Okoboji Wiro Puncher EW620

SPECIFICATIONS

PRODUCT VIDEO

PRODUCT DESCRIPTION

The Okoboji Wiro Puncher EW620 represents the pinnacle of precision wire binding punching technology, meticulously engineered for professional binding operations that demand exceptional accuracy and reliability. This sophisticated electric punching machine serves as the cornerstone of commercial wire binding systems, providing the critical hole punching foundation required for professional-grade wiro binding applications across diverse Indian business environments. Unlike manual punching devices that rely on operator strength and consistency, the EW620’s electric operation ensures uniform hole placement, consistent punch quality, and exceptional productivity that meets the exacting standards of commercial printing and binding operations.

The machine’s intelligent design incorporates precision die moulds and adjustable margin systems (2.5mm, 4.5mm, 6.5mm) that accommodate various document formats whilst maintaining perfect hole alignment for optimal wire insertion and binding quality. With its substantial 20-sheet punching capacity and 120-sheet binding capability, the EW620 efficiently processes both thin documents and substantial reports with equal precision. The electric punching mechanism eliminates operator fatigue whilst delivering consistent results throughout extended production runs, making it an indispensable tool for businesses prioritising both quality and efficiency.

This Okoboji wire puncher particularly excels in environments where punching precision directly impacts final binding quality, such as commercial print shops preparing client materials, corporate offices creating presentation documents, training centres developing course materials, and educational institutions producing academic resources. The EW620’s combination of electric reliability, precision engineering, and professional-grade construction establishes it as an essential component in any serious wire binding operation seeking to deliver consistently exceptional results.

Upgrade Your Experience

Okoboji Wiro & Spiral Binder SW2500

Okoboji Wiro Binder HD W20A A4

Okoboji Wiro Binder Punch W25A 2:1

Okoboji Wiro Binder Punch W25A 3:1

KEY FEATURES

- Precision Electric Punching System : Advanced electric motor delivers consistent punching force and uniform hole placement, ensuring professional results and eliminating variations associated with manual operation methods.

- Substantial 20-Sheet Punching Capacity : Efficiently processes substantial document thickness in single operations, accommodating various paper weights and reducing production time for thick reports and presentations.

- Comprehensive 120-Sheet Binding Capability : Supports extensive document binding projects, enabling creation of substantial manuals, reports, and presentations that meet professional standards and client expectations.

- Adjustable Margin Precision System : Three precise margin settings (2.5mm, 4.5mm, 6.5mm) ensure optimal hole placement for different document types and binding requirements, guaranteeing professional wire insertion and binding quality.

- Professional A4 Document Compatibility : Optimised for standard A4 format documents up to 300mm width, accommodating the most common business document sizes used across Indian commercial and educational environments.

- Advanced Die Mould Technology : Precision-engineered die moulds create clean, accurate holes that facilitate smooth wire insertion and contribute to professional binding aesthetics and functionality.

- Industrial-Grade Electric Operation : Robust electric motor system provides reliable performance for extended commercial use, ensuring consistent productivity and reducing operator fatigue in high-volume binding operations.

- Commercial Production Efficiency : Electric operation significantly improves punching speed and consistency compared to manual alternatives, making it ideal for Okoboji customers requiring professional-grade binding productivity.

FREQUENTLY ASKED QUESTIONS

What document sizes and formats does the Okoboji EW620 wiro puncher accommodate?

The EW620 is optimised for A4 documents and materials up to 300mm width, making it perfect for standard business reports, presentations, manuals, and educational materials commonly used in Indian offices and institutions.

How many sheets can the EW620 punch simultaneously during operation?

The machine can punch up to 20 sheets simultaneously, depending on paper weight and thickness, enabling efficient processing of substantial documents whilst maintaining precision and hole quality throughout the punching process.

What binding capacity does this electric puncher support for completed projects?

The EW620 supports binding projects up to 120 sheets, allowing creation of comprehensive reports, manuals, presentations, and educational materials that meet professional standards and business requirements.

How do the adjustable margin settings benefit different binding applications?

The three margin settings (2.5mm, 4.5mm, 6.5mm) accommodate different document types and binding preferences, ensuring optimal wire placement and professional binding aesthetics for various project requirements and specifications.

What advantages does electric operation provide over manual punching methods?

Electric operation delivers consistent punching force, uniform hole placement, reduced operator fatigue, improved productivity, and professional results that maintain quality standards throughout extended production runs.

Is the EW620 suitable for commercial binding operations and high-volume use?

Yes, the machine's electric motor, robust construction, and precision engineering make it ideal for commercial printing operations, office binding centres, and businesses requiring regular professional-grade document binding.

What die mould specifications and hole patterns does this machine create?

The EW620 features precision die moulds designed for standard wiro binding specifications, creating clean, accurate holes that facilitate smooth wire insertion and professional binding results for various document types.

How does this Okoboji puncher integrate with existing binding equipment and workflows?

The EW620 functions as a dedicated punching component that complements wire closing equipment, allowing businesses to create efficient binding production systems and improve overall workflow productivity and quality.

What maintenance procedures ensure optimal performance and longevity?

Regular cleaning of die moulds, lubrication of moving components, inspection of electrical systems, and periodic professional servicing maintain optimal punching precision and extend equipment lifespan in commercial applications.

What technical support and training does Okoboji provide for the EW620?

Okoboji offers comprehensive operator training, technical documentation, installation support, and ongoing service assistance to ensure successful operation and optimal performance in professional binding environments.

Customers also bought

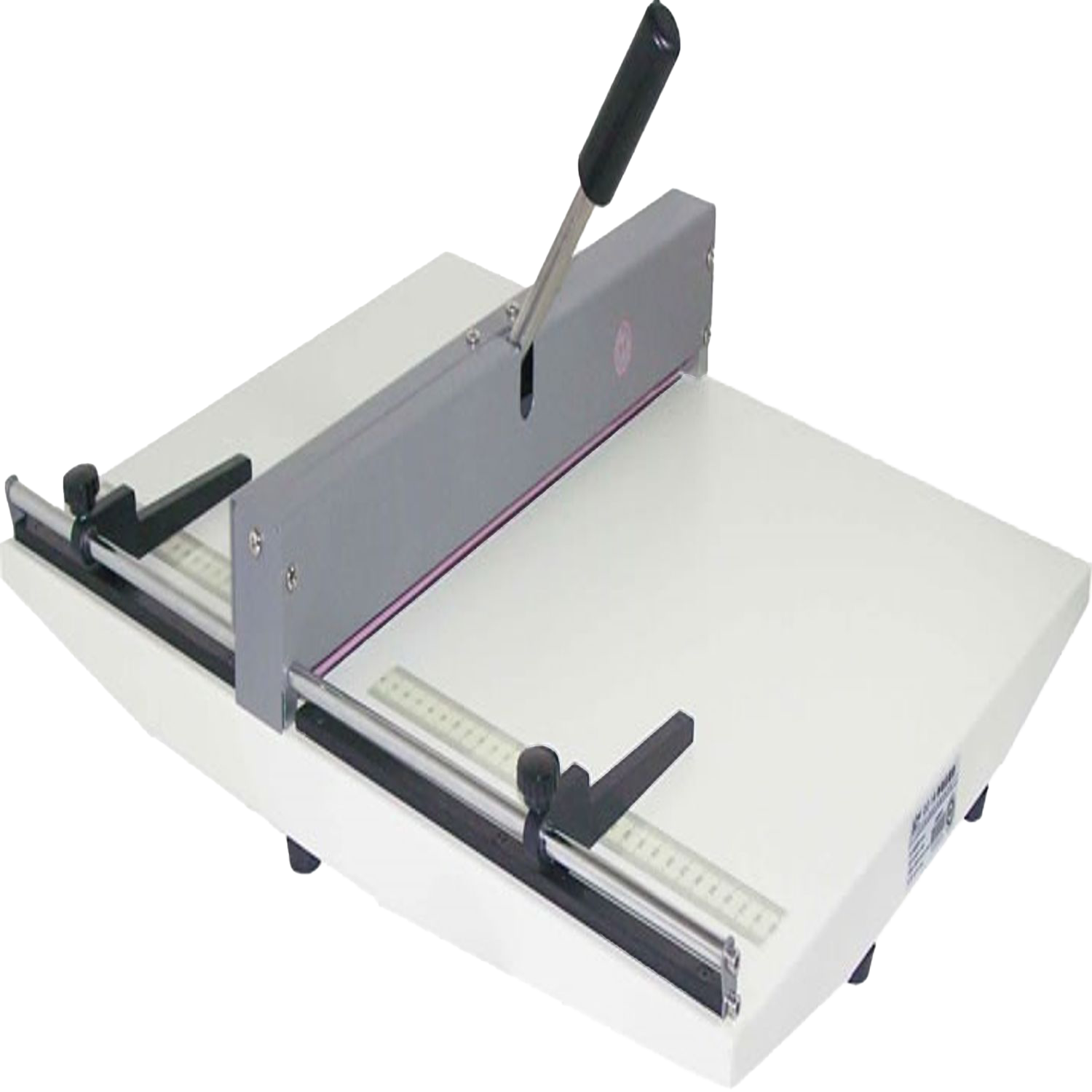

Okoboji Creasing Machine Automatic 12.5" ACM12

Okoboji Paper Creaser Manual A3 Size H460

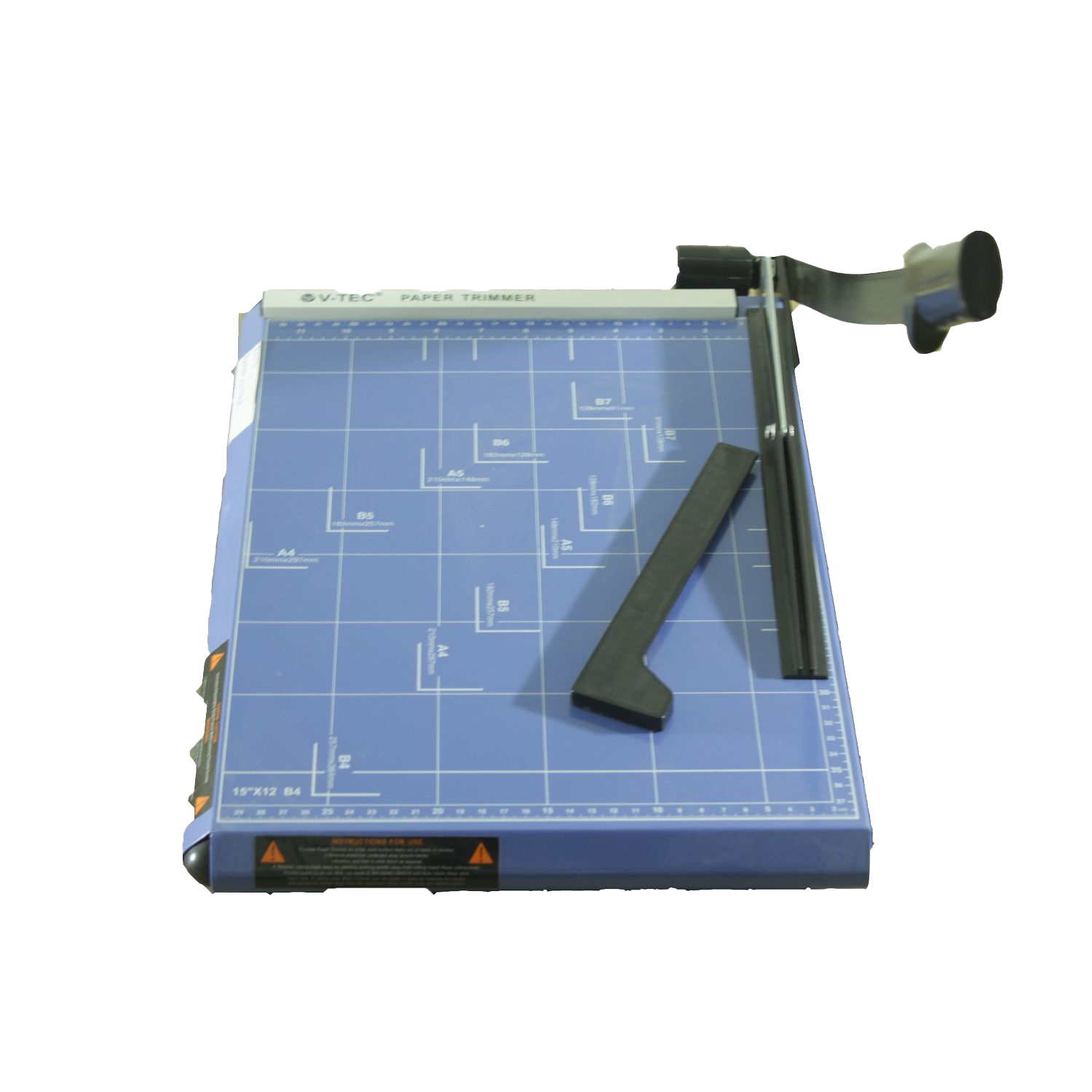

Okoboji Paper Cutter B4