Okoboji PVC CARD CUTTER HEAVY Duty D0012

SPECIFICATIONS

PRODUCT VIDEO

PRODUCT DESCRIPTION

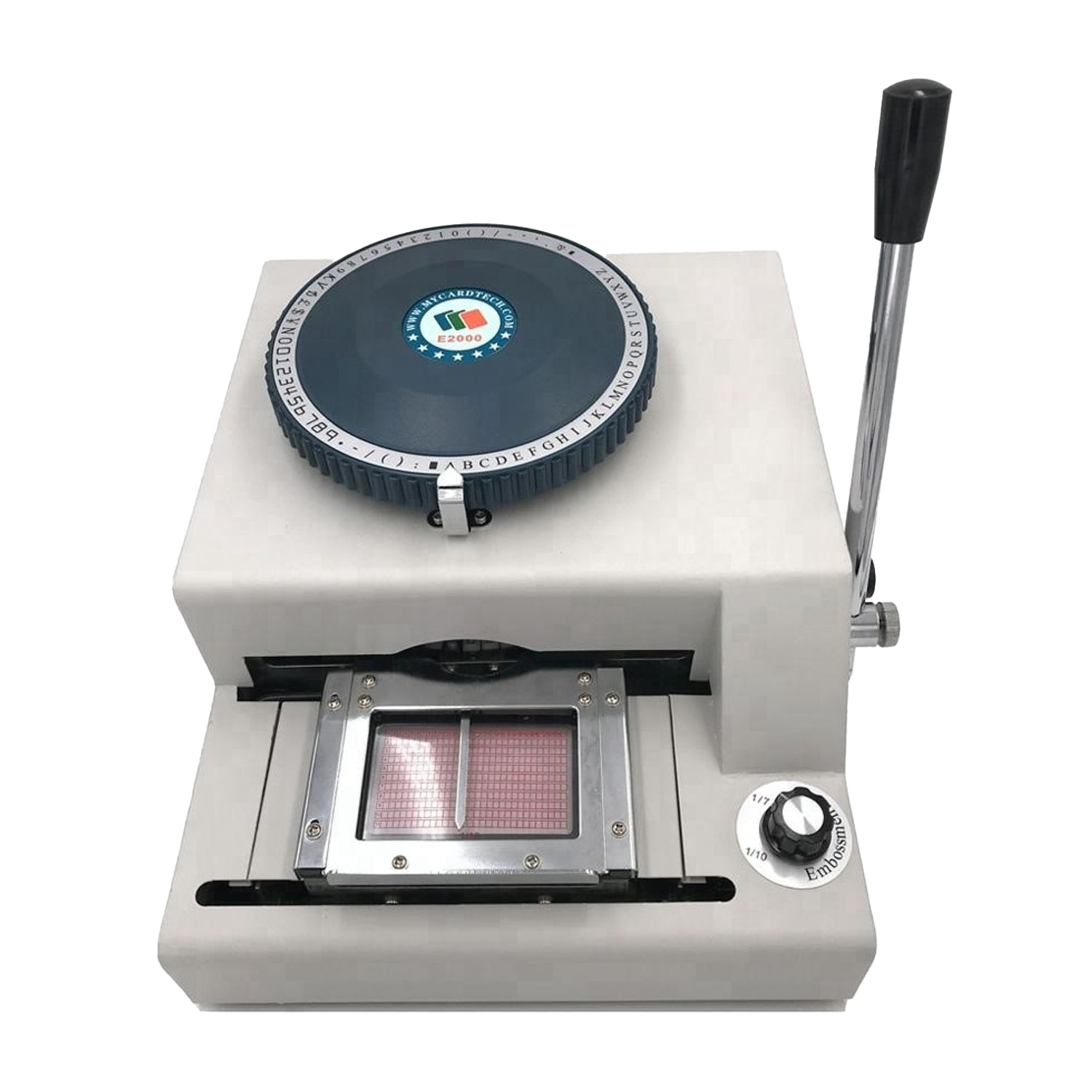

Okoboji’s PVC Card Cutter Heavy Duty D0012 provides superior manual cutting performance specifically engineered for demanding commercial applications requiring robust, reliable card production capabilities. This heavy-duty manual cutter excels in environments where continuous operation, durability, and precision cutting are paramount considerations, making it particularly suitable for established printing services, large corporate facilities, and institutional card production centres across India. The reinforced construction and precision-engineered cutting mechanism ensure consistent performance under intensive use whilst maintaining the operational flexibility and cost-effectiveness that manual operation provides.

The machine’s heavy-duty designation reflects enhanced structural integrity and cutting precision designed to withstand the rigorous demands of professional card production environments. Unlike standard manual cutters, this model incorporates reinforced components and precision manufacturing that deliver superior cutting quality whilst maintaining operational simplicity. The 85.7x54mm cutting size produces standard ISO-compliant cards suitable for identification, access control, and membership applications across diverse Indian organisations. This cutter represents an ideal solution for businesses requiring professional cutting capabilities without the electrical infrastructure requirements or operational costs associated with automated equipment.

Upgrade Your Experience

Okoboji ID Card Fusing A6 20

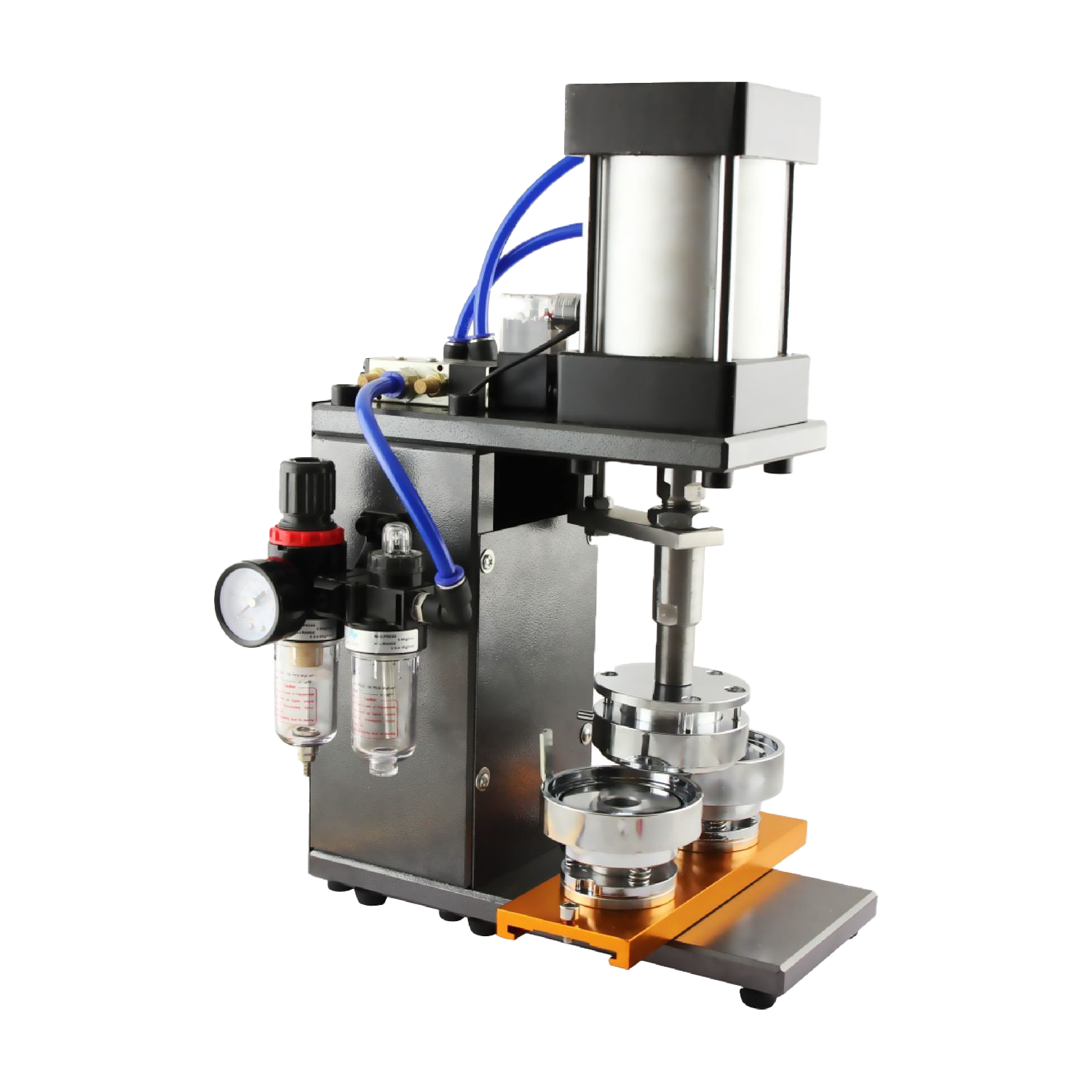

Okoboji ID Card PVC Embossing Machine EM PVC

Okoboji ID Card PVC Foil Tipper WTJ90A

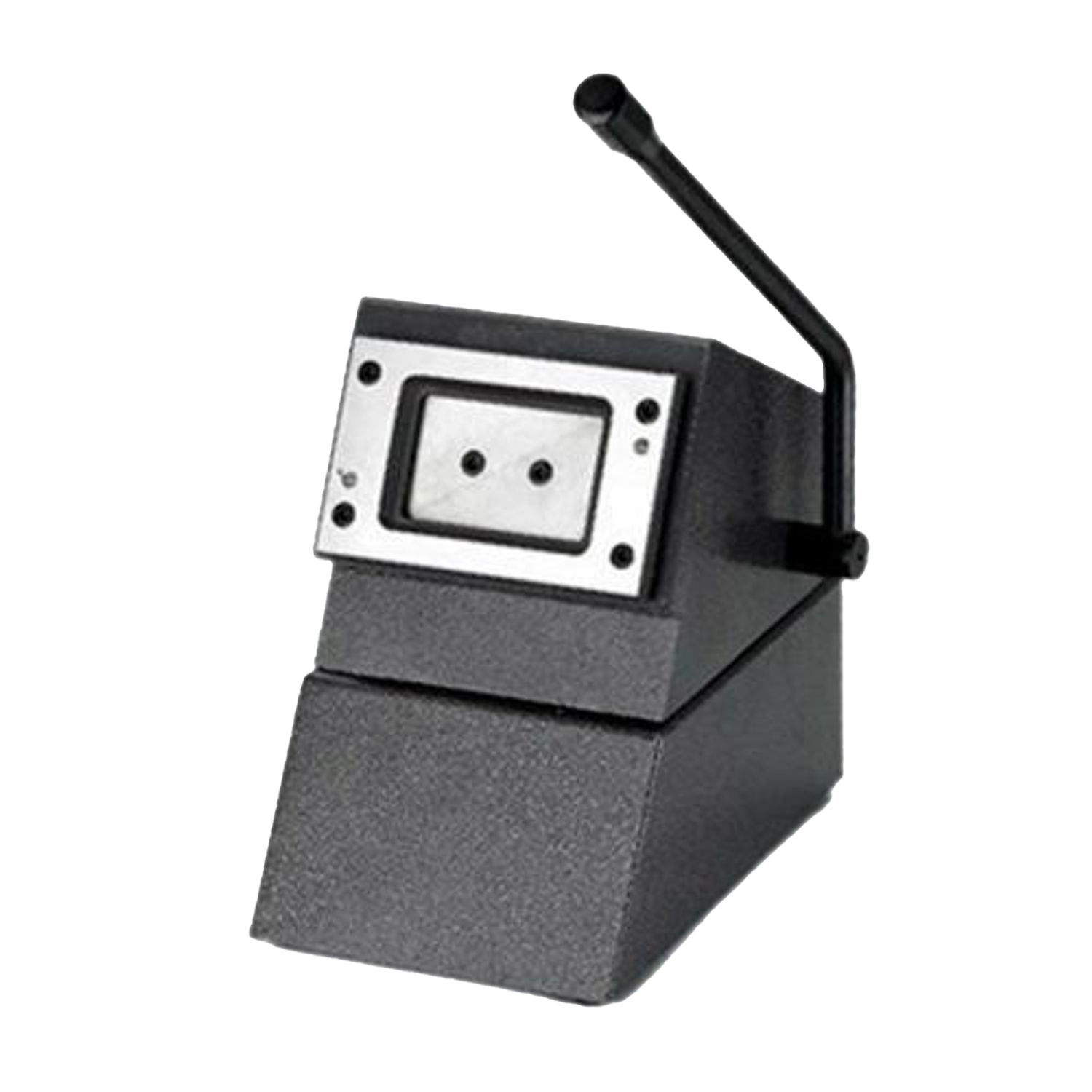

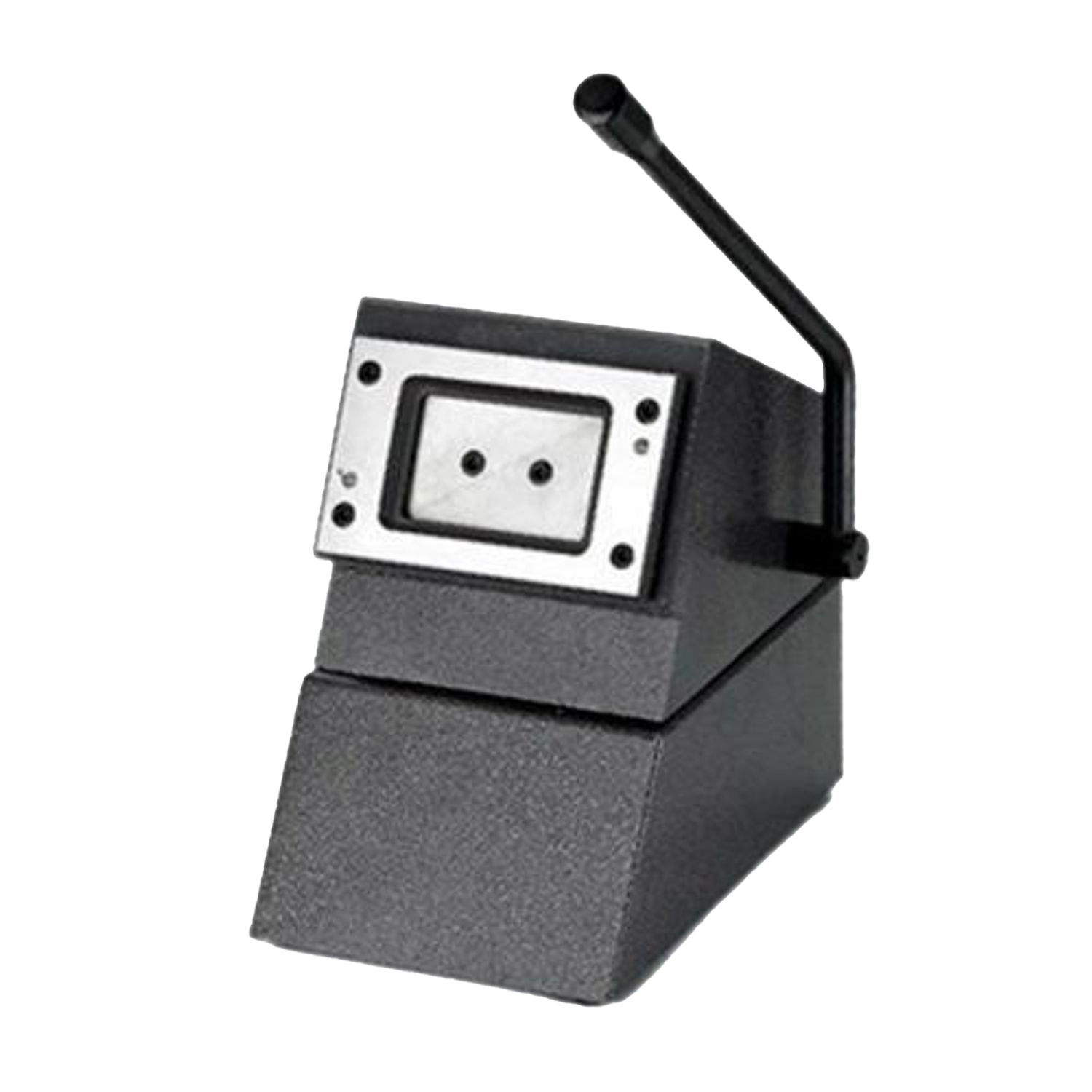

Okoboji PVC Card Cutter 8251

KEY FEATURES

- Heavy-duty construction provides enhanced durability and precision cutting performance suitable for continuous commercial use in demanding Indian business environments

- Robust manual operation eliminates electrical dependencies whilst delivering professional cutting quality comparable to more expensive automated equipment

- Standard 85.7x54mm cutting size ensures ISO-compliant card production suitable for identification, access control, and membership applications across Indian organisations

- Enhanced structural integrity withstands intensive use typical of commercial printing services, corporate facilities, and institutional card production centres

- Precision-engineered cutting mechanism delivers consistent edge quality and dimensional accuracy meeting professional standards required by banks and government offices

- Versatile thickness accommodation (0.1-1.2mm) handles various PVC materials from standard cards to premium thick cards preferred by security-conscious organisations

- Cost-effective manual design provides professional cutting capabilities without ongoing electrical costs or complex maintenance requirements

- Okoboji's proven engineering excellence and comprehensive support network ensure reliable operation and readily available technical assistance for heavy-duty cutting applications

FREQUENTLY ASKED QUESTIONS

What makes this heavy-duty model different from standard manual card cutters?

The heavy-duty design features reinforced construction, enhanced cutting precision, improved durability under continuous use, and superior component quality designed for demanding commercial applications.

Which types of businesses benefit most from heavy-duty manual cutting capabilities?

Established printing services, large corporate facilities, institutional card production centres, government offices, and businesses requiring reliable cutting without electrical infrastructure benefit most from this equipment.

How does the robust construction affect cutting precision and consistency?

Enhanced structural integrity ensures stable cutting pressure, reduces vibration during operation, maintains dimensional accuracy, and provides consistent edge quality throughout extended use periods.

Can this heavy-duty cutter handle specialty PVC materials and security cards?

Yes, the robust mechanism accommodates premium PVC materials, laminated security cards, thick overlay films, and specialty materials requiring precise cutting for security applications.

What maintenance advantages does heavy-duty construction provide over standard cutters?

Reinforced components require less frequent adjustment, withstand intensive use better, maintain cutting precision longer, and provide extended operational lifespan with proper maintenance procedures.

Is operator training different for heavy-duty manual cutters compared to standard models?

Basic operation remains similar, but training emphasises proper technique for utilising enhanced cutting power, safety procedures for robust equipment, and maintenance practices for heavy-duty components.

How does this cutter perform in high-volume manual cutting applications?

The heavy-duty design excels in continuous operation, maintains cutting quality throughout extended sessions, reduces operator fatigue through improved ergonomics, and delivers consistent results under intensive use.

What safety considerations are specific to heavy-duty manual cutting equipment?

Enhanced cutting power requires proper hand positioning, increased attention to safety procedures, secure material positioning, and adherence to Okoboji's safety guidelines for heavy-duty equipment.

How does the investment in heavy-duty manual equipment compare to electric alternatives?

Heavy-duty manual cutters provide professional capabilities without electrical costs, offer operational independence, require minimal maintenance, and deliver excellent value for businesses prioritising reliability and flexibility.

What technical support does Okoboji provide for heavy-duty cutting equipment maintenance?

Okoboji offers specialised heavy-duty maintenance guidelines, technical support for robust equipment, replacement parts availability, and regional service networks ensuring optimal heavy-duty cutter performance.

Customers also bought

Okoboji Digital Foil Printer for Ribbon 150R

Okoboji ID Card PVC Foil Tipper WTJ90A

Okoboji Paper Cutter Digital Hydraulic 680mm