Manual Eyelet Machine

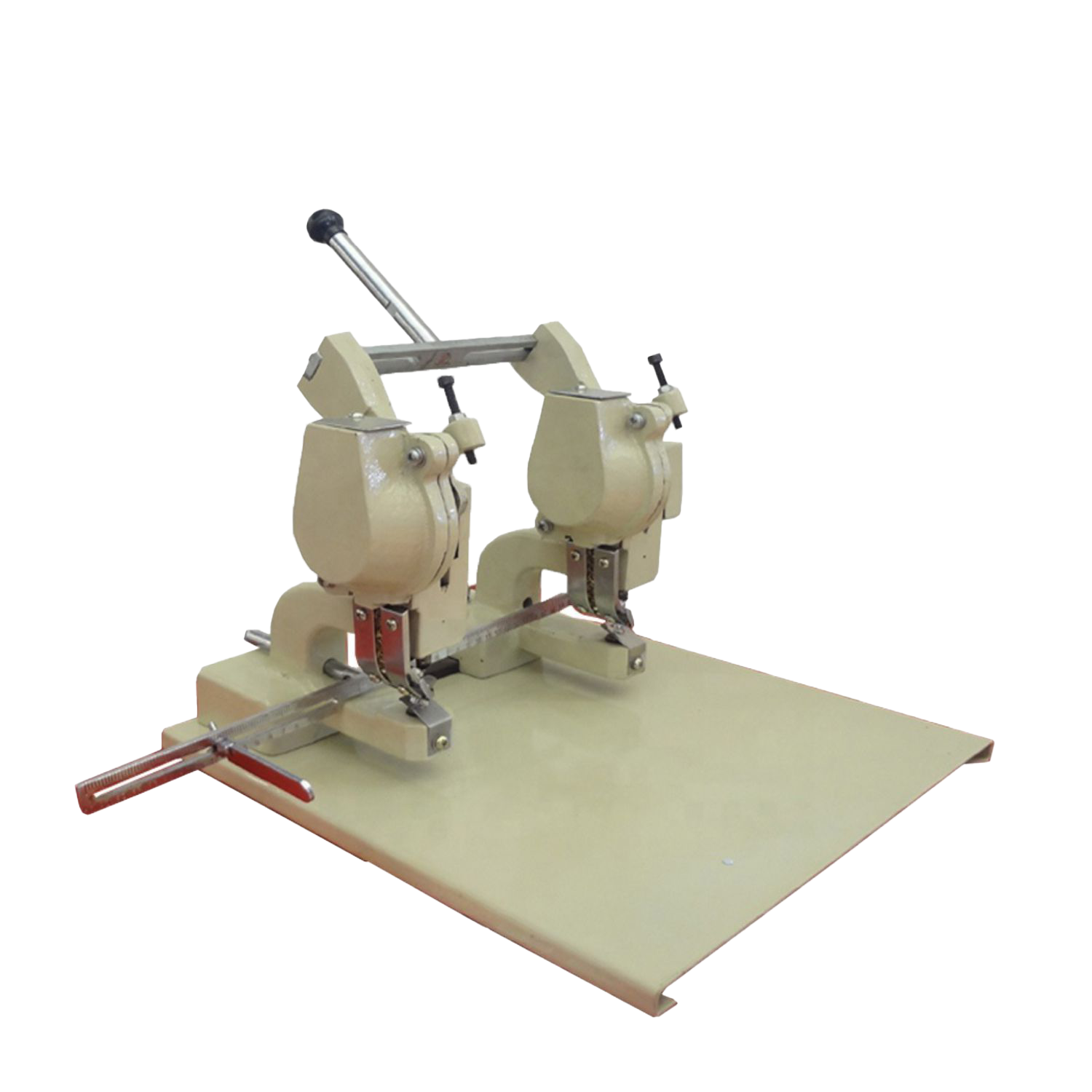

Okoboji Eyelet Manual 2 Head Foot Pedal EPDM2

The Okoboji Manual 2 Head Foot Pedal EPDM2 represents an intelligent evolution in manual eyelet technology, combining the productivity advantages of dual-head operation with the ergonomic benefits of foot pedal control. This machine demonstrates how thoughtful engineering can significantly improve operator efficiency and comfort whilst maintaining the cost-effectiveness and reliability that manual systems provide for growing businesses. The foot pedal operation represents a crucial advancement in manual machine design, allowing operators to keep both hands free for precise material positioning and handling. This ergonomic advantage becomes particularly important during extended production runs, where proper material positioning directly impacts final product quality. The dual-head configuration means operators can achieve twice the productivity of single-head alternatives whilst maintaining the precise control that experienced craftspeople value. Understanding that many businesses operate in environments where consistent power supply may be challenging or where operational costs must be carefully controlled, this Okoboji machine provides professional-grade capability without electrical dependency. The 5.5mm eyelet capacity handles the most commonly required eyelet size across diverse applications, whilst the 80 eyelets per minute capability ensures productivity levels that can satisfy demanding production schedules.

Okoboji Eyelet Manual Single Head 4mm DJC4 4mm

The Okoboji Manual Single Head 4mm DJC4 Eyelet Machine provides exceptional precision and reliability for businesses requiring accurate, controlled eyeleting operations in a compact, cost-effective package. This machine represents the perfect entry point for small-scale manufacturers and workshops seeking professional-grade eyelet installation capabilities without the complexity and expense of larger multi-head systems. Engineered with precision and simplicity in mind, this Okoboji machine excels in applications where quality and control take precedence over high-volume production. The 4mm eyelet diameter specification makes it particularly suitable for delicate work, prototype development, small leather goods, and applications where precise, neat eyelets are essential for both functional performance and aesthetic appeal. The compact desktop design and manual operation make this Okoboji system ideal for workshops with limited space or businesses just beginning to incorporate professional eyeleting into their manufacturing processes. The robust construction ensures reliable performance whilst the manual operation provides the precise control that experienced craftspeople value for detailed, high-quality work.

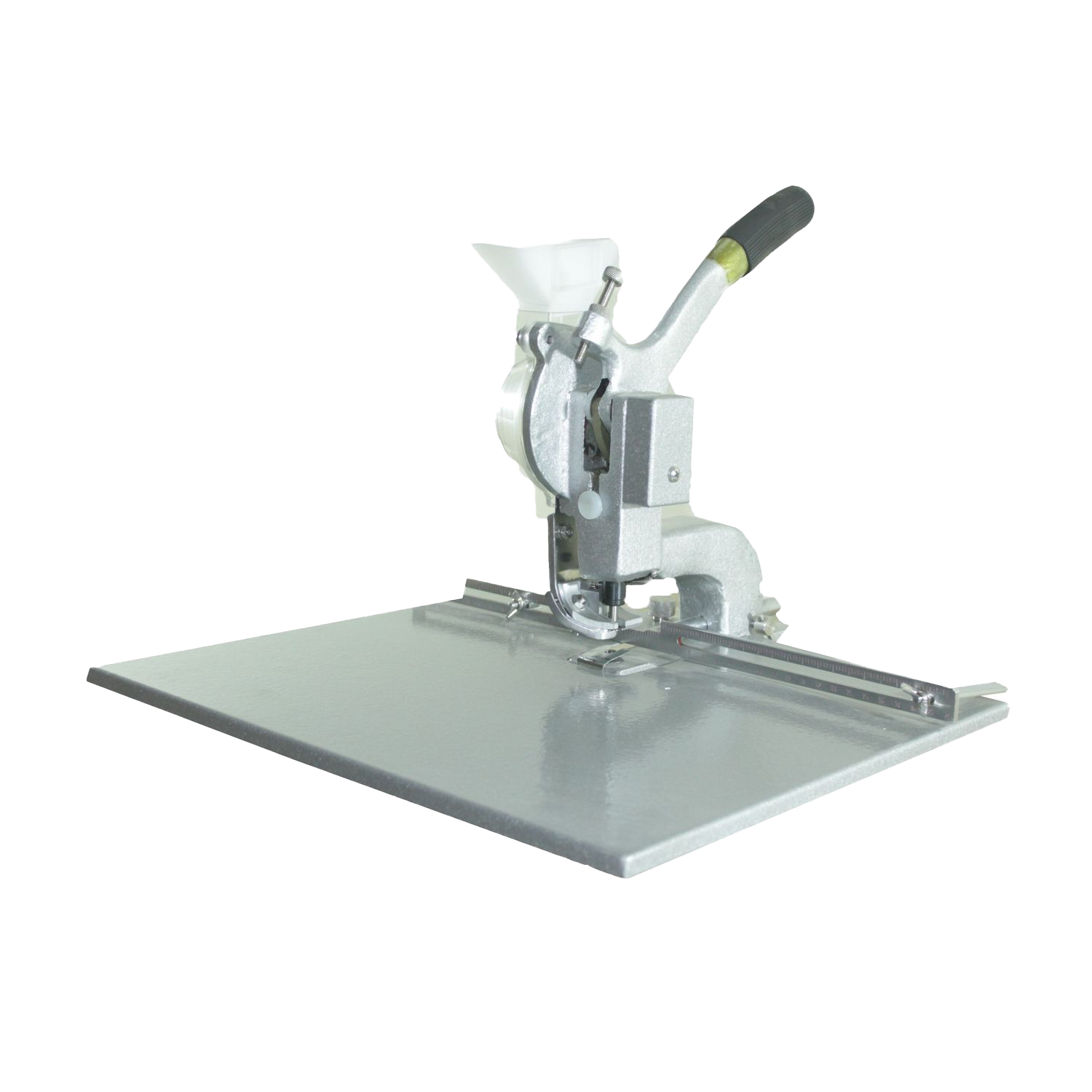

Okoboji Eyelet Desktop Manual DT

The Okoboji Desktop Manual DT represents the most accessible entry point into professional eyelet installation, designed specifically for small workshops, craft businesses, and entrepreneurs who need reliable 5.5mm eyelet capability in an ultra-compact, budget-friendly package. This machine demonstrates how sophisticated engineering can be distilled into an essential tool that delivers professional results without the complexity or cost of larger industrial systems. Understanding that many businesses begin with modest requirements before scaling up, this Okoboji desktop model provides the foundation for quality eyelet work whilst remaining accessible to users with limited space and budget constraints. The manual operation teaches operators the fundamentals of proper eyelet installation, developing skills and understanding that prove valuable as businesses grow and potentially upgrade to more advanced systems. The compact desktop design means this machine can fit into the smallest workshop spaces, making it perfect for home-based businesses, startup operations, or as a secondary machine for specialised applications. Despite its modest size and price point, this Okoboji system maintains the quality standards and precision engineering that ensure consistent, professional results across diverse applications requiring 5.5mm eyelets.

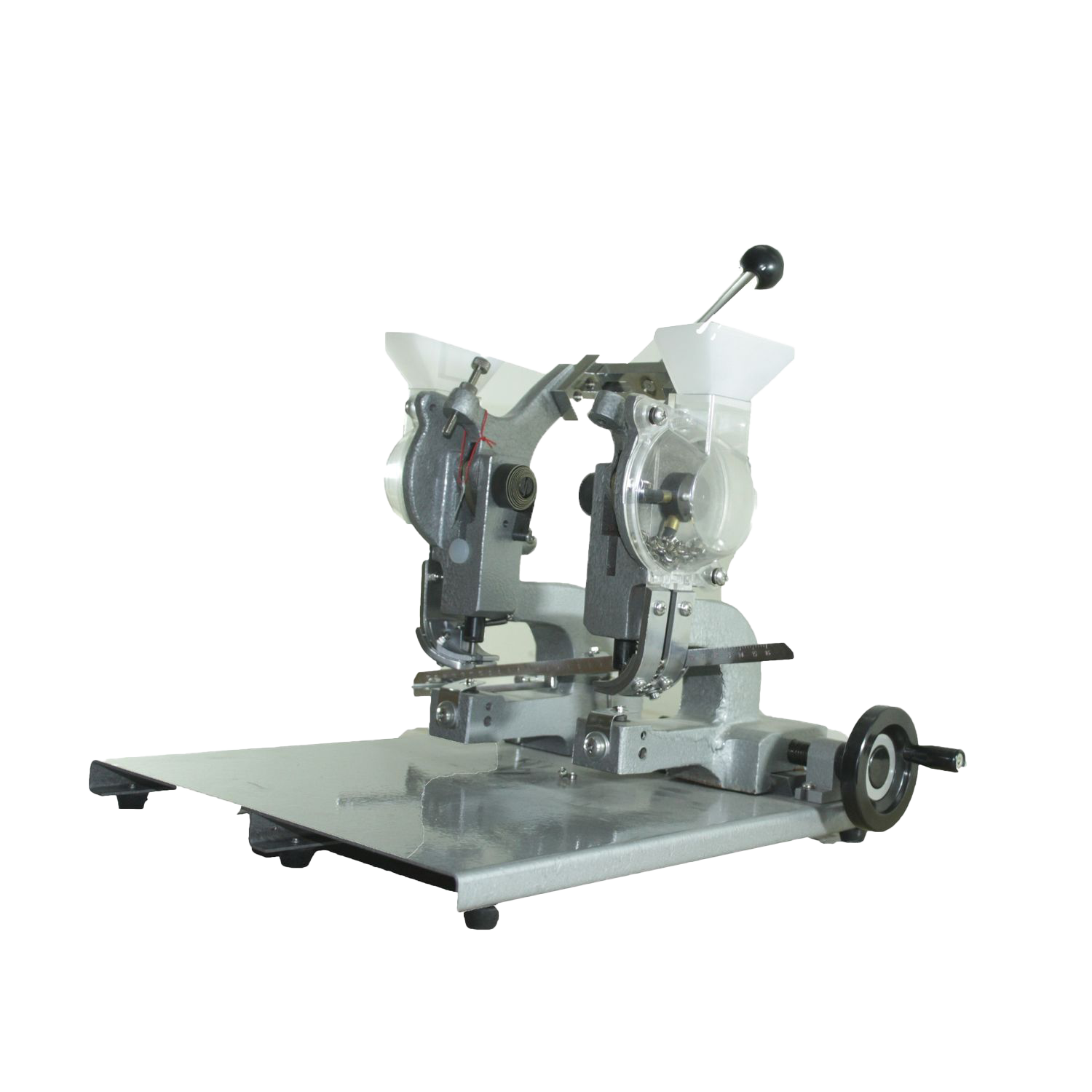

Okoboji Eyelet Manual Dual Head 4mm DJS4 4mm

The Okoboji Manual Dual Head 4mm DJS4 Eyelet Machine represents innovative manual engineering designed specifically for businesses requiring efficient dual-head eyeleting capabilities without dependence on electrical power systems. This machine combines the productivity advantages of dual-head operation with the reliability and simplicity of manual foot-operated functionality, making it an excellent choice for diverse manufacturing environments where power availability may be limited or inconsistent. This robust Okoboji machine excels in medium-scale production environments where the dual-head design significantly improves productivity compared to single-head alternatives whilst maintaining the operational flexibility that manual systems provide. The 4mm eyeleting diameter specification makes it particularly suitable for applications requiring smaller, precise eyelets commonly used in footwear, leather goods, and textile applications throughout Indian manufacturing sectors. The substantial 1200-grain eyelet container capacity ensures extended operation periods without frequent refilling, whilst the foot-operated mechanism allows operators to maintain precise control over the eyeleting process. This Okoboji system delivers excellent value for businesses seeking to improve production efficiency without the infrastructure requirements and operational costs associated with electric or pneumatic alternatives.

Okoboji Eyelet Manual Dual Head 5.5mm DJS4

The Okoboji Manual Dual Head 5.5mm DJS4 Eyelet Machine delivers superior manual eyeleting performance for applications requiring larger eyelet sizes combined with the efficiency benefits of dual-head operation. This machine represents the pinnacle of manual eyelet technology, specifically engineered for businesses that need robust, reliable eyeleting capabilities for heavy-duty materials and applications where 5.5mm eyelets provide optimal strength and durability. Designed with the demands of industrial manufacturing in mind, this Okoboji machine excels in applications involving thicker materials, heavy-duty textiles, tarpaulins, and leather goods where larger eyelets are essential for structural integrity and longevity. The dual-head configuration ensures maximum productivity whilst the manual operation provides the precise control necessary for consistent, high-quality results across demanding applications. The robust construction and thoughtful engineering make this Okoboji system particularly valuable for Indian manufacturers working with diverse materials and requiring the flexibility to operate independently of electrical infrastructure. The substantial build quality and precision engineering ensure reliable performance throughout extended production runs whilst maintaining the operational cost advantages that manual systems provide.

Okoboji Eyelet Manual Single Head 5.5mm DJC4

The Okoboji Manual Single Head 5.5mm DJC4 Eyelet Machine combines the precision of single-head operation with the versatility of larger 5.5mm eyelet capability, delivering exceptional performance for businesses requiring professional-grade manual eyeleting in a compact, controllable format. This machine represents the ideal solution for workshops and manufacturers who need the strength and durability of larger eyelets whilst maintaining the precise control and cost-effectiveness that manual operation provides. Engineered for applications where 5.5mm eyelets provide optimal strength-to-size ratio, this Okoboji machine excels in medium-duty applications including leather goods, canvas work, moderate-weight textiles, and industrial applications where larger eyelets are necessary for durability but where the complexity of multi-head systems is unnecessary. The desktop design ensures easy integration into existing workshop configurations whilst the manual operation provides the precise control valued by skilled operators. The combination of 5.5mm capability with single-head simplicity makes this Okoboji system particularly attractive for businesses transitioning from smaller eyelet sizes or for operations requiring the flexibility to handle diverse applications without the infrastructure requirements of electric or pneumatic alternatives. The robust construction ensures reliable performance throughout demanding manual operation whilst maintaining the operational cost advantages that manual systems provide.

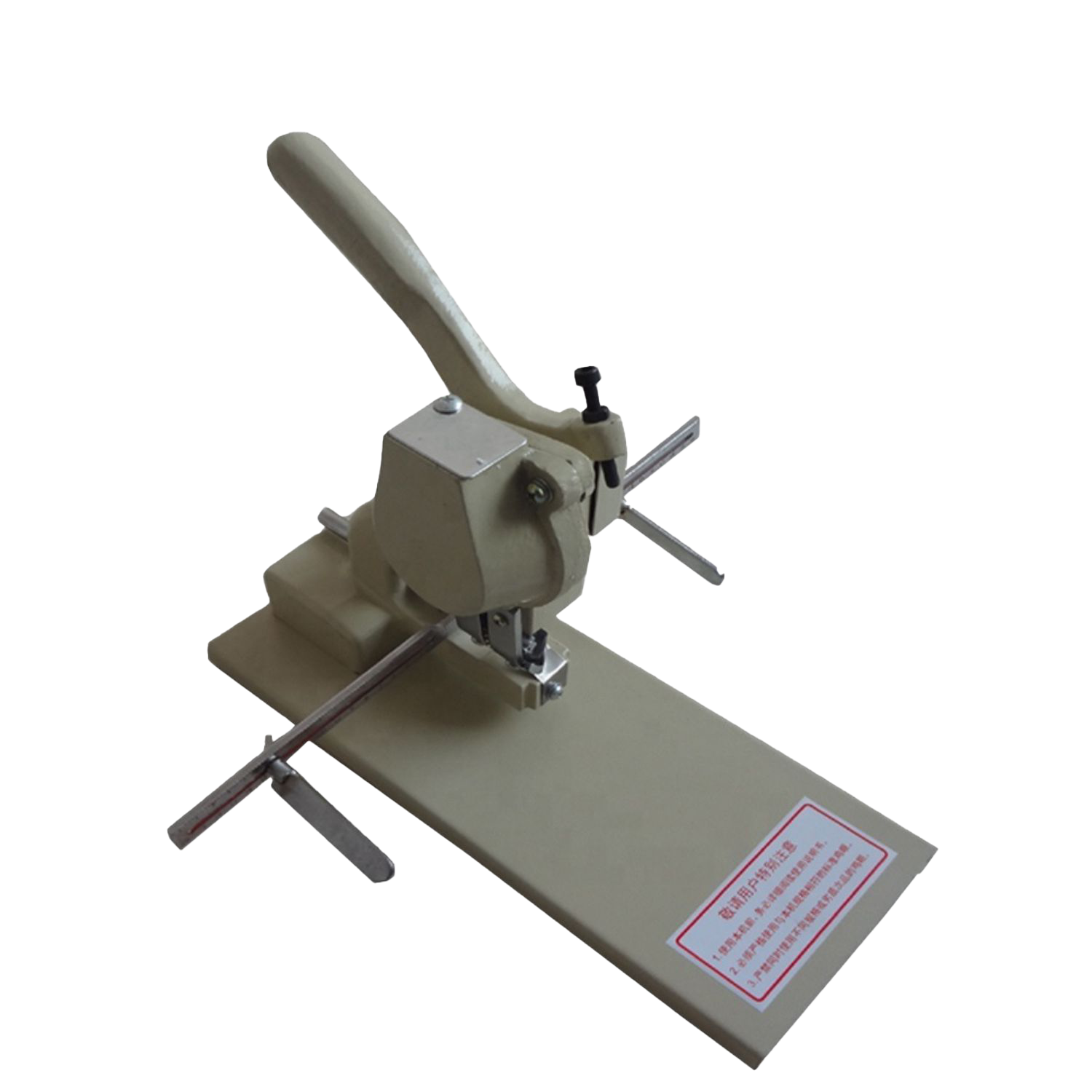

Okoboji Eyelet Manual Single Head Foot Pedal 5.5mm DJJ4

The Okoboji Manual Single Head Foot Pedal 5.5mm DJJ4 represents the perfect synthesis of precision, control, and ergonomic efficiency in single-head manual eyelet technology. This machine demonstrates how focused engineering can create a tool that excels in applications where quality and operator comfort are paramount, providing professional-grade results whilst maintaining the operational advantages that make manual systems invaluable for precision work. This Okoboji machine excels in environments where precision takes precedence over maximum speed, such as custom leather work, prototype development, repair services, or specialised manufacturing where each eyelet must be perfectly positioned. The combination of stand-mounted stability with foot pedal operation creates an optimal working environment for sustained precision work, whilst the manual operation ensures complete operator control over pressure, timing, and positioning. The foot pedal operation fundamentally transforms the manual eyeleting experience by freeing both hands for precise material positioning and manipulation. This ergonomic advantage becomes particularly crucial when working with delicate materials, complex positioning requirements, or applications demanding exact eyelet placement. The single-head design provides operators with complete control over each eyelet installation, enabling the precise adjustments and careful positioning that quality-focused applications require.