Okoboji V Groving Machine DT Manual VGM

SPECIFICATIONS

PRODUCT VIDEO

PRODUCT DESCRIPTION

The Okoboji V Grooving Machine DT Manual VGM represents precision engineering designed specifically for creating perfect fold lines in rigid box manufacturing applications. This expertly crafted manual machine addresses the fundamental requirement for accurate V-groove cutting in cardboard, grey board, and stiff packaging materials, enabling manufacturers to achieve crisp, professional fold lines that ensure boxes maintain their structural integrity and aesthetic appeal. The VGM’s precision mechanisms deliver consistent groove depth and angle accuracy that eliminates common folding problems such as cracked edges, uneven folds, and structural weakness at bend points.

Engineered for versatility and portability, the Okoboji VGM’s compact 20kg design makes it ideal for workshops where space efficiency and operational flexibility are paramount considerations. Despite its lightweight construction, the machine delivers industrial-grade performance with 0.3mm accuracy that meets the exacting standards required for luxury packaging, electronics boxes, and high-end presentation materials. The dual-angle capability (90° and 125°) provides manufacturers with the flexibility to create diverse box styles whilst maintaining the precision that distinguishes professional packaging from amateur alternatives. For businesses requiring reliable, cost-effective grooving solutions without the complexity of automated systems, the Okoboji VGM offers the perfect combination of accuracy, portability, and operational simplicity.

Upgrade Your Experience

Okoboji Box Moon Cutting Machine BMC

Okoboji Compressor 8L OTS550

Okoboji Corner Taping Machine CTM

Okoboji Gluing Machine Hot and Cold 700mm/27.55" GM700

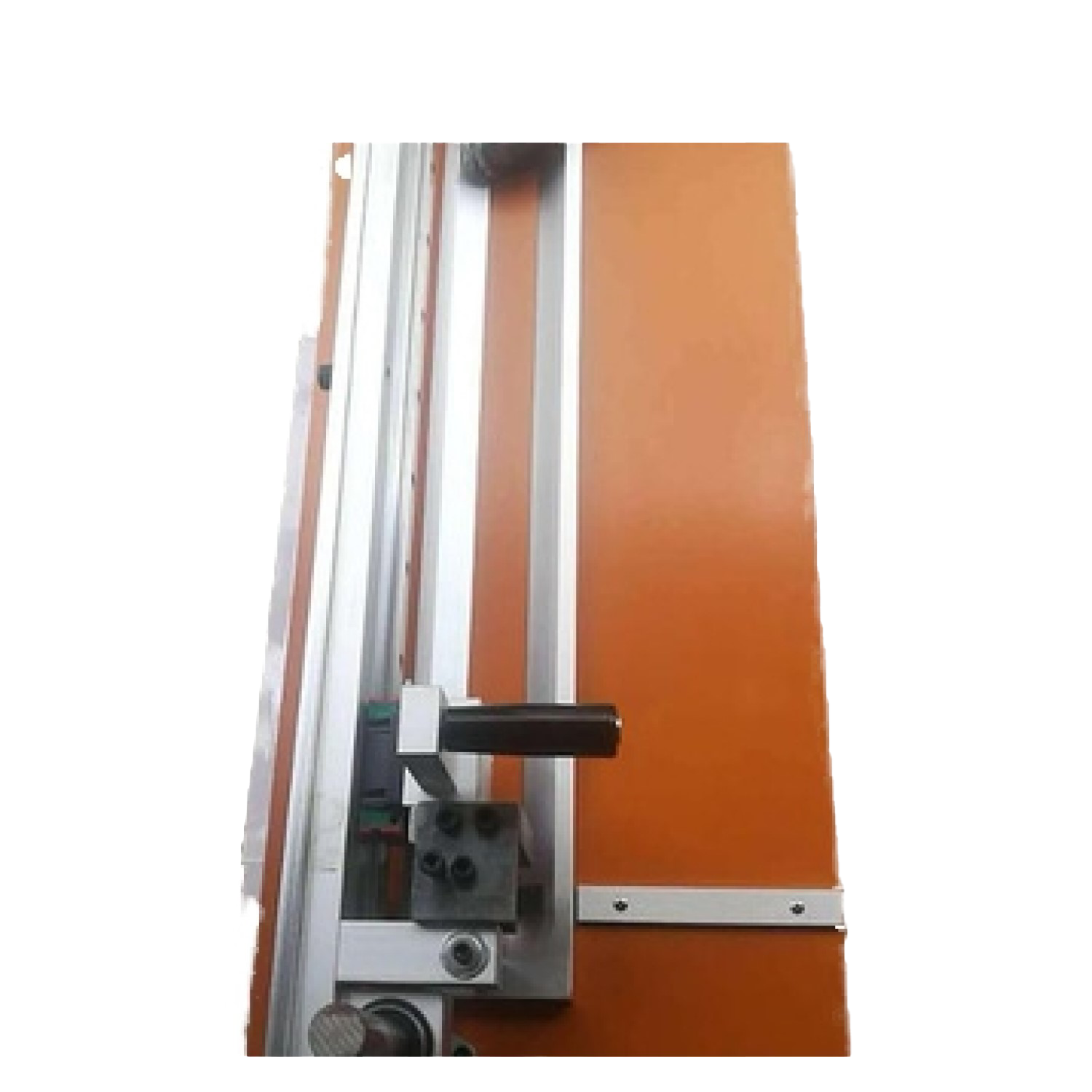

KEY FEATURES

- Exceptional slotting accuracy of 0.3mm ensures precise fold lines that create professional-looking boxes with sharp, clean edges and consistent geometry

- Dual-angle capability (90° and 125°) provides design flexibility for various box styles whilst maintaining precision standards required for high-end packaging applications

- Impressive 550mm slotting stroke accommodates large board sizes, making it suitable for diverse packaging applications from small gift boxes to large presentation cases

- Lightweight 20kg construction enables easy relocation and positioning, ideal for workshops requiring flexible equipment arrangement and multi-station operations

- Variable slot width capability (0-8mm at 90°) and knife depth options (0-3mm depth, 0-7mm width at 120°) accommodate different material thicknesses and folding requirements

- Compact 850*380*120mm footprint maximises workshop space efficiency whilst providing full-sized machine capabilities for professional grooving operations

- Manual operation eliminates electrical requirements and reduces operational costs whilst providing operators with complete control over groove placement and quality

- Okoboji's reputation for reliability ensures consistent performance and long service life, making it an excellent investment for growing packaging businesses

FREQUENTLY ASKED QUESTIONS

What board materials are compatible with the Okoboji V Grooving Machine DT Manual VGM?

The VGM handles stiff grey boards, cardboard, MDF, and various packaging materials from 1-5mm thickness, making it versatile for different rigid box applications.

How does the 0.3mm accuracy benefit box manufacturing quality?

This precision ensures clean, consistent fold lines that prevent cracking, maintain structural integrity, and create the sharp edges essential for professional packaging appearance.

Can operators easily switch between 90° and 125° grooving angles?

Yes, angle adjustment requires simple tool positioning changes that can be completed within 2-3 minutes, enabling efficient production of different box styles.

What operator training is required for effective VGM operation?

Basic instruction typically requires 1-2 hours, with operators achieving proficiency within a day due to the machine's intuitive manual operation and clear positioning guides.

How does the manual operation compare to automatic alternatives in terms of flexibility?

Manual operation provides superior flexibility for prototype development, small batch production, and custom applications where precision placement is more important than speed.

What maintenance procedures ensure optimal VGM performance?

Regular blade sharpening, cleaning of guide systems, and periodic lubrication of adjustment mechanisms maintain accuracy and extend blade life significantly.

Can the VGM handle production volumes suitable for commercial operations?

While designed for precision rather than speed, experienced operators can achieve 200-300 grooves per hour, making it suitable for small to medium production requirements.

What backup and service support does Okoboji provide for the VGM?

Comprehensive support includes replacement blades, adjustment tools, technical guidance, and troubleshooting assistance through Okoboji's service network.

How portable is the machine for multi-location or shared workshop use?

At 20kg with compact dimensions, the VGM is easily relocated by one person, making it ideal for shared workshops or businesses operating multiple locations.

What quality control features help ensure consistent grooving results?

Precision guides, depth adjustment mechanisms, and quality construction ensure repeatable results when proper setup procedures are followed consistently.

Customers also bought

Okoboji Cold &Thermal Laminator 1600mm

Okoboji Eyelet Electric 5.5mm Single Head

Okoboji Eyelet Pneumatic 4 Head Punch EPNQ4