Okoboji Cold & Thermal Laminator L1700T1

SPECIFICATIONS

PRODUCT VIDEO

PRODUCT DESCRIPTION

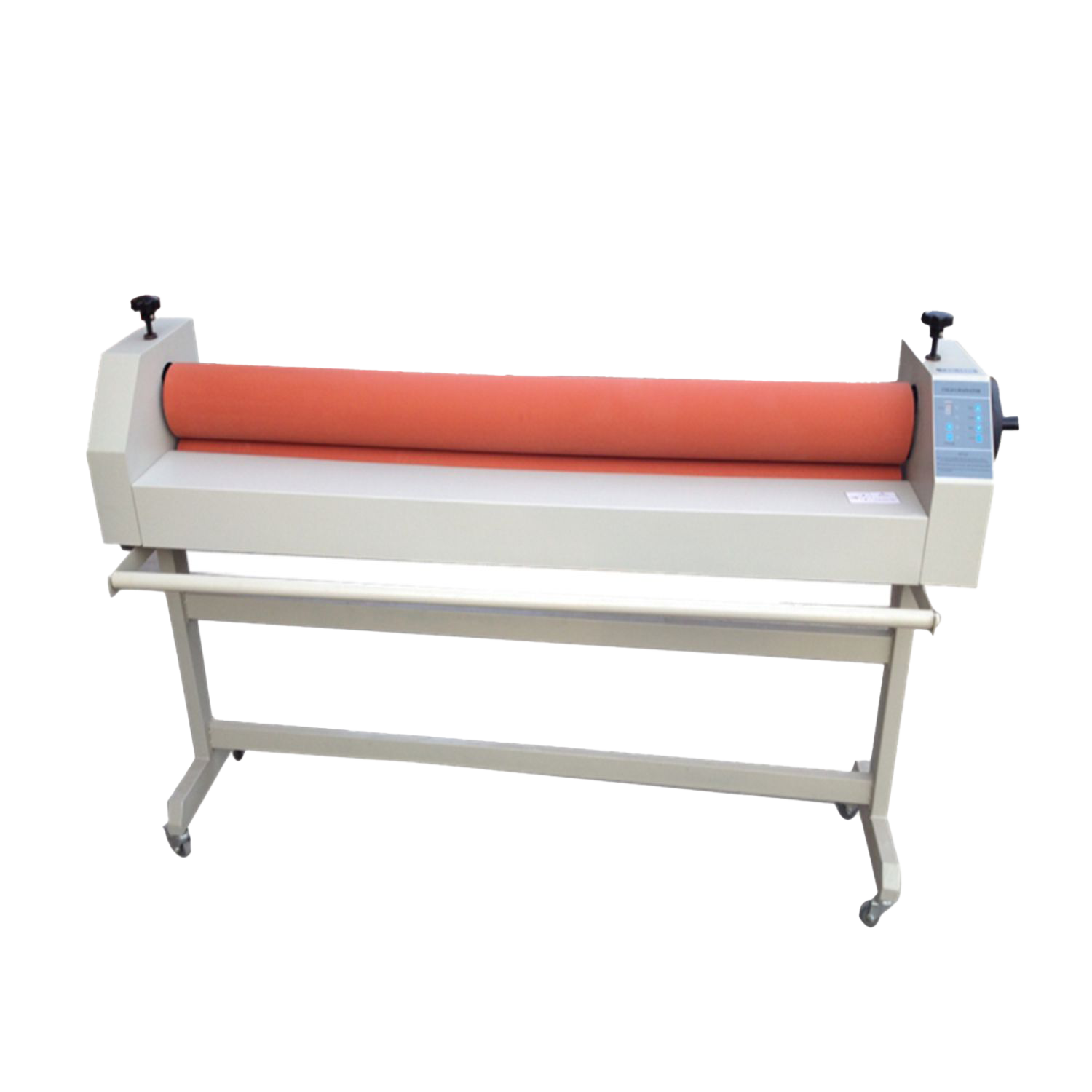

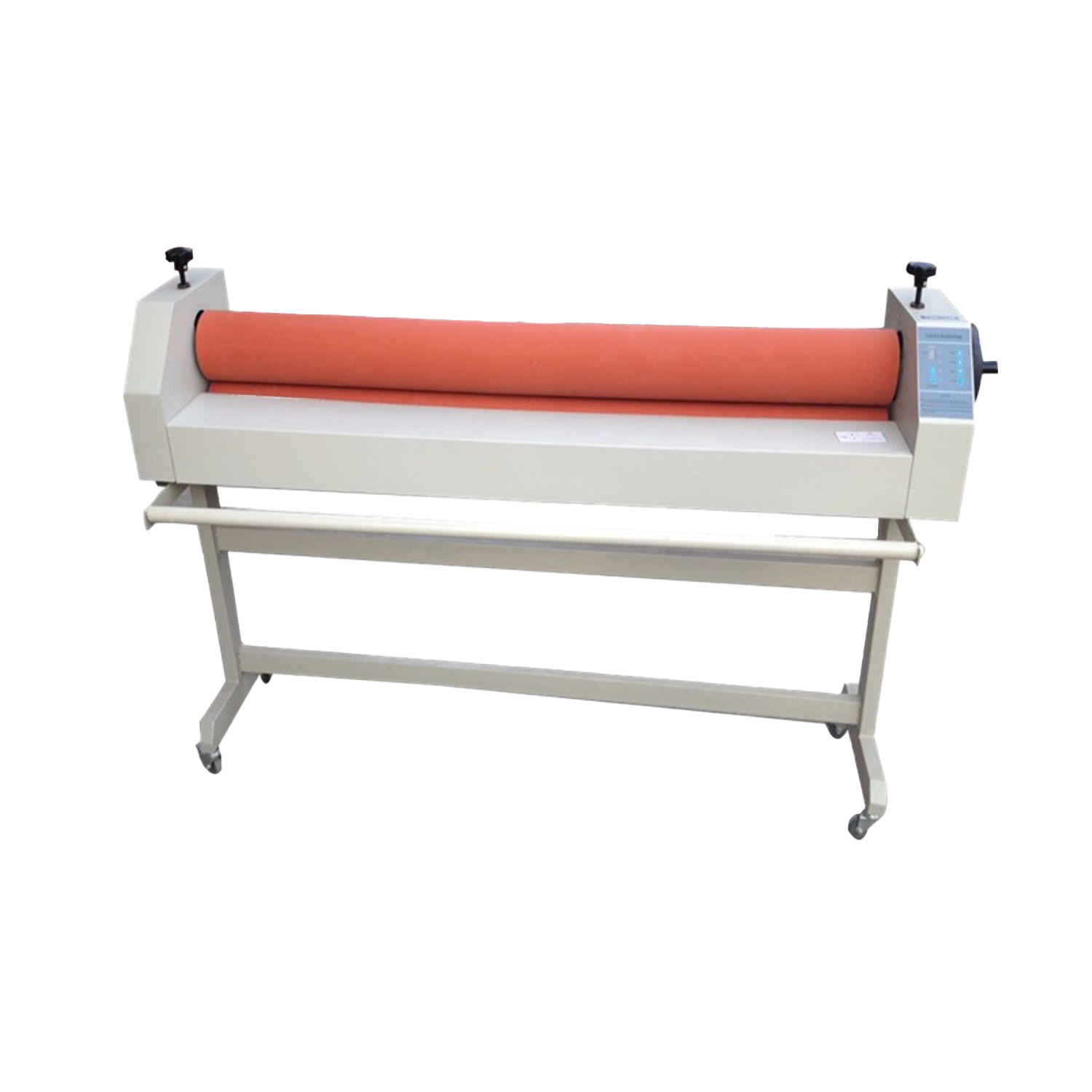

The Okoboji Cold & Thermal Laminator L1700T1 delivers professional dual-mode laminating capability specifically designed for commercial establishments across India requiring both electric efficiency and manual precision in their laminating operations. This versatile 1700mm wide format machine combines the convenience of electric operation with advanced thermal and cold laminating capabilities, making it ideal for print shops, advertising agencies, and commercial businesses handling diverse materials and customer requirements. The sophisticated pneumatic pressure system ensures consistent results whilst the 10m/min processing speed provides excellent productivity for commercial applications demanding quality and efficiency.

Engineered with Okoboji’s commitment to reliability and performance, this electric system features robust 130mm diameter rollers and precision infrared heating up to 60°C, providing optimal processing conditions for both heat-sensitive materials requiring cold lamination and permanent applications demanding thermal bonding. The substantial 240kg construction ensures rock-solid stability during operation, whilst the advanced pneumatic operation eliminates operator fatigue and provides consistent pressure distribution across the full working width. Whether processing protective lamination for valuable documents, creating durable commercial signage, or handling specialty applications requiring specific temperature control, this machine provides the flexibility and capability that modern Indian businesses demand for their professional laminating requirements.

Upgrade Your Experience

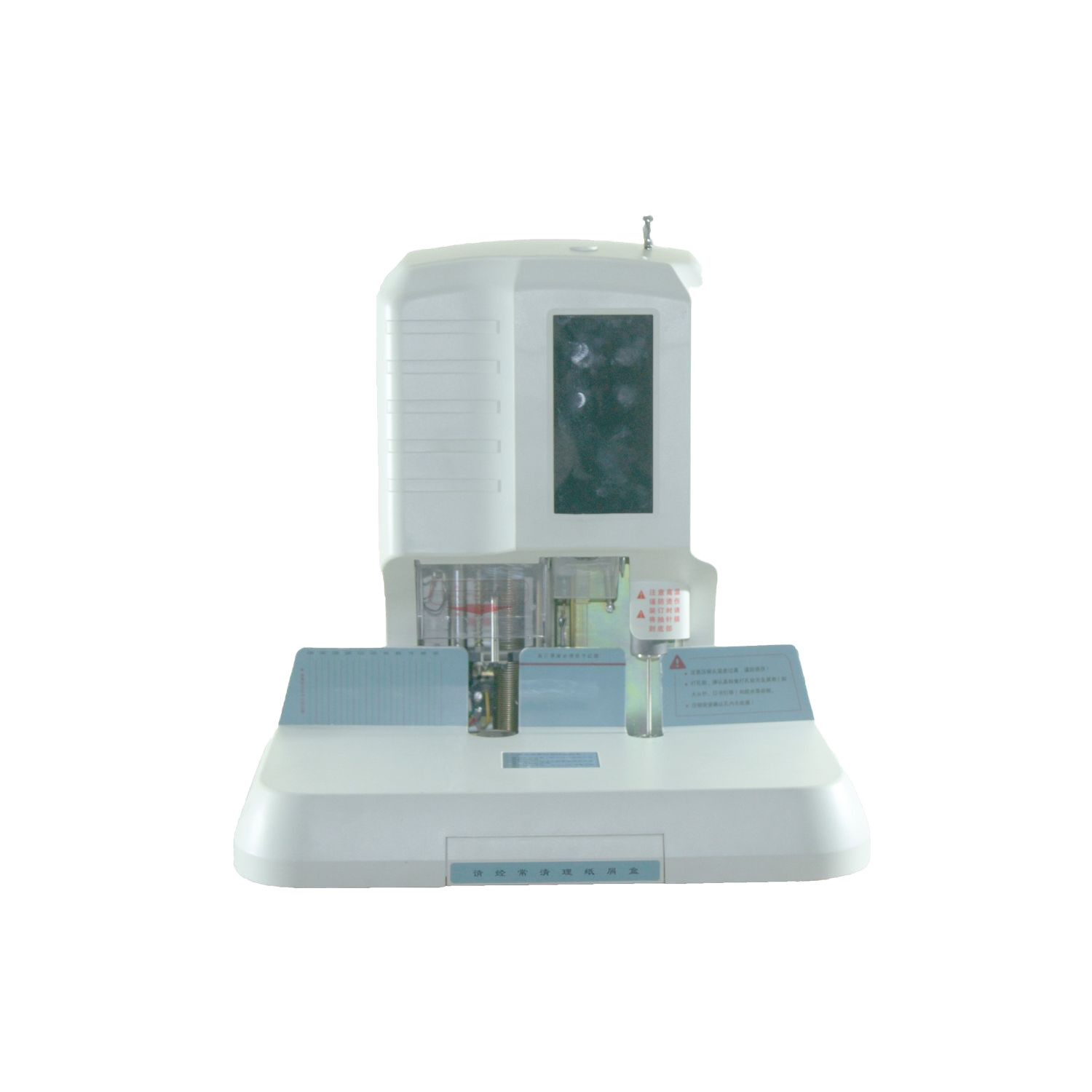

Okoboji Cold Lamination Desktop LBS650

Okoboji Cold Laminator Elec Pneumatic 63" 1600mm

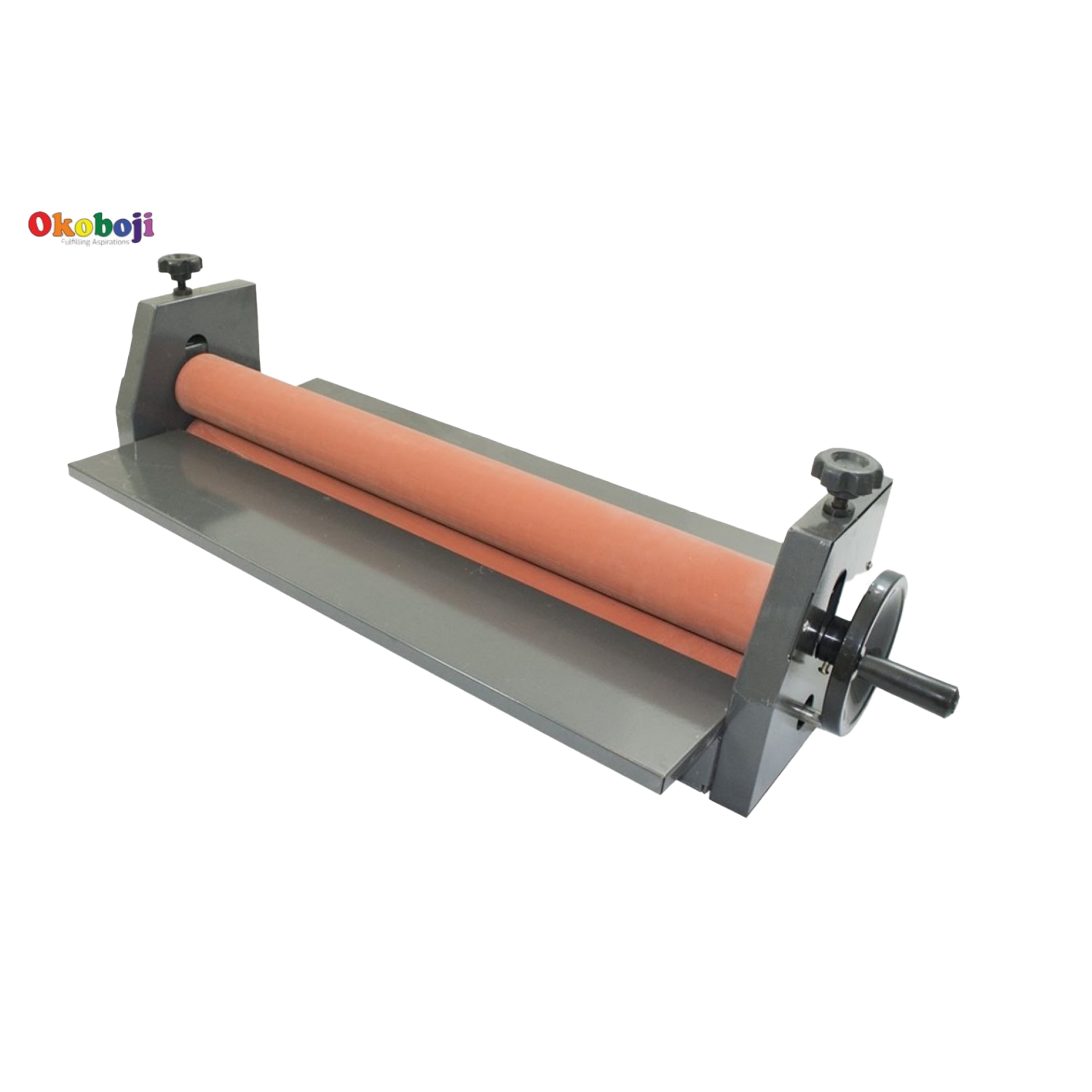

Okoboji Cold Laminator Electric 63" 1600 mm

Okoboji Cold Laminator Electric 650mm

KEY FEATURES

- Model : Okoboji Cold & Thermal Laminator L1700T1

- Max lamination width : 1620mm/63"

- Lifting height for roller : 32mm

- Roller diameter and length : 130mm 1700mm

- Roller up and down : Pneumatic

- Max Speed : 11m/min

- Motor power : 120w

- Heating : Infrared

- Heating power : 2000w

- Max temp : 70°C

- Preheating : 0.5-0.8kw/h

- Electrical requirement : 1N/PE 220V12A

- Machine weight : 220KG

FREQUENTLY ASKED QUESTIONS

What advantages does electric operation provide for this dual-mode Okoboji system?

Electric operation ensures consistent speed and pressure control, eliminates manual operation variables, increases productivity through automated processing, and provides precise temperature control for optimal thermal and cold laminating results.

How does the dual thermal and cold capability benefit commercial operations?

Dual modes allow processing of heat-sensitive digital prints with cold lamination whilst providing thermal bonding for permanent applications, accommodating diverse customer requirements without requiring multiple machines or equipment changes.

What materials can benefit from the 60°C thermal processing capability?

The 60°C thermal setting provides enhanced adhesive activation for permanent signage, protective applications, outdoor graphics, and materials requiring improved bonding strength whilst remaining safe for most substrate types.

How does the pneumatic system enhance commercial productivity?

Pneumatic operation provides automated pressure control, ensures consistent results across production runs, eliminates operator fatigue, and maintains uniform pressure distribution across the 1700mm width for professional quality.

What applications benefit from the 10m/min processing speed?

The 10m/min speed provides excellent productivity for commercial applications including signage production, protective lamination, architectural displays, and medium to high-volume operations requiring balance between speed and quality.

How does the 32mm lifting height accommodate commercial materials?

The 32mm height handles mounting boards, presentation materials, thick substrates, and multi-layer assemblies commonly used in commercial display, signage production, and architectural applications effectively.

What maintenance does this electric dual-mode Okoboji system require?

Regular roller cleaning, pneumatic system pressure checks, electric motor maintenance, infrared heating element inspection, and lubrication of moving components for optimal dual-mode performance and reliability.

Is this machine suitable for businesses requiring both indoor and outdoor applications?

Absolutely, cold mode handles indoor displays and heat-sensitive materials, whilst thermal mode provides enhanced bonding for outdoor signage and applications requiring improved durability and weather resistance.

How does the 240kg construction ensure commercial stability?

The substantial weight provides excellent stability during operation, reduces vibration, maintains consistent pressure across the wide format width, and ensures professional results in demanding commercial production environments.

Does Okoboji provide comprehensive support for this electric dual-mode equipment?

Yes, Okoboji offers professional installation, comprehensive training for electric operation and dual modes, technical support, genuine parts availability, and maintenance guidance across India to ensure optimal commercial performance.

Customers also bought

Okoboji Compressor 8L OTS550

Okoboji Corner Cutter Electric DT W Cover WH08C

Okoboji Paper Cutter Digital Hydraulic 520mm AirBed