for this compact die cutting system?

The cutter works excellently with high-quality papers, security laminates, thin PVC films, and protective coatings optimised for small-format badge applications.

How does the cutting mechanism ensure accuracy during small format operations?

The precision-machined components and enhanced stability provide exact cutting control crucial for small badges where dimensional accuracy is particularly critical.

What maintenance procedures ensure optimal performance for this compact die cutter?

Regular cleaning of cutting surfaces, careful blade inspection, precise lubrication, and proper storage ensure optimal performance for small-format cutting applications.

Does Okoboji provide specialised guidance for optimising small badge cutting operations?

Okoboji offers technical support including design recommendations, cutting techniques, and operational guidance specifically for compact badge cutting applications.

How does this compact die cutter compare to larger alternatives for efficiency and material usage?

Compact cutting offers faster cycle times, reduced material waste, and efficient production particularly advantageous for high-volume small badge applications.

What quality control measures ensure consistent small format cutting performance with this die cutter?

Strict manufacturing tolerances, precision machining, specialised testing, and quality assurance protocols guarantee reliable small cutting and professional results consistently.

Customers also bought

Okoboji Cold Lamination Desktop LBS650

Okoboji Paper Ream Cutter 858 A3

Okoboji Thermal Roll Laminator 358