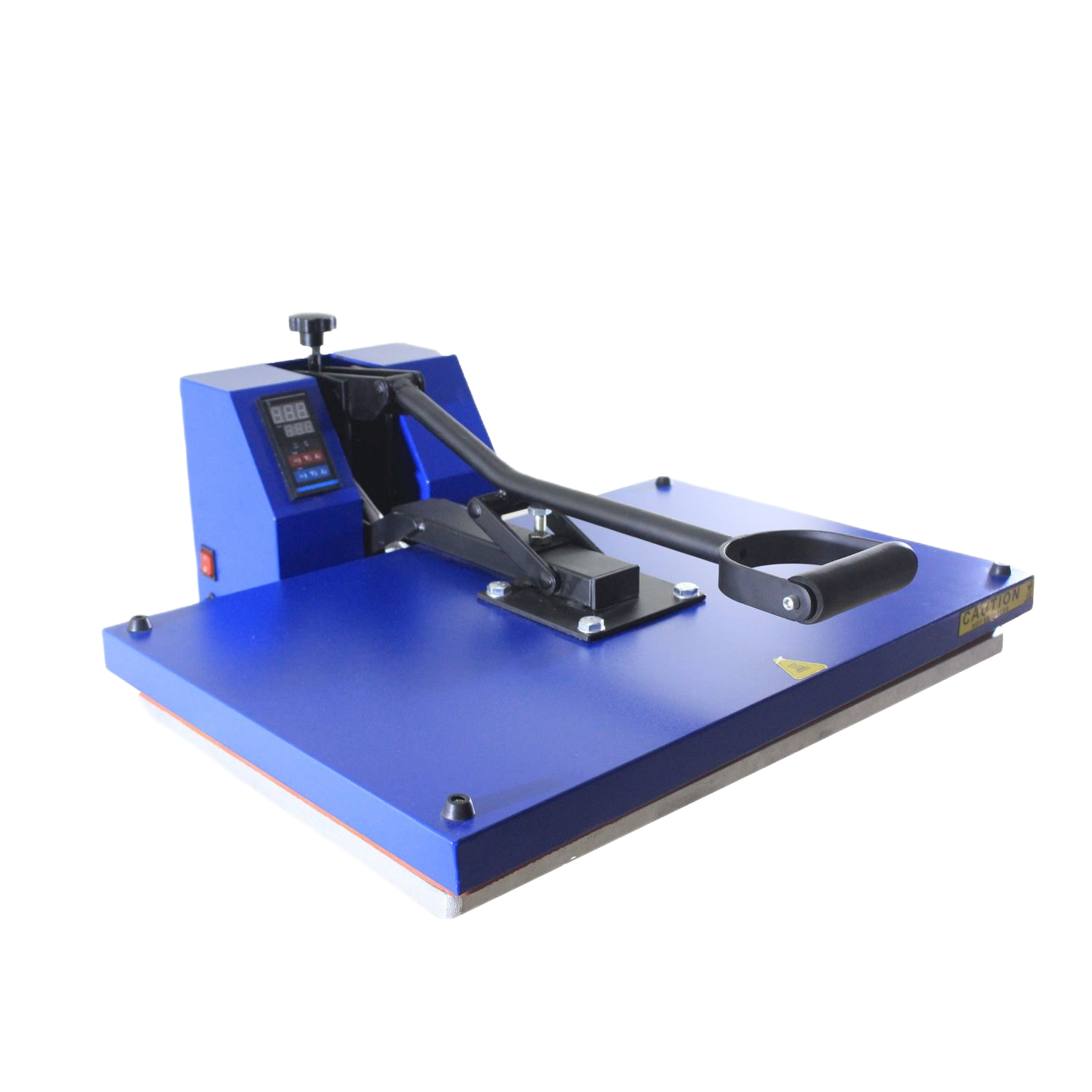

Okoboji Sublimation Heat Press Auto with Slideout SHP15LP3MS

SPECIFICATIONS

PRODUCT VIDEO

PRODUCT DESCRIPTION

The Okoboji Sublimation Heat Press Auto with Slideout and auto open SHP15LP3MS represents cutting-edge automation in heat transfer technology, specifically designed to enhance operational efficiency and workplace safety through intelligent auto-release functionality and innovative slideout drawer design. This advanced clamshell heat press combines manual operation flexibility with automatic release capabilities, featuring a convenient draw-out under plate system that revolutionizes substrate loading and unloading processes for increased productivity and operator convenience.

Engineered with the advanced GY-05 Digital Time & Temperature Control system, this sophisticated heat press provides precision operation parameters whilst the gas spring control mechanism ensures smooth, effortless operation and enhanced operator comfort during extended production runs. The innovative slideout drawer design allows operators to prepare the next job whilst the current transfer is in progress, significantly reducing cycle times and increasing overall production efficiency in commercial sublimation printing operations.

This premium automated heat press is particularly valuable for businesses seeking to improve operational efficiency, reduce operator fatigue, and maintain consistent quality through automated processes. The combination of 15×15 inch capacity, automatic release functionality, and slideout convenience makes it ideal for print shops, promotional product companies, and commercial operations requiring reliable, efficient, and user-friendly equipment that enhances productivity whilst maintaining professional-quality results in the competitive Indian sublimation market.

Upgrade Your Experience

Okoboji Sublimation Combo Heat Press 5in1

Okoboji Sublimation Combo Heat Press DCH800

Okoboji Sublimation Heat Press 4060

Okoboji Sublimation Heat Press Auto Open 3838

KEY FEATURES

- Advanced automatic release functionality with manual operation flexibility provides optimal balance of automation and operator control for enhanced efficiency

- Innovative slideout drawer design with fixed or draw-out under plate options enables efficient substrate preparation and reduces cycle times in commercial operations

- Professional GY-05 Digital Time & Temperature Control system ensures precise operation parameters and consistent results across various sublimation applications

- Gas spring control mechanism provides smooth operation, reduced operator fatigue, and enhanced comfort during extended commercial production sessions

- Optimal 15x15 inch (38x38cm) platen size accommodates standard t-shirts, promotional products, and diverse substrates up to 15-20mm thickness

- 50-degree opening angle optimizes accessibility for substrate placement whilst maintaining compact operational footprint for various workshop environments

- Okoboji's advanced engineering excellence with comprehensive automation features and technical support designed for professional sublimation operations

- Clamshell design with enhanced automation features improves workplace safety, operational efficiency, and production consistency for commercial applications

FREQUENTLY ASKED QUESTIONS

How does the automatic release function improve operational efficiency?

The auto-release eliminates the need for manual opening after each cycle, reducing operator intervention, preventing over-pressing, and allowing operators to focus on substrate preparation and quality control.

What advantages does the slideout drawer design provide for production workflows?

The slideout drawer allows operators to prepare the next substrate whilst current transfer is processing, reducing idle time, increasing throughput, and improving overall production efficiency.

How does the GY-05 digital control system enhance precision compared to standard controllers?

The GY-05 system provides enhanced accuracy, programmable settings, memory functions, and advanced timing controls that ensure consistent results and reduce operator error.

What safety benefits does the gas spring control mechanism provide?

Gas springs ensure smooth, controlled opening and closing, reduce operator strain, prevent sudden movements, and provide consistent pressure application for enhanced workplace safety.

Can the slideout function handle different substrate thicknesses effectively?

Yes, the draw-out design accommodates various substrate thicknesses up to 15-20mm whilst maintaining proper alignment and consistent pressure application for optimal results.

Is the SHP15LP3MS suitable for high-volume commercial production?

The automation features, efficient slideout design, and precision controls make it ideal for commercial operations requiring consistent quality and increased production throughput.

How does the 50-degree opening angle optimize operation and workspace efficiency?

The optimized angle provides easy substrate access whilst maintaining compact footprint, reducing workspace requirements, and ensuring comfortable operation for extended periods.

What training does Okoboji provide for the advanced automation features?

Okoboji offers specialized training covering automatic functions, slideout operation, advanced digital controls, and optimization techniques for maximum productivity.

How does the fixed or draw-out under plate option benefit different applications?

Fixed plates provide stability for standard operations, whilst draw-out plates enable preparation efficiency, making it adaptable to various production requirements and workflows.

What maintenance is required for the gas spring and automation components?

Regular inspection of gas springs, lubrication of moving parts, and system calibration ensure optimal performance. Okoboji provides comprehensive maintenance schedules and support.

Customers also bought

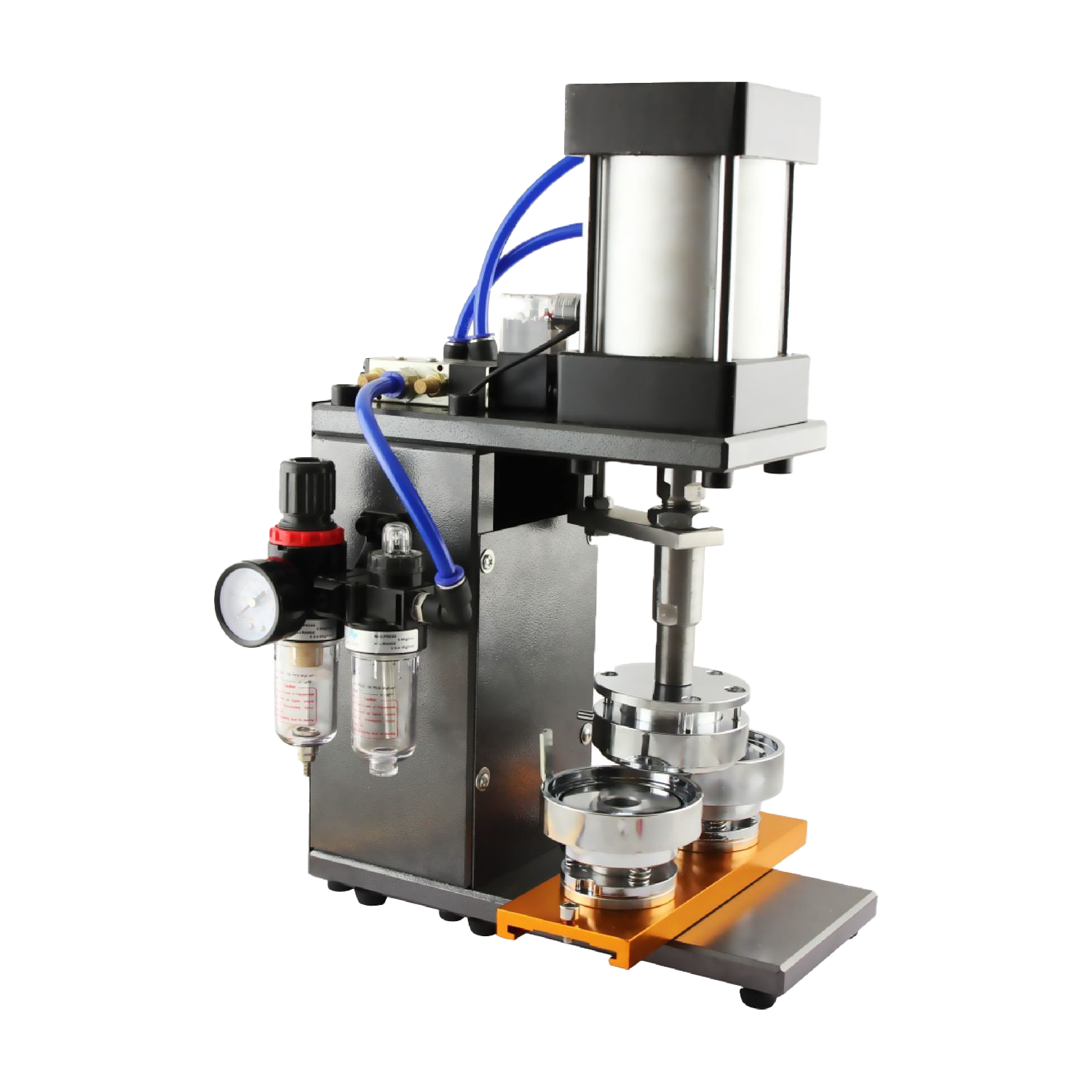

Okoboji Badge Magentic Mould Round 58mm

Okoboji ID Card Fusing A4 100

Okoboji Punch for Badge Pneumatic MAQ